- 1.0What are the core properties of aluminum and aluminum alloys?

- 2.0How is aluminum processed and manufactured?

- 3.0What are the core principles of aluminum structural design?

- 4.0What are the engineering application scenarios for aluminum structures?

- 5.0What are the key considerations for aluminum structural construction and protection?

- 6.0FAQ | Common Engineering Questions on Aluminum Structural Design and Construction

As the second most widely used structural metal after steel, aluminum is valued for its low weight, corrosion resistance, and excellent machinability, making it widely applicable in architecture, transportation, and marine environments. However, aluminum differs significantly from steel in its material behavior, and its design and construction must follow aluminum-specific principles.

1.0What are the core properties of aluminum and aluminum alloys?

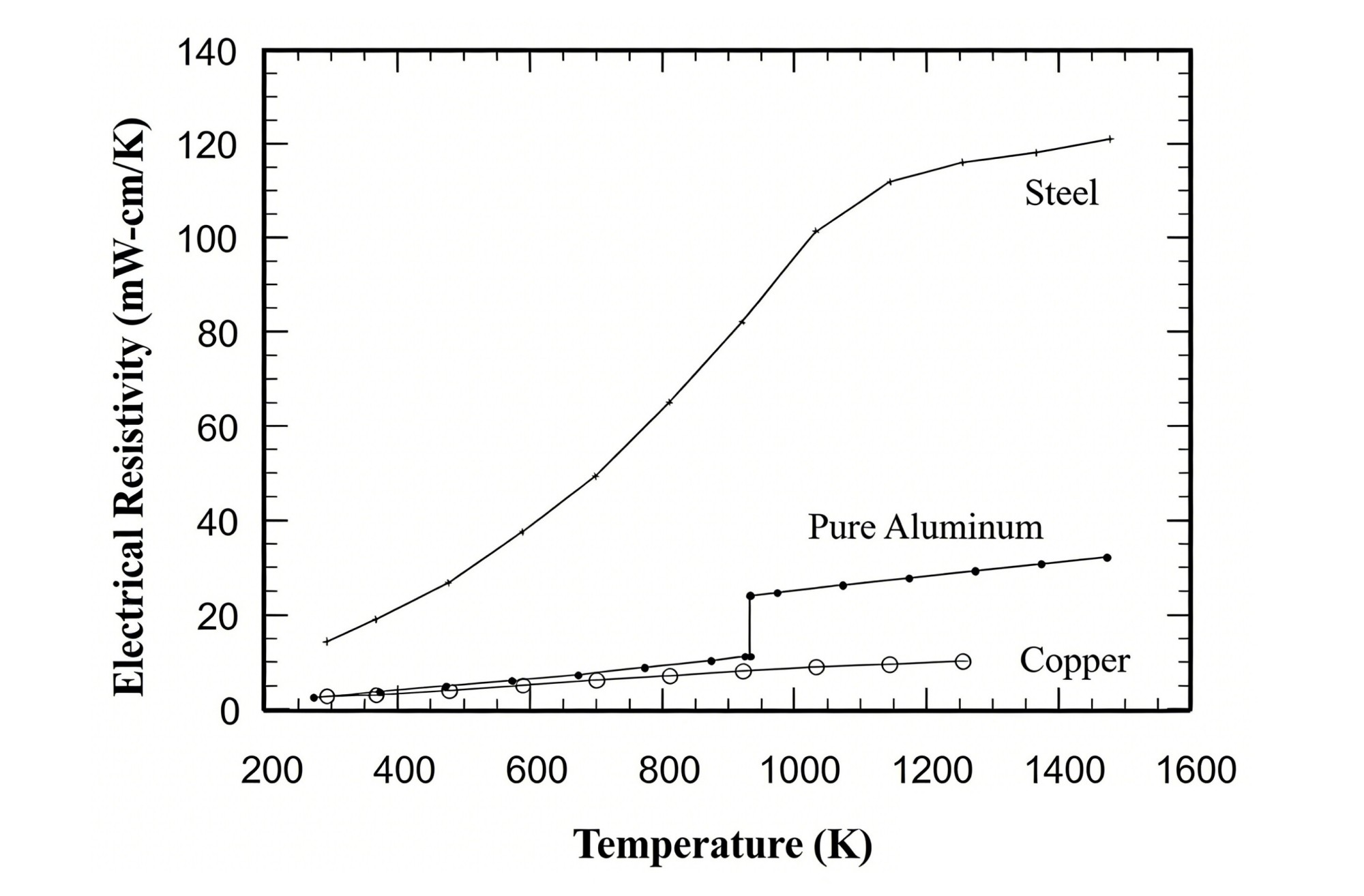

Aluminum is the most abundant metallic element in the Earth’s crust. With a density of only 2,7 g/cm³ (approximately one-third that of steel), an elastic modulus of about 70 kN/mm², and a thermal expansion coefficient significantly higher than that of steel, aluminum requires special attention in deformation control and temperature-induced structural analysis. Pure aluminum has relatively low strength (tensile strength 90–140 N/mm²) and is therefore strengthened through alloying; high-strength aluminum alloys can achieve tensile strengths exceeding 500 N/mm².

1.1Key advantages and limitations:

Vantaggi:

- Low weight and easy handling

- Inherent corrosion resistance provided by a stable surface oxide film

- Excellent extrudability

- Buona saldabilità

- Stable low-temperature performance with no risk of brittle fracture

- Well-suited for cold-bending operations

Limitazioni:

- Higher material cost than steel

- Rapid loss of strength at elevated temperatures

- Softening in the heat-affected zone after welding

- Lower fatigue resistance and buckling capacity compared with steel

