In modern manufacturing, selecting the right metal forming process is critical to ensuring product quality, controlling production costs, and improving overall efficiency. Among the most widely used techniques are metal stamping and metal spinning, each offering unique advantages depending on part geometry, material, and production volume.

While metal stamping uses high-precision dies and presses to shape, contour, or emboss metal sheets—making it ideal for high-volume production—metal spinning employs rotational force to form symmetrical or hollow components, often in smaller batches or custom runs.

This article compares the two processes to help you determine the best fit for your application needs.

1.0What Is Metal Stamping?

Overview of the Metal Stamping Process

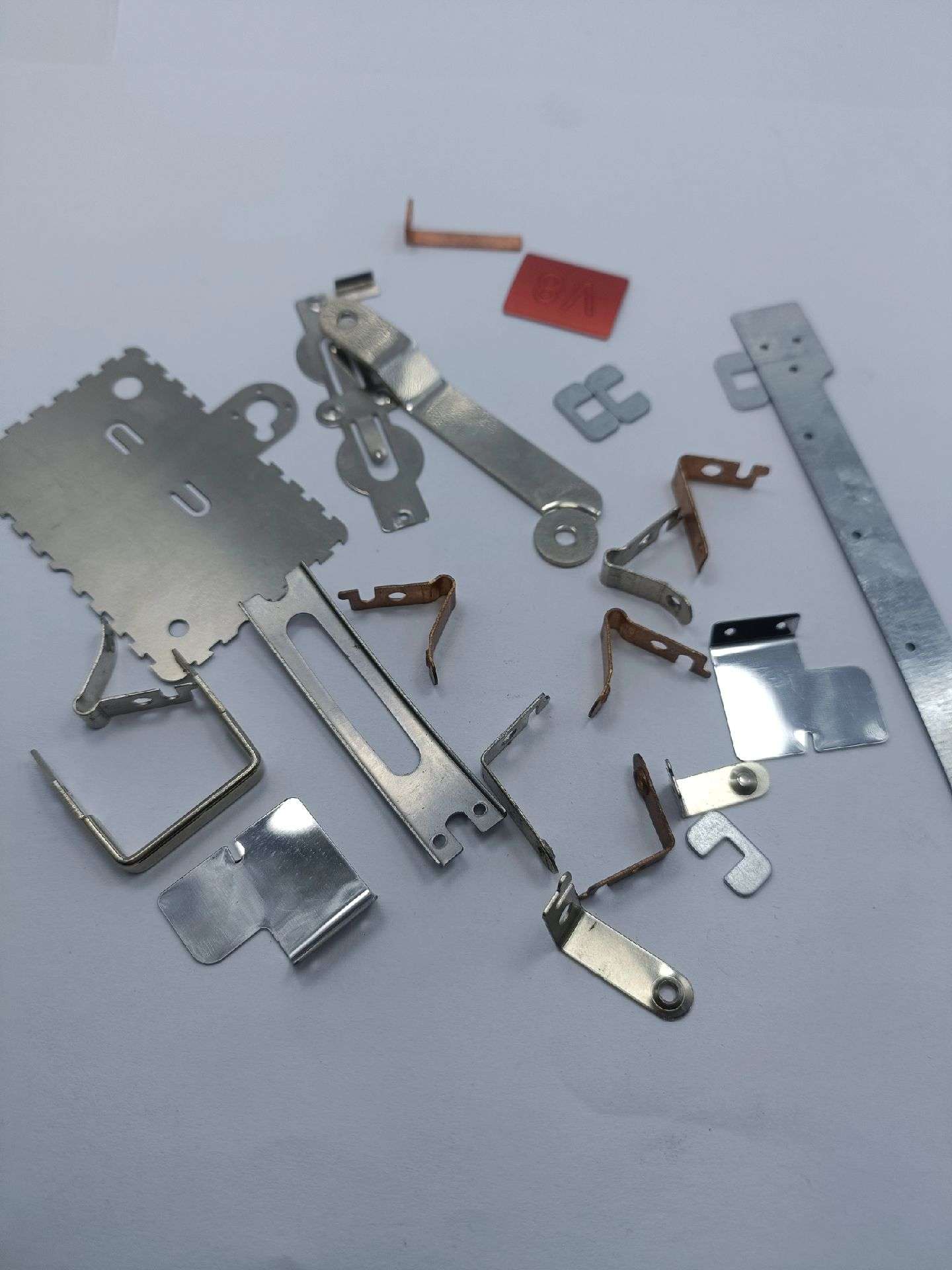

Metal stamping is a high-speed manufacturing process that uses dies and mechanical or hydraulic presses to transform flat metal sheets into specific shapes. By applying high-impact force, the metal can be cut, bent, deep-drawn, or embossed in a single or progressive operation. It is well-suited for large-scale production due to its efficiency and repeatability, often eliminating the need for secondary processing.

Typical Steps in Metal Stamping:

- Blanking: Cutting raw sheet metal into predefined shapes.

- Punching: Creating holes or cutouts in the material.

- Bending: Forming the metal into angles or curves.

- Deep Drawing: Producing hollow or cup-like shapes with depth.

Common Materials Used:

- Cold-rolled steel

- Stainless steel

- Aluminum alloys

