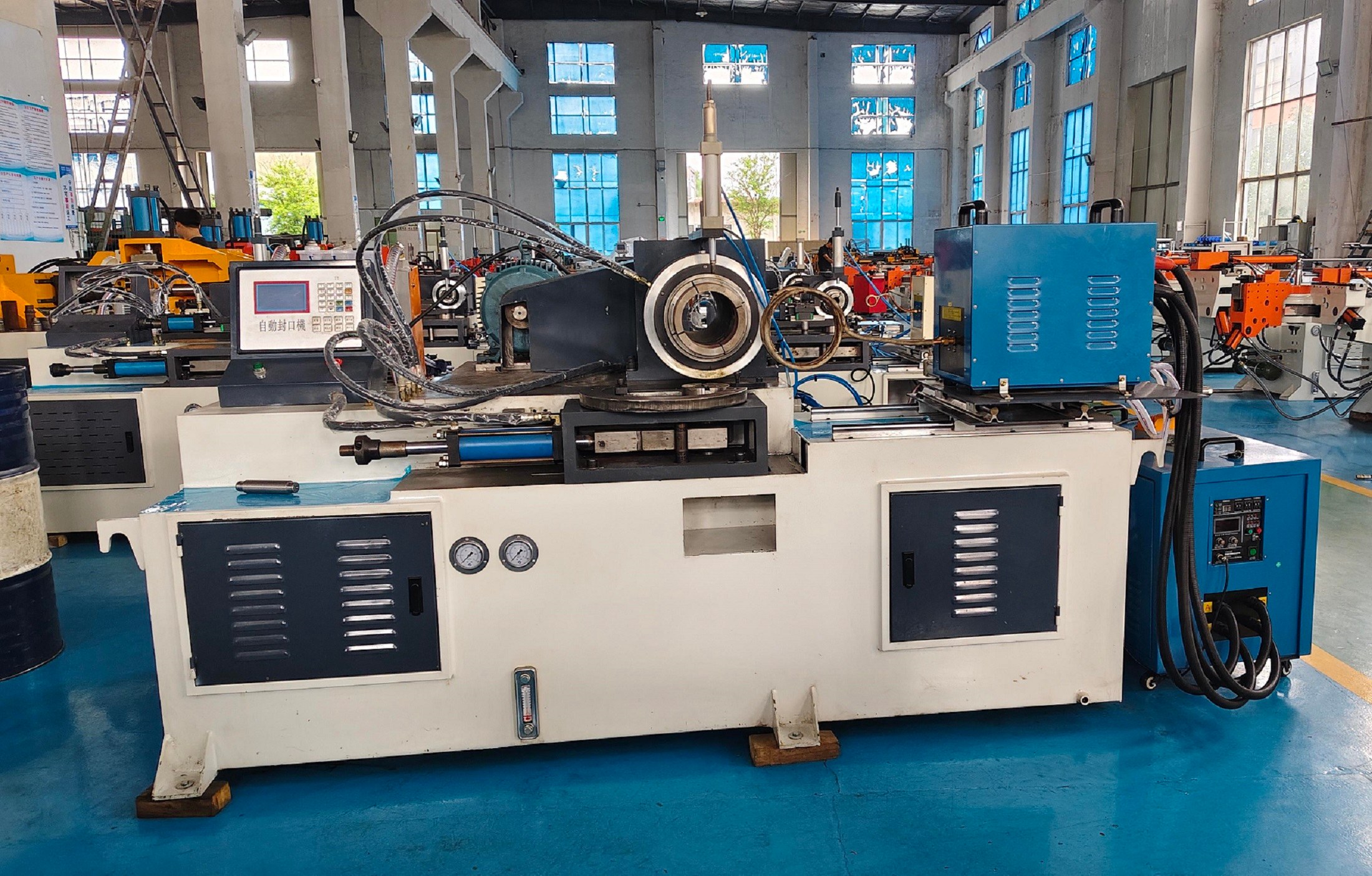

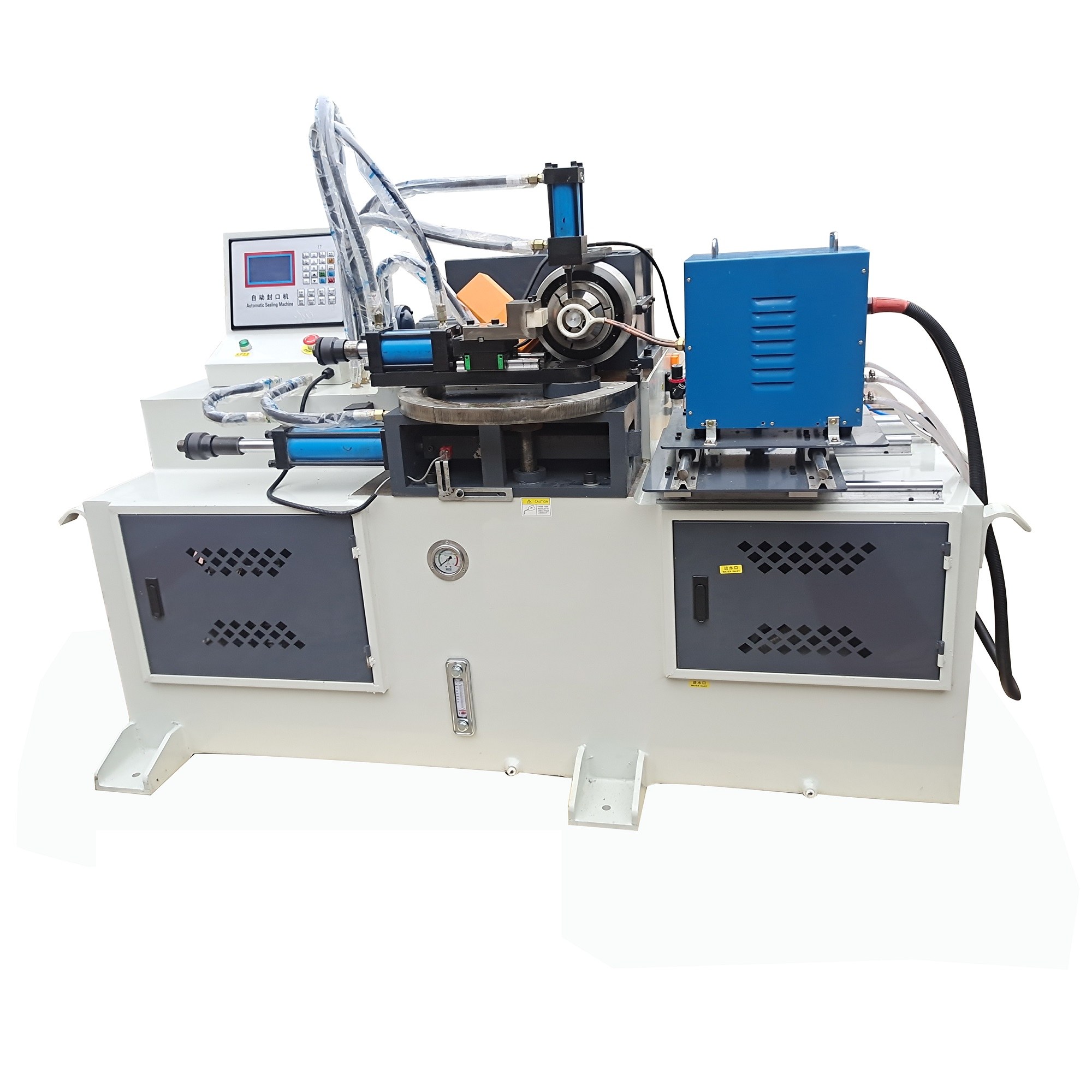

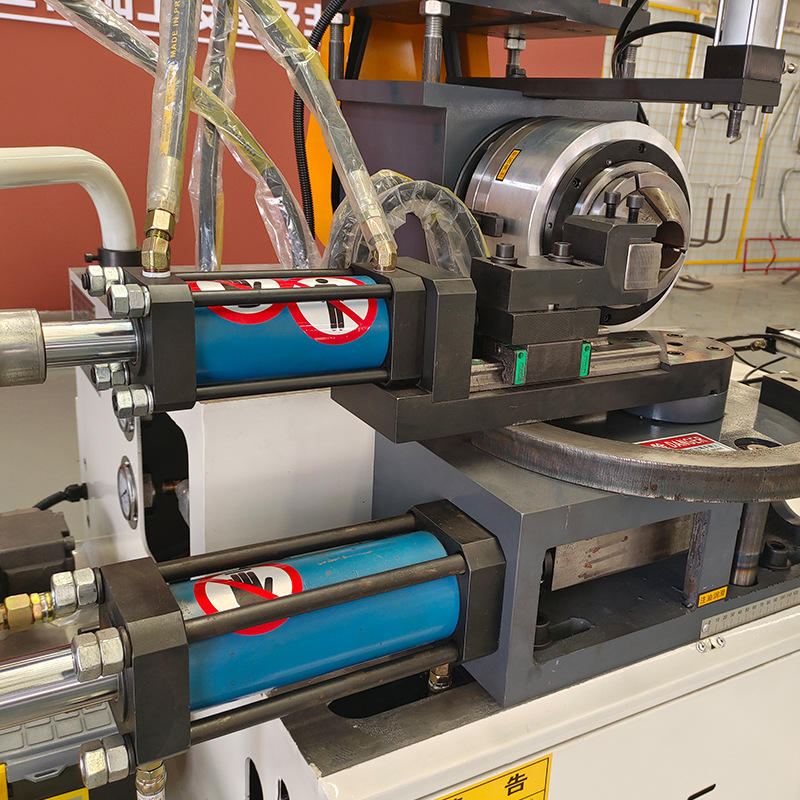

