- 1.0Fundamental Principle of Induction Heating

- 2.0Typical Induction Heating Configurations

- 3.0Typical Application Scenarios of Induction Heating

- 4.0Application Scenarios Classified by Frequency

- 5.0Key Advantages of Induction Heating

- 6.0Key Process Parameters of Induction Heating

- 7.0Basic Configuration and Key Characteristics of Induction Heating Equipment

- 8.0Frequently Asked Questions (FAQ)

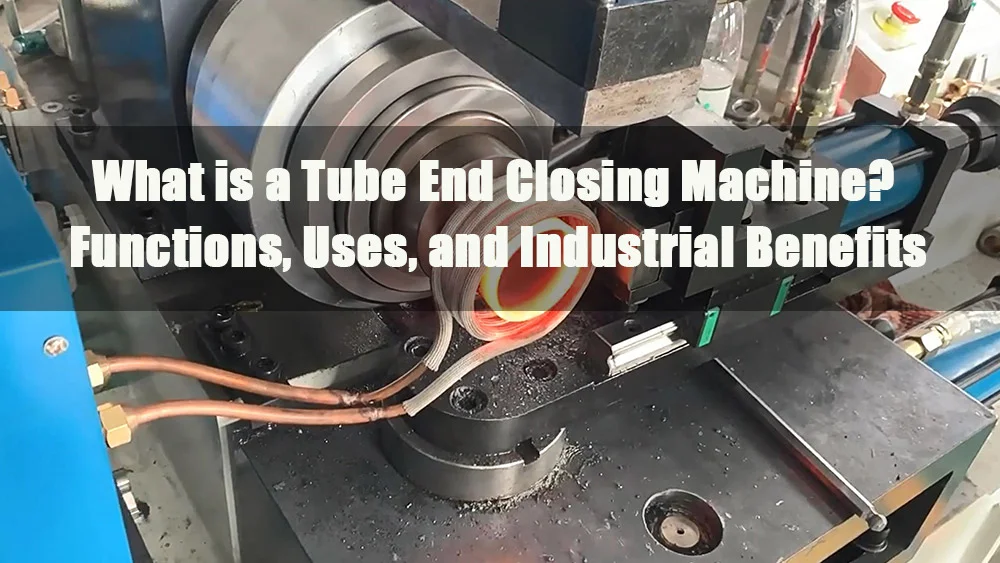

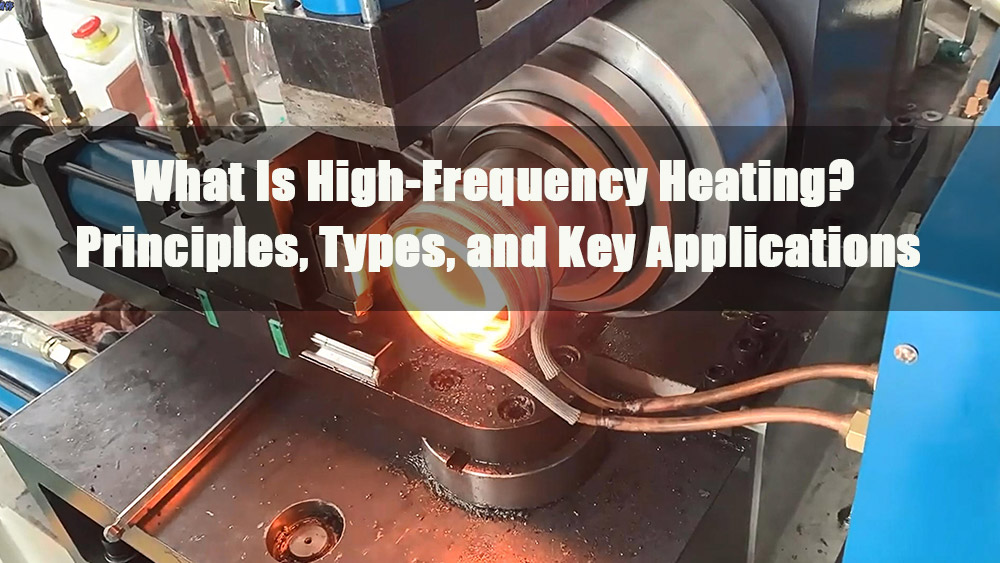

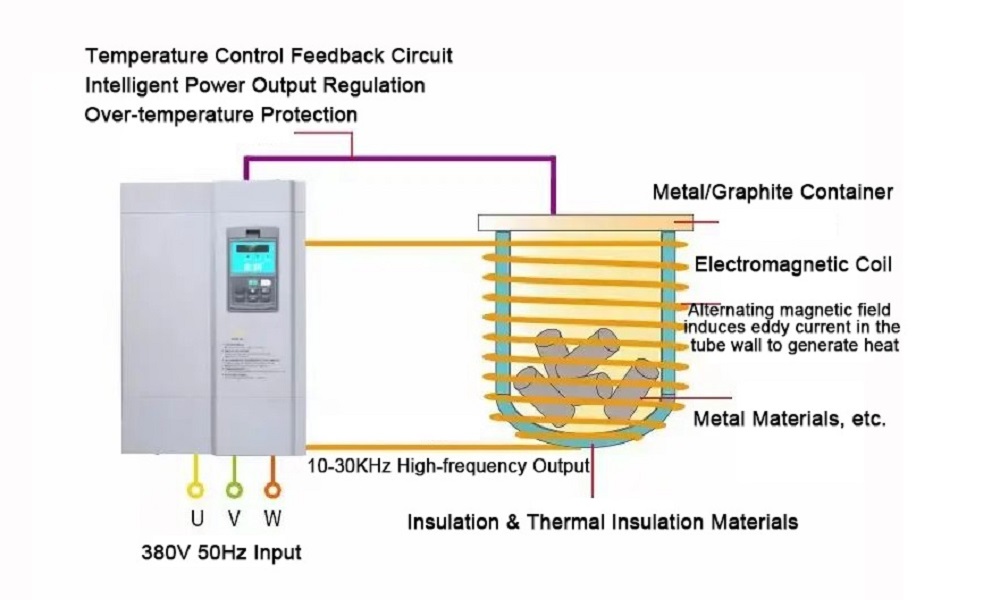

Induction heating is a physical phenomenon within the field of electromagnetics. Owing to its high efficiency, precision, and environmentally friendly characteristics, it plays a critical role in industrial manufacturing and a wide range of application scenarios. In particular, it provides a reliable and controllable heating solution for specialized equipment such as Tube End Closing Machines.

1.0Fundamental Principle of Induction Heating

The essence of induction heating lies in energy transfer and conversion through electromagnetic induction. When an electric current flows through a primary coil acting as an electromagnet, it generates an alternating magnetic field.

