Metal forming, as a vital branch of materials processing engineering, plays a key role in enabling the industrial application of metallic materials. Unlike casting, machining, or joining methods, metal forming relies on plastic deformation under external forces to reshape materials while simultaneously refining their internal grain structure and mechanical properties. This makes it possible to produce components with high strength, uniform microstructure, and excellent forming efficiency.

Depending on deformation temperature and process characteristics, metal forming is categorized into cold working, warm working, and hot working, which further branch into processes such as forging, rolling, drawing, and extrusion. These methods are widely applied in the manufacturing of products such as automotive crankshafts, architectural profiles, aerospace structural parts, and electronic conductors.

1.0Fundamentals of Metal Forming Theory

1.1Classification of Forming Processes

In industrial practice, the shaping of metal products primarily relies on four fundamental process categories, each with distinct technical roles and application scenarios:

- Casting: Molten metal is poured into a mold cavity and solidified to create the desired shape. It is well-suited for mass production of complex parts, though defects such as porosity and shrinkage may occur.

- Machining: Material is removed through cutting or grinding to achieve the final shape. It delivers high dimensional accuracy but has low material utilization, making it suitable for precision finishing.

- Joining: Components are assembled through welding, bolting, or adhesive bonding. This is commonly used for large-scale or complex assemblies.

- Plastic deformation (metal forming): External forces induce permanent plastic deformation in metals, optimizing both structure and performance during forming. It combines efficiency with mechanical advantages and is the central focus of this discussion.

1.2Influence of Metal Crystal Structure on Forming

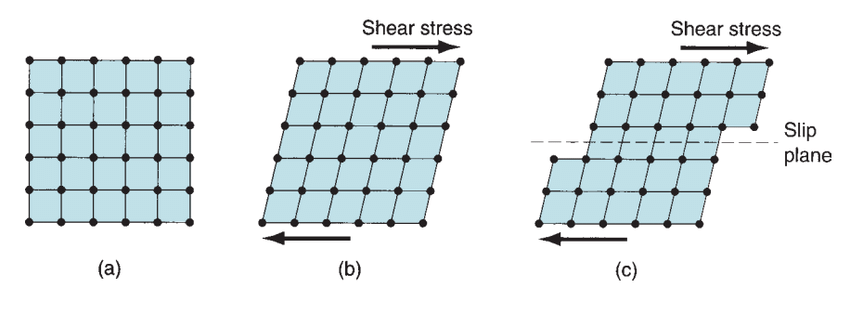

Metals are polycrystalline, composed of irregularly arranged grains, with atoms inside each grain arranged in a periodic lattice. When external forces act on metals, three key changes can occur:

- Grain fragmentation: If stress exceeds the lattice yield limit, grain boundaries slip and grains split.

- Atomic migration: Atoms diffuse along the stress direction, promoting adjustments in grain morphology.

- Lattice distortion: Atoms deviate from equilibrium positions, leading to internal stresses and strain hardening.

The plastic deformability of metals depends on ductility, which correlates positively with grain size. Larger grains have lower boundary resistance and allow greater deformation, while finer grains provide higher strength but greater resistance to deformation. Deformation temperature is another decisive factor: at room temperature, metals are rigid and require higher force to deform, while at elevated temperatures, atomic activity increases and deformation resistance is reduced.

1.3Core Differences Between Cold, Warm, and Hot Working

Cold Working

Definition: Plastic deformation performed below the recrystallization temperature (typically room temperature to 0.3Tₘ, where Tₘ is the melting point). In certain cases, slightly elevated temperatures (e.g., 50–100°C for copper) are used to enhance ductility.

Principle: Recrystallization does not occur. Grains elongate and distort in the stress direction, producing a “fibrous” structure. Lattice distortion causes strain hardening.

Characteristics:

- Advantages: Requires no heating equipment, produces smooth surfaces (Ra ≤ 1.6 μm), ensures high dimensional precision (tolerances up to IT8–IT10), enhances strength and fatigue performance, and avoids oxidation.

