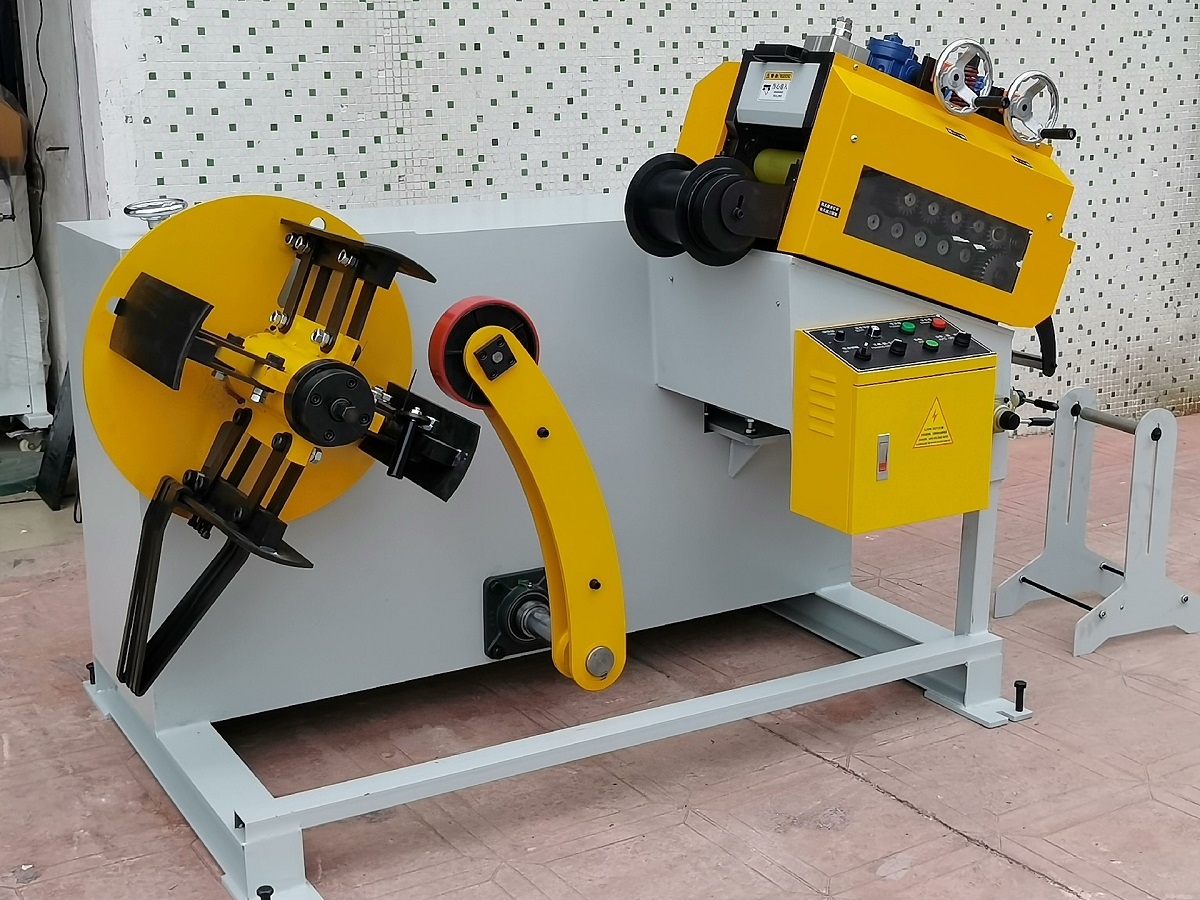

Główne cechy urządzenia 2 w 1: odwijarka i prostownica

- Wysoka precyzja prostowania: Wyposażony w 7 hartowanych rolek (4 górne, 3 dolne) wykonanych z hartowanej, chromowanej na twardo stali stopowej GCr15 (HRC58–62), co zapewnia doskonałą trwałość i odporność na zarysowania.

- Stabilny i niezależny system sterowania: Osobne szafy sterujące silnikami z indywidualnymi falownikami zapewniają płynną pracę i zapobiegają zakłóceniom.

- Niezawodny mechanizm napędowy: Przegub Cardana i przekładnia zębata redukują zużycie i minimalizują ryzyko uszkodzenia na skutek biernego obrotu rolek.

- Szybka i łatwa regulacja: Wskaźniki zegarowe umożliwiają szybką identyfikację punktów poziomowania i dokładne regulacje prostowania.

- Szeroka kompatybilność materiałowa: Nadaje się do zwojów HR, CR, stali nierdzewnej, aluminium i stali ocynkowanej.

- Trwała i sztywna konstrukcja: Komponenty obrabiane maszynowo CNC gwarantują wytrzymałość konstrukcji i długoterminową stabilność.

- Elastyczna kontrola karmienia: Automatyczne podawanie zsynchronizowane z prędkością linii w celu zapewnienia wydajnej pracy.

- Łatwa konserwacja i funkcje bezpieczeństwa: dostępne opcjonalne ramię prasy, osłony ochronne i czujniki bezpieczeństwa.

Typowa linia zastosowań

- Krok 1: Prostownica-rozwijarka – ładuje i prostuje cewkę

- Krok 2: Podajnik serwo NC – podaje cewkę do prasy

- Krok 3: Prasa mechaniczna – wykonuje operację tłoczenia

Opcje dostosowywania

Dostępne z hydraulicznym rozwijakiem, pneumatycznym ramieniem dociskowym, silnikiem prądu przemiennego z falownikiem oraz różnymi konfiguracjami spełniającymi specyficzne potrzeby produkcyjne.

Części opcjonalne

- Ramię prasy pneumatycznej

- Trzpień rozprężny hydrauliczny

- Silnik prądu przemiennego + falownik

- System sterowania pętlą

- Uchwyt zdalnego sterowania

Rozwijarka I Prostownica Stosowany powszechnie w:

- Części LED

- Tłoczenie samochodowe

- Elementy elektroniczne i AGD

- Produkcja ogólnego osprzętu metalowego

Wypełnij ten formularz, aby przesłać zapytanie ofertowe. Jeden z członków naszego zespołu przeanalizuje szczegóły i skontaktuje się z Tobą w ciągu 12 godzin roboczych.