- Copper and brass

Typical Applications:

- Automotive body panels

- Appliance housings

- Structural brackets

- Electrical hardware components

1.1Advantages of Metal Stamping

Metal stamping excels in high-volume production scenarios where consistency and precision are key. The process offers:

- High-speed throughput: Maximizes production rates for large orders.

- Excellent dimensional accuracy: Maintains tight tolerances across all parts.

- Cost-efficiency: Reduces unit cost over large production runs.

- Complex geometries: Capable of forming intricate shapes in a single operation.

- Process automation: Minimizes manual labor and increases repeatability.

- Durable components: Produces parts with high structural strength and longevity.

1.2Limitations of Metal Stamping

While metal stamping offers significant advantages for mass production, it also comes with certain limitations that must be considered during the design and planning stages:

- High initial tooling and setup costs: Designing and manufacturing stamping dies require a substantial upfront investment.

- Not cost-effective for low-volume runs or prototyping: Best suited for high production volumes; small batches often result in poor ROI.

- Limited design flexibility: Once the tooling is completed, making design changes is difficult and costly.

- Less suitable for thick-gauge metals: Stamping thick metal sheets can lead to excessive tool wear and reduced process efficiency.

- Material waste: The process often generates significant scrap material that must be managed or recycled.

2.0What Is Metal Spinning?

