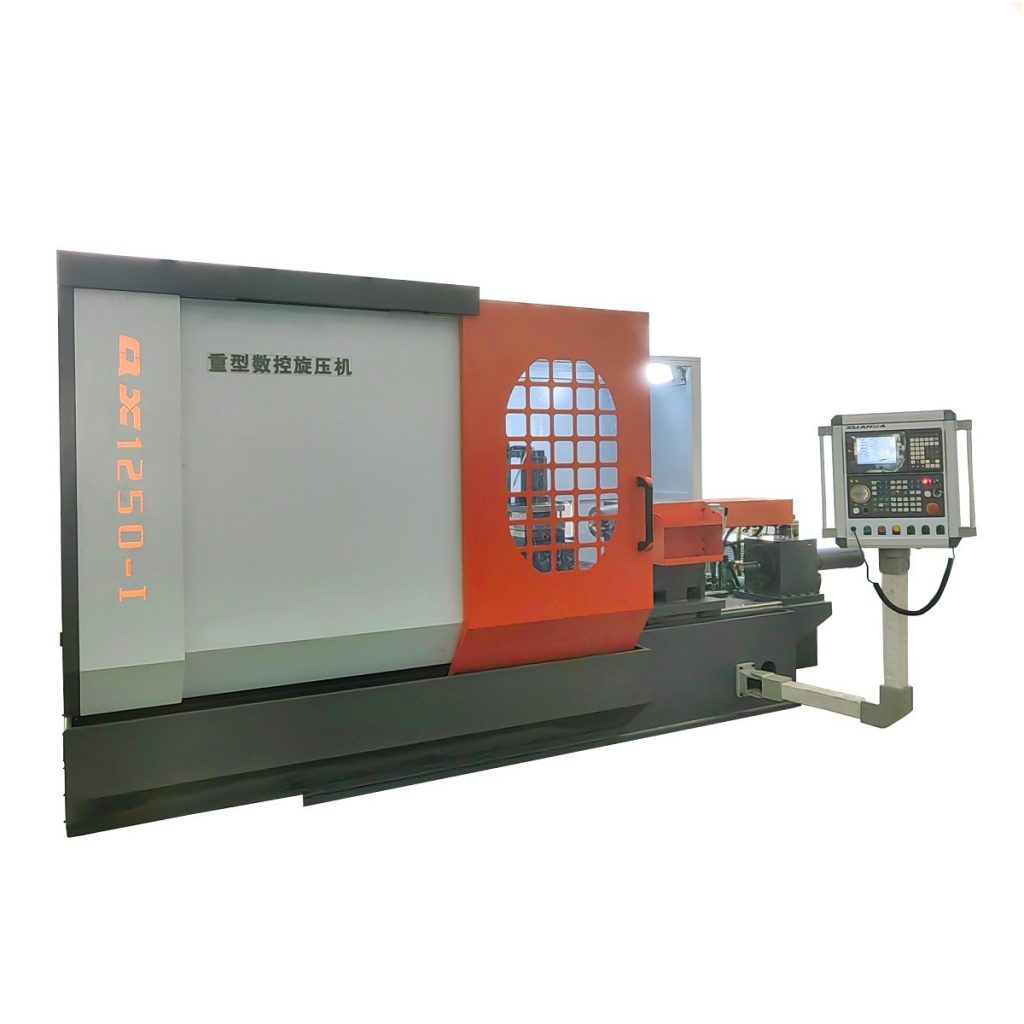

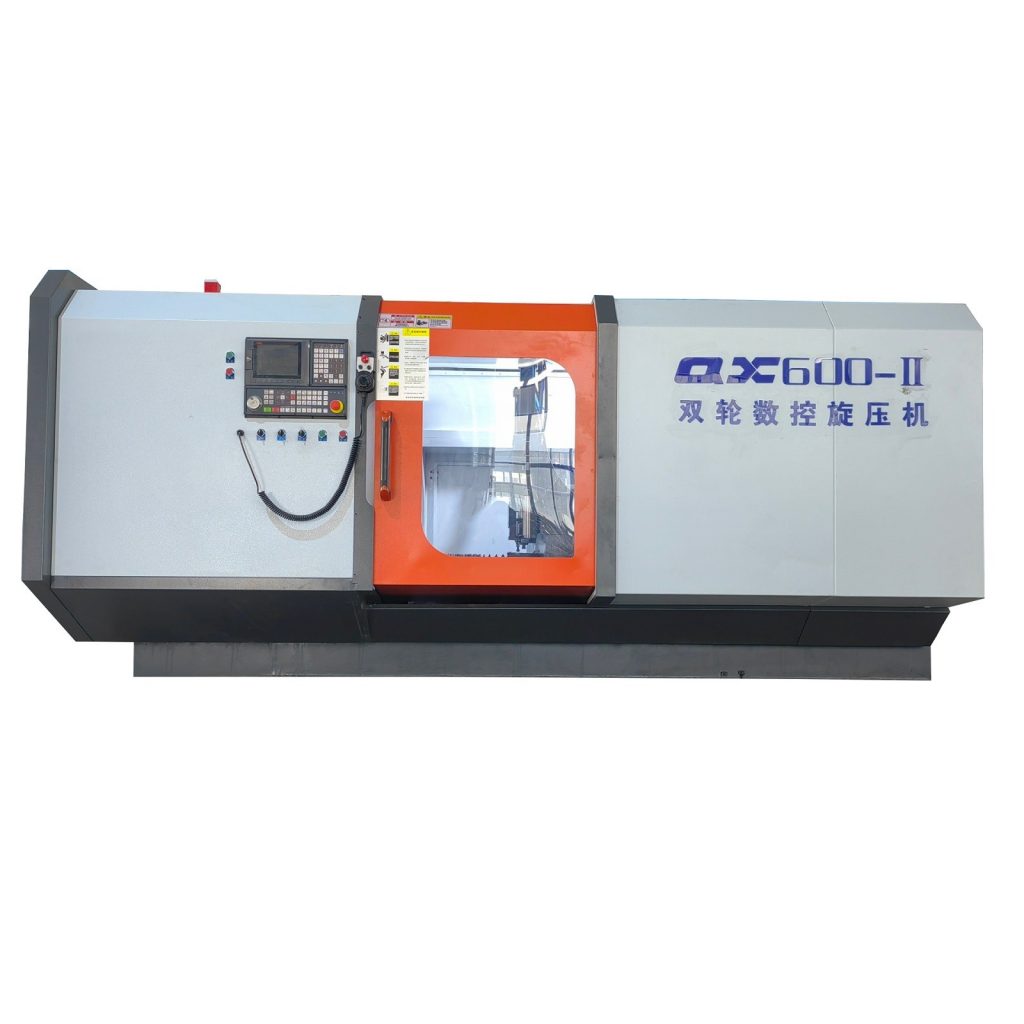

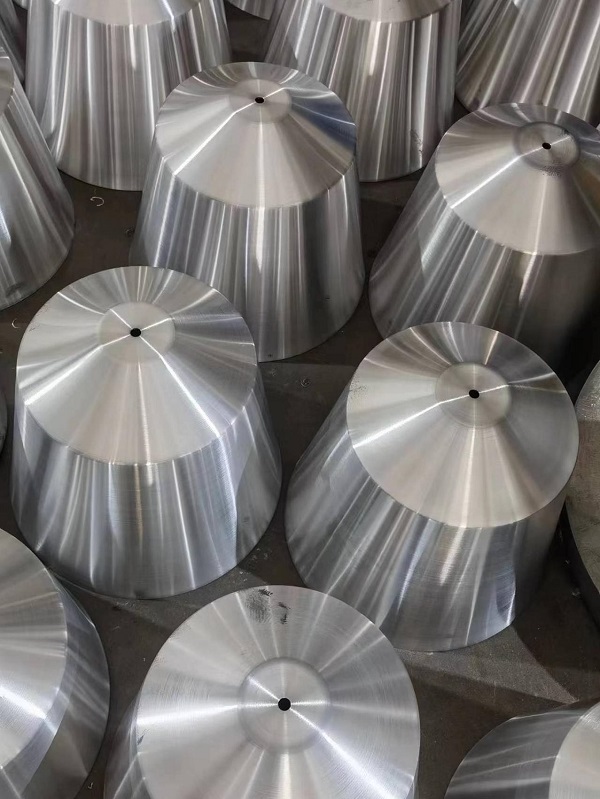

ALEKVS offers 8 series and over 30 models of CNC metal spinning machines, specifically developed for applications in lighting, artware, kitchenware, and automotive parts. These machines can produce horn, bucket, cone-shaped, and parabolic components, and perform trimming, flanging, and rolling — all on a single platform.