- High thermal expansion coefficient

1.2Alloy classification and designation system:

Aluminum alloys are classified into seven series according to their principal alloying elements and are identified by four-digit numbers: 1xxx for pure aluminum, 2xxx aluminum–copper, 3xxx aluminum–manganese, 4xxx aluminum–silicon, 5xxx aluminum–magnesium, 6xxx aluminum–magnesium–silicon, and 7xxx aluminum–zinc–magnesium.

Temper designations indicate the processing condition: non-heat-treatable alloys use the H series (e.g., H14 for half-hard), heat-treatable alloys use the T series (e.g., T6 for solution heat treatment followed by artificial aging), O denotes the annealed condition, and F indicates as-fabricated condition.

1.3Characteristics of commonly used structural alloys:

- 6xxx series: Balanced strength and extrudability, making them the preferred choice for architectural and general structural applications, suitable for high-precision forming.

- 5xxx series: Excellent corrosion resistance, particularly suitable for welded structures.

- 7xxx series: Very high strength, used in heavily loaded or specialized engineering applications.

2.0How is aluminum processed and manufactured?

Aluminum processing and manufacturing encompass three core stages: metal production, forming, and joining, each with its own technical considerations.

2.1Metal production methods:

- Primary production: Alumina is extracted from bauxite using the Bayer process and then reduced to primary aluminum via the Hall–Héroult electrolytic process, which requires substantial electrical energy.

- Secondary production: Scrap aluminum is remelted and reused, suitable for products with lower compositional requirements, offering lower cost and environmental benefits.

2.2Main forming processes:

- Rolled products: Including plates (thickness ≥ 6 mm) and sheets (thickness < 6 mm), produced through hot rolling followed by cold rolling, with strict control of thickness tolerances and surface quality.

