- 1.0Safety Precautions

- 2.0Drill Bit Selection and Applications

- 3.0Pre-Drilling Preparation

- 4.0Core Drilling Steps

- 5.0Special Drilling Scenarios

- 6.0Equipment Upgrade Recommendation (Drill Press)

- 7.0Video:How to Drill Into Metal

- 8.0Frequently Asked Questions (FAQ)

- 8.1What is the best drill bit for metal?

- 8.2Do I always need cutting oil when drilling?

- 8.3How can I prevent drill bits from overheating?

- 8.4Can standard HSS drill bits cut stainless steel?

- 8.5How do I choose the right drill bit?

- 8.6How should drill speed be set?

- 8.7What should I keep in mind when drilling large holes or thick steel plates?

Drilling through metal requires more than just the right tools—it also demands proper technique and preparation. Without the correct drill bit, speed setting, and safety measures, even a simple hole can damage equipment, shorten tool life, or cause injury.

This guide explains the essential steps, from choosing the right drill bit and setting up your workpiece to handling special drilling scenarios. Whether you are working with thin sheet metal, thick steel plates, or large-diameter holes, the following instructions will help you achieve clean, accurate results safely and efficiently.

1.0Safety Precautions

1.1Personal Protective Equipment

- Always wear wraparound safety goggles to prevent eye injuries from flying metal chips.

- Use durable, non-slip work gloves to protect your hands from sharp edges or hot surfaces.

- Avoid loose clothing, dangling jewelry, and keep long hair tied back to prevent entanglement in rotating parts.

- If the work environment is noisy, wear hearing protection such as earmuffs.

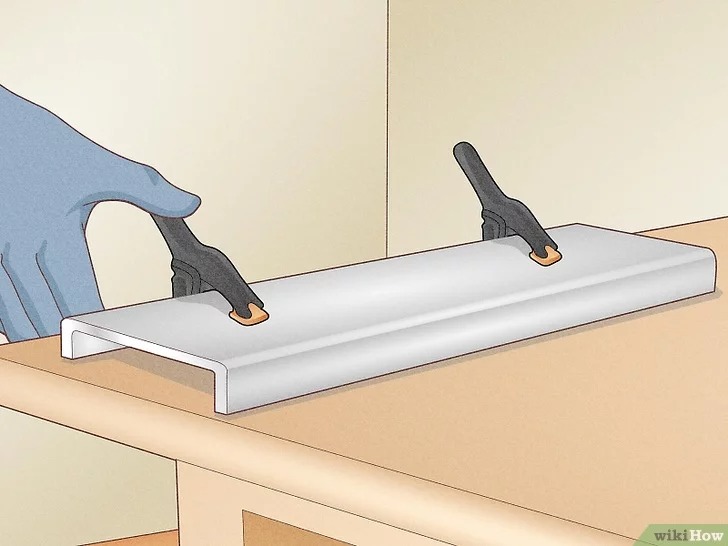

1.2Workpiece Securing Requirements

- Never hold a metal piece with one hand or operate the drill single-handedly.

- Always secure the workpiece to a workbench or a stable base using at least two proper clamps. This prevents the drill bit from binding and the workpiece from spinning, which could cause cuts or injuries.

1.3Chip and Heat Management

- Use a workshop brush to clear away metal chips. Do not remove debris with your hands.

- Metal heats up after drilling due to friction. Allow it to cool naturally or handle it with pliers or gloves to avoid burns.