If a conductive workpiece (typically metal, but also conductive materials such as carbon or graphite) is placed within this field, it effectively forms a short-circuited secondary loop, in which eddy currents are induced. As these eddy currents flow through the material, they encounter electrical resistance and generate heat through the Joule effect.

If the workpiece is made of a magnetic material, a second heating mechanism occurs in the form of hysteresis losses, where repeated reorientation of magnetic domains under a changing magnetic field produces additional heat.

The total heat generated depends on several key factors:

- Electrical power used to create the alternating magnetic field

- Size and geometry of the workpiece

- Material properties of the workpiece

- Degree of coupling between the workpiece and the primary coil

2.0Typical Induction Heating Configurations

Induction heating systems are generally implemented in two main structural configurations, each suited to different application requirements:

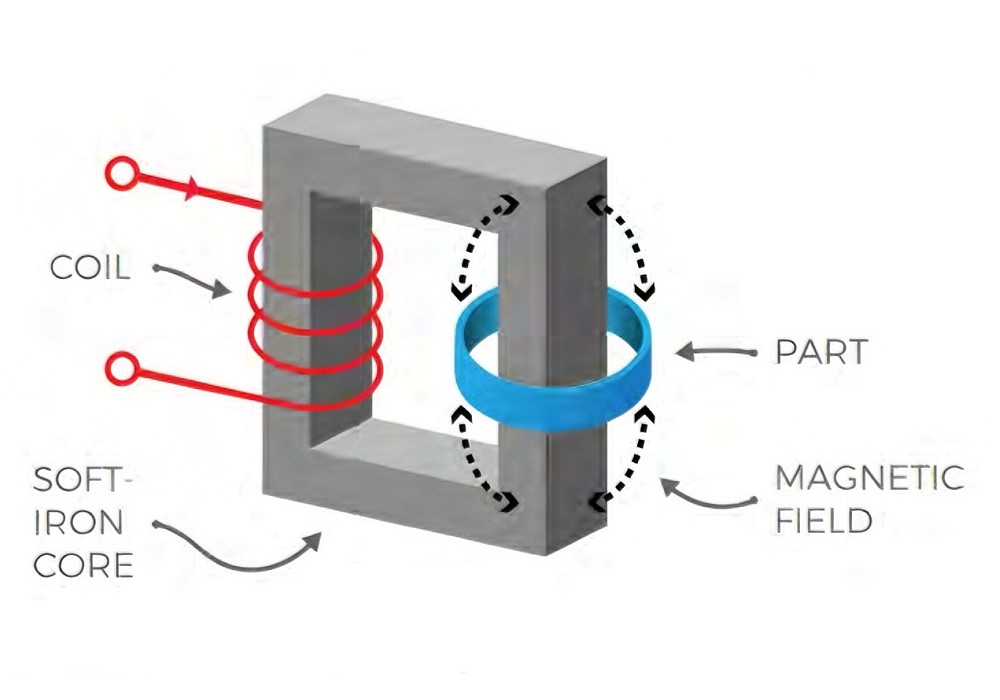

2.1Soft Magnetic Core Configuration

- A shared soft magnetic core transfers the alternating magnetic field from the primary coil (high number of turns) to the workpiece

