- 1.0Key Factors to Consider When Choosing a Plasma Cutter

- 2.0Plasma Cutter Types: Which One Is Right for You?

- 3.0Plasma Cutting Safety Guidelines

- 3.1Protective Clothing and Equipment

- 3.2Recommended Filter Shade Levels for Plasma Cutting and Gouging

- 3.3Noise Protection

- 3.4Ventilation and Fume Extraction

- 3.5Hot Metal and Spark Hazards

- 3.6Electrical Safety

- 3.7Machine Placement and Cooling

- 3.8Power Supply

- 3.9Air Supply Quality

- 3.10Cutting Best Practices

- 3.11Maintenance

- 3.12Certification Marks Overview

1.0Key Factors to Consider When Choosing a Plasma Cutter

Choosing the right plasma cutter depends on your cutting needs, material thickness, portability, and work environment. Below are key factors to consider:

1.1Cutting Thickness & Amperage

- < 6 mm (¼”) Material: Use a low-amperage cutter (≈ 25 A).

- 6–12 mm (¼”–½”) Material: Look for a 50–60 A

- 19–24 mm (¾”–1″) Material or Gouging: Choose 80–100 A output models.

Always select a cutter with enough power above your average cutting thickness to ensure clean, slag-free results.

1.2Duty Cycle

- Duty cycle refers to how long a machine can cut continuously within a 10-minute period before cooling is needed.

- For example, a 60% duty cycle at 50 A means 6 minutes of continuous cutting at full power, followed by 4 minutes of cooling.

⏱️ Higher duty cycles reduce downtime and improve productivity.

1.3Arc Transfer Performance

Choose a machine that enables:

- Smooth, quick transition from pilot arc to cutting arc

- Longer transfer distances, which make cutting and gouging easier and more forgiving for the operator

1.4Portability & Size

For mobile or shipboard applications:

- Select a lightweight, portable model

- Consider features like an undercarriage, shoulder strap, or built-in cable/torch storage

- A small footprint is ideal for limited workspace

1.5Durability & Filtration

- Look for protected controls, such as cages around filters and other sensitive parts

- Built-in air filters are crucial to remove oil and moisture from compressed air

Contaminated air can cause internal arcing and reduce cutting quality.

1.6User Interface & Ergonomics

- Prefer machines with a clear, intuitive control panel

- On-unit guides and settings improve setup and troubleshooting

- For handheld units, ensure the torch is comfortable and ergonomic to reduce fatigue and improve cut quality

1.7Power Compatibility

Ensure the cutter is compatible with your onboard power supply:

- Phases:1-phase or 3-phase

- Voltage:115V, 230V, 380V, or 440V

- Frequency:50 Hz or 60 Hz

Many modern units are auto-switching and support dual-voltage and dual-frequency operation.

1.8After-Sales Support

Select a manufacturer or supplier that provides:

- Global service network

- Readily available spare parts

Reliable support ensures long-term productivity and minimal downtime.

1.9Hidden Cost: Consumables and Service Life

Plasma cutting torches use several consumable components—including the retaining cap, shield, nozzle, electrode, and swirl ring—which require regular replacement as cutting performance degrades.

- These parts should be replaced before failure to maintain cut quality and protect the torch.

- Consumables represent a hidden operating cost that adds up over time.

Choose a plasma system with fewer consumable parts to reduce replacement frequency and total cost.

When comparing machines, check the manufacturer’s rated consumable life—but ensure you’re comparing the same usage data (e.g., cut time, amperage, material type) across different models.

1.10Built-in Air Compressor: Convenience vs. Practicality

Some small plasma cutters come with a built-in compressor, which can be useful when:

- External compressed air is not available

- The available air supply is of poor quality(contains water or oil)

However, be aware:

- The internal compressor will increase the weight of the unit

- Onboard environments like ships usually have reliable access to compressed air, making this feature less essential

Before choosing a model with a built-in compressor, evaluate whether your air supply is clean and consistent enough for plasma cutting.

2.0Plasma Cutter Types: Which One Is Right for You?

When choosing a plasma cutter, one of the most important distinctions is how the machine is operated. Based on the control method, plasma cutters fall into two main categories:

2.1Handheld Plasma Cutter

Handheld plasma cutters are compact and easy to operate, making them ideal for:

- On-site repairs and maintenance

- Automotive bodywork and fabrication

- General workshop use for cutting thin to medium-thickness metal

Key Features:

- Manual operation with a trigger-activated torch

- Lightweight and portable

- Quick setup and minimal training required

- Most models support cutting up to 1 inch (25 mm) with proper amperage

Best For:

Contractors, metalworkers, HVAC technicians, and anyone needing a mobile cutting solution.

