Roll forming has become a vital process in sheet metal fabrication and profile manufacturing, gaining industry attention for its high efficiency, precision, and advanced automation capabilities. For manufacturers aiming to boost productivity, reduce costs, or expand product diversity, investing in a roll forming line can be a critical step toward long-term growth.

However, determining whether this technology is the right fit requires a comprehensive evaluation based on production goals, budget constraints, and equipment performance. This article provides an in-depth look at the four basic types of roll forming machines, outlines the technical features of both standard and automated lines, and highlights core investment factors such as equipment cost, production efficiency, system integration, and operational maintenance, helping you make informed decisions and maximize your return on investment.

1.0Four Basic Types of Roll Forming Lines

1.1Roll Forming Terminology Table

| Term | Definition |

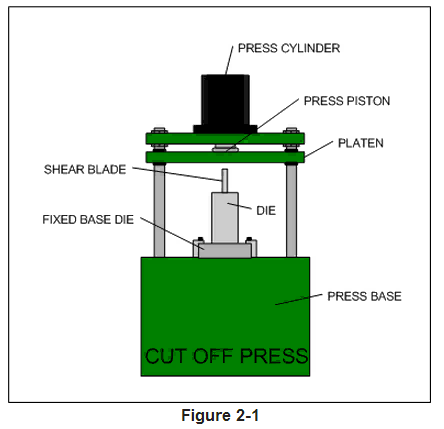

| Die | The tooling inside the press that performs punching or cutting. It may include a punch, blade, shear, saw, or gagged die set. |

| Flying Die | A die that performs press operations while the material is moving. The die travels with the material—also referred to as “non-stop.” |

| Stopping | The material pauses for press operations. Also known as “stop-to-cut” or “stop/start.” |

| Closed Loop | A servo system is used to control position or speed. The die or material movement is precisely synchronized. |

| Open Loop | No servo feedback. Control is based on a material-mounted encoder. |

| Boost | In open-loop flying die setups, a pneumatic or hydraulic cylinder helps match die speed to material flow. |

| Kicker | A mechanical boost that drives the die forward using press motion—linked directly to the press stroke. |

| Die Accelerator | Used in closed-loop flying die systems; refers to the servo-actuated system that synchronizes the die with material speed. |

| Actuator | Mechanical components (ballscrew, belt & pulley, rack & pinion) connecting the servo system to the die. |

Roll forming machines generally fall into four basic categories, defined by two key parameters: whether the material stops during cutting, and whether the system uses closed-loop servo control. These types are:

- Open-Loop Stop

- Open-Loop Flying Die

- Closed-Loop Stop

- Closed-Loop Flying Die

Other custom or hybrid configurations are often based on variations or combinations of these four. Understanding these types is essential for navigating more complex system architectures.

Classification Basis:

Roll forming lines are categorized according to:

- Control System: Whether a closed-loop servo system is used for precise positioning and feedback.

- Operating Mode: Whether material stops during press operations or continues moving (flying die operation).

