- 1.0Classification and Applications of Metal Sawing Machines

- 2.0Power Hacksaw: Structure, Blades, and Operating Process

- 3.0Bandsaw: Vertical and Horizontal Types Explained

- 4.0Blade Selection and Wear Indicators

- 5.0Special Attachments for Bandsaws

- 6.0Operating and Safety Guidelines

- 7.0Coolant Guidelines

- 8.0Conclusion:

- 9.0FAQ: Common Questions About Metal Bandsaws

Metal bandsaws are indispensable in modern metalworking, offering unmatched precision, versatility, and efficiency for cutting metals of various sizes and hardness. From small repair workshops to large-scale industrial production, understanding the types of bandsaws, proper blade selection, operating procedures, and maintenance practices is crucial for maximizing productivity and extending equipment life.

1.0Classification and Applications of Metal Sawing Machines

Power Hacksaw

- Features: A reciprocating sawing machine that uses a single straight blade (4–14 TPI). The design is simple, with a rotating vise that allows straight or angled cuts.

- Applications: Ideal for small to medium production runs, straight or miter cutting tasks. Frequently used in repair workshops and for rough machining of parts.

- Suitable Materials: Medium- and low-hardness metals such as 45# steel and aluminum alloys. Cutting speed and efficiency are lower compared to bandsaws.

Bandsaw

- Features: Equipped with a continuous loop blade, bandsaws deliver high efficiency, precise cuts, and versatile performance. They are the most widely used sawing machines in metalworking.

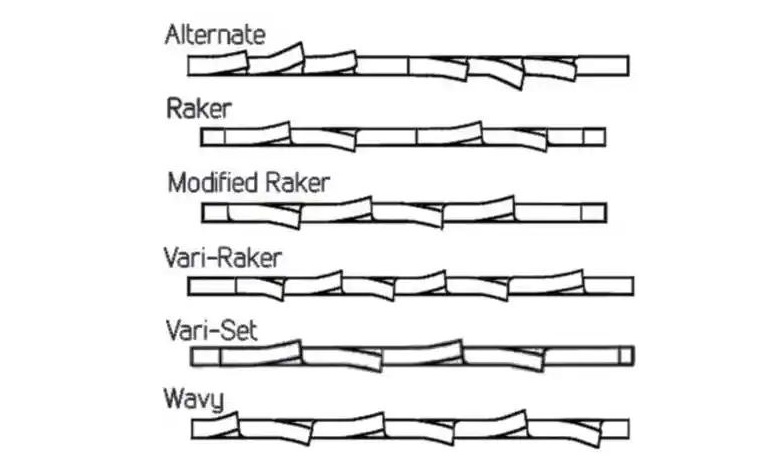

- Blade Options: 6–32 TPI, with raker, wave, or straight teeth available to match different materials and cutting requirements.

- Main Types:

