- 1.0Types of Press Brakes: Which One Is Best for Metal Fabrication?

- 2.0Types of Press Brakes by Control System – Manual, NC, or CNC?

- 3.0Structural Types of Press Brakes: C-Frame vs H-Frame vs 3-Point

- 4.0Press Brake Buying Guide: How to Choose the Right Machine in 5 Steps

- 5.0How to Choose the Right Number of Axes for Your Press Brake?

- 6.0How to Choose the Right Press Brake Supplier?

- 7.0Key Additional Considerations When Purchasing a Press Brake

- 8.0Hidden Costs of Purchasing a Press Brake

1.0Types of Press Brakes: Which One Is Best for Metal Fabrication?

Press brakes are essential forming machines designed to bend sheet metal into desired shapes. Widely used across sheet metal fabrication, machinery manufacturing, and construction components, press brakes vary significantly depending on their drive systems and functional capabilities. Here’s a breakdown of the most common types:

1.1Mechanical Press Brake

Mechanical press brakes operate using a flywheel and crankshaft mechanism. Though based on a traditional design, they are well-suited for high-volume processing of thin to medium gauge materials. Despite lower automation levels, they remain competitive in cost-sensitive applications thanks to fast cycle times and low maintenance demands.

| Item | Description |

| Drive Type | Flywheel + Crankshaft |

| Accuracy | Moderate; ±1° angle repeatability; no dynamic compensation |

| Material Thickness | 0.5–6 mm (thin to medium sheets) |

| Tonnage Range | Typically 40–160 tons |

| Cycle Speed | Fast; ideal for repetitive parts |

| Control System | Manual or semi-automatic with limit switches |

| Energy Consumption | High; motor runs continuously |

| Maintenance | Simple; mainly lubrication and clutch inspection |

| Typical Applications | Brackets, toolboxes, edge flanges, basic enclosures |

| Suitable For | Small job shops, cost-sensitive manufacturers |

1.2Hydraulic Press Brake

Hydraulic press brakes use a dual-cylinder hydraulic system to drive the ram. Known for their rigid frame and moderate bending accuracy, they are the most widely adopted type in the industry today.

| Item | Description |

| Drive Type | Dual hydraulic cylinders |

| Accuracy | Medium; ±0.3–0.5 mm repeatability |

| Material Thickness | 1–20 mm (primarily medium to thick sheets) |

| Tonnage Range | Commonly 40–800 tons, customizable to 1600+ tons |

| Cycle Speed | Moderate; influenced by stroke length and flow rate |

| Control System | Basic NC controller or touchscreen-based CNC |

| Energy Consumption | Moderate; intermittent hydraulic operation |

| Maintenance | Regular checks on seals and hydraulic fluid cleanliness |

| Typical Applications | Construction steel plates, mold bases, machinery panels |

| Suitable For | General fabrication, heavy industries, OEMs |

1.3Electro-Hydraulic Servo Press Brake

Combining hydraulic power with servo valve closed-loop control, electro-hydraulic press brakes deliver high precision, real-time synchronization, and intelligent compensation—making them ideal for precision sheet metal work.

| Item | Description |

| Drive Type | Dual-cylinder electro-hydraulic servo system |

| Accuracy | High; ±0.01 mm positioning, ±0.5° angle |

| Material Thickness | 0.5–25 mm |

| Tonnage Range | 40–1000 tons (modular, expandable) |

| Cycle Speed | High-speed; rapid return stroke |

| Control System | Advanced CNC (e.g., Delem, ESA, Cybelec) |

| Energy Consumption | Energy-saving; motor activates on demand |

| Maintenance | Intelligent diagnostics, reduced oil requirements |

| Typical Applications | Electrical cabinets, medical enclosures, aerospace parts |

| Suitable For | Automated workshops, high-end manufacturers, smart lines |

1.4Electric Press Brake

Electric press brakes are powered entirely by servo motors, eliminating the need for a hydraulic system. They offer clean, fast, and precise operation, particularly ideal for applications requiring high repeatability and low noise.