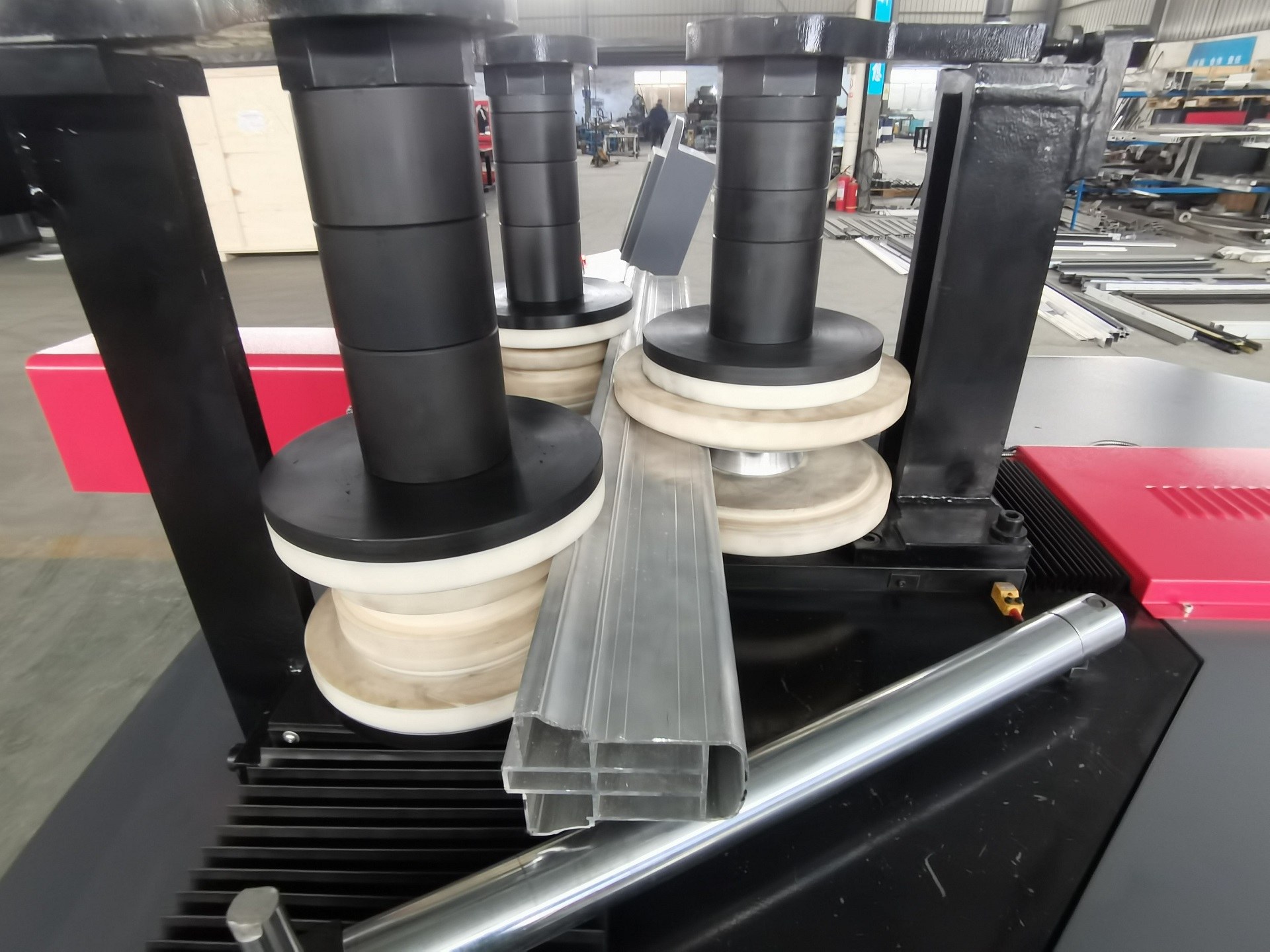

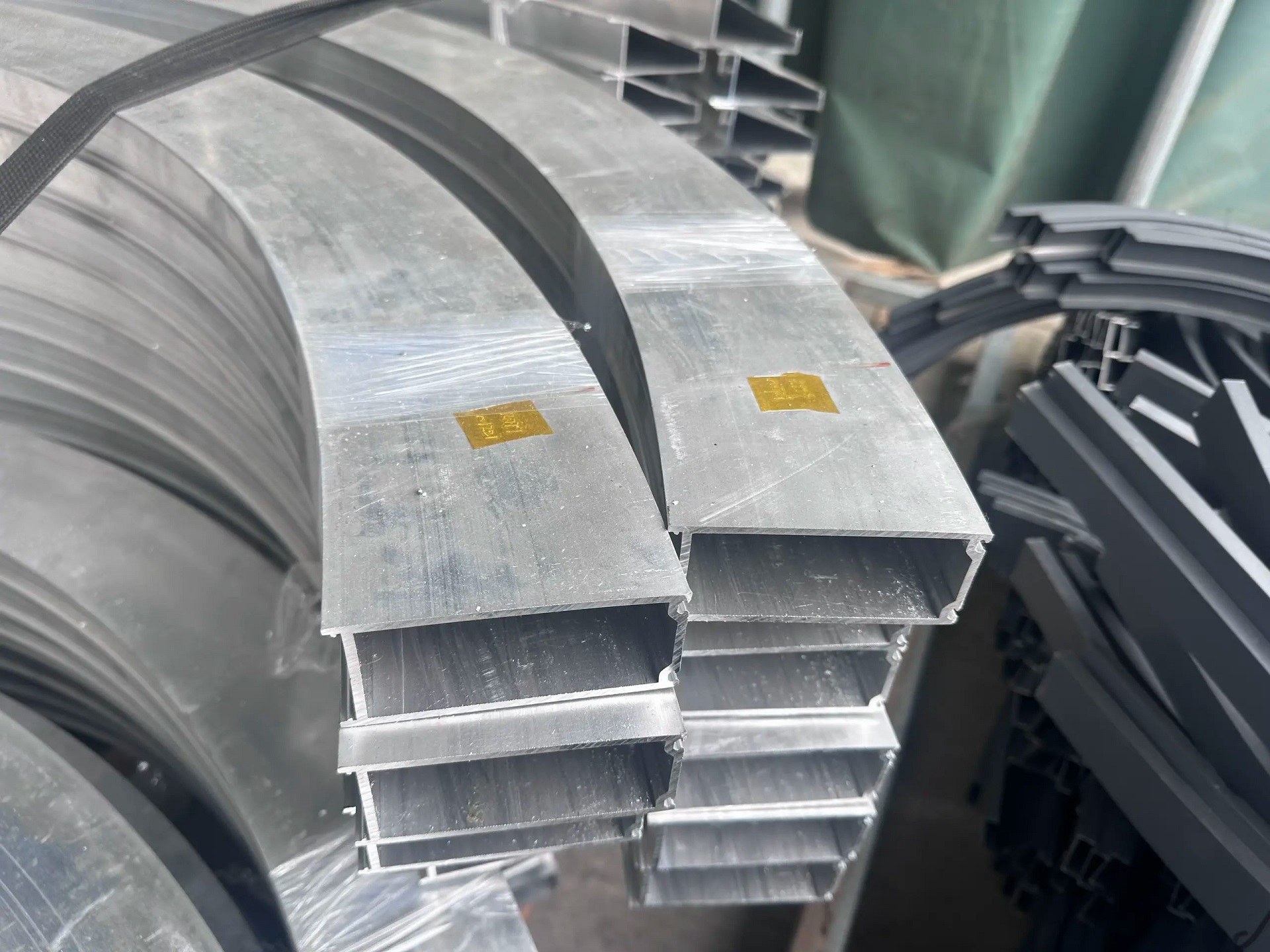

- Extruded profiles: The core forming process for aluminum, capable of producing complex and hollow cross-sections. Key parameters include extrusion ratio (typically optimized within 30–50), die design, and subsequent heat treatment. Profiles can be further processed using aluminum profile bending machines to meet special structural requirements.

- Tube manufacturing: Includes extruded tubes, drawn tubes (seamless, high dimensional accuracy), and welded tubes (lower cost, suitable for thin-walled applications).