- Limitations: Requires significantly higher force (e.g., cold forging of low-carbon steel needs 30–50% higher load than hot forging), demands high-capacity equipment, reduces ductility (risk of cracking), often requires intermediate annealing to relieve work hardening, and may leave residual stresses.

Warm Working

Definition: Deformation performed in the intermediate range between cold and hot working (0.3Tₘ–0.5Tₘ), balancing the accuracy of cold working with the formability of hot working.

Principle: Temperatures are sufficient to lower deformation resistance and reduce strain hardening, but not high enough for complete recrystallization. Partial recovery occurs without grain coarsening typical of hot working.

Characteristics:

- Advantages: Tool loads reduced by 20–30% compared to cold working, improved ductility, fewer annealing steps required, dimensional accuracy close to cold working (IT9–IT11), and only mild oxidation or decarburization.

- Limitations: Requires precise temperature control (fluctuations ≤ ±20°C), equipment with thermal regulation, and has limited material applicability (mainly aluminum and copper alloys).

Hot Working

Definition: Plastic deformation performed above the recrystallization temperature (0.5Tₘ–0.8Tₘ), characterized by simultaneous deformation and recrystallization.

Principle: At elevated temperatures, atoms have sufficient energy for new strain-free grains to form, eliminating strain hardening. If residual heat is excessive, new grains may grow too large, reducing mechanical performance.

Characteristics:

- Advantages: Low deformation resistance (only 1/5 to 1/3 of cold working), high ductility (deformation >50%), absence of residual stress, grain refinement enhances mechanical properties, and lower equipment load requirements.

- Limitations: Requires significant heat input (e.g., steel forging at 1100–1150°C), prone to oxide scale formation (5–10 μm thick), lower dimensional accuracy (IT12–IT14), lower part consistency, and severe tool wear due to high temperatures.

Technical Significance of Recrystallization Temperature

The recrystallization temperature serves as the critical threshold separating cold and hot working. It is defined as “the lowest temperature at which deformed grains are fully replaced by strain-free new grains.” Recrystallization reduces strength and hardness (by 20–40%) while improving ductility (elongation can increase by over 50%). Specific ranges vary by material: steel (600–900°C), aluminum alloys (200–300°C), and copper alloys (300–400°C). In practice, hot working is terminated 50–100°C below the recrystallization temperature to prevent excessive grain growth.

2.0Forging Processes and Their Technical Characteristics

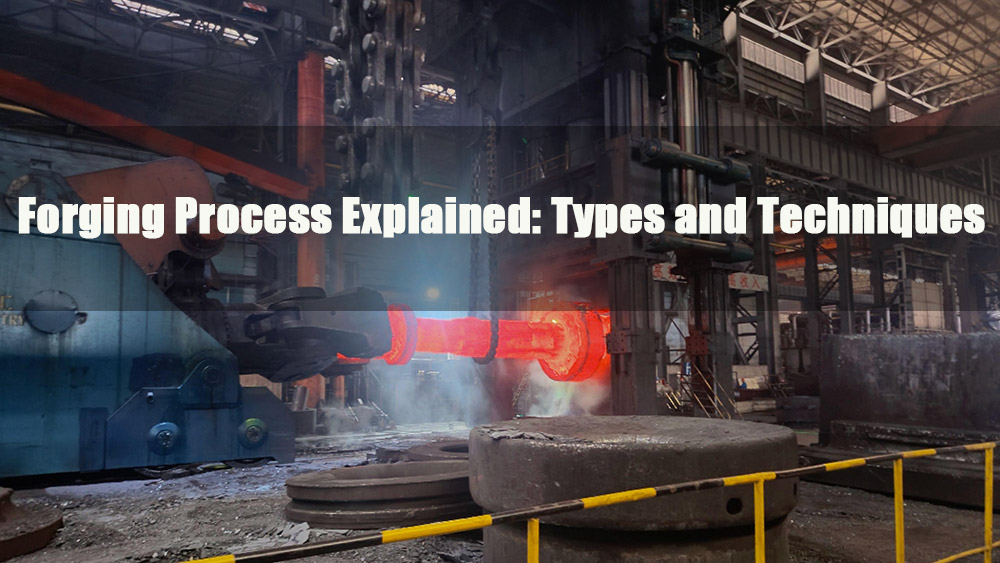

2.1Basic Concept of Forging

Forging is a metal forming process that uses localized compressive force to shape materials. The core principle relies on the impact or pressure of a hammer or die to force the metal to conform to the die cavity or to achieve desired shape control.