| Item | Description |

| Drive Type | Servo motors with ball screws or gear drives |

| Accuracy | Ultra-high; ±0.005 mm positioning, ±0.01 mm repeatability |

| Material Thickness | 0.3–6 mm (mainly thin sheets) |

| Tonnage Range | Typically 35–130 tons |

| Cycle Speed | Extremely fast; instant response |

| Control System | Fully CNC; supports remote and automated operation |

| Energy Consumption | Very low; power only used during operation |

| Maintenance | Minimal; no hydraulic fluid required |

| Typical Applications | Precision enclosures, stainless cabinets, cleanroom equipment |

| Suitable For | Medical devices, 3C industry, high-end sheet metal shops |

1.5Drive System Comparison Table

| Feature | Hydraulic | Servo Motor | Electro-Hydraulic | Electric |

| Drive Principle | Hydraulic cylinders | Servo motor + mechanical drive | Hydraulic + servo valve control | Full-electric, ball screw or gear |

| Control Accuracy | Medium; affected by pressure fluctuations | High; closed-loop servo control | High; balanced force and precision | Ultra-high; minimal positioning error |

| Response Speed | Slow to moderate | Fast | Fast and stable | Extremely fast |

| Energy Efficiency | Low; continuous hydraulic loss | High; on-demand motor use | Moderate; hydraulic pump required | Highest; power used only when active |

| Maintenance | High; oil and piping require care | Low; simple motor maintenance | Moderate; both motor and oil involved | Very low; no hydraulic fluid |

| Tonnage Range | 10–3000 tons | 5–250 tons | 50–2000 tons | 5–250 tons |

| Common Uses | Heavy-duty components, bridge plates | Precision parts, small batches | Automated high-end lines | Clean, quiet, repeatable jobs |

| Pros | High torque, wide application | High precision, low energy use | Balance of force and precision | Energy-efficient, low-noise, clean |

| Cons | Noisy, high power loss | Limited force output | Complex structure, higher cost | Force limited for ultra-heavy loads |

2.0Types of Press Brakes by Control System – Manual, NC, or CNC?

In addition to mechanical differences, press brakes are also categorized by control methods—from fully manual models to intelligent CNC machines. Choosing the right level of automation can significantly impact your productivity, precision, and overall operational efficiency.

2.1Manual Press Brake

Ideal for basic operations and small-batch production

Manual press brakes rely entirely on operator adjustments to set the backgauge position and ram travel. With a simple and economical design, they are best suited for beginners, small workshops, or sample prototyping.

| Item | Description |

| Control Method | Manual adjustment of backgauge, angle, and stroke |

| Drive System | Typically mechanical or hydraulic |

| Positioning Accuracy | Low; relies on operator skill, ±1 mm repeatability |

| Efficiency | Slow; suitable for low-frequency, non-repetitive tasks |

| Backgauge System | None or basic mechanical stop; manually adjusted |

| User Skill Level | Easy to learn; ideal for entry-level use |

| Maintenance | Very low; minimal electronics, easy mechanical upkeep |

| Typical Applications | Prototyping, repair shops, simple bracket fabrication |

| Suitable For | Individual workshops, training labs, small factories |

| Energy Consumption | Low to moderate depending on drive type |

2.2NC Press Brake (Numerical Control)

Equipped with basic automation, ideal for standard production needs

NC press brakes use encoders and a basic controller to automate the Y-axis (ram) and X-axis (backgauge). They offer moderate precision and are well-suited for standard repetitive tasks.

| Item | Description |

| Control Method | Basic numeric control (Y and X axes), optional R/Z axes |

| Drive System | Hydraulic or electro-hydraulic |

| Positioning Accuracy | Moderate; ±0.2–0.5 mm repeatability |

| Efficiency | Medium to high; supports job memory and auto positioning |

| Backgauge System | Electrically driven, typically 2-axis (X + R) |

| Programming Interface | Digital display with button menus; simple logic |

| Common Controller Brands | Estun E21, E300, Delem DA-41T |

| Typical Applications | Metal doors, enclosures, tool cabinets, hardware parts |

