1.0How to Hand Polish Aluminum Diamond Plate

Hand polishing is a simple and effective way to remove oxidation and restore the original metallic shine of aluminum diamond plate. This method doesn’t require power tools—just a few household items and a good aluminum polish.

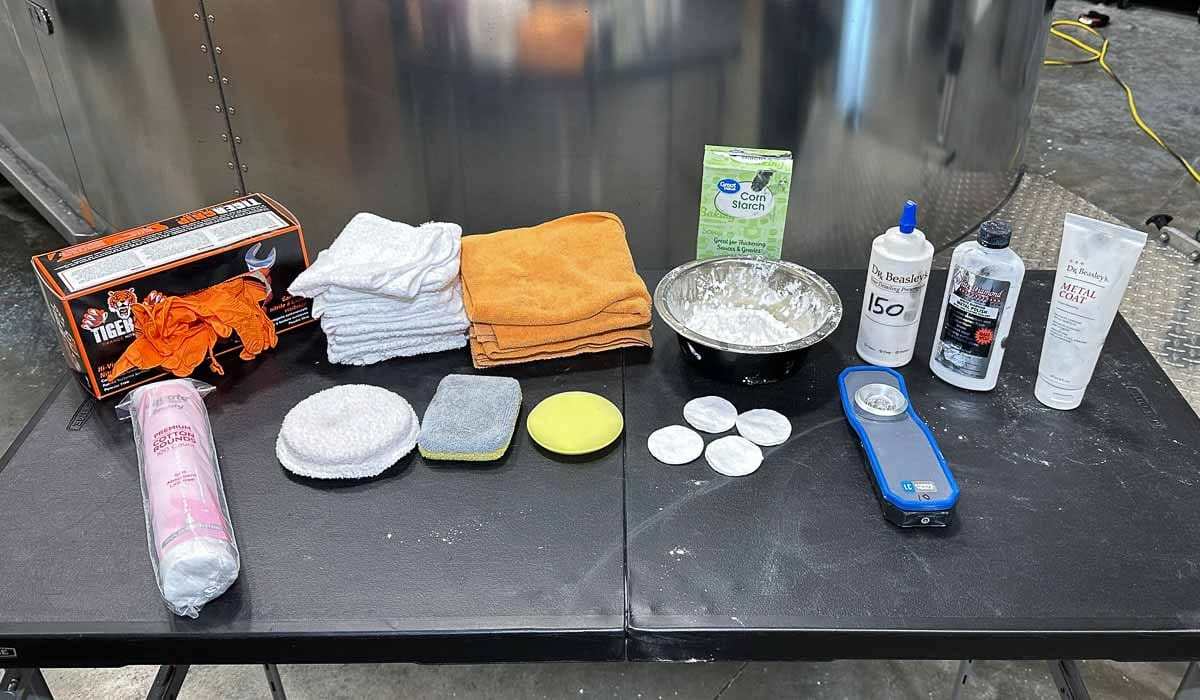

1.1Tools and Materials You’ll Need

- Aluminum polish (formulated for metal surfaces)

- Nitrile gloves (to protect your hands)

- Terry cloth (cut into 6″ × 6″ squares)

- Old T-shirt (also cut into small squares for final polishing)

- Foam or microfiber applicator pad

- Metal ceramic coating (optional, for protective sealing)

- Cotton pads (optional, for polishing tight areas)

- Cornstarch (optional, helps remove excess polish residue)

1.2Choose the Right Cloth Based on Oxidation Level

- Heavy Oxidation / Long-Term Neglect:

Start with a terry cloth to remove the dull, oxidized layer. The fabric’s texture works well with abrasive polishes for deeper cleaning. - Light Oxidation / Surface Still Shiny:

Use an old T-shirt for light polishing. Its softer texture is ideal for restoring gloss and preserving the plate’s pattern.

1.3Step-by-Step Hand Polishing Instructions

- Clean the Surface:

Wash the aluminum plate with water and a neutral cleaner to remove dirt and grease. Dry thoroughly. - Prepare the Polish:

Shake the polish bottle well. Apply a small amount to your cloth or foam pad. - Wipe Along the Pattern:

Using moderate pressure, rub the surface back and forth, following the grain or diamond pattern for about a minute. - Check Results and Wipe Off Residue:

Use a clean cloth or cotton pad to remove any leftover polish. If residue remains, lightly dust the area with cornstarch and wipe again. - Polish in Sections With Slight Overlap:

Work in small zones, slightly overlapping previous sections to ensure a consistent shine across the surface. - Evaluate and Adjust:

- If the shine looks good, move on to the next section.

