ALEKVS M51 Bi-Metal Bandsaw Blade – Premium OEM Cutting Solution for Hard Metals

The ALEKVS M51 offers flexible OEM customization and outperforms standard blades such as M42. With over 30% longer service life, stable precision under high temperatures and heavy loads, and minimal maintenance, it efficiently handles both soft and hard metals.

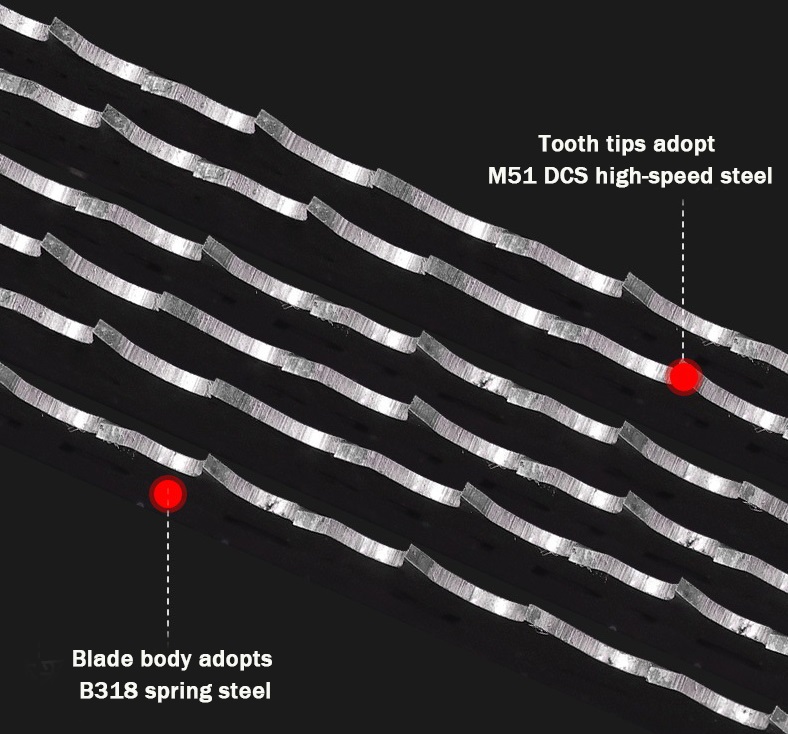

Core Material & Structure

- Tooth Tips: Crafted from M51 DCS high-speed steel (HSS) with 10% cobalt and tungsten, delivering exceptional red hardness (heat resistance) and wear resistance.

- Blade Body: Adopts B318 spring steel with superior mechanical properties—high toughness, wear resistance, and crack prevention. The band body hardness reaches HRC 50–53, ensuring excellent rigid fatigue strength.

- Bimetal Construction: The M51 HSS tooth tips are fused with the B318 spring steel backing via advanced vacuum electron beam welding, creating a robust bond that withstands heavy loads and high temperatures.

Key Performance Parameters

- Tooth Hardness: 67–70 HRC (equivalent to ~1000HV), ensuring extreme wear resistance even on hardened materials.

- Cobalt Content: 10% in tooth tips, enhancing heat stability (up to 1000°C) and extending service life under prolonged cutting.