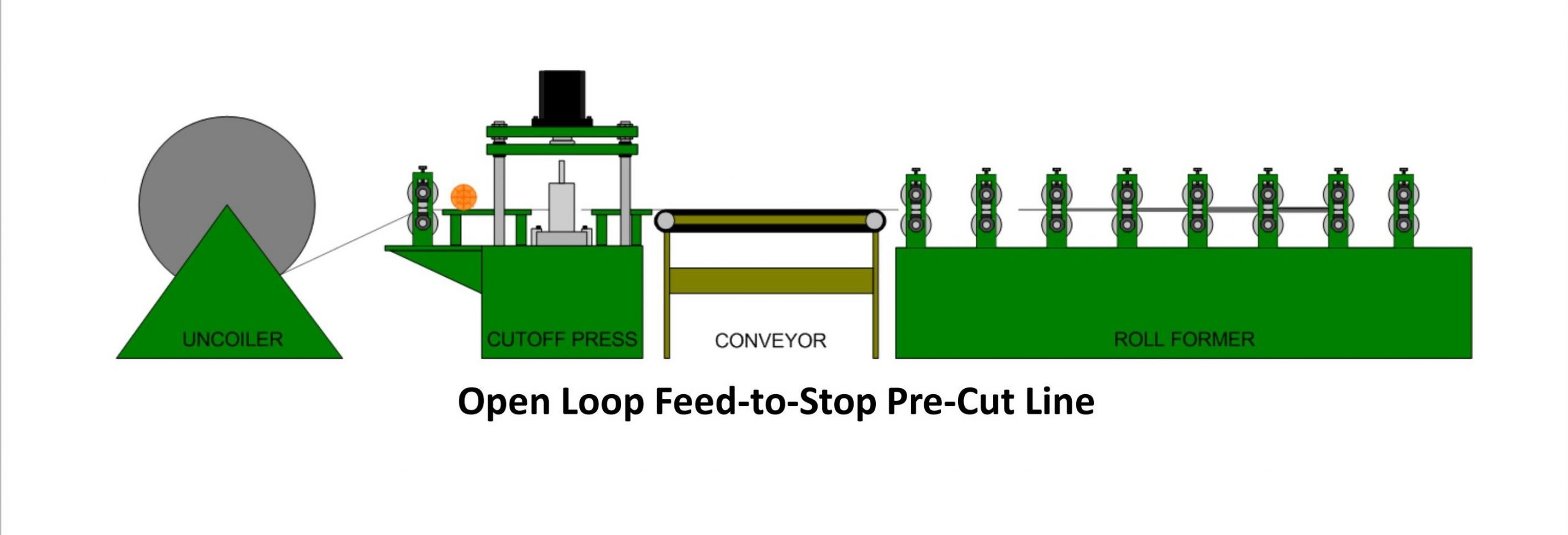

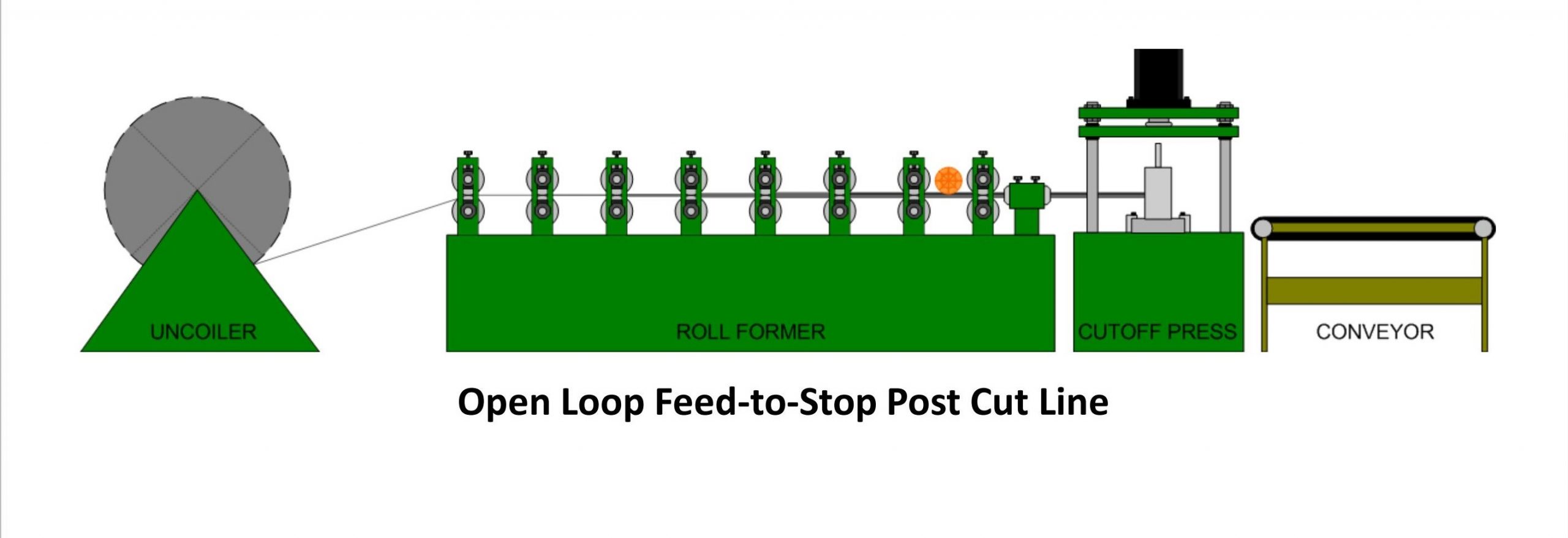

1.2Open-Loop Stop

- Control: Open-loop

- Operation: Material stops for cutting or punching

- Cost: Low

- Accuracy: Moderate

- Output: Low

This configuration uses open-loop controls to position the material, which is stopped before each press cycle.