- By temperature : forging is categorized as hot forging (above recrystallization temperature), cold forging (at room temperature), and warm forging (intermediate temperatures).

- By die constraint: forging can be divided into open-die forging and closed-die forging.

2.2Main Types of Forging Processes

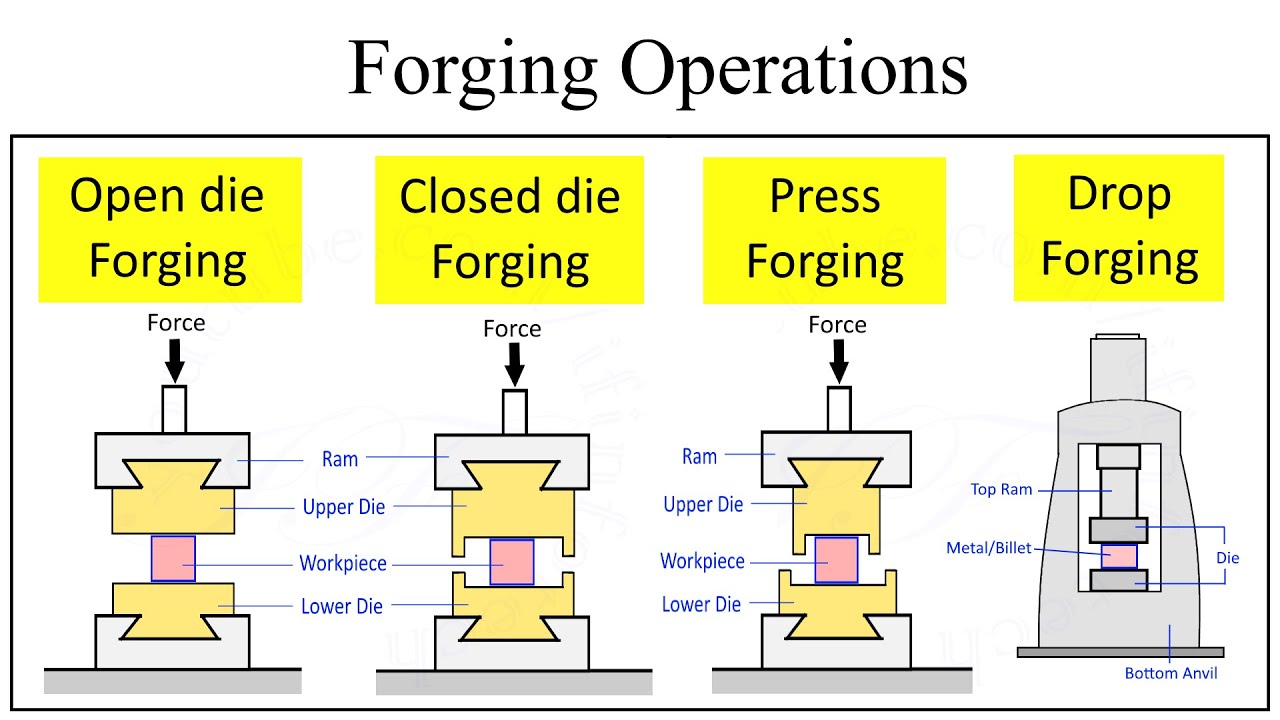

Open-Die Forging

Principle: Metal deforms between dies without an enclosed cavity. The upper die is attached to a ram, the lower die fixed to an anvil, and repeated hammering gradually brings the workpiece closer to its intended shape.

Applications: Large or asymmetrical components such as generator rotors and marine crankshafts, typically in single-piece or small-batch production.