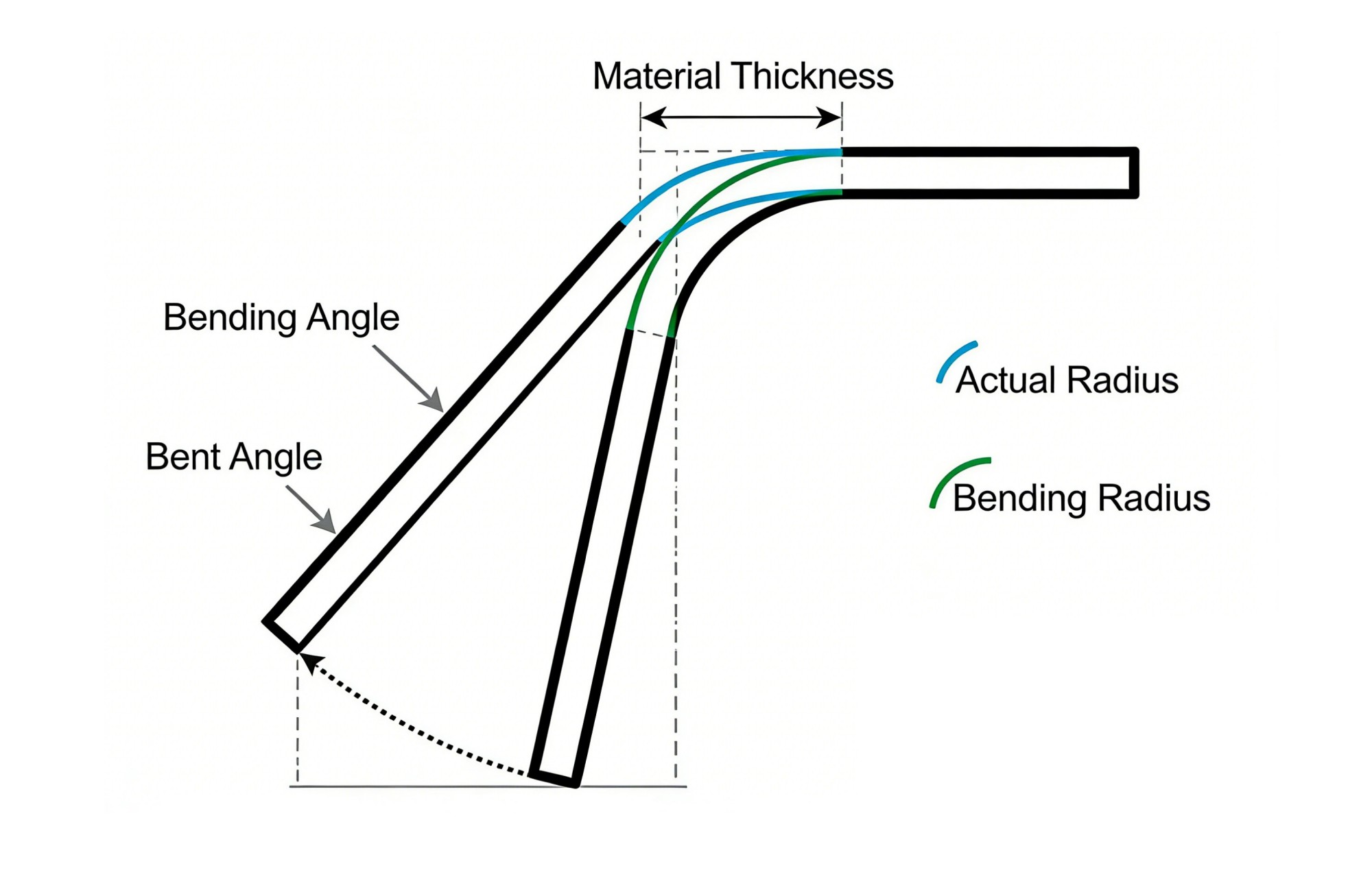

- Bending forming: Aluminum profile bending machines are specifically designed to accommodate the material characteristics of aluminum, enabling precise control of bending angles and springback. They are particularly effective for cold bending of heat-treatable alloys such as the 6xxx series, reducing the risk of stress corrosion cracking during forming. Complex extruded sections can be bent with an appropriate minimum bending radius design, preserving the original structural strength of the profile. This approach is widely used in curtain wall framing, vehicle structures, and similar applications.

2.3Selection of joining techniques:

- Mechanical fastening: Includes bolted connections (stainless steel or aluminum alloy bolts are recommended), riveting for lightweight structures, and slip-critical high-strength bolted joints where slip factors must be controlled.

- Welding: MIG welding is commonly used for its high efficiency and suitability for medium-thickness components, while TIG welding provides higher precision for thin sections. Friction stir welding, an emerging solid-state process, produces no molten pool and results in minimal softening of the heat-affected zone.

- Adhesive bonding: Typically uses epoxy-based adhesives and requires strict surface preparation (degreasing, abrasion, and anodizing). It is suitable for structures with high aesthetic and stiffness requirements.

3.0What are the core principles of aluminum structural design?

Aluminum structural design is based on the limit state design approach, requiring verification of three fundamental limit states: ultimate strength, serviceability, and fatigue. The design philosophy centers on the specific material behavior of aluminum and structural load-transfer mechanisms, while also accounting for dimensional and sectional changes introduced during manufacturing.

3.1Design methods and parameters:

- Load partial factors: Load partial factors shall be determined in accordance with the applicable design codes. Values vary between countries and regions; any figures mentioned here are illustrative only and should not be treated as universal requirements.

- Material partial factors for members, 1.3–1.6 for welded joints, and ≥1.6 for bonded joints.