| Suitable For | General fabrication, mid-volume production shops |

| Energy Consumption | Moderate; motor cycles on demand |

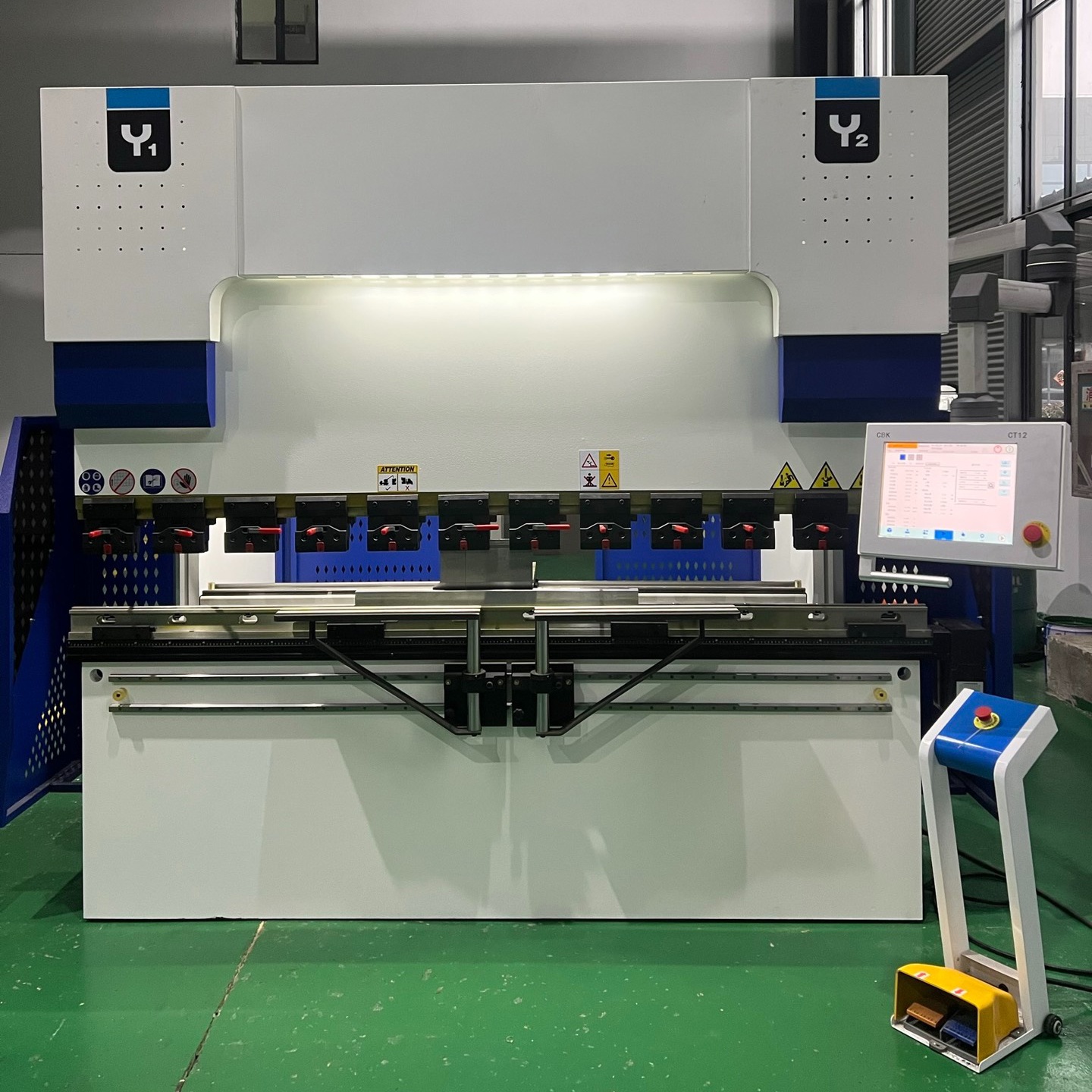

2.3CNC Press Brake (Computerized Numerical Control)

Full automation for high-precision and complex bending sequences

CNC press brakes use a multi-axis closed-loop servo control system for precision and flexibility. Capable of controlling 6+ axes (Y1/Y2/X/R/Z1/Z2), they support complex bend sequences and high repeatability—ideal for advanced manufacturing.

| Item | Description |

| Control Method | Multi-axis CNC control (6+ axes) |

| Drive System | Electro-hydraulic or electric |

| Positioning Accuracy | High; ±0.01 mm repeatability, ±0.5° angle accuracy |

| Efficiency | High; supports offline programming, simulation, batch import |

| Backgauge System | Multi-axis servo-controlled, fully synchronized |

| Programming Interface | Graphical interface (e.g., Delem DA-66T/69T, ESA S660), supports 3D simulation |

| Additional Features | Real-time compensation, angle correction, collision avoidance |

| Typical Applications | Precision parts, medical devices, aerospace panels |

| Suitable For | Advanced manufacturing, automation lines, smart factories |

| Energy Consumption | Energy-efficient, demand-based power usage |

.jpg)