Characteristics: High flexibility, low tooling cost, but low dimensional accuracy (tolerance ±5–10 mm). Requires additional machining and relies heavily on operator skill.

Closed-Die Forging

Principle: Metal deforms inside an enclosed die cavity. Single or multiple strikes ensure the cavity is fully filled. This can be subdivided into impression-die forging (with flash) and flashless forging.

Applications: Symmetrical parts produced in medium to large batches, such as gear blanks and bolt heads.

Characteristics: High dimensional accuracy (tolerance ±0.5–2 mm), good surface finish, uniform structure. However, tooling cost is significantly higher (5–10 times that of open-die tools), and precise die alignment is required.

Upset Forging

Principle: Axial compression reduces metal length and increases cross-sectional area. A typical application is bolt head production. To prevent buckling, unsupported billet length must not exceed three times its diameter.

Applications: Bar stock with diameter ≤200 mm, suitable for both cold and hot states. Common products include fasteners, valves, and couplings.

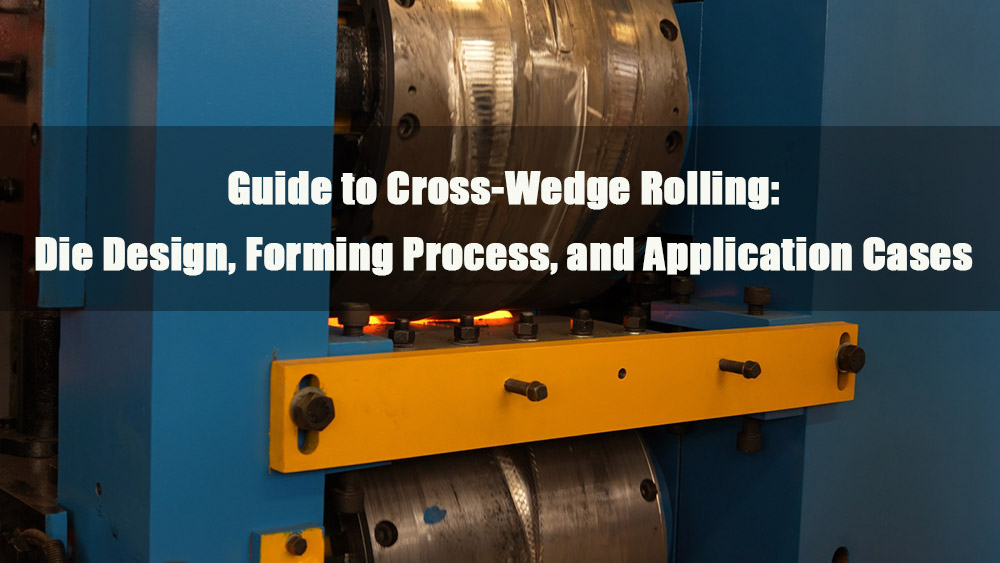

Roll Forging

Principle: Using a roll forging machine, heated bars are progressively compressed and elongated by eccentric rolls with forming grooves, allowing precise control over the cross-sectional shape.

Applications: Ideal for long shaft components such as leaf springs and axles, roll forging is commonly used as a preforming step before subsequent forging operations.

Characteristics: Offers high productivity (3–5 times that of open-die forging) and excellent material utilization (≥90%). However, it is generally limited to parts with symmetrical cross-sections.

2.3Forging Equipment and Defects

Core Equipment Types

- Hydraulic presses: Capacity 5–500 MN, apply slow, uniform pressure for even deformation. Suitable for large parts and precision forging.

- Mechanical presses: Capacity 900 kN–110 MN, use flywheel and crank mechanisms for force transmission, operating at 10–50 strokes per minute. Suitable for medium-batch production.

- Steam/pneumatic hammers: Generate impact force through gravity or compressed air, with capacities of 400–8000 kg. Commonly used for open-die forging of small components.