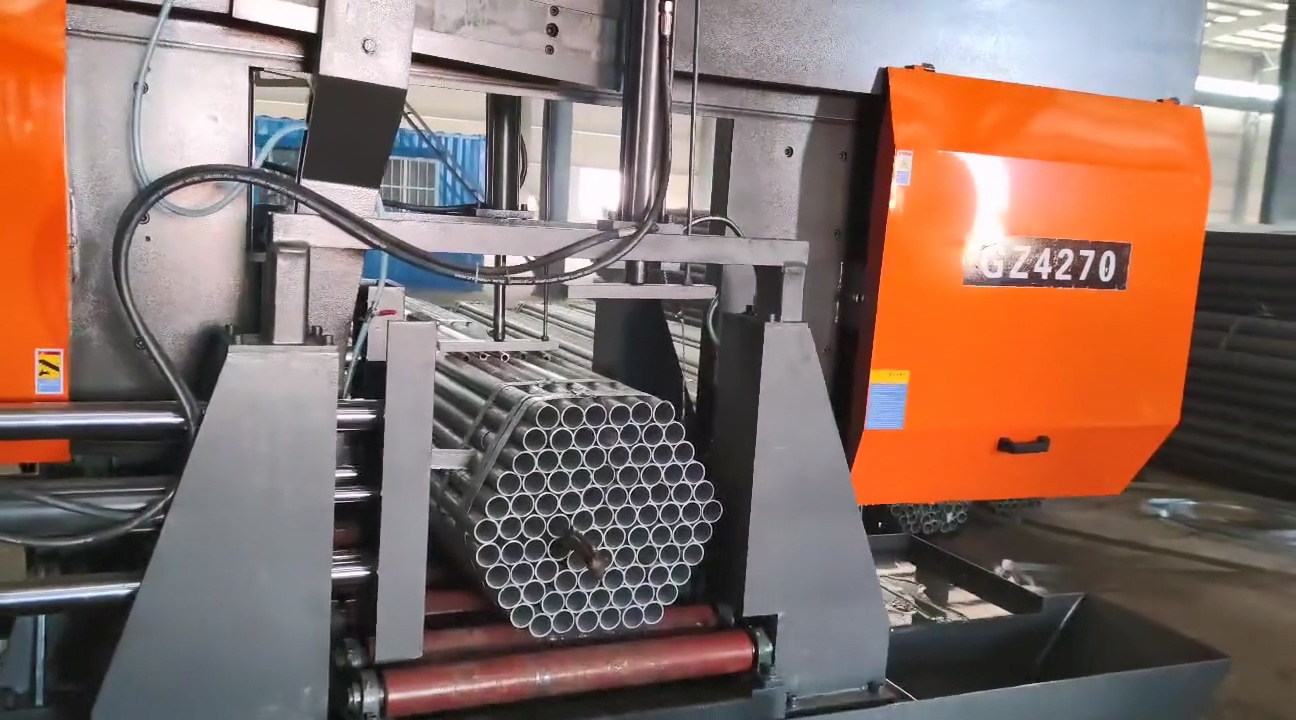

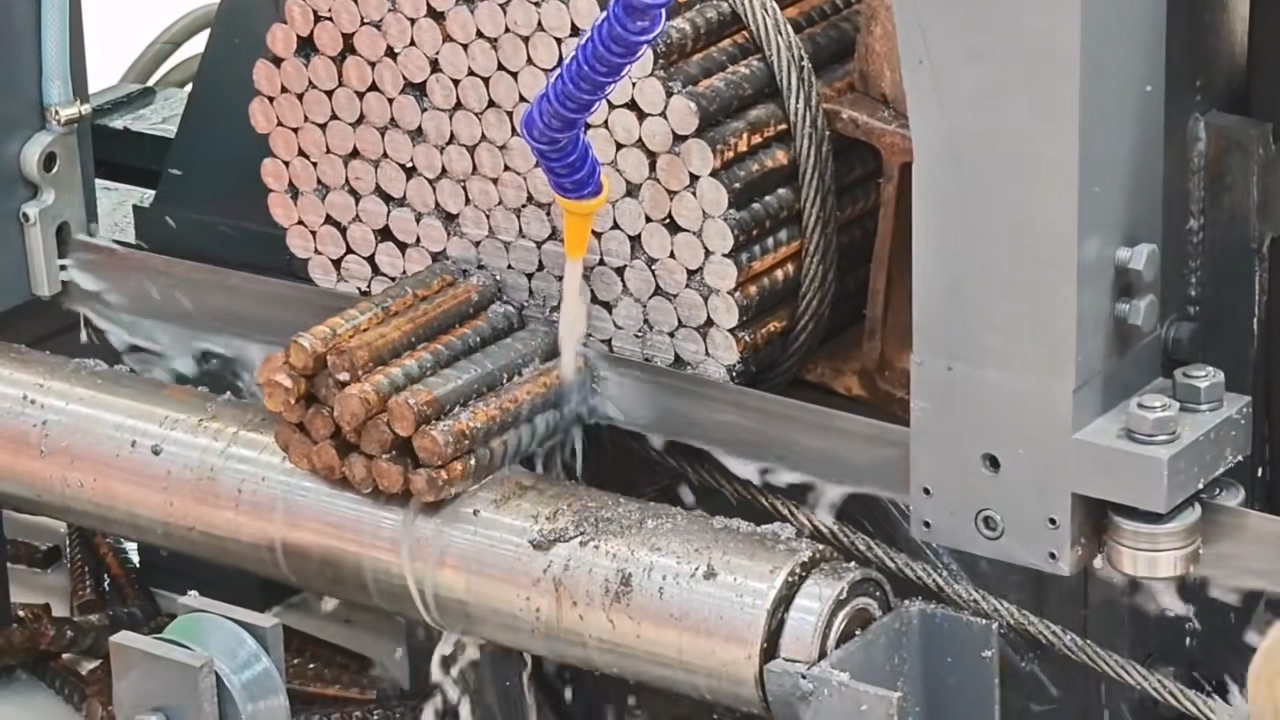

- Horizontal Bandsaw: Hydraulic-driven for efficient, straight, and fixed-length cutting of bars and plates. Delivers high material utilization rates of over 98%.

- Vertical Bandsaw: Blade is positioned vertically, making it suitable for curved shapes, irregular profiles, and internal cuts—commonly used for molds and artistic workpieces.

- CNC Bandsaw: Offers automatic programming for large-volume and complex cutting jobs, widely applied in the automotive and aerospace industries.

- Features: Uses a rotating circular blade for high-speed cutting. Cutting precision is positioned between power hacksaws and bandsaws.