- If it’s still dull, switch to a stronger cloth, apply more polish, or repeat the process.

Tips and Cautions

- Don’t press too hard—excess force may damage the pattern.

- Always use a clean cloth to avoid scratching the surface with trapped debris.

- Applying a ceramic metal coating afterward can help protect the shine and slow oxidation.

- For heavily oxidized or large dull areas, consider using a power polisher as a backup.

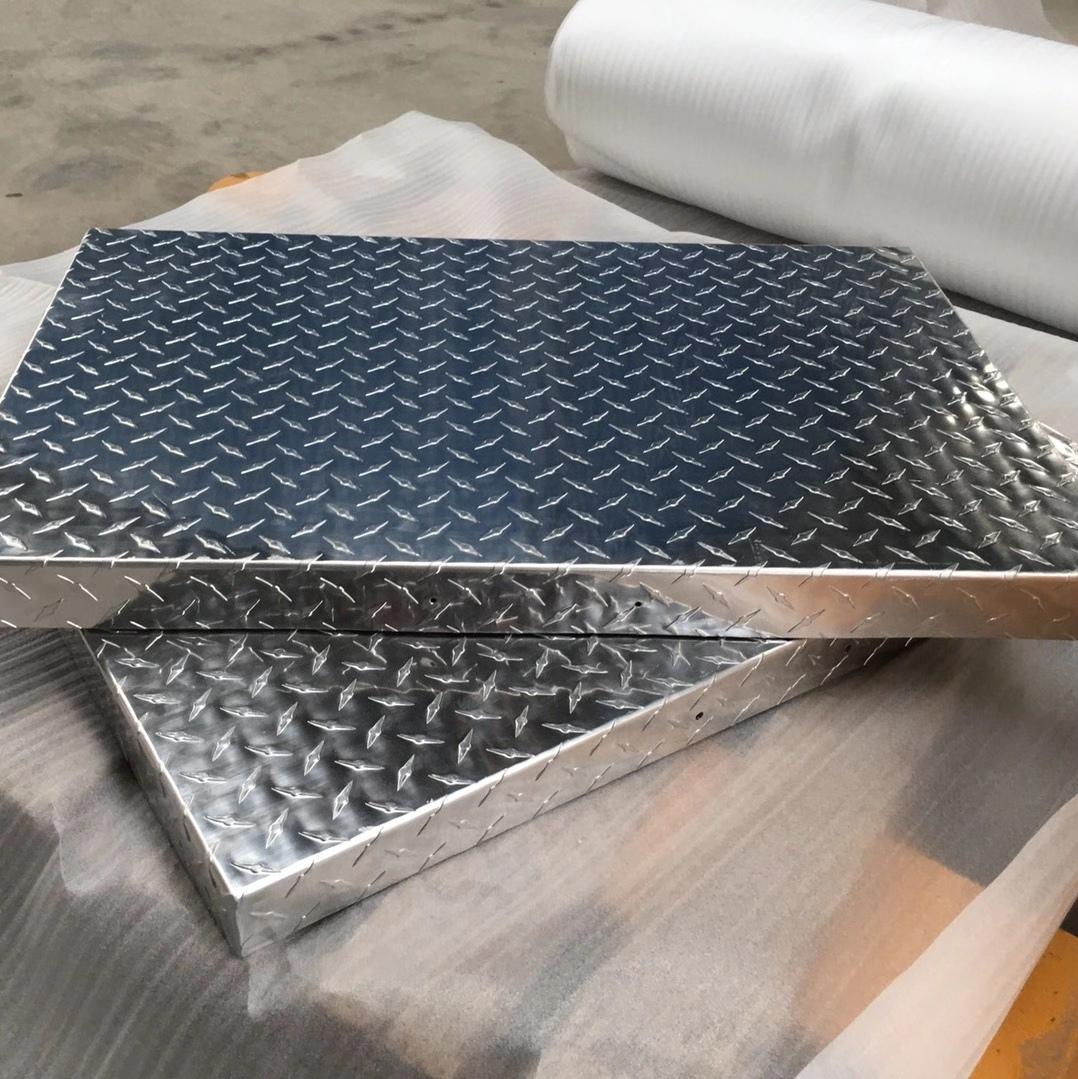

2.0What Is Aluminum Diamond Plate?

Aluminum diamond plate—also known as checker plate, tread plate, or floor plate—is a type of aluminum sheet featuring a raised pattern on one side and a smooth surface on the other. The most common pattern is the diamond shape, designed to enhance both grip and visual appeal. Lightweight, corrosion-resistant, and slip-resistant, it’s a popular material in industrial and construction settings.