Overview of the Metal Spinning Process

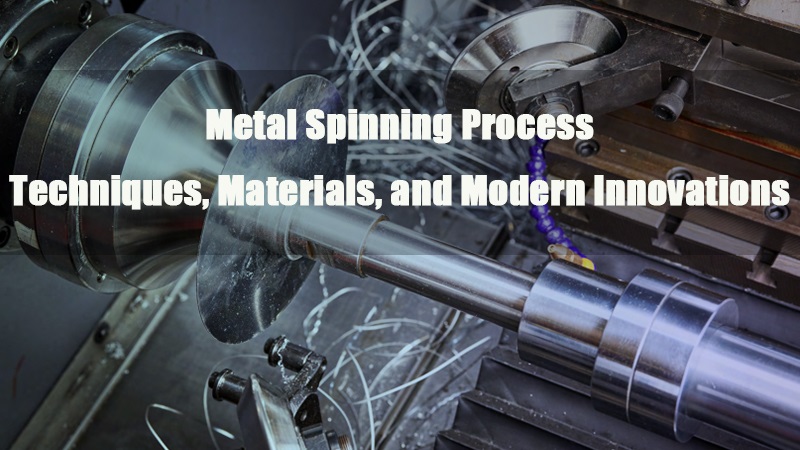

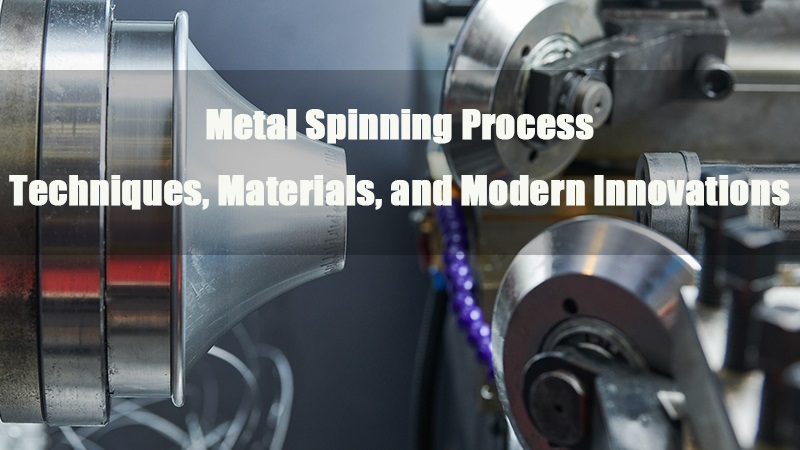

Metal spinning, sometimes compared to traditional pottery techniques, transforms flat metal blanks into symmetrical, hollow shapes using localized force and continuous rotation. Much like a potter shapes clay on a wheel, early metal spinning methods were inspired by this concept and have since evolved into a precise, versatile process widely used in aerospace, automotive, food processing, lighting, pharmaceutical, and defense industries.