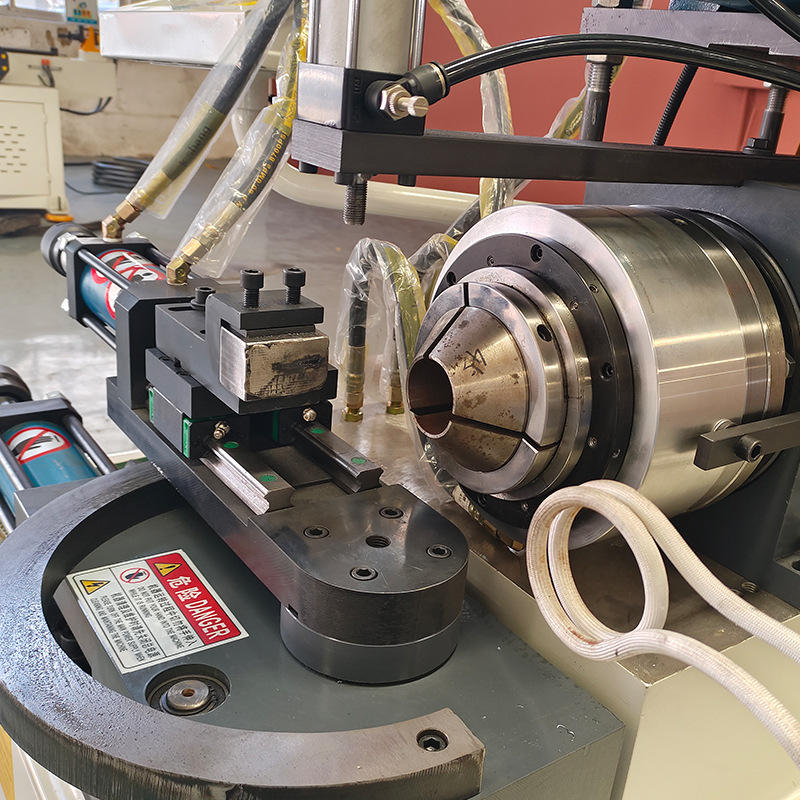

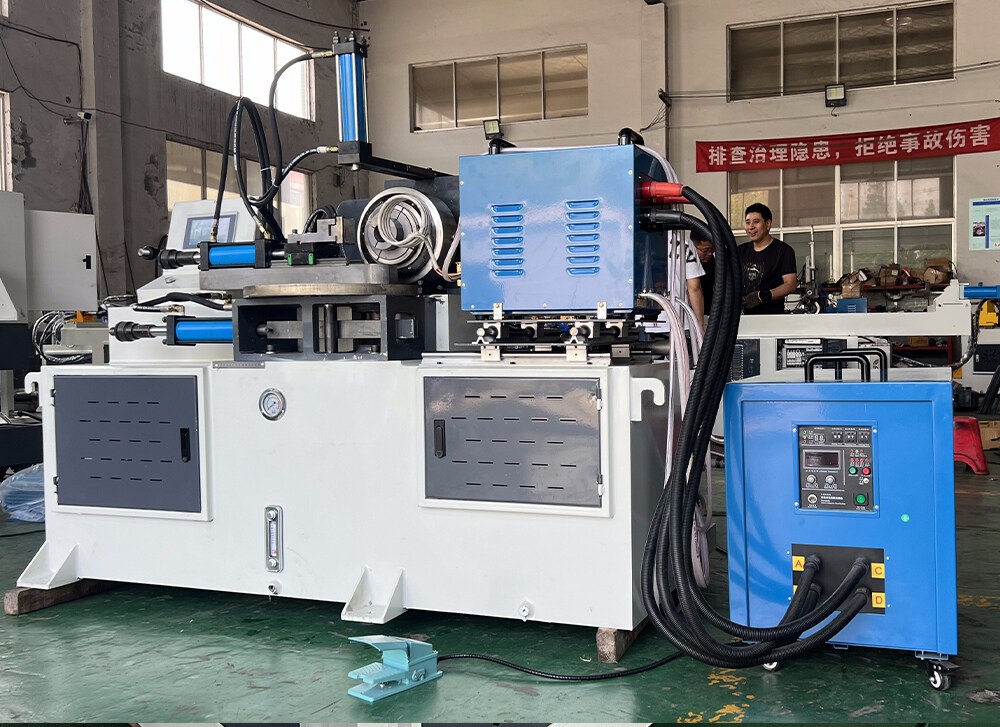

Automatic Tube End Closing Machine Images

Tube End Closing Machine Features