- Main Types:

- Metal Circular Saw: Designed for cutting steel, aluminum, and stainless steel, including pipes and profiles.

- Woodworking Circular Saw: Uses fine-tooth or ground-tooth blades for accurate wood cutting, widely used in furniture production.

- Cut-off Circular Saw: Specialized for fixed-length cutting of materials such as rebar and bearing blanks.

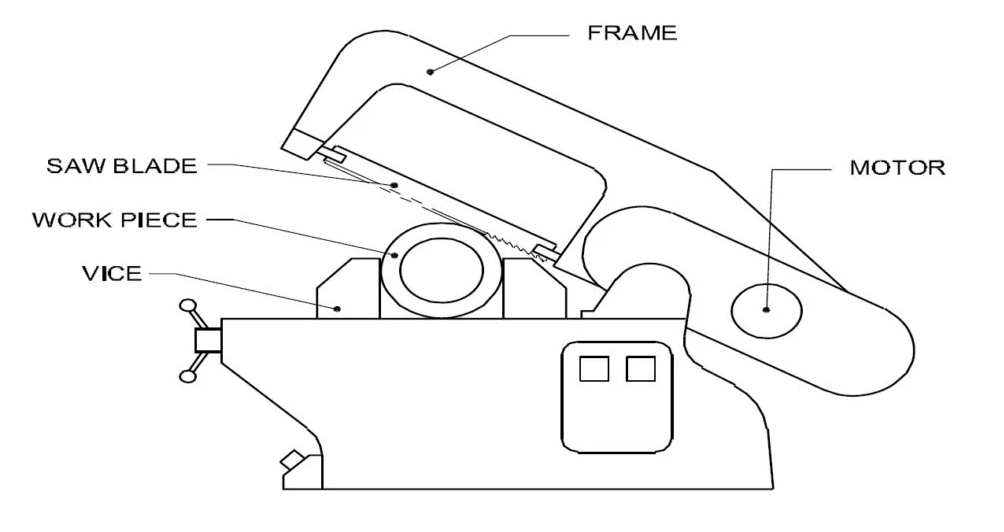

2.0Power Hacksaw: Structure, Blades, and Operating Process

Core Structure

- Base:Built-in coolant tank and pump; the top worktable supports the vise and workpiece. Internal baffles allow chips to settle.