Process Variants:

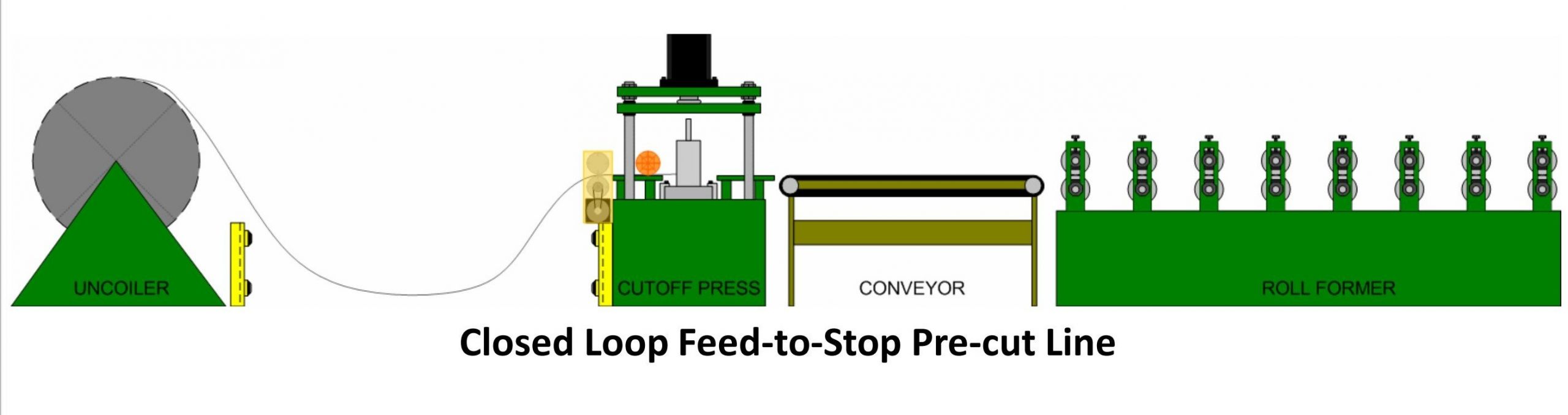

- Post-Cut: The material is roll-formed first, then cut using a stationary die. Suitable for most standard applications.

- Pre-Cut: The material is cut to length before entering the forming section. This setup has slower throughput but lower tooling costs, ideal for budget-sensitive operations.