2.0Drill Bit Selection and Applications

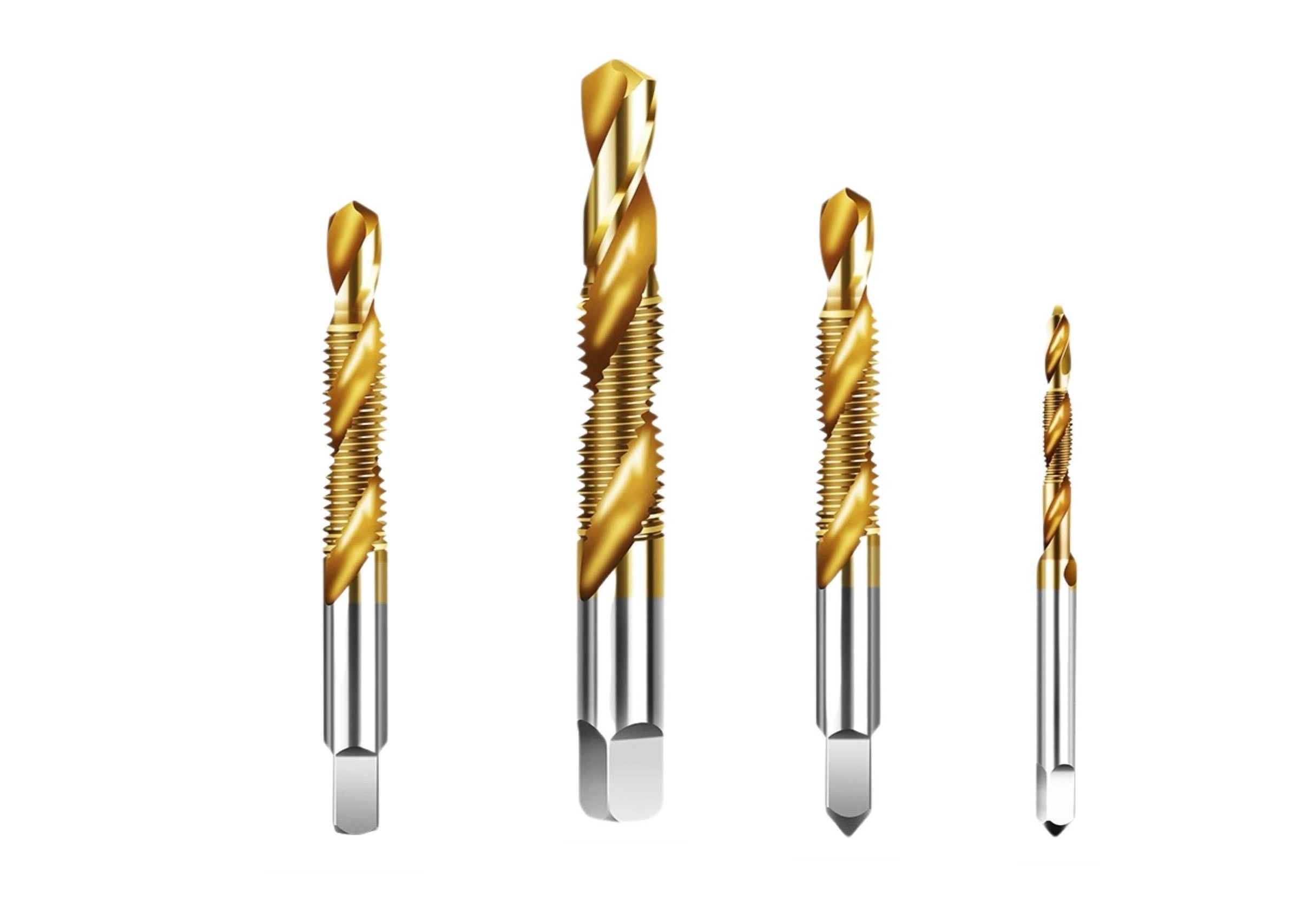

Different metals and drilling needs require the right type of drill bit. The following chart shows suitable options:

| Drill Bit Type | Core Features | Best for Applications |

| High-Speed Steel (HSS) | Low cost, general purpose | Softer metals like aluminum, brass, cast iron; single or occasional drilling |

| Cobalt Drill Bits | High hardness, heat resistance, long lifespan | Hard metals like stainless steel, hardened steel; frequent drilling tasks |

| Titanium Nitride (TiN) Coated | Friction- and heat-resistant, lasts up to 6× longer than HSS | Various metals, ideal when tool life is a priority |

| Step Drill Bits | Tapered design, drills multiple hole sizes | Thin metal sheets (e.g., steel boxes, stainless sinks) requiring holes of different diameters |

| Hole Saws for Metal | Ring-shaped cutting, smooth edges | Large holes over 12.7 mm (0.5 in) in thin sheet metal |

Note: Prefer drill bits with a 135° split-point tip. This reduces wandering and lowers feed pressure, making it especially effective for hardened metals.