2.2CNC Plasma Cutter

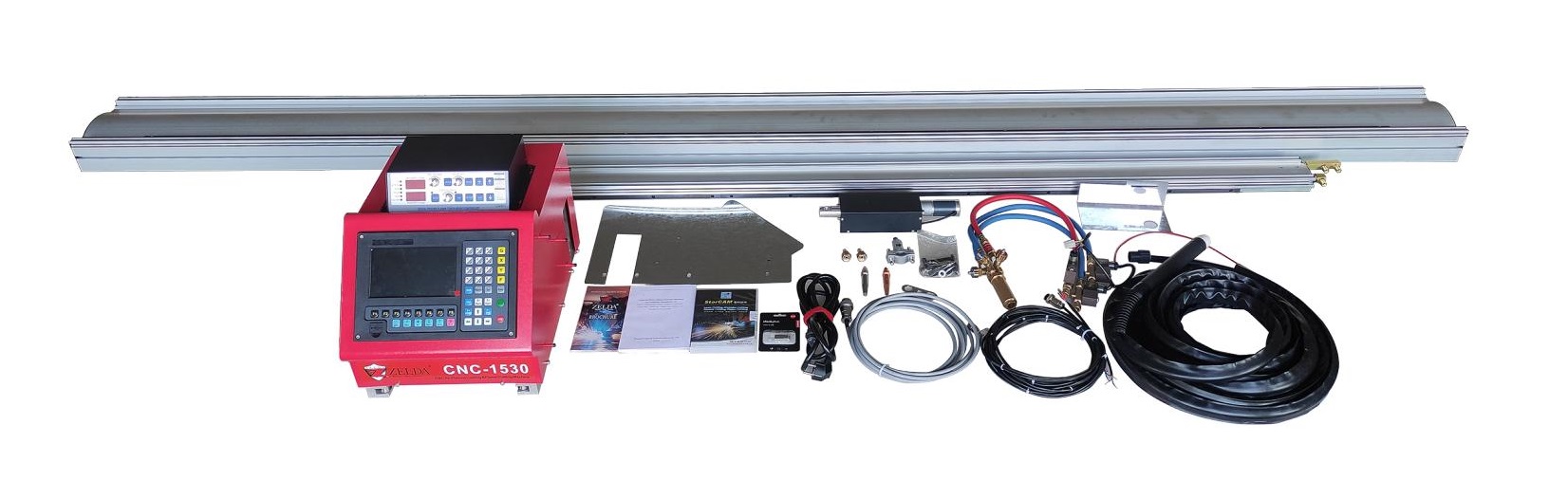

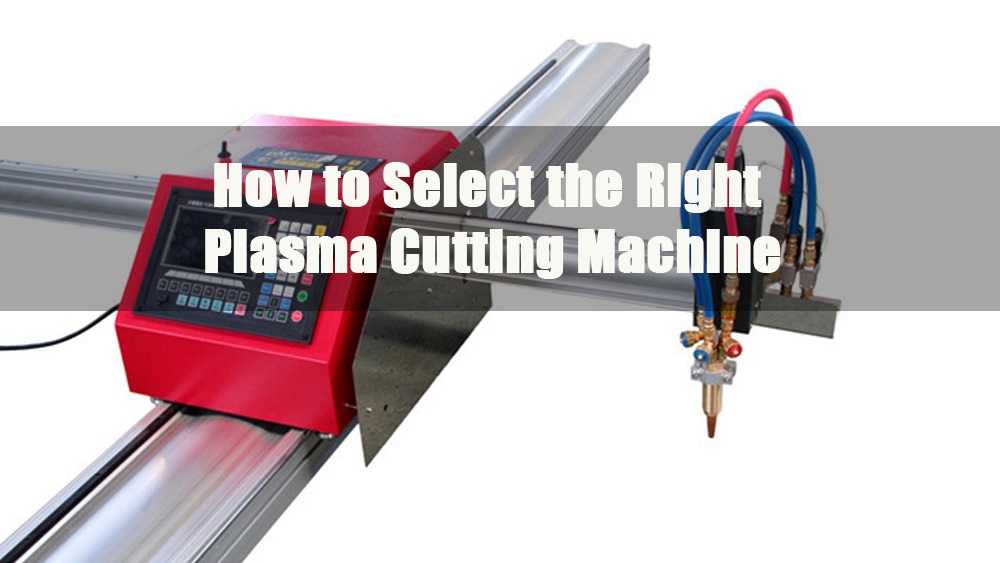

CNC Plasma Plate Cutting Machine

CNC (Computer Numerical Control) plasma cutters are automated systems designed for precise, repeatable cutting tasks. They are commonly used in industrial settings where high productivity and accuracy are essential.

Key Features:

- Controlled by software and programmable for complex shapes

- Mounted on cutting tables with linear guides and motors

- Ideal for mass production or detailed metal design work

- Compatible with CAD files for custom cuts

Best For:

Metal fabrication shops, manufacturers, and businesses require large-volume or high-precision cutting.

CNC Plasma Tube Cutting Machine

Also known as CNC tube plasma cutters or pipe plasma cutting machines, these systems specialize in cutting round, square, or rectangular tubes. They can perform complex operations like bevel cutting, slotting, and saddle cuts, making them essential in industries such as steel structures, piping, automotive, and construction.