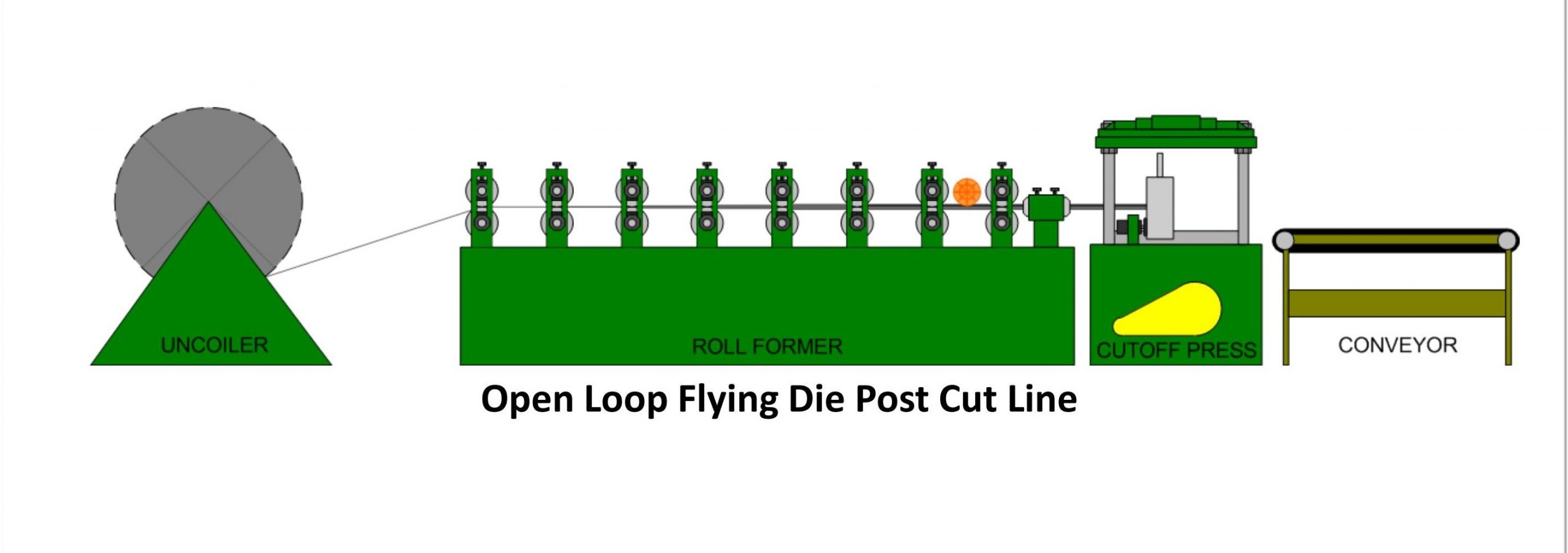

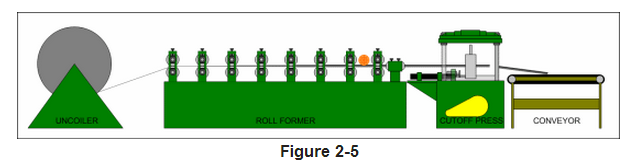

1.3Open-Loop Flying Die

- Control: Open-loop

- Operation: Cutting while the material is in motion

- Cost: Low

- Accuracy: Moderate (±0.032″ / 0.81 mm)

- Output: High

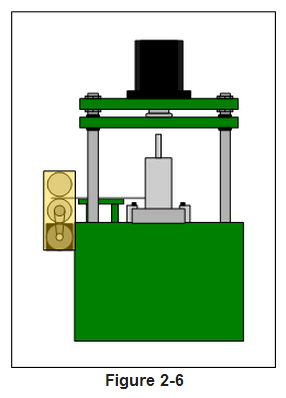

A flying die system executes cutting as the material moves, with the die traveling to match material’s speed.

Additional Notes:

The die typically returns via a spring or pneumatic cylinder.

In cases where material strength is insufficient to support the die mass, a boost cylinder can be added to assist acceleration and reduce drag load.

1.4Closed-Loop Stop

- Control: Closed-loop servo

- Operation: Material stops for cutting

- Cost: Medium to high

- Accuracy: High (±0.003″ / 0.076 mm)

- Output: Moderate

This system uses servo feedback to control material positioning and improve the repeatability of cutting or punching operations.

Technical Notes:

Servo-driven feed rollers are typically used.

If feed slip is an issue, a material encoder can be added to improve feedback accuracy and ensure precision.