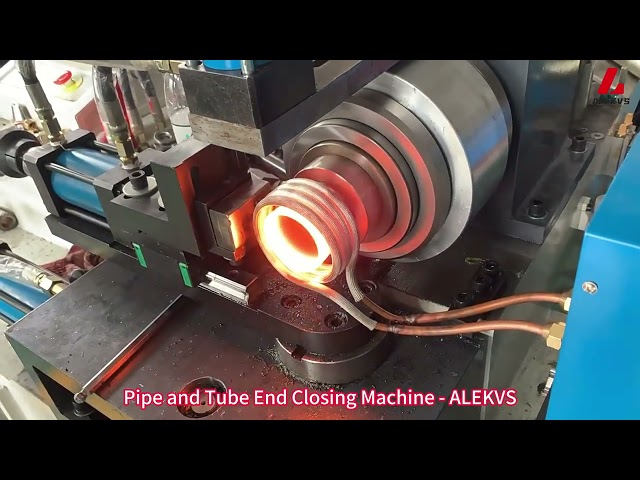

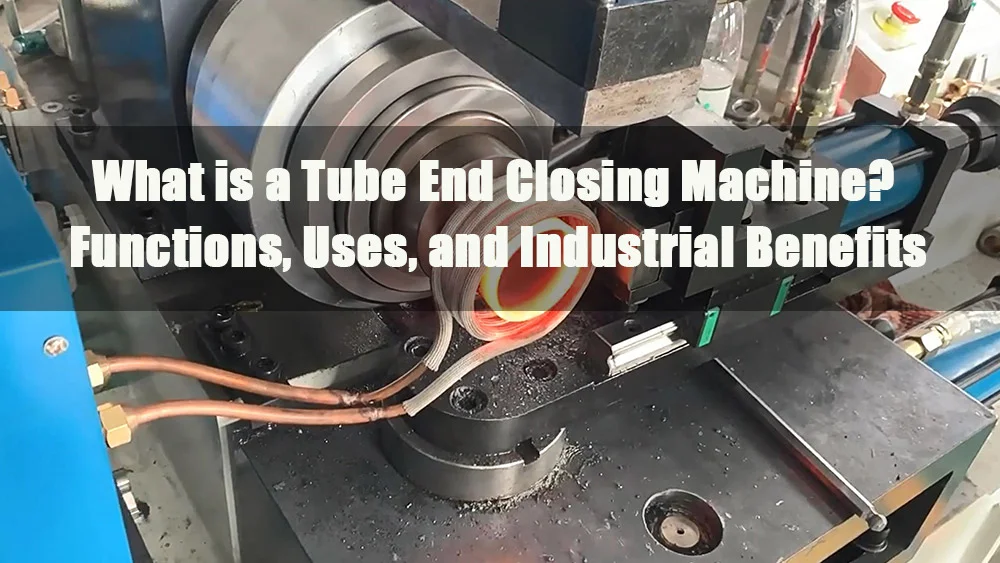

High-Efficiency Sealing Performance