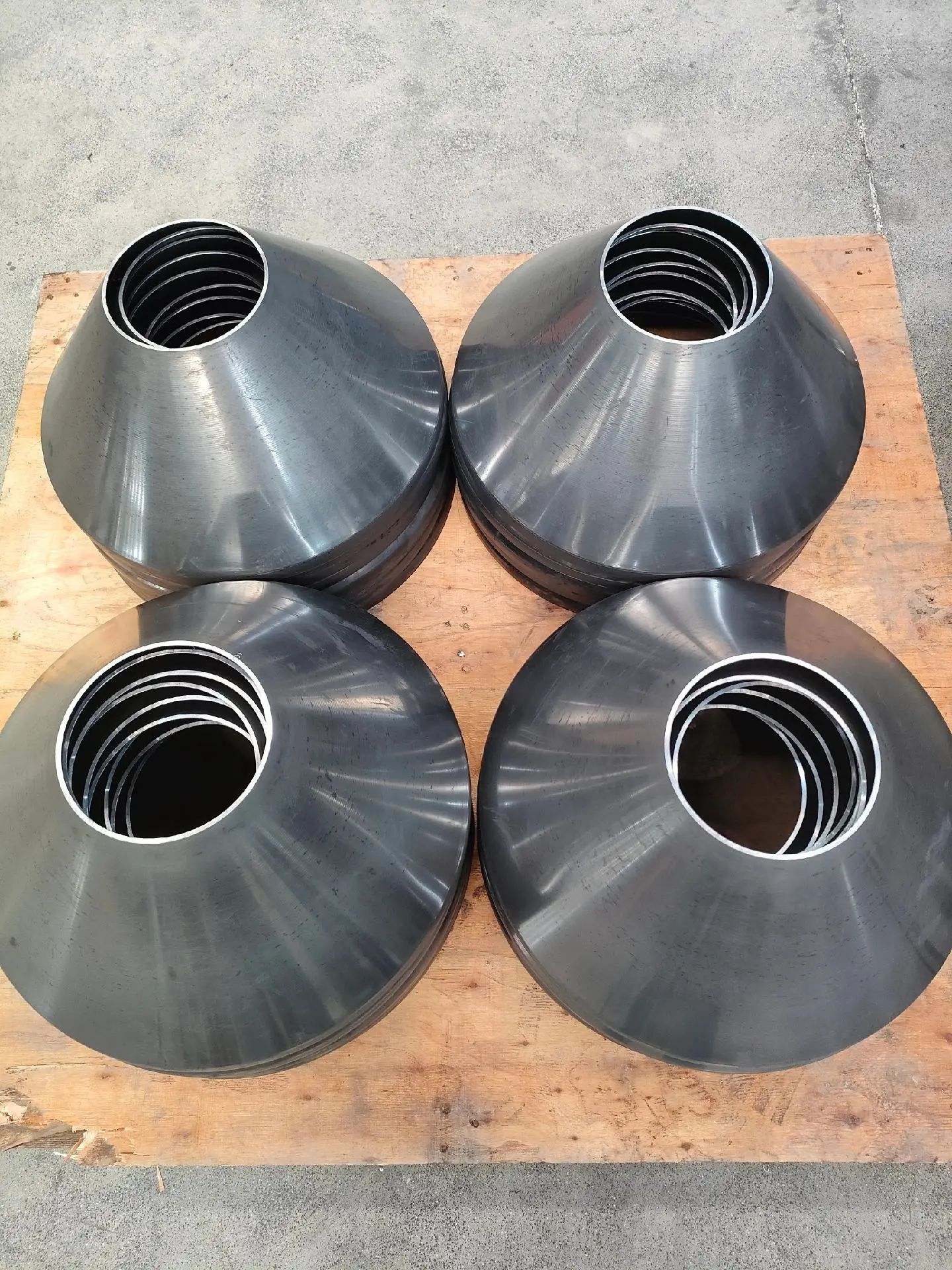

During the spinning process, a metal blank is rotated at high speed—typically on a metal spinning machine lathe—while a roller or forming tool applies pressure, gradually shaping the material over a mandrel (also called a spinning chuck). The method leverages the ductility of metals and is ideal for producing axisymmetric parts such as cones, cylinders, domes, and hemispheres.

2.1Key Characteristics of the Metal Spinning Process

- Application Scope: Best suited for axisymmetric components like cones, cylinders, and spherical caps.

- Feed Method: Tools can be fed manually or automatically using CNC-controlled systems.

- Production Type: Ideal for low- to medium-volume production and high-strength parts.

2.2Precision Metal Spinning Workflow

- Blank Preparation: The metal disc or blank is cut to the required size.

- Setup: The blank is mounted onto a mandrel, which is secured to a spinning lathe.

- Spinning/Forming: As the blank rotates at high speed, a roller or forming tool gradually presses it against the mandrel, shaping it into the desired form.

- Finishing: The formed part is trimmed and fine-tuned to meet dimensional and surface requirements.

Although metal stamping remains a dominant method in high-volume part production, it presents challenges for small-batch or fluctuating demand scenarios. In such cases, metal spinning offers a more agile and cost-effective alternative by reducing tooling investment and improving supply chain flexibility.

2.3Common Materials Used

- Aluminum

- Copper

- Stainless steel

- Titanium

- Nickel alloys

2.4Typical Products

- Lighting reflectors and housings

- Cookware bodies

- Pressure vessel end caps

- Aerospace radomes

- Loudspeaker enclosures

2.5Advantages of Metal Spinning

- Cost-effective for low-volume runs: Lower tooling costs make spinning ideal for small to medium production volumes.

- Flexible production: Shorter setup times and simplified tooling reduce lead times.

- High-quality output: Spinning maintains excellent surface finish and structural integrity.

- Adaptability to order size: Easily scalable for varying production quantities.

3.0Comprehensive Comparison: Metal Spinning vs. Metal Stamping

3.1Cost Comparison: Metal Spinning vs. Metal Stamping

Metal stamping requires high initial investment in custom tooling, making it ideal for high-volume production. However, for low- to medium-volume runs (typically under 10,000 units), metal spinning presents a more economical alternative. Tooling for spinning is significantly less expensive—often a fraction of the cost of stamping dies, and lead times are significantly shorter—often just a few weeks, compared to several months for stamped tooling.

For manufacturers seeking greater design flexibility and faster time-to-market without committing to costly, long-lead tooling, metal spinning offers a strategic advantage.