- Vise:Adjustable to clamp workpieces of different sizes or shapes. Some models can rotate for miter cutting.

- Frame:Supports the hacksaw blade; engages the workpiece only on the cutting stroke (return stroke is free), reducing blade wear.

- Speed Change Mechanism:Adjustable strokes per minute (SPM), typically with fast/medium/slow settings to match different metal cutting speeds.

- Adjustable Feed Clutch:Controls feed rate in thousandths of an inch. Slips under overload to prevent blade breakage.

Blade Selection Guidelines

- Material:High-speed steel or tungsten steel; teeth hardened while the body retains toughness.

- Tooth Forms:Raker, wave, or straight; kerf is slightly wider than the blade to prevent binding.

- Tooth Pitch (TPI):Ranges from 4–14 teeth per inch. Coarse teeth for soft materials; fine teeth for harder materials.

- Replacement Timing:Replace dull blades directly; re-sharpening is not recommended.

Operating Procedure

- Marking and Measuring:Scribe the cutting line on the workpiece surface.

- Clamping and Alignment:Check the squareness of the vise and blade; rotate the vise for miter cuts.

- Stroke Adjustment:Manually move the frame to confirm the stroke is centered, preventing blade collision with the workpiece.

- Batch Cutting:Use a stop gauge to ensure consistent length across multiple pieces.

- Parameter Settings:Adjust stroke speed and feed rate according to material hardness, then start cutting.