- Key calculation basis: Design is based on the 0.2% proof stress (f₀) and the ultimate tensile strength (fᵤ), with due consideration of plastic deformation, local buckling, and the modified cross-sectional properties resulting from fabrication processes.

3.2Key calculation considerations:

- Heat-affected zone (HAZ) softening: Welding causes localized strength reduction; for 6xxx series alloys, the reduction may reach up to 50%. This effect must be accounted for using softening factors and effective section methods.

- Local buckling: Slender plate elements such as webs and flanges are susceptible to local buckling. Sections should be classified as compact, non-compact, or slender, and their load-bearing capacity calculated using the effective width method.

- Member design: Beams require checks for bending strength, shear capacity, web crippling, and lateral–torsional buckling. For axial members, tension members are verified for local failure and overall yielding, while compression members must consider the interaction of global buckling and local buckling.

- Fatigue design: Based on stress range and S–N curves, allowable stress ranges are determined according to detail categories. The effects of HAZ softening and stress concentration must be included, with particular attention paid to the integrity of the fabricated cross-section.

3.3Recommendations for material and product design:

- Selezione del materiale: 6xxx series alloys are generally preferred; 5xxx series alloys are recommended for corrosive environments; 7xxx series alloys are suitable for heavily loaded structures.

- Section design: Take advantage of extrusion to create integrated and complex cross-sections, reducing the number of connections. Bending radii should be standardized where possible, and compound bending avoided to ensure compatibility with manufacturing processes.

- Mass production: Profiles with a single bending type can be processed continuously in batches using aluminum profile bending machines, while complex components should be prototyped first to establish reliable process parameters.

4.0What are the engineering application scenarios for aluminum structures?

Owing to their distinctive advantages, aluminum structures are widely adopted across multiple sectors. The application of aluminum profile bending machines varies according to the specific demands of each scenario.

4.1Building applications:

Including curtain wall systems, doors and windows, partitions, and roof space frames. These typically use 6xxx series extruded profiles formed through bending processes, with emphasis on the balance between stiffness and visual quality. Certain applications also require thermal insulation and acoustic performance, with sound insulation levels reaching up to 40 dB.

4.2Transportation sector:

Covering railway car bodies, truck bodies, and high-speed ferries. Lightweight design is a key objective, often achieved through a combination of welding and adhesive bonding. Aluminum profile bending machines are used for forming complex frame geometries, with strict requirements for fatigue performance and corrosion resistance.

4.3Applicazioni specializzate:

- Marine engineering: Offshore platforms and ship superstructures commonly use corrosion-resistant 5xxx series alloys.

- Low-temperature structures: Aluminum’s excellent low-temperature performance makes it suitable for structures in cold regions.

- Military and aerospace: High-strength 7xxx series alloys are applied in military bridging systems and aircraft structural components, with certain complex parts requiring high-precision forming and processing.

5.0What are the key considerations for aluminum structural construction and protection?

The construction of aluminum structures places particular emphasis on connection quality, deformation control, and corrosion protection. In addition, the operation of fabrication equipment must follow standardized procedures to prevent structural safety risks arising from improper processing.

5.1Construction preparation and cutting operations:

- Storage: Aluminum components should be stored in dry conditions to prevent water contamination and surface staining.

- Taglio: Shearing, sawing, and plasma cutting are acceptable methods. Flame cutting is not permitted, as it can cause excessive burr formation and surface damage.

- Perforazione: Drilling speeds are higher than those used for steel. For small diameters, it is recommended to pre-punch approximately 75% of the final hole diameter before drilling, reducing the risk of tearing.

- Bending operations: Cold bending allows accurate control of deformation. For heat-treatable alloys that require bending in the T4 condition, forming should be carried out within the available time window prior to artificial aging (typically within two hours after quenching) to achieve high-precision shaping. Subsequent artificial aging restores full material strength. As a dedicated piece of equipment, aluminum profile bending machines effectively control springback during this process and are particularly well suited to the cold bending requirements of 6xxx series alloys.

5.2Quality control of joint construction:

- Welding: Heat input must be carefully controlled to minimize HAZ softening. MIG welding is suitable for medium-thickness components, while TIG welding is preferred for thin sections. Matching filler metals should be selected.

- Bolted connections: Austenitic stainless steel bolts are recommended. Washers should be used to prevent direct contact between dissimilar metals.