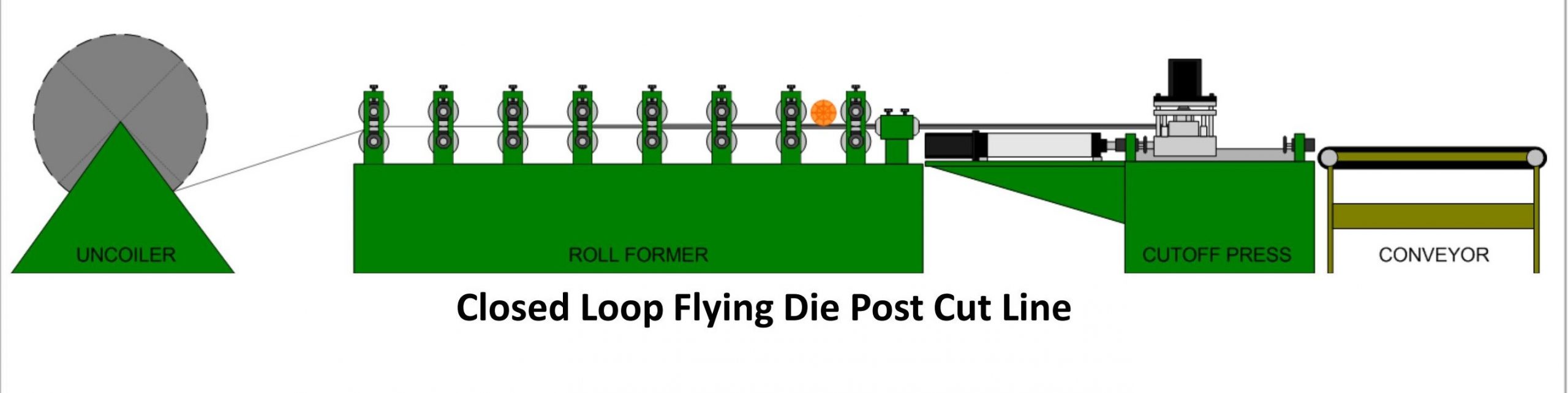

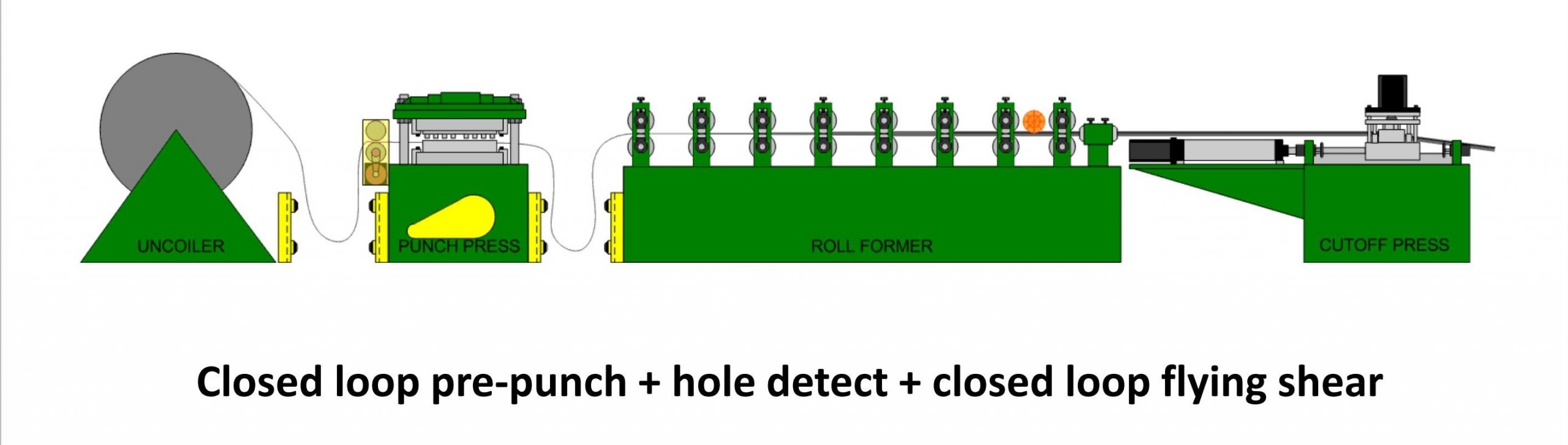

1.5Closed-Loop Flying Die

- Control: Closed-loop servo

- Operation: Cutting while the material is in motion

- Cost: Highest

- Accuracy: Extremely high (±0.015″ / 0.38 mm, up to ±0.0002″ / 0.005 mm)

- Output: Highest (up to 600 fpm / 183 mpm)

This is the most advanced configuration, capable of high-speed, high-precision forming and cutting using a servo-synchronized flying die system.

System Design:

The die is driven by a ballscrew actuator.

A precision servo motor couples mechanically with the die via splined couplings to ensure exact synchronization.

The control system continuously adjusts the die motion to match material speed and position in real time.

1.6Summary Comparison Table

| Type | Control System | Cutting Condition | Accuracy (inch) | Cost | Best For |

| Open-Loop Stop | Open-loop | Stopped | Moderate (~±0.03) | Low | Standard, cost-sensitive production |

| Open-Loop Flying | Open-loop | Continuous | Moderate (±0.03) | Low | Medium-speed continuous operation |

| Closed-Loop Stop | Closed-loop servo | Stopped | High (±0.003) | Medium–High | Precision punching or cutting |

| Closed-Loop Flying | Closed-loop servo | Continuous | Very High (±0.0002) | Highest | High-speed, high-precision output |

2.0Standard Roll Forming Lines

Roll forming technology has become a cornerstone in modern sheet metal fabrication and profile manufacturing due to its efficiency, precision, and high level of automation. A standard roll forming line, equipped with flexible design and advanced control systems, is capable of meeting diverse industry requirements.