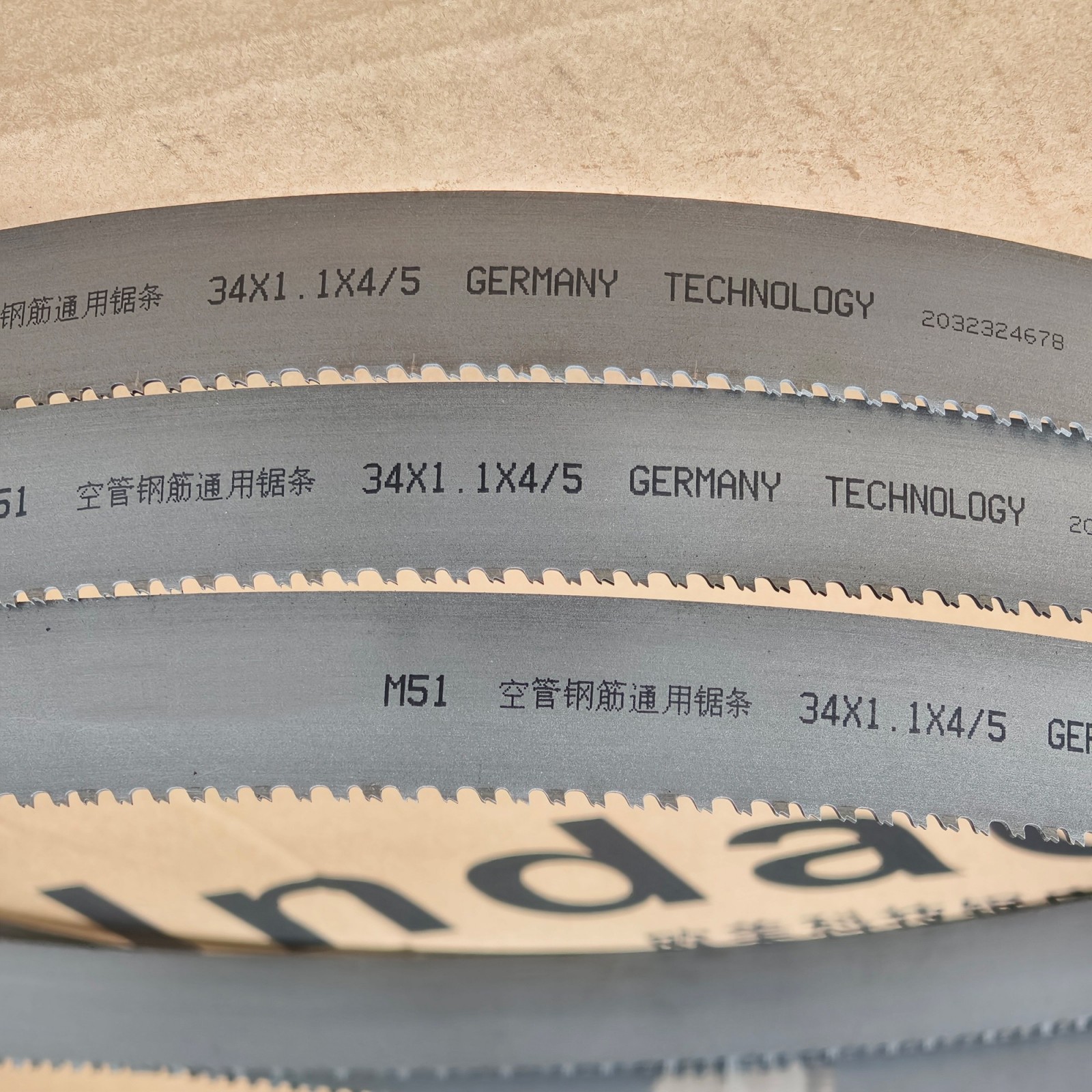

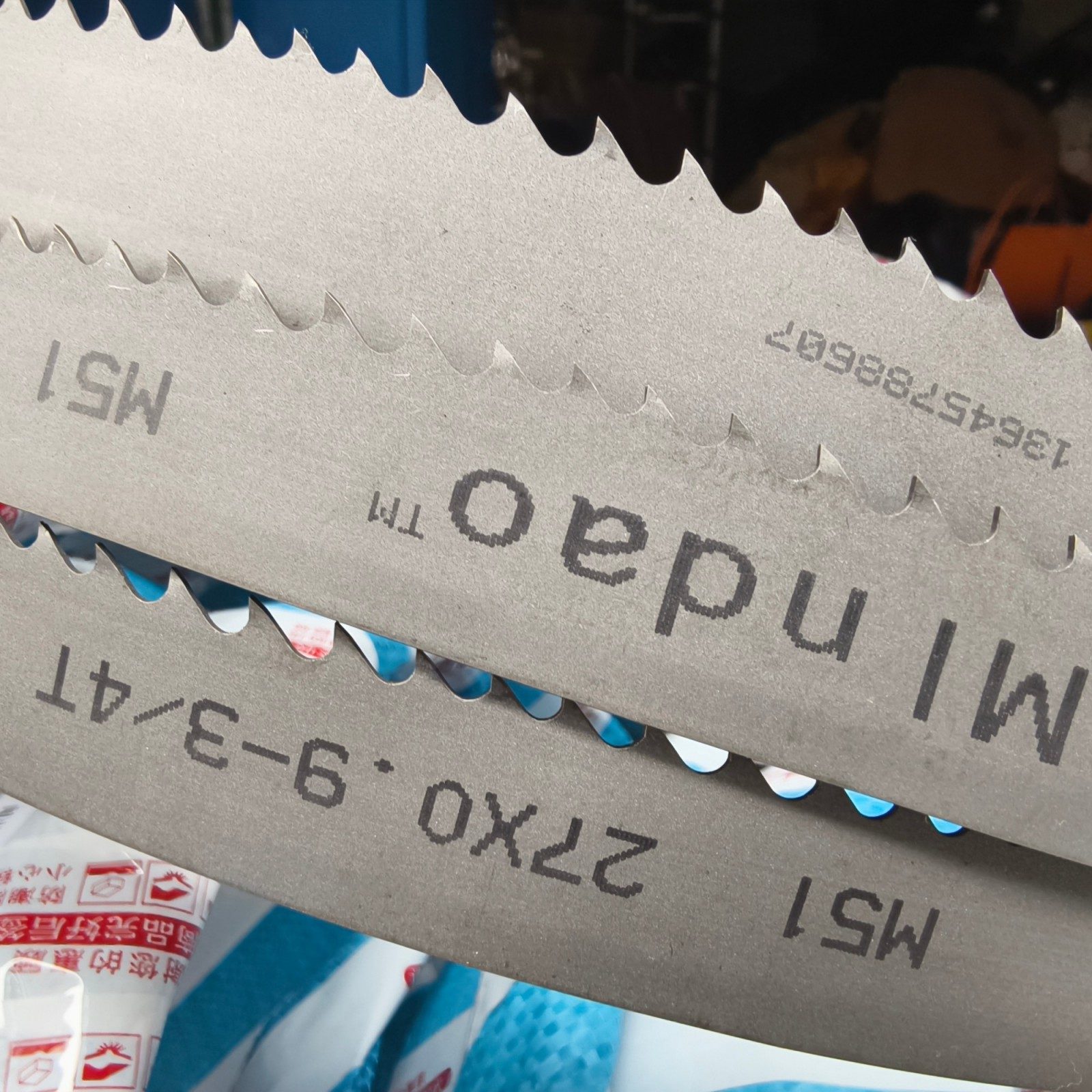

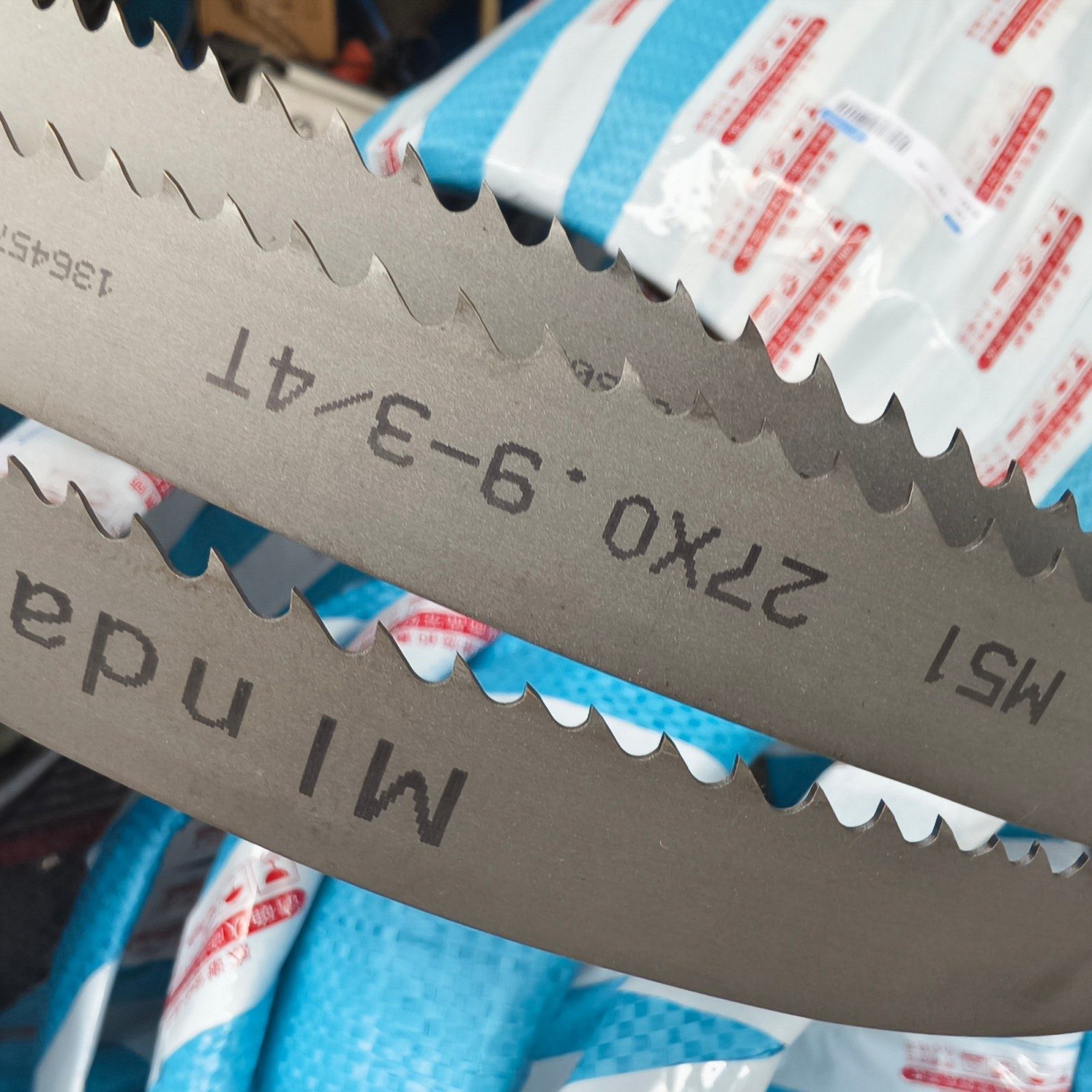

- Available Sizes: Widths ranging from 27mm to 34mm, compatible with various medium-to-heavy-duty bandsaw machines.