2.4Control System Comparison Table

| Feature | Manual Press Brake | NC Press Brake | CNC Press Brake | Fully Automated Smart Press Brake |

| Control Principle | Pure manual adjustment | Basic numeric control | Multi-axis closed-loop CNC | Sensor-integrated AI control |

| Automation Level | None; fully manual | Semi-automatic | Highly automated | Fully automated with self-learning |

| Positioning Accuracy | Low; skill-dependent | Moderate (±0.2–0.5 mm) | High (±0.01 mm) | Ultra-high; real-time error adjustment |

| Operation Difficulty | Simple; hands-on | Moderate; basic CNC knowledge | Advanced; requires skilled programming | High; needs specialized training |

| Typical Use Cases | Prototypes, repair work | Standard batch production | Complex precision products | Smart manufacturing, flexible lines |

| Applications | Education, small repairs, workshops | Home appliance panels, hardware | Aerospace, medical, elevator panels | Unattended production, Industry 4.0 |

| Maintenance | Low; mechanical focus | Medium; controller maintenance | High; CNC + servo systems | High; complex, professional support required |

| Programming | None | Menu-based simple programs | Graphical programming with CAD import | AI programming, cloud optimization |

| Equipment Cost | Low | Moderate | High | Very high |

3.0Structural Types of Press Brakes: C-Frame vs H-Frame vs 3-Point

Understand how the machine frame affects bending capability, precision, and scalability

Press brakes are also classified by their structural configuration, which directly impacts rigidity, load capacity, workspace access, and machine footprint. Selecting the appropriate structure helps optimize production efficiency for your application needs.

3.1Open Frame Press Brake (C-Frame Design)

Compact structure for light to medium-duty bending

The open-frame press brake features an accessible C-shaped frame, making it easy to load and unload workpieces. While cost-effective and easy to maintain, this design offers lower rigidity, making it suitable for small to medium-sized components and lower tonnage operations.

| Feature | Specification |

| Frame Type | Open “C” frame on one or both sides |

| Rigidity | Moderate; potential for deflection under heavy load |

| Typical Tonnage | 20–250 tons |

| Precision | Moderate; deformation may affect accuracy |

| Suitable Workpieces | Small to medium parts; size limited by frame opening |

| Visibility & Operation | Open access improves tool changes and handling |

| Installation Space | Compact footprint; easy to install |

| Maintenance | Easy to access; exposed components simplify diagnosis |

| Typical Applications | Sheet metal parts, control panels, HVAC flanges, cabinet plates |

| Suitable Users | Start-up fab shops, low-volume production lines |

3.2Closed Frame Press Brake (Gantry/H-Frame Design)

High-rigidity structure for heavy-duty and precision applications

Closed-frame press brakes feature a fully enclosed gantry-style frame—welded or cast—for maximum strength and deformation resistance. Ideal for high-tonnage, multi-axis bending and consistent accuracy across long production runs.

| Feature | Specification |

| Frame Type | Welded or cast gantry (H-frame) structure |

| Rigidity | Very high; suitable for continuous heavy-duty use |

| Typical Tonnage | 160–3000 tons |

| Precision | High; works with compensation systems for consistent angles |

| Suitable Workpieces | Large steel plates, structural panels |

| Installation Requirements | Requires more floor space and foundation support |

| Expandability | Supports multi-axis CNC, automatic handling systems |

| Maintenance | Protected components; requires scheduled servicing |

| Typical Applications | Bridge components, construction machinery, pressure vessels |

| Suitable Users | Heavy fabrication shops, structural steel manufacturers |

3.3Tandem Press Brake (Split Frame / Multi-Machine System)

Multiple machines synchronized for ultra-long part bending

Tandem press brakes synchronize two or more identical machines using electronic control. Designed for bending ultra-long profiles or oversized structural parts with high accuracy and uniformity.