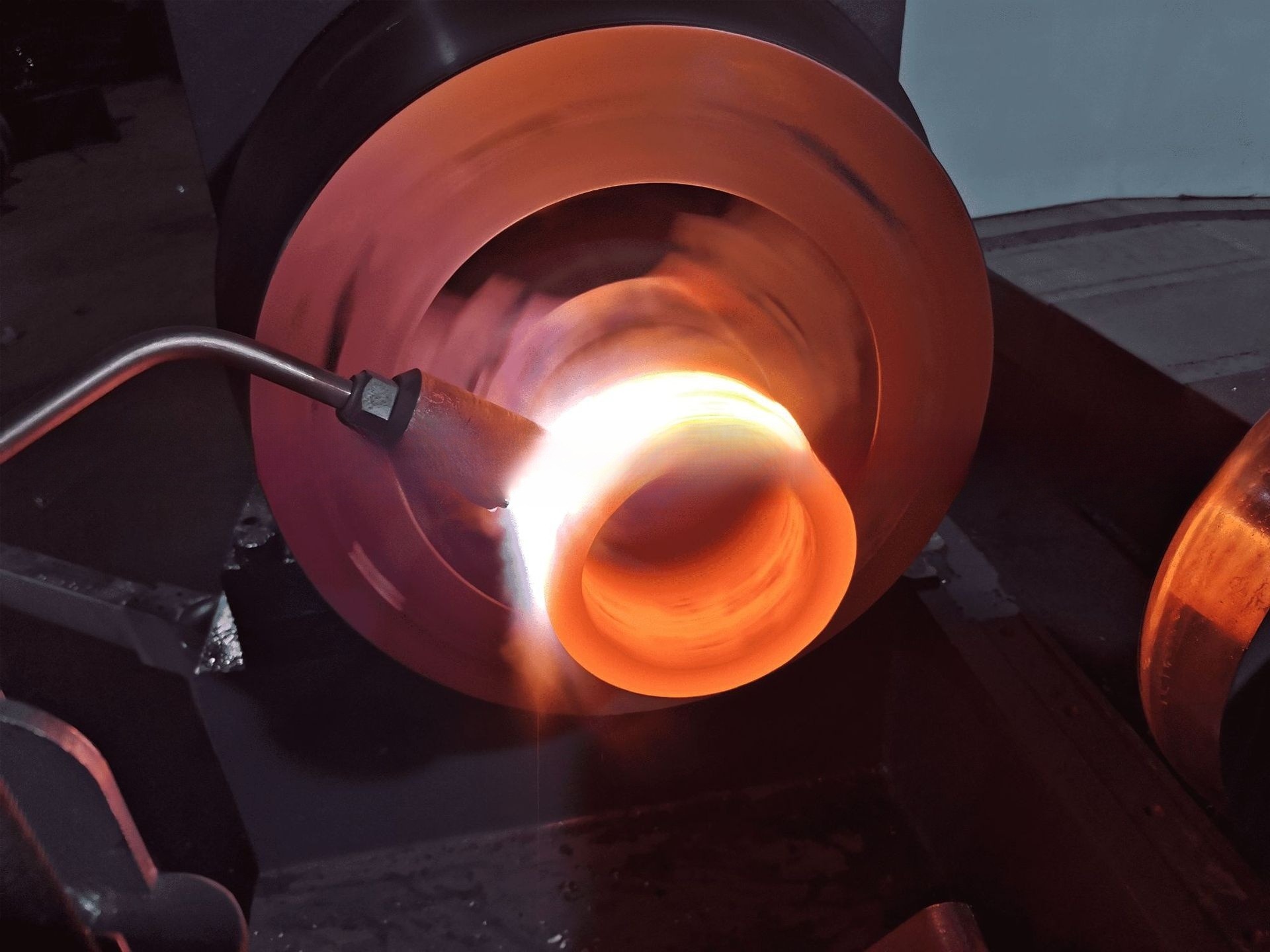

ALEKVS CNC spinning machines are practical, professional, and powerful. Designed for high production efficiency, they complete a wide range of spun parts in a single setup. They support multiple spinning techniques, including metal spinning, flow forming, neck-in, and shear spinning, and are compatible with carbon steel, stainless steel, aluminum, and copper.