- Workpiece acts as a single-turn, short-circuited secondary coil

- Follows turns ratio and electromagnetic energy conservation principles, producing low voltage and very high current

- Ideal for concentrated heating tasks (e.g., tube-end preheating in Tube End Closing Machines)

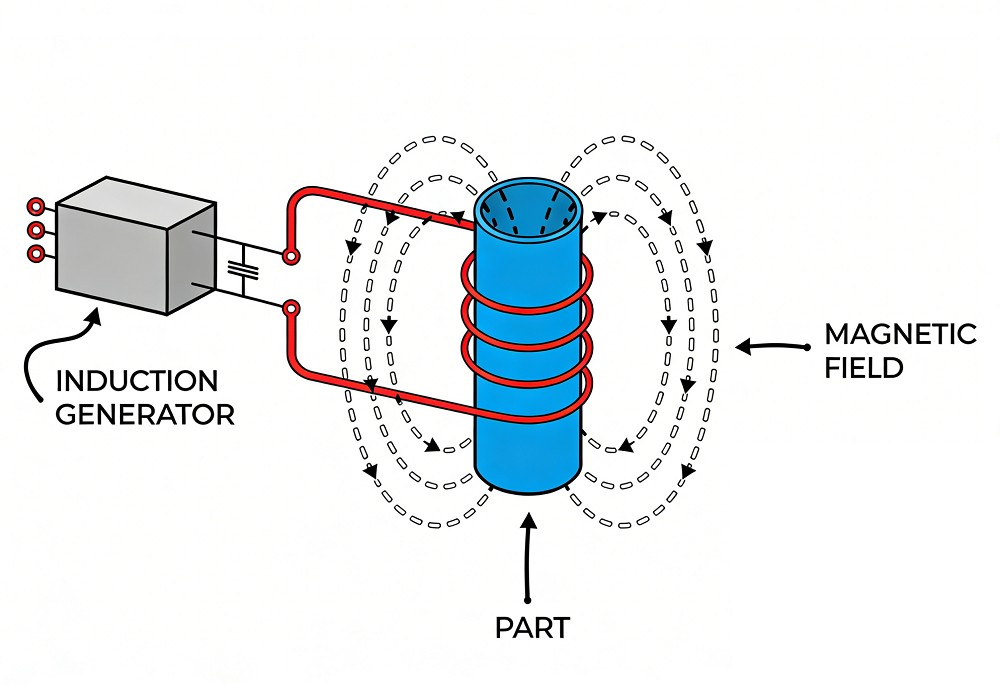

2.2Direct Coupling Configuration

- Primary coil positioned directly around the workpiece

- Workpiece placed directly within the alternating magnetic field (no soft magnetic core)

- Offers higher heating efficiency

- Suitable for continuous, high-throughput production processes

3.0Typical Application Scenarios of Induction Heating

The application range of induction heating is extensive and is commonly classified according to the level of power induced within the workpiece:

3.1High-Power Applications

- Induction melting

- Welding, soft soldering, and brazing (rapid heating to melting/joining temperatures)

3.2Low-Power Applications

- Heat treatment: Surface/localized hardening of bearings, gears, bushings, pulleys, couplings (improves hardness and wear resistance)

- Thermal assembly (shrink fitting): Heating components for expansion during assembly, cooling for tight interference fit

- Specialized applications:

- Bonding of metal to glass or plastics

- Indirect heating (cooking, plastic injection molding, packaging sealing)

- Tube-end heating and sealing in Tube End Closing Machines

4.0Application Scenarios Classified by Frequency

Induction heating can be tailored to specific requirements based on operating current frequency:

4.1Low-Frequency Induction Heating (50 or 60 Hz)

- Uses standard mains frequency

- Cost-effective solution with deep heat penetration

- Enables gradual, uniform heating of large workpieces

4.2Medium-Frequency Induction Heating (5–500 kHz)