2.1Key Features:

Modern roll forming machines typically offer the following core advantages:

- Technical Reliability: Built for long-term continuous operation with minimal downtime, ensuring stable production.

- High Flexibility: Quick and easy tool changeover allows rapid adaptation to different shapes and profile sizes.

- Support for Flexible Manufacturing: Integrated with advanced software and programming for efficient, waste-free operations.

- Multi-Function Processing: Capable of handling pre-punching, slotting, post-punching, bending, roll forming, and flying cut-off in a single line.

ALEKVS specializes in the design and manufacturing of high-performance roll forming lines, combining extensive industry experience with a strong focus on equipment reliability, safety, and flexibility. All systems support rapid die change and accommodate a wide range of profile dimensions, making them ideal for various industrial applications in sheet metal processing.

3.0Fully Automated Roll Forming Lines

Fully automated roll forming lines are engineered for high-efficiency, large-scale metal profile production. These systems integrate decoilers, automatic seam welders, roll forming mills, and smart stacking units—delivering a complete end-to-end automation solution from raw coil to finished stack.

The production line features multiple roll forming channels and modular configurations for leveling, alignment, forming, and cutting. Flip and stacking systems are equipped with clamping grippers, servo-guided rails, vacuum robotic arms, and intelligent positioning modules, ensuring efficient, safe, and orderly product handling.

3.1Technical Advantages:

- Full-Process Automation: Automatic coil loading and welding, continuous feeding, inline cutting, and stacking—no manual intervention required.