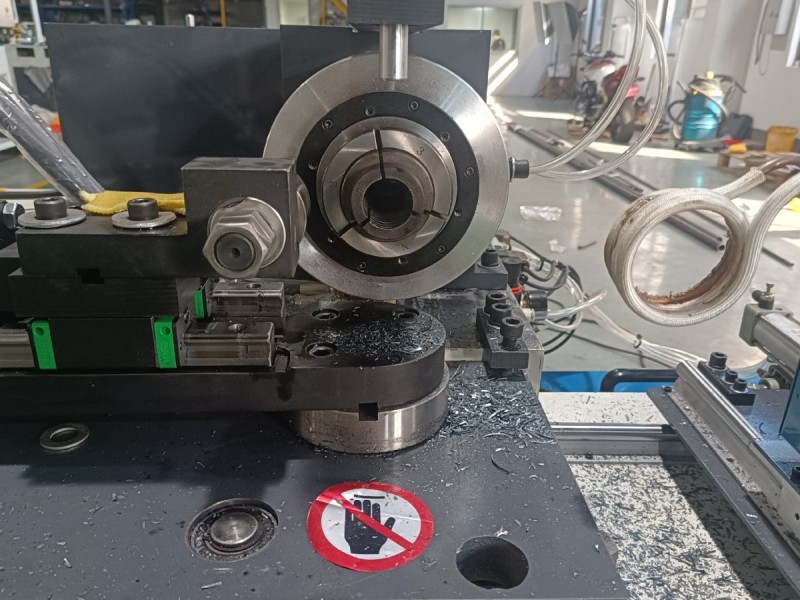

- Forms either flat-head or round-head structures according to the die shape.

- Supports fully closed sealing or partial hole retention as needed.

- Ensures uniform heating and stable pressure, preventing cracks and ensuring tight sealing.