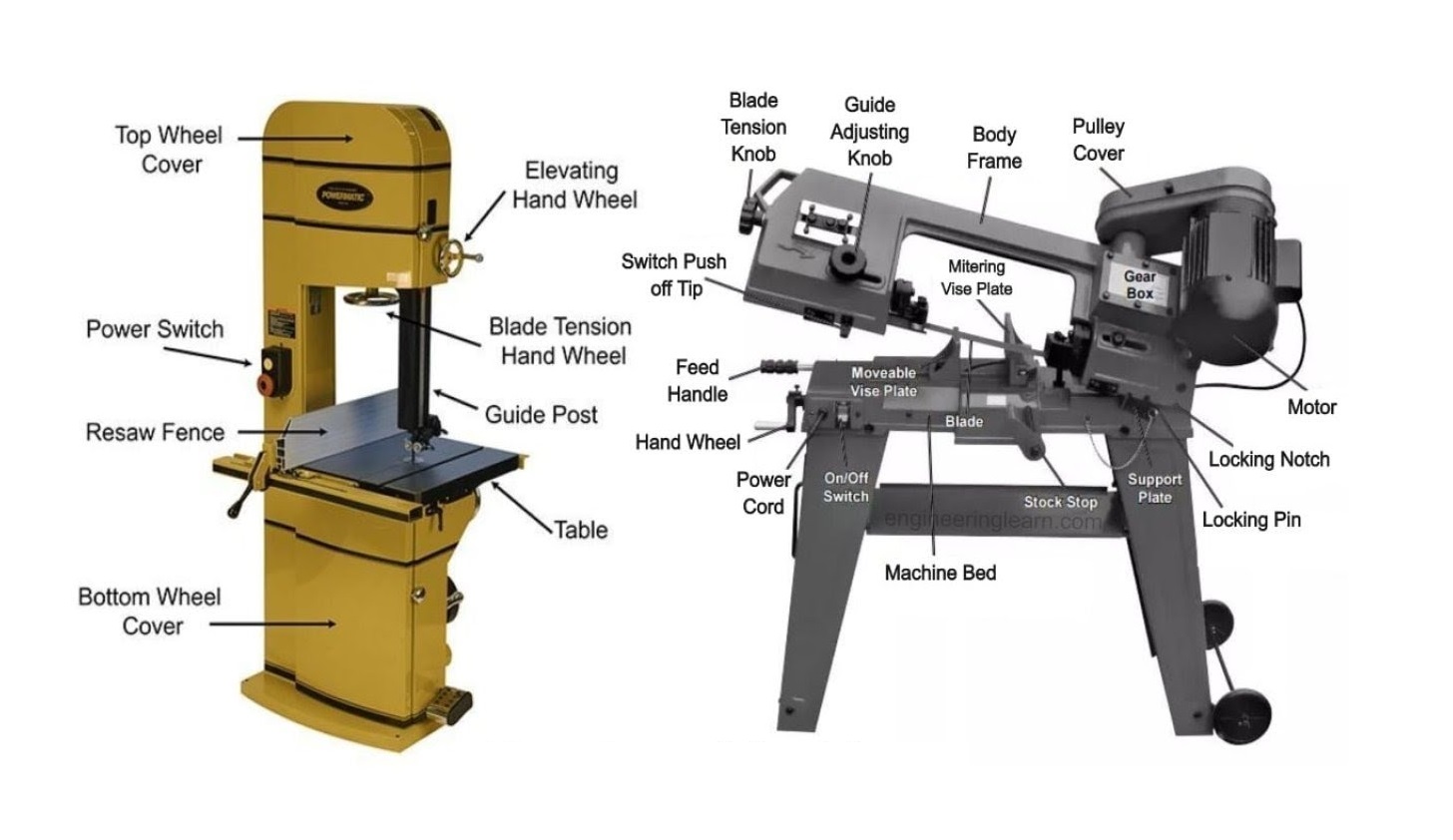

3.0Bandsaw: Vertical and Horizontal Types Explained

(1) General Features

Continuous loop blade ensures fast chip removal.

Blade Types: Supplied either in coil form (50–500 ft, requires welding into a loop) or pre-welded loops (ready to use without welding).

(2) Vertical Bandsaw (Contour and Curve Cutting)

- Head:Includes the idler wheel, drive motor, tension adjustment, air nozzle, and upper guide post.

- Column:Equipped with speed indicator dial and blade welder.

- Base:Houses the drive wheel, motor, gearbox, lower guide, and power feed mechanism.

- Key Characteristics:

- Throat depth determines the maximum workpiece size that can be cut.

- Suitable for contour and curve cutting; material feed can be manual or power-assisted.

- Large workpieces require planned cutting paths to avoid collisions.

(3) Horizontal Bandsaw (Efficient Straight Cutting)

- Blade System:Saw blade runs on drive and idler wheels, with roller guides to maintain straight cutting accuracy.

- Vise:Fixed jaw can be set at an angle; movable jaw self-aligns automatically.

- Control System:Hydraulic lifting mechanism adjusts feed pressure and blade tension. Some models include feed rate charts for operator reference.

- Coolant System:Base integrates a coolant tank and pump, cooling the blade while flushing chips.

- Advantages:

- High efficiency, ideal for batch and fixed-length cutting.

- Stop gauges can be used to ensure consistent workpiece lengths across multiple cuts.

4.0Blade Selection and Wear Indicators

Selection Principles

- Material:Special alloy steel; teeth are hardened while the blade body is annealed for toughness.

- Tooth Form:Raker teeth are general-purpose; wave teeth are preferred for thin-walled materials.

- Tooth Pitch (TPI):6–32 teeth per inch, selected according to the material type and workpiece dimensions.

- Blade Width:Wide blades are recommended for straight cutting; narrow blades are ideal for contour and curve cutting.

Signs of Blade Wear

- Cutting deviates from the scribed line.

- Chips appear as small particles (except when cutting cast iron).

- Manual feeding becomes slower or fails to cut effectively.

- Teeth lose their sharpness and cutting efficiency.

5.0Special Attachments for Bandsaws

- File Bands:Replace the saw blade for filing operations; available in coarse, medium, and fine teeth.

- Polishing Belts:Fabric-based with coarse, medium, or fine grit; used for removing tool marks or achieving a high-gloss finish.