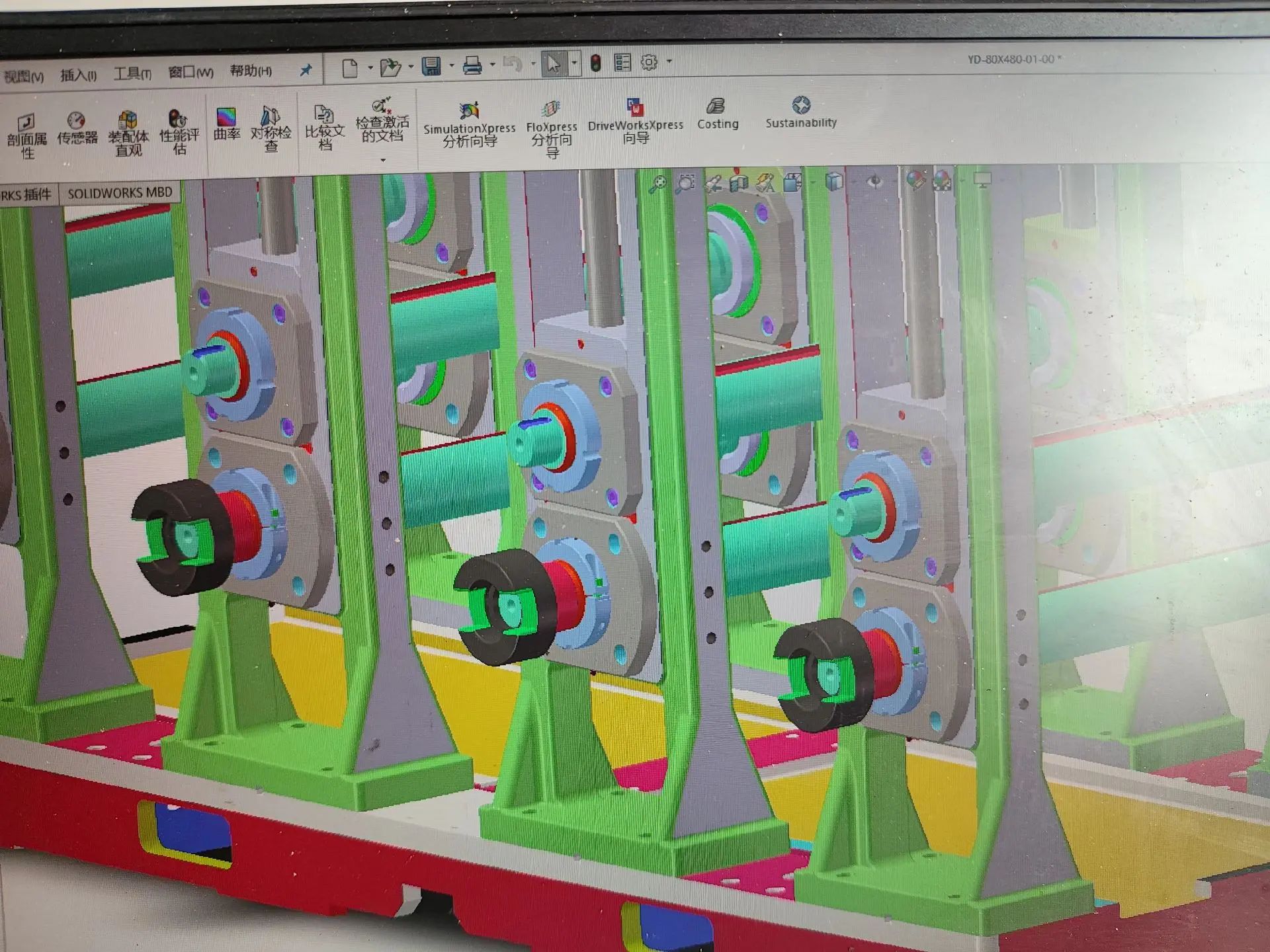

- Multi-Stage Precision Forming: The roller stations are designed with progressive deformation segments to achieve complex profile geometry with high accuracy.

- Adaptive Alignment System: Left-right alignment and vertical offset rollers ensure accurate and stable coil tracking throughout the line.

- Modular Servo-Controlled Platform: Independent servo-controlled sliding platforms enable precise robotic handling and stacking operations.

- High Flexibility and Scalability: Supports various materials, thicknesses, and profile cross-sections; equipment parameters can be configured based on specific production needs.

This system is ideal for the mass production of C-channels, U-channels, cable trays, solar panel supports, door tracks, light steel framing, and more, making it a key enabler for intelligent automation in modern metal processing.

4.0Key Factors to Consider When Investing in a Roll Forming Line

Roll forming lines are essential equipment in sheet metal fabrication and profile manufacturing. To ensure a sound investment, several critical factors must be evaluated to balance capital costs with long-term production efficiency.

4.1Machine Cost & Service Life:

- Initial Investment: A standard roll forming line—including decoilers, cutoff systems, and control electronics—typically ranges from $100,000 to $500,000, depending largely on the number and size of forming stands. Mid-sized systems generally fall between $150,000 and $250,000.

- Durability: These systems are engineered for longevity, with no practical lifespan limit. When properly maintained and not subjected to misuse, they exhibit extremely low failure rates and minimal replacement part costs.

- Design Stability: While ongoing improvements are made in accuracy, ease of use, and wear resistance, the core mechanical architecture has remained stable and reliable over time.

4.2Production Throughput & Changeover Costs:

- Standard Speed: Most roll forming lines operate at 100 feet per minute (fpm), or roughly 30 meters per minute, with speed adjustable based on production needs.

- Typical Daily Output: Accounting for loading, threading, cleaning, and other downtime, the average daily output reaches 25,000 to 30,000 feet (7,600 to 9,100 meters)in an 8-hour shift.

- Changeover Efficiency: While changeover cost varies with company size, product variety, and job complexity, roll forming is widely recognized for low conversion costs and high production efficiency compared to other metal forming processes.

- Control System Optimization: Modern electric and computer controls significantly enhance flexibility and responsiveness in production transitions.

4.3Production Planning & System Integration:

Current technologies allow roll forming lines to integrate seamlessly with ERP (Enterprise Resource Planning) or MRP (Manufacturing Resource Planning) systems to enable order-driven, automated scheduling.

Typical integration includes:

- Direct import of production parameters(lengths, quantities, hole patterns) from order systems

- Automatic control system adjustments to minimize manual intervention

- Profile labeling or inkjet marking for easy tracking and identification

- Real-time production data feedback for quality control and performance monitoring

Such integrations can be added through retrofitting existing systems or designed into new installations, provided the facility is equipped with the necessary hardware and software infrastructure to support real-time data communication.

4.4Operation, Maintenance & Training:

Beyond hardware, long-term stability and performance depend on:

- Scheduled preventive maintenance to extend service life

- Spare parts inventory planning to minimize downtime

- Professional training for operators, ensuring safe and efficient use

- Standardized production management to boost overall operational effectiveness

References

www.amscontrols.com/kb/roll-forming-the-four-basic-machine-types/