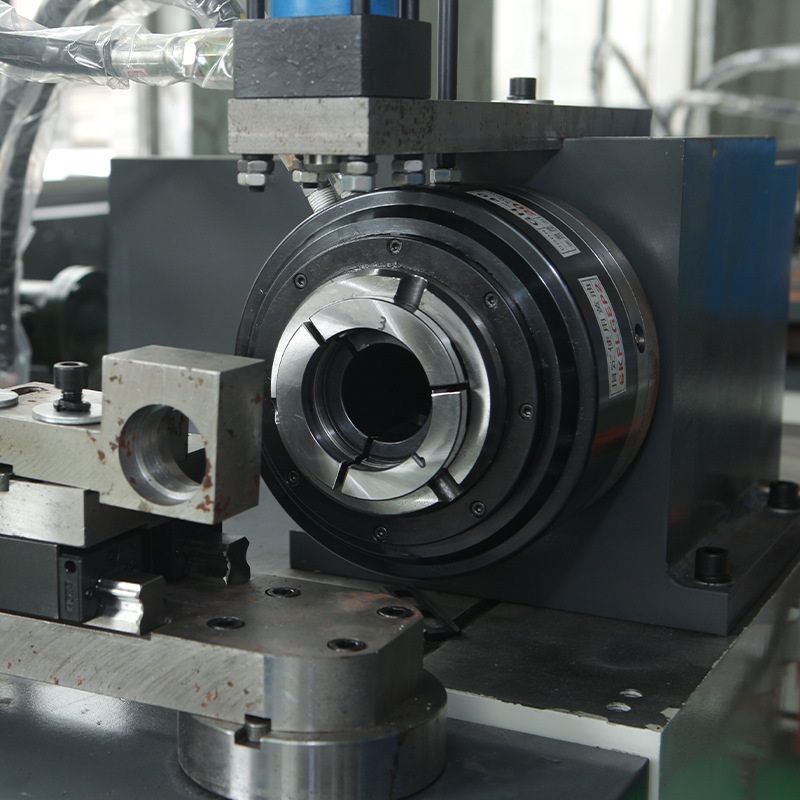

Multi-Material Compatibility

- Suitable for stainless steel, carbon steel, copper, aluminum, and iron tubes.

- Compatible with round or square tube profiles.

- Widely used in gas springs, shock absorbers, heat exchangers, strollers, bicycles, and automotive parts.

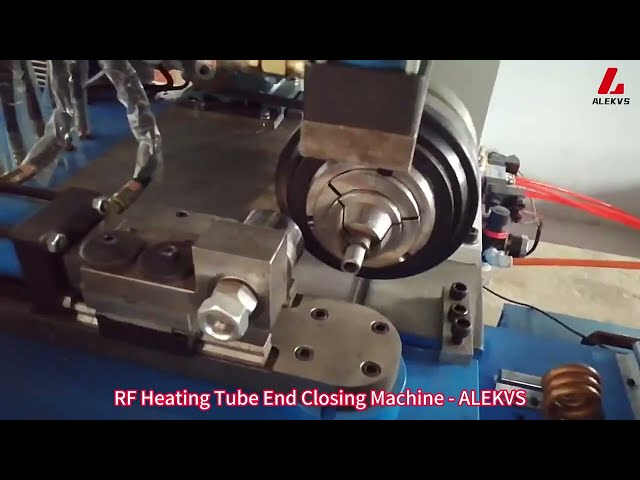

Advanced Control System

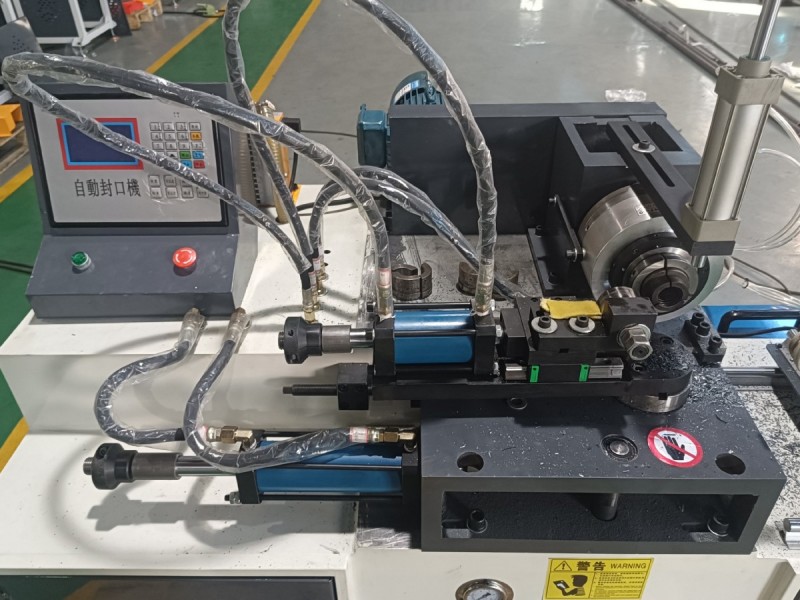

- Equipped with PLC + touch screen and microcontroller, enabling fully automatic operation.

- Precisely sets parameters such as heating time, temperature, and forming pressure.

- Offers both manual and automatic operation modes for flexible control.