3.0Pre-Drilling Preparation

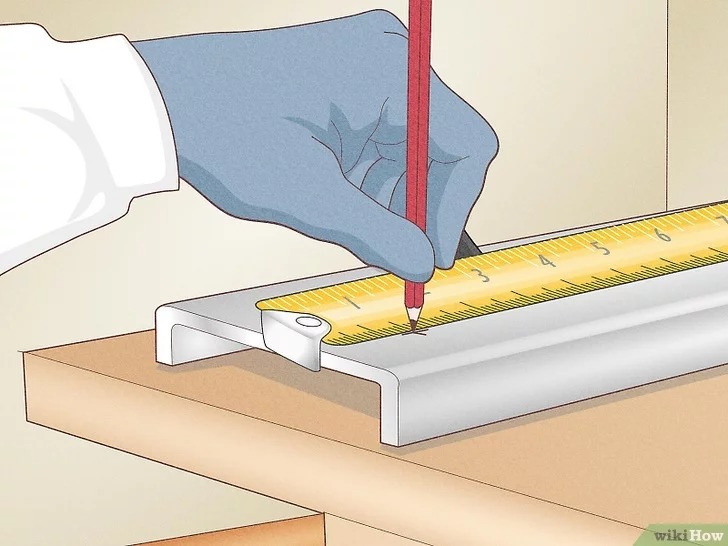

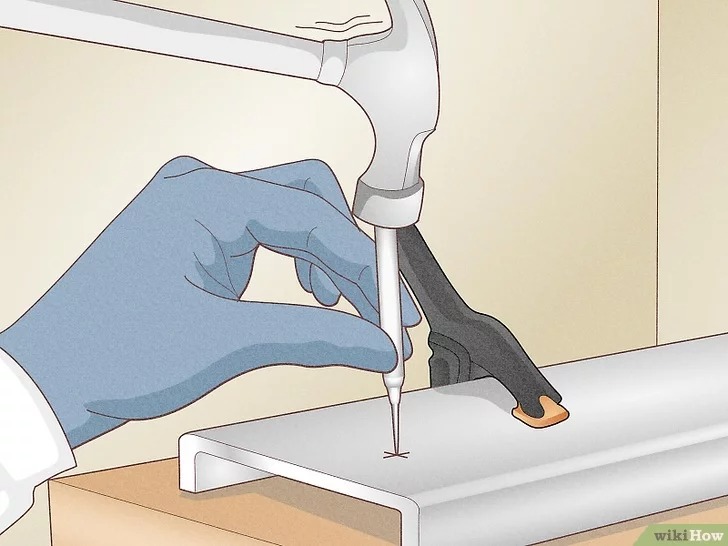

3.1Marking and Positioning

- Measure and mark the center of the hole according to requirements.

- Use a center punch and hammer to create a 1–2 mm (0.04–0.08 in) indentation (“dimple”). This ensures the drill bit tip seats securely without wandering.

- In urgent cases, a nail can be used as a substitute for the punch, but accuracy must be checked again.

3.2Lubrication and Cooling

- When drilling steel with a thickness ≥ 3.175 mm (1/8 in), always apply cutting fluid or multipurpose oil at the drill site. This reduces heat from friction and extends drill bit life.

- For softer metals such as aluminum, brass, or cast iron, lubrication may be skipped. However, if the hole diameter exceeds 12.7 mm (0.5 in), applying a small amount of lubricant is still recommended.

3.3Equipment Check

- Use a variable-speed drill and confirm the speed adjustment works properly.

- If using a new drill, preset the speed according to drill bit size and metal hardness (refer to the next section “Core Drilling Steps”).

4.0Core Drilling Steps

4.1Speed Settings

- Small twist bits (1.588–4.763 mm / 1/16–3/16 in): 2800–3200 RPM.

- Large twist bits (17.463–25.4 mm / 11/16–1 in): 350–1000 RPM.

- For hard metals such as stainless steel, reduce speed by 10–15% to prevent overheating and dulling of the bit.