3.2Process Comparison: Metal Spinning vs. Metal Stamping

| Comparison Criteria | Metal Spinning | Metal Stamping |

| Cost-Efficiency in Low Volumes | Lower tooling cost makes it ideal for small to medium runs. | Most cost-effective for large production volumes; less economical for small runs. |

| Flexibility & Precision | Capable of forming complex, deep-drawn shapes with minimal waste; work hardening enhances strength. | High consistency and accuracy for large batches; ideal for streamlined production. |

| Labor Requirements | Requires skilled operators or CNC systems for precision forming. | Highly automated; minimal manual intervention in mass production. |

3.3Metal Stamping vs. Metal Spinning: Performance Comparison Table

| Aspect | Metal Stamping | Metal Spinning |

| Production Speed | Very high; optimized for mass production | Moderate; better suited for low-to-mid volume or custom parts |

| Tooling Costs | High; requires custom dies | Low; often uses simple tooling or none at all |

| Part Geometry | Best for flat parts, shallow draws, and bends | Ideal for deep-drawn, axisymmetric shapes (cylinders, cones) |

| Equipment | Presses and stamping dies | Manual or CNC spinning lathes |

| Material Utilization | Moderate; scrap is common | High; near-net shaping with minimal waste |

| Part Strength | Depends on material and die design | High; work hardening during spinning increases durability |

| Design Flexibility | Limited; changes require retooling | High; easy to modify shapes or dimensions |

3.4Summary: Pros and Cons of Each Process

| Process | Advantages | Disadvantages |

| Metal Stamping | – Ideal for high-volume, standardized production – Fast, consistent output – Mature, well-established technology |

– High tooling costs and long lead times – Inflexible for design changes – Less cost-effective for small runs |

| Metal Spinning | – Cost-effective for smaller batches – Flexible design and shorter tooling lead times – Strong, work-hardened parts with minimal waste |

– Slower than stamping for high-volume jobs – Labor-intensive unless CNC controlled – Limited to symmetrical shapes |

4.0When to Choose Metal Stamping Over Metal Spinning?

Although both metal stamping and metal spinning are essential metal forming processes, they serve different production needs. Choosing the right method depends on factors like production volume, part geometry, tooling cost, and lead time.

Metal stamping is often the best choice when:

- High-volume production is required: Stamping offers exceptional throughput and is highly cost-effective when producing tens or hundreds of thousands of identical parts.

- Precision and repeatability are critical: Once stamping dies are created, they can produce parts with tight tolerances and consistent quality.

- Automation is a priority: Stamping processes can be fully automated, reducing labor costs and human error.

- Flat or shallow parts are involved: Stamping is ideal for parts with 2D or shallow 3D features like brackets, panels, or housings.

- Post-processing must be minimized: Stamped parts often require little or no secondary machining or forming.

Metal spinning, on the other hand, may be a better fit when:

- You need low-to-medium production volumes: Spinning has lower tooling costs and setup requirements.

- Designs are still evolving: Spinning tooling is easier and cheaper to modify, making it suitable for prototype or flexible production.

- The parts are axisymmetric: Components like cones, domes, cylinders, and hemispheres are ideal for spinning.

- You’re working with specialty materials: Spinning allows work hardening during forming, enhancing strength without adding steps.

5.0How to Choose the Right Metal Forming Process?

Choosing between stamping and spinning should be based on a comprehensive evaluation of the following factors:

| Decision Factor | Recommended Process |

| Product shape is rotationally symmetrical | Metal spinning is more suitable |

| Requires high-volume, automated production | Stamping is preferable |

| Limited budget and need for rapid development | Metal spinning has lower startup costs |

| Pursuit of high-strength, lightweight parts | Metal spinning outperforms stamping |

| Product shape is complex and changes frequently | Metal spinning offers more flexibility |

6.0Metal Stamping VS Metal Spinning: Not Opposing, But Complementary

Metal stamping and metal spinning are not opposing competitive processes but complementary methods based on the shape of the part and production needs. For manufacturers, correctly understanding the technical characteristics, cost structures, and applicable scenarios of both processes will help make more informed process choices and enhance product competitiveness.

Ultimately, you need to consider the job specifications when choosing between stamping and spinning. If you are producing tens of thousands of parts and have ample delivery time, stamping is the industry standard, capable of accurately producing your parts in large volumes. However, if you want to produce smaller batches with greater flexibility and cost-efficiency, metal spinning can produce smaller batches at a lower cost and with shorter lead times.

Should you choose stamping or spinning? The answer is often hidden in the contours of your design drawings.