3.0Plasma Cutting Safety Guidelines

Plasma cutting involves high voltage, high temperatures, and intense radiation. In addition to basic PPE requirements, the following safety measures must be followed to ensure operator safety and equipment reliability.

3.1Protective Clothing and Equipment

- Wear dark-colored leather or woolen clothing to shield against the intense visible and invisible (ultraviolet and infrared) radiation emitted by the plasma arc.

- Avoid cotton-based clothing, as ultraviolet radiation can cause it to deteriorate rapidly.

- Dark clothing helps reduce light reflection, especially under the welding helmet, where reflected UV rays can cause burns to the face and neck.

- Use protective eyewear with filter lenses that conform to ANSI Z49.1 standards to ensure proper protection for your eyes.

3.2Recommended Filter Shade Levels for Plasma Cutting and Gouging

| Arc Current (Amps) | Minimum Shade Number | Recommended Shade Number |

| Under 40 | 5 | 5 |

| 40–60 | 6 | 6 |

| 60–80 | 8 | 8 |

| 80–300 | 8 | 9 |

| 300–400 | 9 | 12 |

Always ensure all personnel in the cutting area are adequately protected with proper PPE and follow facility safety protocols.

3.3Noise Protection

When cutting thicker materials, hearing protection should be worn to prevent damage from high noise levels.

3.4Ventilation and Fume Extraction

- The plasma arc generates ozone and other harmful gases due to air breakdown.

- Adequate ventilation or local exhaust systems must be used to remove these fumes from the workspace.

- Never operate in enclosed or poorly ventilated areas without proper fume control.

3.5Hot Metal and Spark Hazards

- Sparks can travel over 11 meters (35 feet). Keep flammable materials away from the cutting area.

- Do not wear clothing with cuffs or exposed pockets, which may trap molten material.

- Always wear insulated gloves and flame-resistant protective clothing.

circuit in the moment the shield

cup is removed.

3.6Electrical Safety

- Plasma cutters operate at low amperage but high voltage.

- Open-circuit voltage often exceeds 300 VDC; cutting voltage is approximately 100 VDC.

- The torch connection must comply with EN 60974 standards:

- It must be secured with tools (not hand-removable)

- It must prevent electrical exposure and accidental disconnection.

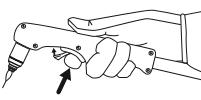

- Torches should include built-in safety features such as:

- Safety interlock circuits that disable the arc when consumables or the shield cup are removed.

- Mechanical safety catches over the trigger to prevent accidental firing.

3.7Machine Placement and Cooling

- Position the machine as far from the cutting location as possible to prevent dust intake.

- Maintain clear airflow for cooling. Dust can accumulate inside the machine and affect performance.

3.8Power Supply

Avoid using extension cords for the primary power cable to reduce voltage drop and overheating.

3.9Air Supply Quality

The air entering the plasma cutter must be clean, dry, and free from oil or moisture.

Moisture can cause:

- Shortened consumable life

- Premature torch failure

To test for moisture, run the machine in “air set” mode and place a piece of paper under the tip. If moisture appears, inspect the air system or install a dryer.

3.10Cutting Best Practices

- Use edge starts instead of pierce starts when possible. Edge starts extend the consumable life by reducing metal blowback into the tip.

- Ensure the return clamp is placed on clean, bare metal. Remove any rust, paint, or coating to improve conductivity.

- Position the return clamp as close to the cutting area as possible, ideally on the workpiece itself.

- Inspect all cables regularly for wear, loose connections, or damage that could resist current flow.

3.11Maintenance

Every six months, remove the plasma cutter’s cover and blow out internal dust using dry compressed air to keep electrical components clean.

3.12Certification Marks Overview

- SUS Mark: Indicates compliance with IEC 60974-1, suitable for use in environments with increased risk of electric shock.

- CSA Mark: Shows that the product meets U.S. and Canadian safety standards, certified by CSA International or other NRTL labs like UL or TÜV.

- CE Mark: Declares conformity with applicable European Directives (e.g., Low Voltage, EMC, RoHS, RED). Only products with the CE mark near the data plate are EU-compliant.

- RoHS Mark: Indicates that the product meets the requirements of the EU Restriction of Hazardous Substances (RoHS) Directive.

- EAC Mark: Confirms compliance with safety and EMC standards for export to Russia, Belarus, and Kazakhstan (Eurasian Customs Union).

- GOST-TR Mark: Indicates conformity with Russian Federation product safety and EMC regulations.

- RCM Mark: Signifies compliance with EMC and safety standards in Australia and New Zealand.

- CCC Mark: Indicates that the product has been tested and meets China’s Compulsory Certification (CCC) requirements for product safety.

- UkrSEPRO Mark: Confirms compliance with Ukrainian safety and EMC standards for CE-certified products exported to Ukraine.

- Serbian AAA Mark: Indicates that the CE version of the product meets Serbia’s safety and EMC regulations.