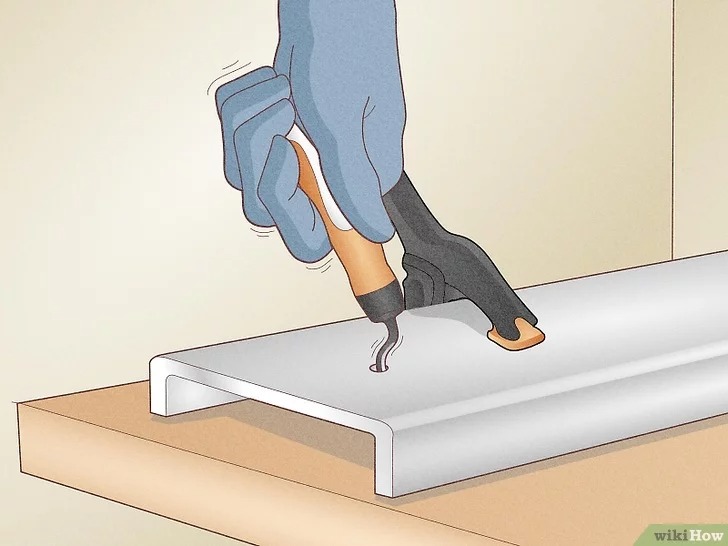

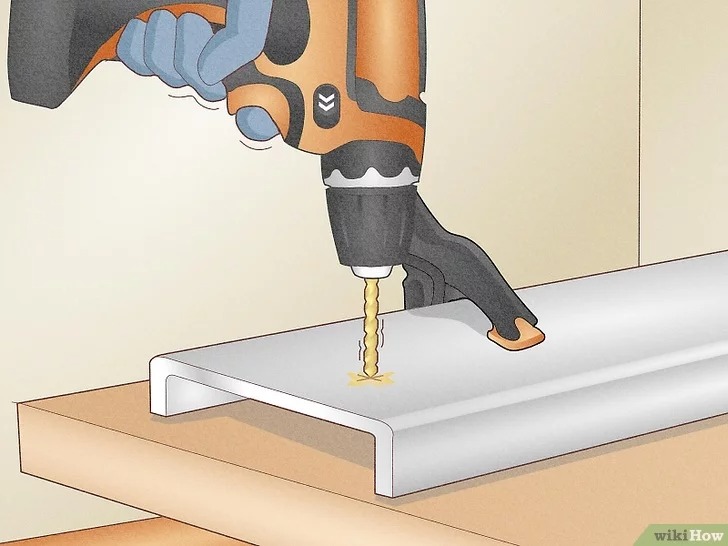

4.2Drilling Technique

- Before starting, ensure the drill bit tip is aligned with the indentation and the drill is perpendicular to the workpiece.

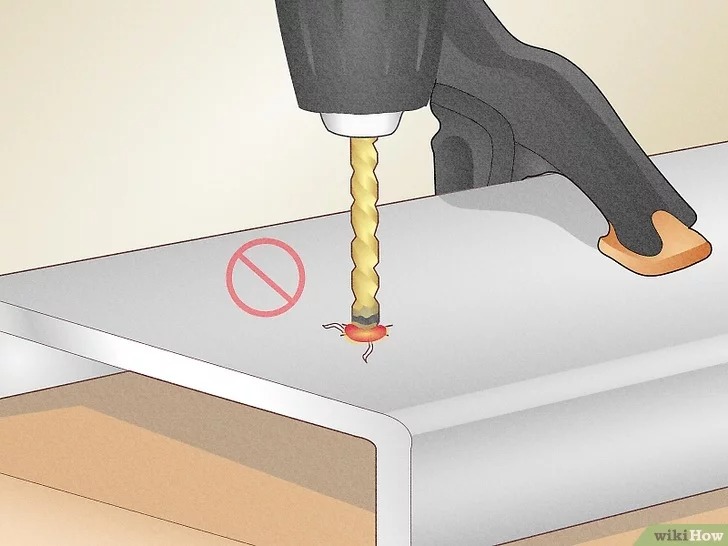

- Apply steady, light pressure during feeding. Do not force the bit, as this can cause bending or breakage.

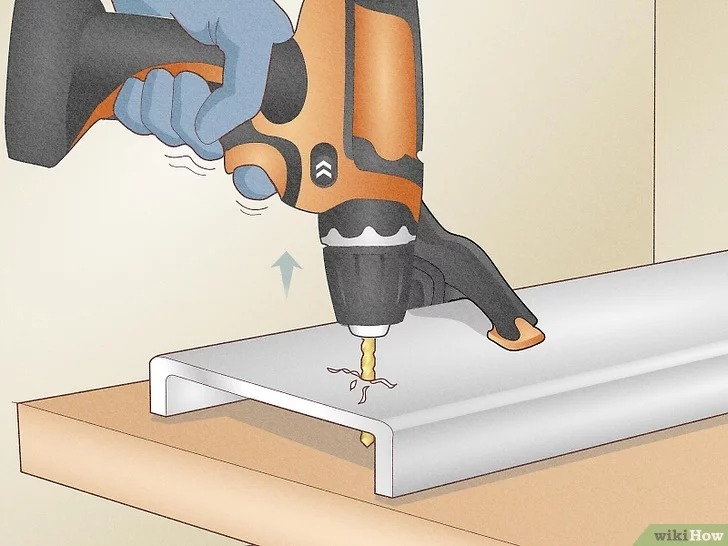

- For deep holes, pause every 10 seconds to withdraw the bit, clear chips, and allow cooling before resuming.