| Feature | Specification |

| Frame Type | Multiple connected machines operating in sync |

| Synchronization | Servo/hydraulic coordination + electronic control |

| Bending Length | 6–16 meters (customizable for longer) |

| Control System | Unified advanced CNC (e.g., DA-69T multi-machine sync) |

| Synchronization Accuracy | High; real-time compensation ensures uniform bending |

| Suitable Workpieces | Shipping container panels, long brackets, large steel structures |

| Installation | Modular transport, assembled on site |

| Typical Applications | Ship hull panels, railway bodies, wind tower sections, power towers |

| Suitable Users | Specialized equipment manufacturers, extra-long part fabricators |

| System Complexity | High; requires expert setup and maintenance |

3.4Bottom-Moving Press Brake

Fixed ram design; bending by lifting the lower beam

In this design, the ram remains stationary while the worktable moves upward to perform the bend. Known for compactness and precise die alignment, this type is ideal for repeatable precision forming, albeit with a slightly slower cycle time.

| Feature | Specification |

| Frame Type | Fixed ram, upward-moving worktable |

| Common Drive | Hydraulic press + guided slide mechanism |

| Typical Tonnage | 40–400 tons |

| Precision | High; excellent die centering and alignment |

| Cycle Time | Slower but stable |

| Visibility | Excellent view of top tool during bending |

| Die Change | Compact space; requires skilled handling |

| Typical Applications | Precision enclosures, electrical cabinets, lab equipment panels |

| Suitable Users | Precision sheet metal shops, high-end production lines |

| Rigidity | Medium to high, depending on bed structure |

3.5Structural Form Comparison Table

| Feature | Open Frame (C-Type) | Closed Frame (Gantry-Type) | Tandem (Multi-Machine) | Bottom-Moving |

| Structure | C-shaped open frame | Gantry-style closed frame | Electrically synced multi-machine | Fixed ram, movable table |

| Rigidity | Moderate; may deform | Very high; ideal for heavy loads | Strong in combination | Medium to high |

| Tonnage Range | 20–250 tons | 160–3000 tons | Over 6 meters length, custom tonnage | 40–400 tons |

| Precision | Moderate | High, with compensation system | High, synchronized compensation | High, precise alignment |

| Operation | Easy access and tooling | Requires space and foundation | Complex setup, field assembly | Excellent process visibility |

| Workpiece Type | Small to mid-size parts | Heavy, thick plates | Ultra-long structural items | Precision panel components |

| Maintenance | Easy; exposed components | Planned maintenance cycle | Requires expert service | Moderate; tight space layout |

| Typical Uses | Small-batch sheet metal | Bridge plates, machinery frames | Containers, wind towers | Precision enclosures, cabinets |

| Suitable Shops | Startups, small workshops | Large manufacturers | Specialized long-part fabricators | High-precision production |

| Footprint | Compact | Large, with heavy base | Flexible but space-intensive | Moderate, space-efficient |

4.0Press Brake Buying Guide: How to Choose the Right Machine in 5 Steps

4.1Define Your Processing Needs and Material Characteristics

Before selecting a machine, clearly assess:

- Material type(carbon steel, stainless steel, aluminum, etc.): Each has different tensile strength and springback properties, affecting bending force and die selection.

- Sheet thickness and length: Thicker and longer sheets require greater bending force and higher bed rigidity.

- Bending angles: Complex angles or tight radii call for high-precision equipment.

- Production scenario: If processing both thick and thin sheets, opt for a CNC press brake with large tonnage and multiple axes.

4.2Determine Required Tonnage and Bending Length

Bending force = Material thickness × Bending length × Material tensile strength / Constant (based on die opening)

Use an online bending force calculator for estimation, and always reserve a 20–30% safety margin.

Ensure the machine length exceeds the maximum workpiece size.

Example Recommendation:

| Workpiece Type | Thickness | Length | Suggested Parameters |

| Stainless Steel | 6 mm | 3000 mm | ≥160 tons / 3200 mm |

| Aluminum + Steel Mix | 1.5–5 mm | ≤1200 mm | 80 tons / 2000 mm CNC |

4.3Focus on Control System and Automation Features

The controller defines your efficiency and forming accuracy.

Recommended features include:

- CNC controller: Program storage, angle correction, automatic parameter setup

- Automatic backgauge: Improves repeatable positioning

- Deflection compensation and real-time angle feedback

- Automatic tool change(ideal for low-volume, high-mix production)

- MES integration, remote monitoring, and intelligent path planning

4.4Evaluate Machine Stability and After-Sales Support

Structural reliability is crucial for long-term precision:

- High-strength welded frame

- Optimized cylinder placement

- Anti-fatigue drive system

Maintenance factors:

- Easy die replacement

- Quick access to consumables (e.g., hydraulic oil, filters)

- Remote diagnostics and fast response services

After-sales support: Choose established brands with a local service network, technical training, and spare parts inventory to minimize operational risks.