Typical Forging Defects and Causes

| Defect Type | Cause | Impact |

| Cold shuts/folds | Poor metal flow causing surface overlaps, often at corners | Reduced fatigue strength, crack propagation risk |

| Pitting | Scale embeds into the surface during hot forging | Degraded surface quality, requires additional grinding |

| Die misalignment | Improper die alignment causing cavity mismatch | Dimensional inaccuracy, may result in scrap |

| Internal cracks | Uneven heating or excessive deformation speed inducing internal stress | Breaks material continuity, lowers load capacity |

| Overheating/burning | Temperature exceeds solidus, causing grain boundary melting | Material embrittlement, loss of load-bearing capacity |

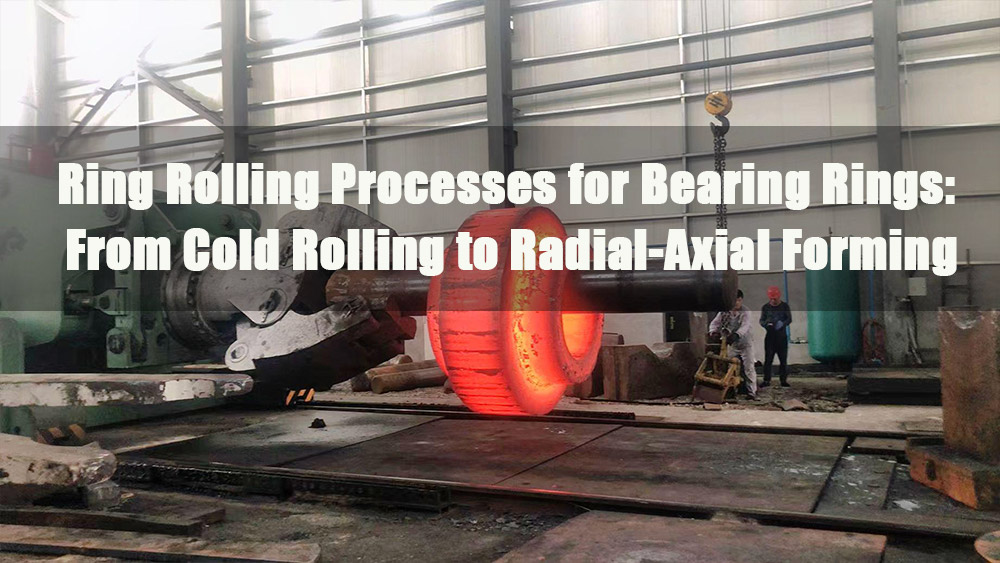

3.0Rolling Processes and Their Technical Characteristics

3.1Basic Principle of Rolling

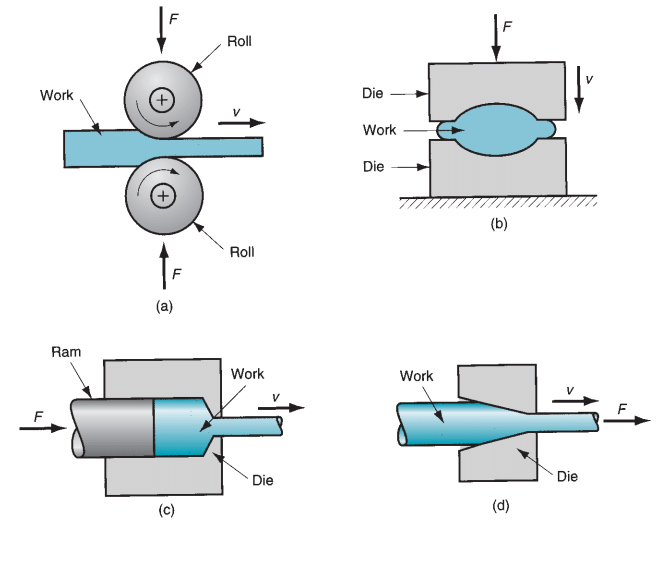

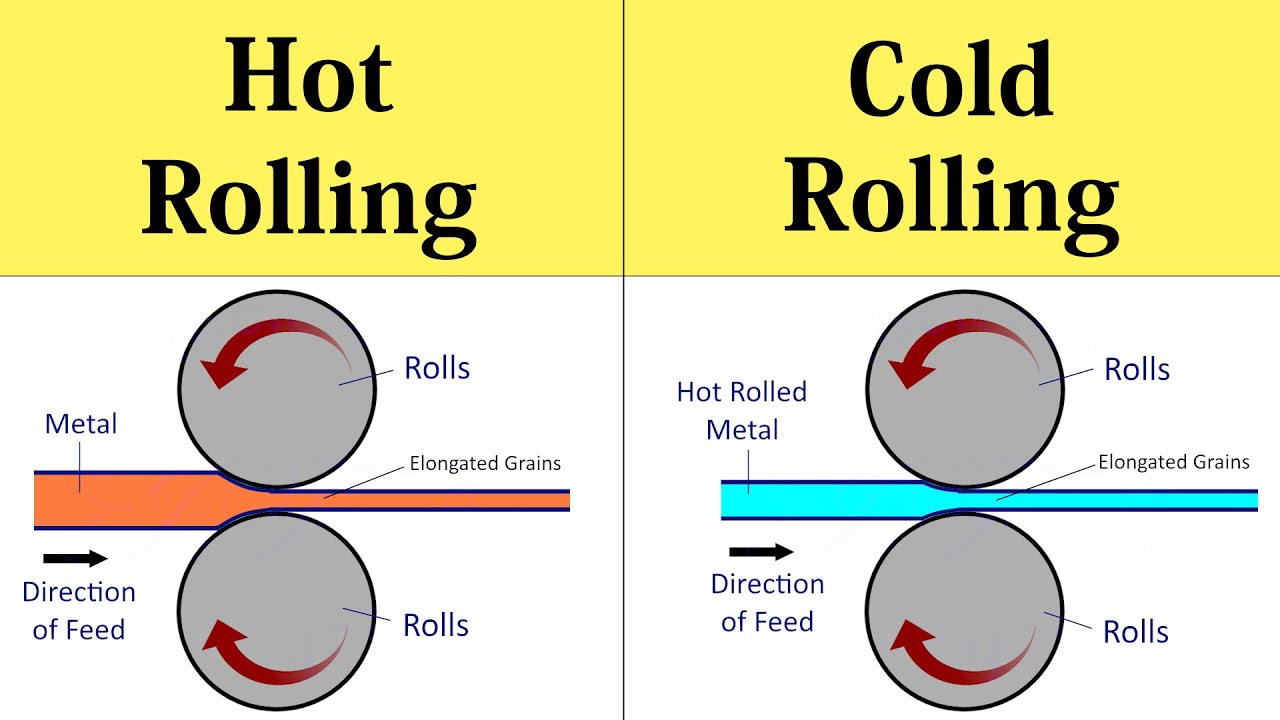

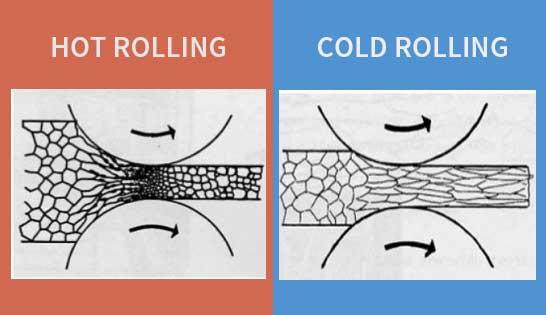

Rolling is a continuous forming process in which cylindrical rolls compress and elongate metal, reducing its cross-sectional area while increasing length. The key parameters include reduction (thickness decrease), reduction ratio (reduction/initial thickness), and spread (increase in width). Based on temperature, rolling can be divided into hot rolling (above recrystallization temperature) and cold rolling (at room temperature), with significant differences in microstructure and property control.