Key Benefits of Aluminum Diamond Plate

- Excellent Slip Resistance: The raised pattern provides traction and helps prevent slips, improving safety.

- Corrosion Resistant: Aluminum naturally resists oxidation, making it suitable for humid or outdoor environments.

- Lightweight & Easy to Work With: Lighter than steel, aluminum is easier to cut, weld, and install.

- Attractive Finish: Its bright metallic look adds a modern touch, offering both function and visual appeal.

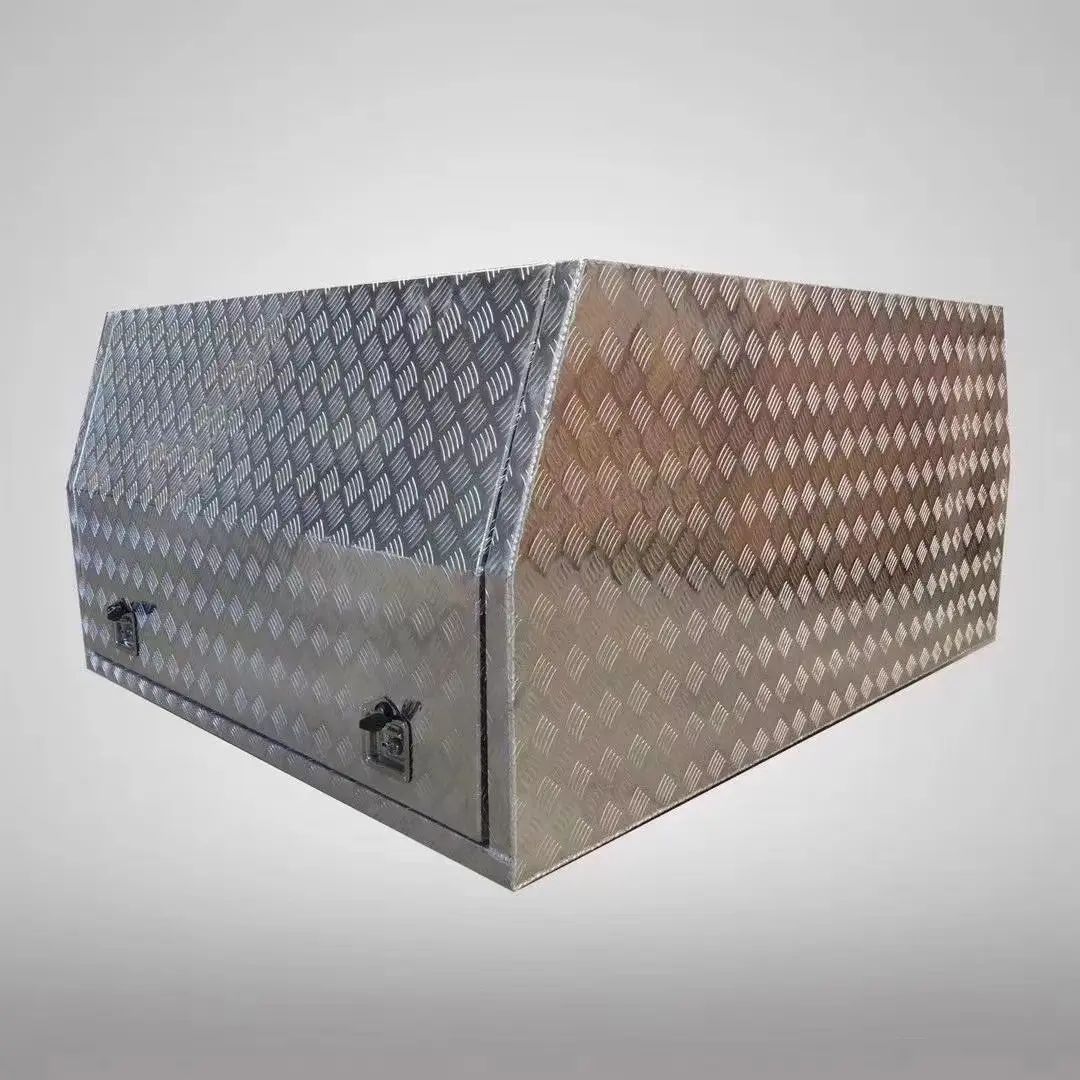

Common Applications of Aluminum Diamond Plate

- Construction: Used for stair treads, platform walkways, ramps, and other slip-resistant surfaces.