4.5Balance Operating Costs with Future Expandability

Price is only part of the equation. Consider:

- Energy efficiency, including standby power management

- Durability and price of consumables

- System scalability(robot integration, auto-feeding, etc.)

- Compliance with international certifications(CE, UL, ISO)

5.0How to Choose the Right Number of Axes for Your Press Brake?

Understanding Control Axes: A Key to Performance and Automation

The number of control axes is a critical factor when evaluating the performance and automation level of a press brake. It directly influences precision, efficiency, and processing flexibility.

5.1▍Single-Axis for Basic Operations

Entry-level press brakes are typically equipped with only one control axis—Y-axis, which governs the vertical motion of the ram, pressing the upper die into the lower die to perform the bend.

For example, the ALEKVS HPA-P hydraulic workshop press brake adopts a single-axis system, with manual parameter adjustment via the machine body. It is ideal for basic sheet metal processing with low complexity.

5.2▍Multi-Axis for High-Precision Forming

Modern CNC press brakes can be equipped with up to 10 control axes, enabling highly accurate, automated, and repeatable operations.

Take the ALEKVS HPB CNC press brake for example. It supports a multi-axis CNC control system capable of managing:

- Backgauge positioning (X, R, Z axes)

- Synchronized ram movement (Y1/Y2 axes)

- Crowning compensation

- Upper die tilting and more

These features significantly enhance forming consistency and overall productivity.

6.0How to Choose the Right Press Brake Supplier?

A Strategic Guide for Reliable Equipment Investment

Selecting a trustworthy press brake supplier is crucial—not only for equipment quality and lead time, but also for long-term service, productivity, and operational stability. The following six dimensions offer a comprehensive framework to assess supplier capabilities:

6.1Experience and Industry Reputation

- Prioritize suppliers with years of proven experience in manufacturing press brakes.

- Review their past project cases, customer portfolios, and industry-specific applications to gauge technical maturity and product stability.

- Evaluate customer feedback, partner endorsements, and export performance as indicators of brand credibility.

6.2Customization and Integration Capability

- Can the supplier tailor machine specifications, optional modules, or non-standard structures based on your requirements?

- Do they offer automation integration solutions, such as robotic loading/unloading or automatic tool changers?

- Are there multiple options for tooling, backgauge systems, and control units to accommodate various production layouts and bending needs?

6.3After-Sales Service and Technical Support

- Does the supplier offer fast-response technical support via phone, remote access, or on-site visits?

- Do they maintain a sufficient inventory of spare parts to minimize downtime?

- Are installation, training, commissioning, and routine maintenance services provided?

📌 Tip: Give preference to suppliers with local service teams or global distribution networks. This ensures quicker support and greater maintenance efficiency.

6.4Certifications and Quality Assurance

- The supplier should hold relevant international certifications such as ISO 9001, CE, or UL, which indicate compliance with quality standards.

- Inspect whether the supplier has a robust quality control system, pre-delivery inspection process, and traceable warranty policy in place.

6.5On-Site Installation and Operator Training

Choose suppliers that offer turnkey services, including full installation, commissioning, and training support.

Training programs should cover:

- Basic operations and safety protocols

- Troubleshooting common issues

- Routine maintenance and upkeep

- Software usage and parameter adjustment

6.6Control System: The Core of Smart Manufacturing

- User-friendly interface: Touchscreen operation, multi-language support

- Efficient program management: Quick access to bending programs, automatic angle compensation, intelligent collision avoidance

- System compatibility: Able to integrate with MES systemsfor digitalized production management

- Customizable parameters: Adapts to different materials and processing workflows

📌 Final Tip: A good supplier is not just an equipment manufacturer, but a long-term partner in your production success. Evaluate not only what they offer now, but how well they can support your evolving needs.

7.0Key Additional Considerations When Purchasing a Press Brake

Ensure Safety, Stability, and Long-Term ROI

Beyond core specifications such as tonnage and bending length, there are several critical supporting factors that directly impact the safety, reliability, and lifecycle return on investment of a press brake. These include safety features, maintenance needs, installation space, and software systems.