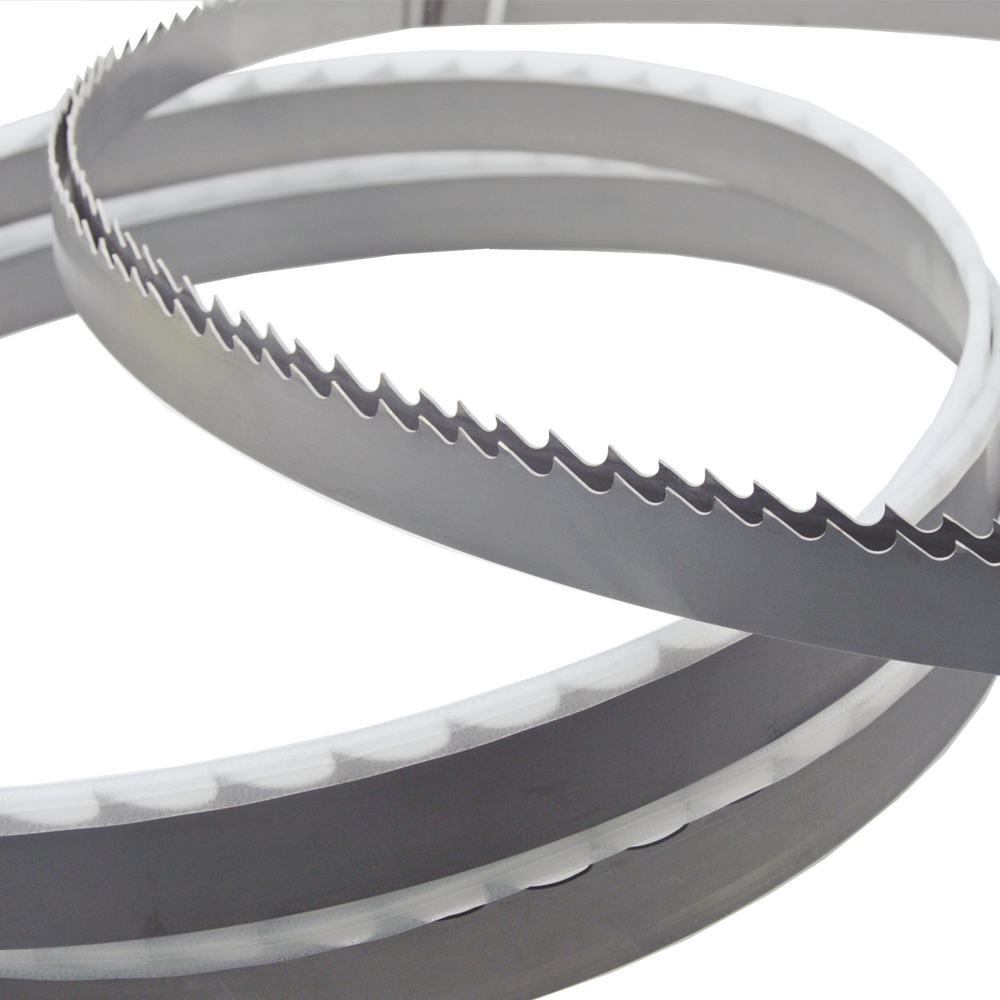

Tooth Design & Process Advantages

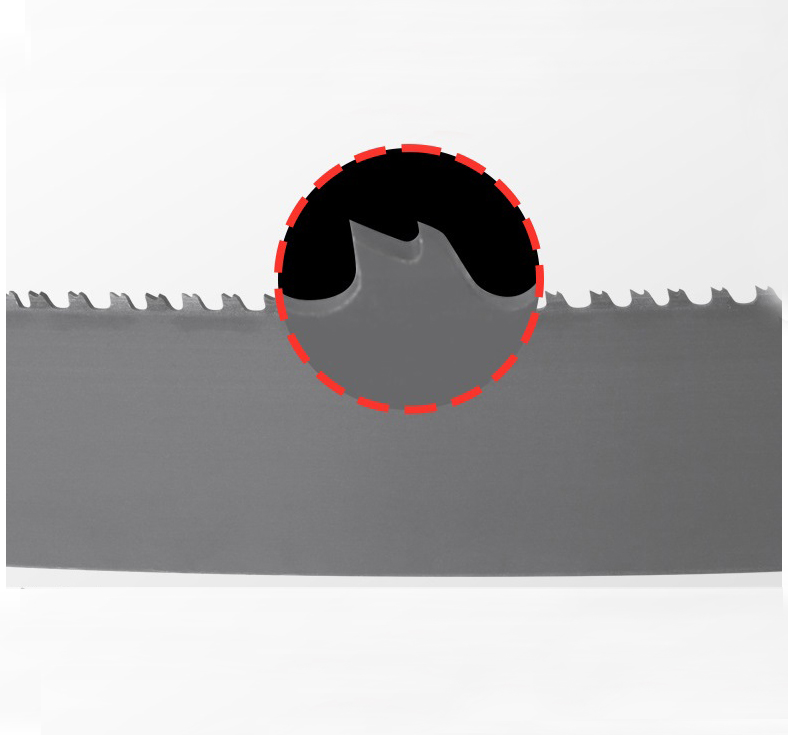

- Enhanced Chip Evacuation: Larger chip groove capacity improves chip removal efficiency, reducing clogging and boosting cutting speed.

- Impact-Resistant Geometry: Features a micro-inclined tooth tip design with an arched relief angle, alleviating impact forces to prevent tooth breakage during high-stress cutting.

- Precision Heat Treatment: Quenching with two-way tempering technology ensures stable tooth dimensions and internal stress balance, avoiding chipping or curling.

Applicable Materials & Scenarios

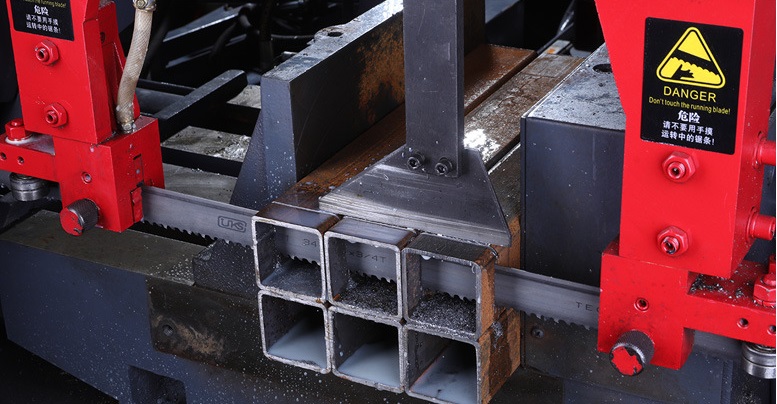

The M51 blade excels at cutting hard, tough, and high-temperature materials, including:

- Ferrous Metals: Carbon steel, structural steel, cast iron, low-alloy steel, hardened steel, bearing steel, die steel, tool steel, high-hardness steel, surface-hardened steel.

- Exotic Metals: Titanium (low-density alloys), nickel alloys, Inconel, high-temperature alloy steel, zinc alloys.

- Non-Ferrous Metals: Aluminum blocks, copper alloys.

- Profiles: Round steel, channel steel, thick-walled pipes, and large cross-section workpieces.

Please fill out this form to submit a request for quote. One of our team members will review the details and be in touch within 12 business hours.