3.2Comparison Between Hot Rolling and Cold Rolling

| Technical Indicator | Hot Rolling | Cold Rolling |

| Temperature range | Steel: 1100–1150°C, Aluminum: 360–520°C | Room temperature to 0.3Tₘ |

| Microstructural change | Deformation and recrystallization occur simultaneously, producing refined and uniform grains | Grains elongate and distort, leading to strain hardening |

| Surface quality | Thick oxide scale (5–10 μm), poor finish (Ra ≥ 6.3 μm) | No oxide scale, excellent finish (Ra ≤ 1.6 μm) |

| Dimensional accuracy | Tolerance ±0.1–0.5 mm | Tolerance ±0.01–0.1 mm |

| Mechanical properties | Moderate strength, good ductility | Higher strength (20–40% greater than hot-rolled), lower ductility |

| Applications | Rough forming of profiles and thick plates | Final forming of thin sheets, strips, and precision profiles |

3.3Rolling Mill Types and Rolling Defects

Core Rolling Mill Types (by roll configuration)

- Two-high mill: Simple structure, available in reversing type (rolls rotate in both directions, used for rough rolling) and non-reversing type (single direction, used for simple sections).

- Three-high mill: Upper, middle, and lower rolls rotate alternately in opposite directions, enabling back-and-forth rolling of the workpiece. Suitable for medium and thick plates.

- Four-high mill: Composed of small-diameter work rolls (apply pressure) supported by large-diameter backup rolls (prevent bending). Commonly used for sheets and strips.

- Cluster mill: Work rolls with extremely small diameters (≤10 mm) are supported by multiple backup rolls. Suitable for producing ultra-thin strips such as aluminum foil (thickness ≤0.01 mm).

Typical Rolling Defects and Control Measures

- Wavy edges: Caused by roll bending leading to excessive edge reduction. Controlled by roll crown design (slightly larger diameter at the center).

- Zipper cracks: Result from insufficient ductility or excessively low rolling temperature. Controlled by preheating billets to an appropriate temperature.

- Lamination (alligatoring): Occurs when uneven deformation induces excessive central tensile stress. Controlled by optimizing reduction ratio (≤30% per pass).

- Folds: Caused by excessively low reduction, leading to overlapping surface metal. Controlled by ensuring a minimum reduction of ≥5% per pass.

4.0Drawing and Extrusion Processes

4.1Metal Drawing

Definition and Core Characteristics

Drawing is a process in which tensile force pulls a metal billet through a die opening, reducing its cross-sectional area. The key distinction from extrusion lies in the force direction: drawing uses “pulling,” while extrusion relies on “pushing.” Based on product size, drawing is categorized into:

- Bar drawing: Cross-section ≥10 mm², used for manufacturing shafts. Performed on a drawing machine with pulling forces ≤150 tons.

- Wire drawing: Cross-section ≤10 mm², used for wires and springs. Requires multiple passes (diameters can be reduced to as small as 0.0025 mm) with diamond dies to ensure precision.

- Tube drawing: Uses a mandrel to control inner diameter, either fixed or floating. Commonly applied for finishing seamless tubes.

Process Advantages and Limitations

- Advantages: High dimensional accuracy (tolerance IT7–IT9), excellent surface finish (Ra ≤0.8 μm), capable of producing complex cross-sections such as shaped bars.

- Limitations: Limited deformation per pass (diameter reduction ≤20%), requiring multiple passes with intermediate annealing. Best suited for small cross-section parts.