- Circular Cutting Attachment:Allows cutting of inner and outer circles; requires a drilled center hole for positioning.

- Angle Saw Guide:Twists the blade 30° for cutting long workpieces.

- Miter Cutting Guide:Positions the workpiece against a miter head for angled cutting.

- Radius/Contour Cutting:Requires drilling a starting hole to prevent blade binding. For internal contours, the blade must be welded into a loop before cutting.

6.0Operating and Safety Guidelines

Speed and Feed Selection

Soft Materials (Aluminum, Copper): Use high speed (high FPM) and gradually increase feed pressure once cutting stabilizes.

- Hard Materials (Tool Steel):Use low speed (low FPM) with light feed; reduce feed pressure when encountering hard spots.

- Start-up Phase:Select speed according to material; begin with light feed, then increase after initial entry.

- Workpiece Width:Wide workpieces require heavier feed; narrow workpieces require lighter feed.

Safety Practices

- Keep hands away from the blade; confirm safety before operation.

- Always disconnect power before installing or removing blades.

- Use push blocks, jigs, or wood blocks when feeding material on vertical bandsaws.

- Be aware of blade tension and elasticity to prevent injury.

- Coolant contains rust inhibitors; handle with proper protection.

7.0Coolant Guidelines

Most military-grade bandsaws are designed for dry cutting, though some are equipped with cooling systems.

- Coolant Type:Water–oil emulsions are commonly used to cool the blade and flush chips.

- Rust Prevention:Always ensure proper anti-rust measures to avoid corrosion on both the machine and the workpiece.

8.0Conclusion:

Proper selection, operation, and maintenance of metal bandsaws are key to achieving high-quality cuts, reducing downtime, and ensuring long-term reliability. By choosing the right blade, following safety protocols, using appropriate accessories, and regularly maintaining your equipment, you can significantly improve cutting efficiency and consistency.

Whether you are performing straight cuts, complex contours, or batch production, a well-managed bandsaw is a powerful tool for precision metalworking.

9.0FAQ: Common Questions About Metal Bandsaws

What is the main difference between horizontal and vertical bandsaws?

Answer: Horizontal bandsaws are designed for high-efficiency, straight-line cutting and fixed-length production. They are ideal for harder materials and long or heavy workpieces. Vertical bandsaws, on the other hand, are better suited for contour or profile cutting, small-batch jobs, and multi-variety production. They offer greater flexibility but lower efficiency.

How do I choose the right bandsaw blade?

- Material:Choose special high-speed steel or tungsten steel; teeth are hardened for durability.

- Tooth Form:Raker teeth are general-purpose; wave teeth are recommended for thin-walled or contour cutting.

- Tooth Pitch (TPI):Ranges from 6–32; select according to material hardness and workpiece thickness.

- Blade Width:Wide blades are best for straight cuts, while narrow blades are ideal for curve cutting.

How automated are horizontal bandsaws?

Modern horizontal bandsaws can be equipped with hydraulic feed, automatic material feeding, and stop gauges. These features enable a full cycle of “clamping–cutting–unloading,” significantly boosting productivity in batch operations.

How can I tell when a bandsaw blade needs replacement?

- Cutting deviates from the scribed line or cannot follow it accurately.

- Chips appear abnormal in shape (excluding cast iron).

- Manual feeding becomes noticeably slower or stalls.

What safety precautions should I follow when using a metal bandsaw?

Always disconnect power before operating or changing blades, and keep hands away from the blade.

- Use push blocks, jigs, or wood blocks when operating vertical bandsaws.

- Never position fingers close to the blade while cutting.

- Coolant contains rust inhibitors; wear protective gloves and safety glasses.

How can I extend the service life of a bandsaw?

- Regularly inspect and maintain the hydraulic system, guide rails, and tensioning mechanism.

- Replace worn blades promptly; re-sharpening is not recommended.

- Keep coolant clean and replace it periodically.

- Avoid collisions between workpieces and the saw head, and prevent overload cutting.