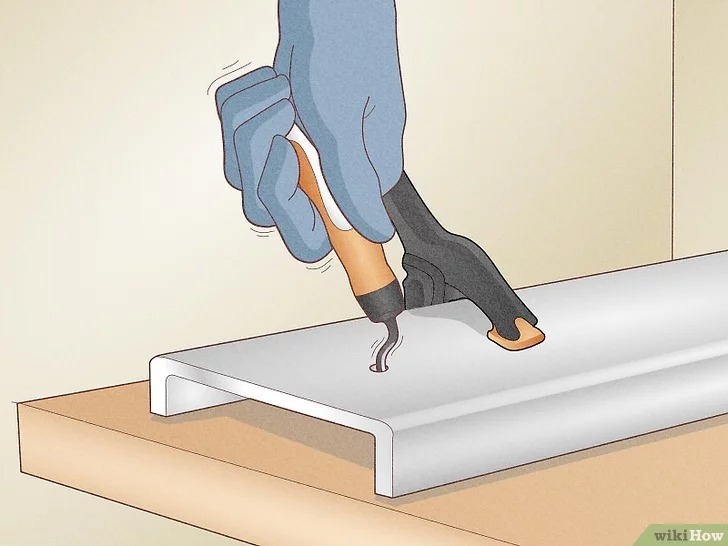

4.3Hole Enlargement and Deburring

- For holes larger than 6.35 mm (1/4 in), first drill a pilot hole of 3–4 mm (1/8 in), then step up gradually with larger bits.

- After drilling, use a deburring tool or a drill bit slightly larger than the hole. Rotate manually around the edge to remove sharp burrs.

5.0Special Drilling Scenarios

5.1Thin Metal Sheets (thickness < 3mm)

- Use a “plywood sandwich” method: clamp the metal sheet between two pieces of plywood and secure the stack before drilling. This prevents deformation and keeps the drill bit from wandering.

5.2Thick Steel Plates (thickness > 6.35mm / 1/4 inch)

- Reduce spindle speed to about 80% of the standard rate and apply more cutting fluid.

- For best results, drill halfway through from one side, then flip the workpiece and finish the hole from the other side. This reduces stress on the drill bit and improves hole accuracy.

5.3Large Holes (diameter > 25.4mm / 1 inch)

- Use a hole saw designed for metal, with plywood backing to protect the work surface and stabilize the saw guide.

- Withdraw the hole saw frequently to clear chips and prevent binding.

6.0Equipment Upgrade Recommendation (Drill Press)

For high-precision or large-volume metal drilling, a dedicated drill press is recommended. Benefits include:

- Provides stable vertical feed, eliminating hand-drill wobble and ensuring hole accuracy.

- Equipped with a cast-iron worktable, adjustable for height and tilt, to handle different workpiece sizes.

- Easy speed adjustment via pulley changes, allowing compatibility with different metals.

- Requires proper metal clamps to secure the workpiece—never adjust the workpiece or drill press while running.

Note: Bench-top drill presses start at around $200. Floor-standing models are better suited for larger workpieces—choose based on project scale.

7.0Video:How to Drill Into Metal

8.0Frequently Asked Questions (FAQ)

8.1What is the best drill bit for metal?

- For soft metals like aluminum or brass: use High-Speed Steel (HSS) drill bits.

- For hard metals such as stainless steel or hardened steel, or for repeated drilling: use cobalt drill bits.

- For thin sheet metal with multiple hole sizes: use step drill bits.

8.2Do I always need cutting oil when drilling?

- For steel with thickness ≥ 3.175mm (1/8 inch), cutting oil is essential.

- For softer metals like aluminum or brass, cutting oil is optional—but recommended for large holes or hard metals to extend bit life.

8.3How can I prevent drill bits from overheating?

- Run at the proper low speed.

- Apply cutting oil when needed.

- Always use sharp bits.

- Feed steadily without forcing.

- For deep holes, withdraw the bit periodically to clear chips and cool down.

8.4Can standard HSS drill bits cut stainless steel?

- It is possible, but difficult. HSS bits tend to overheat and dull quickly.

- A cobalt drill bit with cutting oil is recommended, with speed reduced by 10–15%.

8.5How do I choose the right drill bit?

- For soft metals (aluminum, brass): HSS drill bits.

- For hard metals (stainless steel): cobalt or TiN-coated drill bits.

- For thin sheet metal: step drill bits.

- For large holes: use a hole saw designed for metal.

8.6How should drill speed be set?

- Small diameter bits (1/16–3/16 inch): high speed, about 2800–3200 RPM.

- Large diameter bits (11/16–1 inch): slower speed, around 350–1000 RPM.

- For hard metals like stainless steel: reduce speed further by 10–15%.

8.7What should I keep in mind when drilling large holes or thick steel plates?

- For large holes (> 25.4mm / 1 inch): use a hole saw and clear chips frequently.

- For thick steel plates: lower speed, increase cutting fluid, and if needed, drill from both sides to reduce drill bit load.

Reference

https://www.wikihow.com/Drill-Metal