Supported Materials

- Carbon steel

- Stainless steel

- Aluminum

- Copper

- Brass

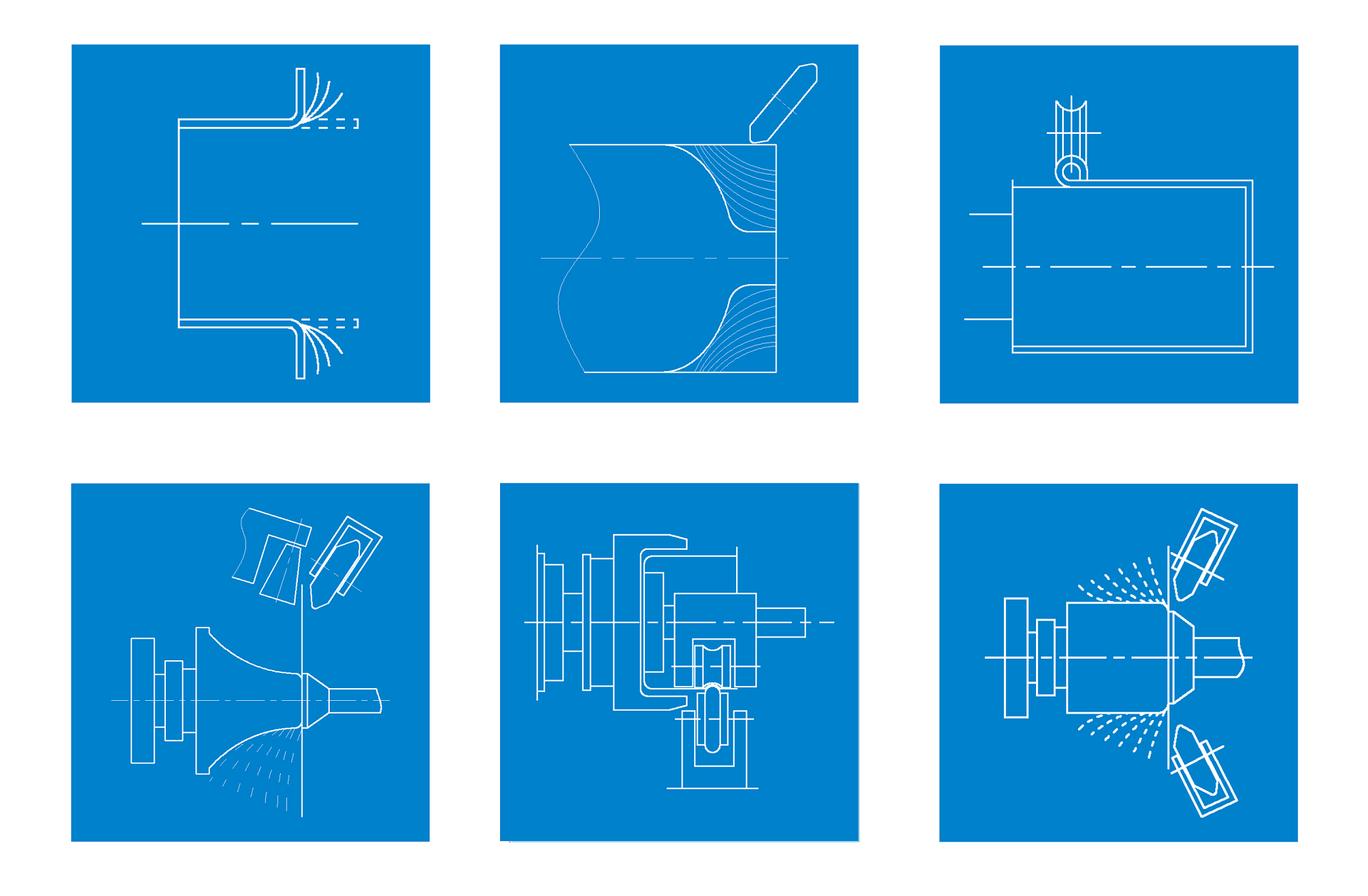

Process Capabilities

- Metal spinning

- Flow forming

- Neck-in forming

- Shear spinning

- Trimming, flanging, rolling (on the same machine)

Shape Flexibility

- Cylinder

- Toroid

- Cone

- Hemisphere

- Parabolic