- Transportation: Found in truck beds, ambulance floors, and fire truck interiors.

- Industrial Settings: Ideal for equipment platforms, machine bases, and safety step areas.

- Decorative Uses: Great for toolboxes, wall panels, and display cabinet backs.

Surface Care and Maintenance

While aluminum diamond plate has a naturally shiny finish, it can lose its luster over time due to:

- Oxidation and Contaminants: Exposure to moisture and airborne pollutants can form oxidation or leave surface stains.

- Wear and Scratches: Frequent foot traffic or improper cleaning can leave marks on the aluminum.

- Environmental Exposure: UV rays, humidity, and coastal air can accelerate dulling and aging.

To Restore Shine:

- Hand Polishing: Use a cloth wheel and polishing compound to manually buff the surface.

- Power Tool Polishing: For more intricate textures, a small polishing machine with a ball polishing attachment works well.

- Regular Cleaning and Drying: Wipe down with a neutral cleaner and keep the surface dry to slow oxidation.

3.0How to Achieve a Mirror Finish on Aluminum Diamond Plate

Want to give your aluminum diamond plate a mirror-like shine? While most people stop at basic oxidation removal and polishing steps, achieving a professional-level finish requires careful material choice, polishing technique, and the final, meticulous touch.

The secret lies in using cotton pads for the final polishing phase.

3.1Why Choose Cotton Pads Instead of Old T-Shirts?

| Material Comparison | Features | Polishing Performance |

| Old T-shirt Cotton | Soft, woven texture | Great for initial polishing, removes oxidation layers |

| Cotton Pads (Cotton Rounds) | Extremely soft, no woven texture | Ideal for final-stage polishing, achieving a mirror finish |

Cotton pads lack the woven textile pattern found in T-shirts, which means they won’t leave fine scratches on the aluminum surface. This “no-texture” structure is perfect for achieving the ultra-fine polishing needed for a mirror finish.

3.2Step-by-Step Guide for Hand Polishing to a Mirror Finish

- Prepare Materials

- High-quality aluminum polish

- Cotton pads (round, untextured)

- Microfiber towel (for wiping off residue)

- Apply Polish Evenly

- Squeeze a small amount of polish onto the cotton pad.

- Gently spread the polish over a small area of the diamond plate.

- Polish Along the Pattern

- For areas with visible texture, gently rub back and forth following the existing pattern.

- For smooth, non-textured surfaces, move in circular or straight motions depending on the best shape for the area.

- Observe and Wipe Off Excess Polish

- Use a microfiber towel to gently wipe off any leftover polish, avoiding scratches.

- Check the shine for uniformity and decide if additional polishing is needed.

3.3Advanced Tips and Results Observation

- If doing a second round of polishing, simply switch to a clean cotton pad and repeat the process.

- Under strong light, you may still notice very fine swirl marks or scratches, which are a natural result of the aluminum’s surface quality and the manual process.

- Use a high-color flashlight to evaluate the “mirror-level” effect and see if it meets expectations.

Tip: For particularly rough or scratched aluminum, a mirror finish requires first completing the basic sanding and oxidation removal. Without this, the surface defects will still affect the final reflection quality.

4.0Video -DIY How to polish Diamond Plate no BS

5.0How to Easily Clean Aluminum Diamond Plate

The best way to clean aluminum diamond plate depends on where it’s used and how dirty it is. Below are common cleaning methods based on use cases—from household décor to industrial surfaces and even mirror-finish aluminum.

5.1Light Cleaning (Home or Decorative Use):

Best for: Wall panels, garage doors, toolbox exteriors

Steps:

- Mix a cleaning solution: Combine warm water with a few drops of mild dish soap.

- Wipe the surface: Use a soft cloth or sponge—avoid steel wool or abrasive pads.

- Rinse thoroughly: Use clean water to remove any soap residue.

- Dry completely: Wipe with a microfiber towel to prevent water spots.

5.2Moderate Cleaning (Outdoor, Vehicle, or Light Industrial Use):

5.3Best for: Truck steps, flooring plates, toolboxes, walkways Recommended Tools and Methods:

- Use a soft-bristle or nylon brush to scrub off stubborn grime.

- Apply an aluminum-safe degreasing cleaner, like Simple Green.

- Rinse with a low-pressure water hose to remove all chemical residue.

- Finish by drying with a clean cloth to prevent oxidation.

References

www.drbeasleys.com/blog/2024/10/29/how-to-polish-aluminum-diamond-plate