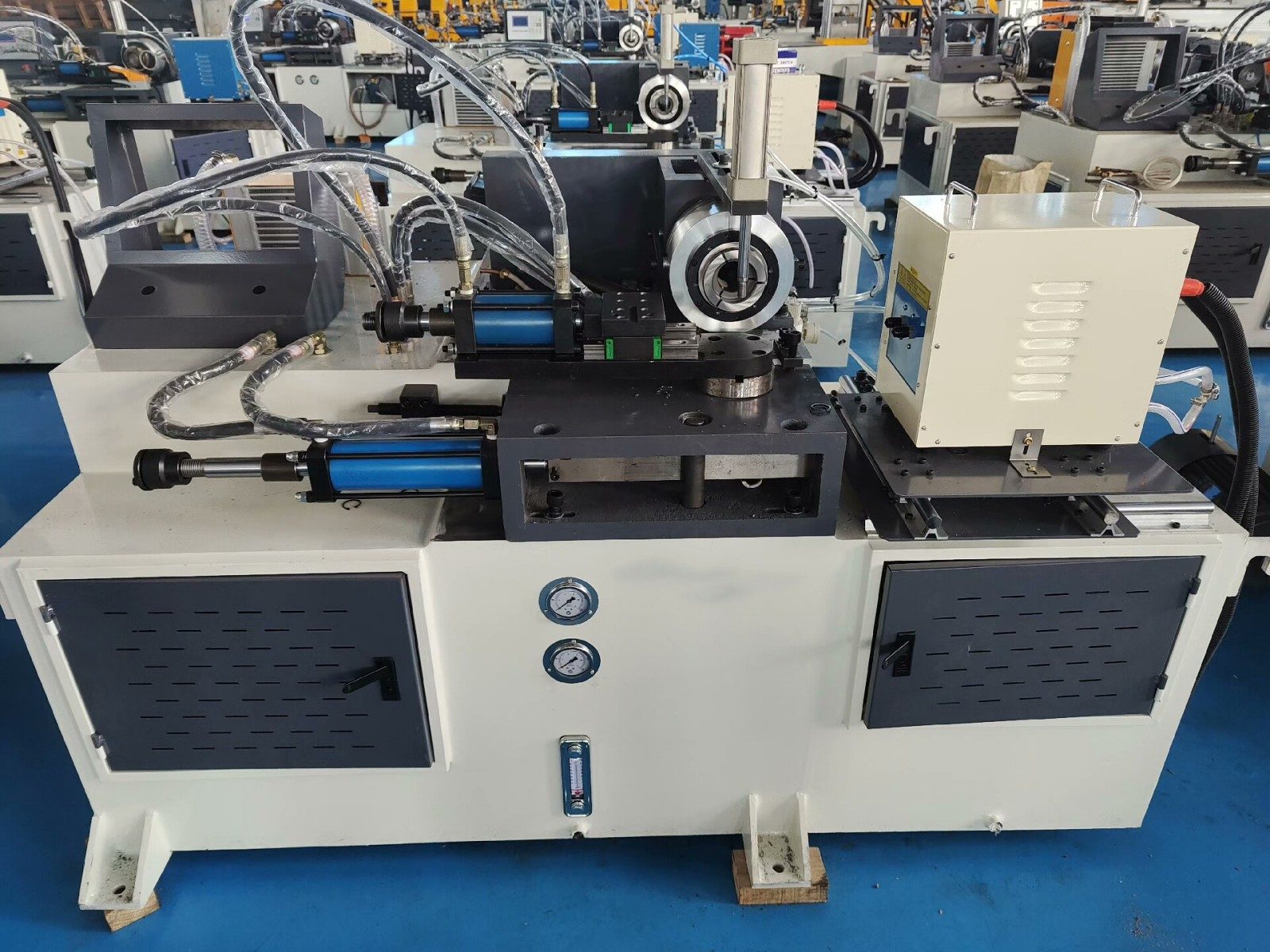

Optional Configurations – NC Tube End Closing Machine

- Automated loading and unloading system for mass production.

- Servo feeding and positioning system for improved dimensional accuracy.

- Custom die sets for different tube diameters and end shapes.

- Integrated cooling cabinet for continuous heavy-duty operation.

Typical Applications

- Boiler and heat exchanger tubing

- Automotive brake and fuel lines

- Motorcycle and bicycle frame tubes

- Furniture metal tubes

- Gas stove and burner tubes

- Shock absorbers and hydraulic cylinders

Please fill out this form to submit a request for quote. One of our team members will review the details and be in touch within 12 business hours.