- Suitable for high-power, localized or sub-surface heat treatment

- Heat penetration depth decreases with increasing frequency

- Allows precise heating of selected workpiece areas

| Frequency Range | Penetration Depth | Heating Characteristics | Typical Applications |

| Low frequency (50–60 Hz) | Deep | Gradual, uniform bulk heating | Large workpieces, overall heating |

| Medium frequency (5–500 kHz) | Medium to shallow | Localized, controlled heating | Surface or sub-surface treatment, tube-end heating |

5.0Key Advantages of Induction Heating

Compared with conventional heating methods (flame heating, furnace heating, oil bath heating), induction heating offers distinct technical advantages:

- Rapid heating: Immediate heating upon power application (no preheating time), reducing production waiting periods and improving throughput

- High energy efficiency: Heat generated directly within the workpiece (eliminates external heat transfer losses); no unnecessary system heating/cooling cycles; instant power cutoff when no workpiece is present

- High cleanliness: No direct contact between heat source (primary coil) and workpiece, preventing corrosion, residue contamination, or material degradation from open flames

- Enhanced safety: Inherently safe design; no special safety measures for external heat sources; no ambient oxygen consumption; no fumes or harmful emissions

- Ease of control: Fully electrically driven with excellent controllability; supports remote control, sensor integration, and real-time heating process monitoring via data logging

- Consistent product quality: User-friendly process control ensures uniform heating across workpieces; predefined heating profiles produce high-quality products with minimal residual internal stresses

- Easy production integration: Compact footprint; convenient workpiece loading/unloading; no special operator safety or fume extraction measures required (reduces line modification efforts and operating costs)

6.0Key Process Parameters of Induction Heating

The effectiveness of induction heating depends on critical process parameters, which must be precisely defined based on workpiece characteristics:

- Frequency: Primary factor determining heat penetration depth (higher frequency = shallower penetration); low frequency for large workpieces, high frequency for small components/surface heating

- Power: Determines workpiece heating intensity; adjusted based on material volume and target temperature

- Temperature setpoint: Final required temperature (single fixed value or temperature-time profile) for controlled heating and stress minimization

- Coil/inductor geometry: Designed to match workpiece shape for optimal coupling; directly impacts heating efficiency and temperature uniformity

- Material properties: Workpiece must be electrically conductive (resistivity influences penetration depth and eddy current heat generation); magnetic materials offer additional hysteresis loss heating (higher efficiency)

7.0Basic Configuration and Key Characteristics of Induction Heating Equipment

7.1Basic Configuration

From a functional perspective, core components include:

- Electromagnet (primary coil)

- Electronic oscillator or mains power supply (delivers alternating current to generate magnetic field)

- Industrial applications require additional auxiliary systems:

- Material handling devices

- Power cabinets

- Process control systems

- User interfaces

- Cooling systems

7.2Key Technical Characteristics

Industrial induction heating equipment incorporates the following features to meet production requirements:

- Energy-efficient operation: Capacitive compensation corrects power factor, minimizing phase displacement and active power losses during high-current operation

- Compact footprint: Occupies limited floor space relative to workpiece size, enabling easy integration into diverse production lines

- Advanced temperature control:

- Basic temperature setpoint control

- Ramp heating (gradual power increase)

- Differential temperature control (monitors inner/outer temperature difference with defined maximum allowable limit)

- Operational convenience: Streamlined touch-screen interface with multi-language support; real-time display of system status (parameters, temperature, fault codes); alarm/failure guidance

- Extensive communication capabilities: Ethernet for remote parameter control; USB for process data export (supports quality traceability)

- Customized solutions: Tailored designs for specific functional requirements or application scenarios

8.0Frequently Asked Questions (FAQ)

8.1Can non-magnetic materials be heated using induction heating?

Yes. The fundamental requirement is electrical conductivity (not magnetic properties). Non-magnetic conductive materials (e.g., aluminum, copper alloys) are heated via Joule heat from induced eddy currents. Since there is no hysteresis loss heating, parameters (power, frequency) must be adjusted to ensure sufficient efficiency.

8.2Is induction heating suitable for small tube-end sealing operations in Tube End Closing Machines?

Yes, it is fully applicable. Medium-frequency induction heating (5–500 kHz) enables precise localized heating of tube ends to meet sealing temperature requirements. Rapid, clean, non-contact heating ensures sealing integrity and surface quality, while the compact equipment design allows easy integration into production lines.

8.3How can internal stresses in the workpiece be avoided during induction heating?

The key is implementing a controlled heating profile:

- Use ramp heating to gradually increase input power (prevents sudden temperature rises)

- Employ differential temperature control to monitor and limit inner/outer temperature gradients

- Select appropriate frequency and temperature setpoints based on material properties to ensure uniform heating

Reference

https://en.wikipedia.org/wiki/Induction_heating