4.2Extrusion

Principle and Classification

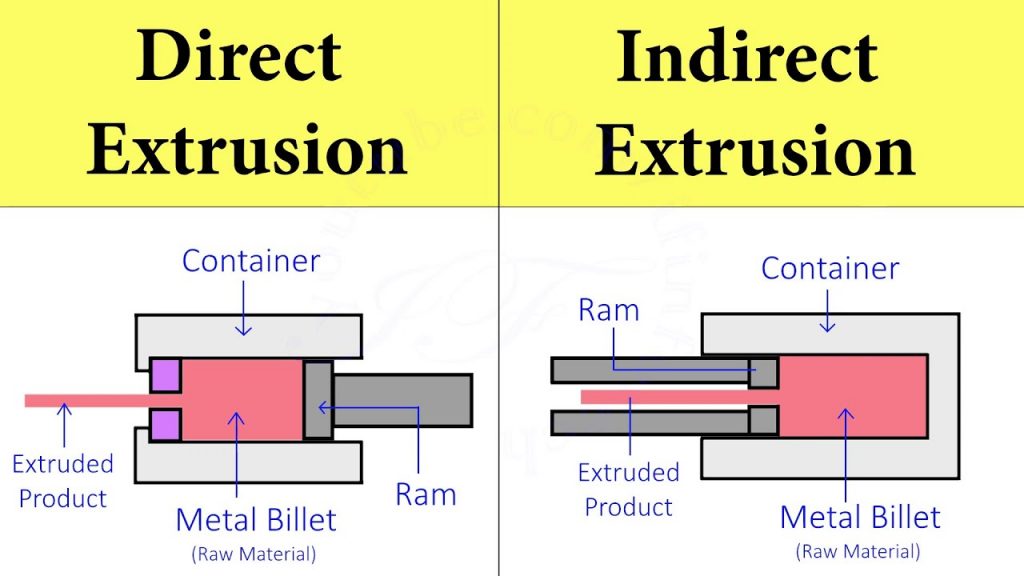

Extrusion places metal in a closed chamber and applies pressure through a ram, forcing it through a die to produce long products with cross-sections matching the die opening. By temperature and force direction, extrusion is divided into:

- Hot extrusion: Performed at 0.5Tₘ–0.75Tₘ, with pressures of 35–700 MPa. Widely used for aluminum and copper alloy profiles such as window frames and aerospace structures.

- Cold extrusion: Performed at room temperature to 0.3Tₘ. Applied to steel and aluminum precision parts such as cans and gear blanks. Enables near-net-shape forming.

- Direct (forward) extrusion: Metal flows in the same direction as the ram. Friction against the container must be overcome, making it suitable for simple cross-sections.

- Indirect (backward) extrusion: Metal flows opposite to the ram motion, eliminating container friction. Well-suited for complex hollow profiles.

Typical Extrusion Defects

- Surface cracks: Caused by excessively high extrusion temperature or speed, where surface stress exceeds tensile strength.

- Pipe defects: Uneven flow causes oxide scale and inclusions to be drawn into the product center.

- Internal cracks: High tensile hydrostatic stress at the die deformation zone center leads to void formation.

- Surface seams: Residual material from previous extrusion remains on the die surface and is imprinted on the product.

5.0Conclusion

Metal forming technologies are core enablers in modern manufacturing, ensuring efficient material utilization and precise control of mechanical properties. Each process carries distinct technical characteristics and application boundaries:

- Cold working (cold forging, cold rolling, cold drawing): Suitable for high-precision, high-strength components, but requires high-tonnage equipment and intermediate annealing.

- Hot working (hot forging, hot rolling, hot extrusion): Best for large deformation and large parts, with easy formability but lower precision and poorer surface quality.

- Warm working: Balances the advantages of cold and hot working, applicable for medium-precision and medium-batch components, but demands strict temperature control.

- Process-specific strengths: Forging excels in complex three-dimensional shapes; rolling is optimized for continuous long profiles; drawing is suited to small, precise cross-sections; extrusion enables complex and hollow profiles.

In practice, process selection should consider material characteristics (e.g., ductility, recrystallization temperature), product requirements (accuracy, strength, production volume), and cost constraints. Optimization of process parameters such as temperature, deformation speed, and die design helps reduce defects and improve both product quality and production efficiency.

Looking ahead, the development of metal forming will focus on intelligent temperature control, precision die design, and sustainable practices (such as oxidation-free hot forging) to meet the rising performance demands of advanced manufacturing industries.

References

www.researchgate.net/figure/Basic-bulk-deformation-processes-a-rolling-b-forging-c-extrusion-and-d-drawing_fig26_325178996

www.researchgate.net/figure/Deformation-of-a-crystal-structure-a-original-lattice-belastic-deformation-with-no_fig12_325178996

www.youtube.com/watch?v=YuQFhbRaWD0