- Adhesive bonding: Surface preparation, including degreasing and abrasion, is critical. Adhesive layer thickness and curing conditions must be strictly controlled.

5.3Corrosion protection measures:

- Surface treatments: Anodizing enhances corrosion resistance and appearance, while powder coating provides both decorative and protective functions.

- Contact protection: Dissimilar metal interfaces must be electrically insulated, for example by applying primer coatings or using non-conductive gaskets, to prevent galvanic corrosion.

- Environmental adaptation: In corrosive environments, corrosion-resistant alloys such as the 5xxx series should be selected, with additional protective coatings applied where necessary.

6.0FAQ | Common Engineering Questions on Aluminum Structural Design and Construction

What is an aluminum structure in engineering applications?

In engineering practice, an aluminum structure refers to a structural system in which aluminum and aluminum alloys are used as the primary load-bearing materials. Typical components include beams, columns, frames, trusses, and shell structures. Compared with steel structures, aluminum structures are characterized by low weight, high corrosion resistance, and excellent extrusion capability, and are widely applied in building construction, transportation, and marine engineering.

What are the main differences between aluminum and steel structures?

There are significant differences in material behavior between aluminum and steel structures. Aluminum has a lower elastic modulus and a higher coefficient of thermal expansion, resulting in greater deformation under the same loading conditions. In addition, the mechanical properties of aluminum alloys are more sensitive to welding and forming processes. As a result, aluminum structures cannot directly adopt steel design methods and must follow design rules tailored to the specific characteristics of aluminum materials.

How are aluminum alloys classified for structural use?

Aluminum alloys used in structural engineering are commonly classified into the 1xxx to 7xxx series based on their principal alloying elements. Among them, the 6xxx series is the most widely used for building and general structures due to its balanced strength, corrosion resistance, and extrudability. The 5xxx series performs well in corrosive environments, while the 7xxx series is applied in special engineering scenarios requiring high strength.

What design method is commonly used for aluminum structures?

Aluminum structures are typically designed using the limit state design method, with verification of ultimate limit states, serviceability limit states, and fatigue limit states. Particular attention is given to the effects of heat-affected zone softening due to welding, local buckling of slender elements, and the influence of material temper and fabrication processes on structural performance.

How does welding affect the strength of aluminum structures?

Welding introduces a heat-affected zone in aluminum alloy members, where yield strength and tensile strength are generally lower than those of the base material. This effect is especially pronounced in 6xxx series alloys. In engineering design, the load-bearing capacity of welded regions is usually adjusted by applying softening factors or effective section methods.

What is aluminum profile bending, and why is it important?

Aluminum profile bending refers to the forming of extruded aluminum profiles under cold or controlled temperature conditions. This process is widely used in curtain wall framing, space structures, and transportation systems. It enables complex geometries to be achieved while reducing the number of welded joints, thereby improving overall structural integrity and appearance.

How can springback be controlled during aluminum bending?

Due to the relatively low elastic modulus of aluminum alloys, springback is more pronounced during bending. In practice, springback is controlled by selecting appropriate minimum bending radii, optimizing forming parameters, and using bending equipment specifically designed for aluminum materials, thereby improving forming accuracy and consistency.

What are the common connection methods for aluminum structures?

Common connection methods for aluminum structures include bolted connections, riveting, welding, and structural adhesive bonding. Each method differs in load-bearing capacity, fatigue performance, and construction requirements, and should be selected based on structural function, environmental conditions, and maintenance considerations.

How is corrosion protection handled in aluminum structures?

Although aluminum alloys possess inherent corrosion resistance, protective measures are still required in aggressive environments or where dissimilar metals are in contact. Typical methods include anodizing, powder coating, and the use of insulating layers at dissimilar metal interfaces to reduce the risk of galvanic corrosion.

What standards are commonly referenced for aluminum structural design?

In international engineering practice, aluminum structural design commonly references EN 1999 (Eurocode 9) and related national standards. These codes address the mechanical behavior and manufacturing characteristics of aluminum materials and provide specific requirements for member design, connection detailing, and construction tolerances.

Riferimento

https://de.meviy.misumi-ec.com/info/en/blog-en/materials-en/26888/

https://clintonaluminum.com/which-aluminum-alloy-bends-best/

https://www.thefabricator.com/thefabricator/article/bending/bending-aluminum-101-how-to-bend-6061-t6-aluminum