7.1Safety Measures: The Foundation of Secure Operation

Press brakes are heavy-duty machines that operate under high force and pressure. Adequate safety mechanisms are essential to prevent accidents and injuries:

- Emergency stop system: Instantly shuts off power during emergencies to prevent further damage or injury.

- Protective devices: Physical guards and photoelectric sensors detect foreign objects and halt machine operation immediately.

- Interlock mechanisms: The machine only starts when all safety components are correctly engaged (e.g., power cutoff when guard doors are open).

- Anti-repeat control: Prevents unintended repeated actions due to pedal misoperation.

- Two-hand operation control: Requires both hands to press start buttons simultaneously to avoid accidental activation.

- Maintenance lockout: Prevents unintended startup during servicing.

- Clear safety labels and warning signs: Mark hazardous zones such as high voltage, heat, or pinch points.

- Operator safety training: Suppliers should provide professional training on safety practices and emergency handling.

📌 Recommendation: Always choose machines with comprehensive safety configurations to ensure a secure production environment.

7.2Price Range and Investment Recommendations

Price spectrum: Press brakes range from $5,000 (manual models) to $500,000+ (fully automated CNC systems).

Cost-performance ratio:

- Entry-level models are suitable for basic processing or startups.

- High-end machines offer greater efficiency and reduced labor costs—ideal for long-term ROI.

Total investment analysis: In addition to initial cost, consider:

- Operating costs(electricity, consumables)

- Tool change frequency and cost

- Productivity gain per shift

These factors help estimate the payback period more accurately.

7.3Space Planning and Installation Requirements

Measure your available workshop space before purchase.

Allow for:

- Machine footprint

- Loading/unloading area

- Service access around the machine

Check machine height, foundation requirements, and floor loading capacity to ensure safe and stable installation.

By factoring in these additional considerations, you not only choose a press brake that fits your current needs—but also lay the foundation for safe, scalable, and cost-effective long-term operation.

8.0Hidden Costs of Purchasing a Press Brake

Understand the Total Cost of Ownership (TCO) Beyond the Price Tag

When investing in a press brake, the purchase price is only the beginning. To make a truly cost-effective decision, it’s essential to consider hidden costs that affect overall ROI, long-term performance, and daily production efficiency.

8.1Operating & Consumable Costs

Operator Wages

Skilled operators often command higher wages, but they typically deliver:

- Greater accuracy

- Fewer mistakes

- Higher output per shift

Investing in talent can reduce overall scrap rates and rework costs.

Hydraulic Oil & Tooling Wear

- Hydraulic fluidmust be changed periodically based on usage hours.

Using long-life, high-quality oil can reduce service frequency and extend system lifespan. - Tooling costsdepend on material quality (e.g., hardened steel tools) and proper tool-workpiece matching.

Choosing the right tooling minimizes wear and replacement frequency.

Energy Consumption

Energy-efficient press brakes help lower utility bills.

However, they may sacrifice speed or tonnage.

Balance is key—evaluate power savings against production throughput.

8.2Downtime Costs

Unexpected downtime is one of the most expensive hidden costs in manufacturing. During idle time, operator wages continue while productivity drops to zero.

Ways to Reduce Downtime:

- ✅ Consult existing customers about reliability and after-sales support

- ✅ Ensure timely availability of spare partsand choose brands with a solid component reputation

- ✅ Review manufacturer maintenance schedulesand preventive maintenance plans

- ✅ Investigate country of origin and manufacturing quality standards

📌 Example: Many top-tier press brake manufacturers are based in Europe, known for:

- Skilled labor

- Robust industrial base

- Reasonable manufacturing costs

- Innovative design culture

8.3Calculating Cost Per Hour (CPH)

A practical way to compare press brakes with similar specs is by evaluating the operating cost per hour.

Cost Per Hour (CPH) =

(Machine Purchase Cost + Annual Operator Wages + Annual Maintenance Costs) ÷ Total Operating Hours per Year (including planned downtime)

Use CPH alongside brand reputation to make informed purchasing decisions and avoid false economies.

By understanding these hidden costs, buyers can look beyond the sticker price and select a press brake that delivers true long-term value, not just initial affordability.

References

www.pressandshear.com/brake-press-machines-guide/

guide.directindustry.com/choosing-the-right-press-brake/

www.southernfabsales.com/blog/5-things-you-need-to-know-when-buying-a-press-brake