- 1.0Why Are Steel Balls So Important?

- 2.0Materials Used in Steel Ball Manufacturing

- 3.0Step-by-Step Steel Ball Manufacturing Process

- 3.1Step 1: Cutting Steel Slugs

- 3.2Step 2: Forming the Raw Ball

- 3.3Step 3: Flash Removal (Flashing Process)

- 3.4Step 4: Soft Grinding (Optional Step)

- 3.5Step 5: Heat Treating for Hardness and Strength

- 3.6Step 6: Descaling (Removing Oxide Layer)

- 3.7Step 7: Precision Grinding of Hardened Steel Balls

- 3.8Step 8: Lapping – Superfinishing the Surface

- 3.9Step 9: Washing, Inspection, and Sizing

- 3.10Steel Ball Grades and Tolerances

- 4.0Recommended Video: How Steel Balls Are Made

- 5.0Applicable International Standards for Steel Balls

- 6.0Quality Control in Every Stage

- 7.0Modern Innovations in Steel Ball Manufacturing

- 8.0Frequently Asked Questions (FAQ)

- 9.0Conclusion

- 10.0Table 1: Types of Steel Balls

- 11.0Table 2: Key Properties and Specifications

- 12.0Table 3: Industry Standards and Certifications

Steel balls are some of the most important components in modern industry. Though small in size, they are vital in enabling smooth, precise rotational movement in a wide range of mechanical systems. From automotive transmissions to aerospace instruments, precision steel balls are everywhere.

1.0Why Are Steel Balls So Important?

Steel balls serve as the rolling elements in ball bearings and are widely used in:

- Industrial and automotive bearings

- Aerospace components requiring extreme reliability

- Electric motors and power tools

- Valves and flow control systems

- High-precision measuring devices

- Electronics, medical devices, and more

Their role is simple yet critical: reduce friction, distribute loads, and maintain precise alignment between rotating parts.

2.0Materials Used in Steel Ball Manufacturing

The manufacturing process begins with careful material selection. The material chosen depends on the end-use requirements.

2.1Common materials include:

- Chrome Steel (AISI 52100)– Excellent hardness and wear resistance.

- Stainless Steel (e.g., AISI 440C, 316, 420)– Used in corrosive or moisture-prone environments.

- Carbon Steel– Economical, used in non-critical applications.

- Special Alloys– For magnetic properties, high temperatures, or specialized applications.=

Steel comes in rod or wire form and is thoroughly tested for chemical composition and mechanical properties before processing.

3.0Step-by-Step Steel Ball Manufacturing Process

3.1Step 1: Cutting Steel Slugs

Steel wire is cut into small pieces called slugs, each slightly larger than the final ball. This ensures that enough material is available for shaping and flash removal in later steps.

3.2Step 2: Forming the Raw Ball

Steel balls can be formed using two primary methods, depending on the required size, material, and precision: cold heading and hot forming.

Cold Heading (Cold Forming)

In the cold heading process, steel slugs are pressed into rough spheres (called raw balls) between two semi-spherical dies under pressures of up to 20 tons. The steel is in a soft, annealed condition at this stage, making it easier to deform without cracking.

Cold heading not only shapes the steel into a spherical form but also refines the internal grain structure, improving its strength and dimensional stability. This method is widely used for producing high-precision steel balls for bearings, automotive components, and precision instruments, where consistent size and surface quality are critical.

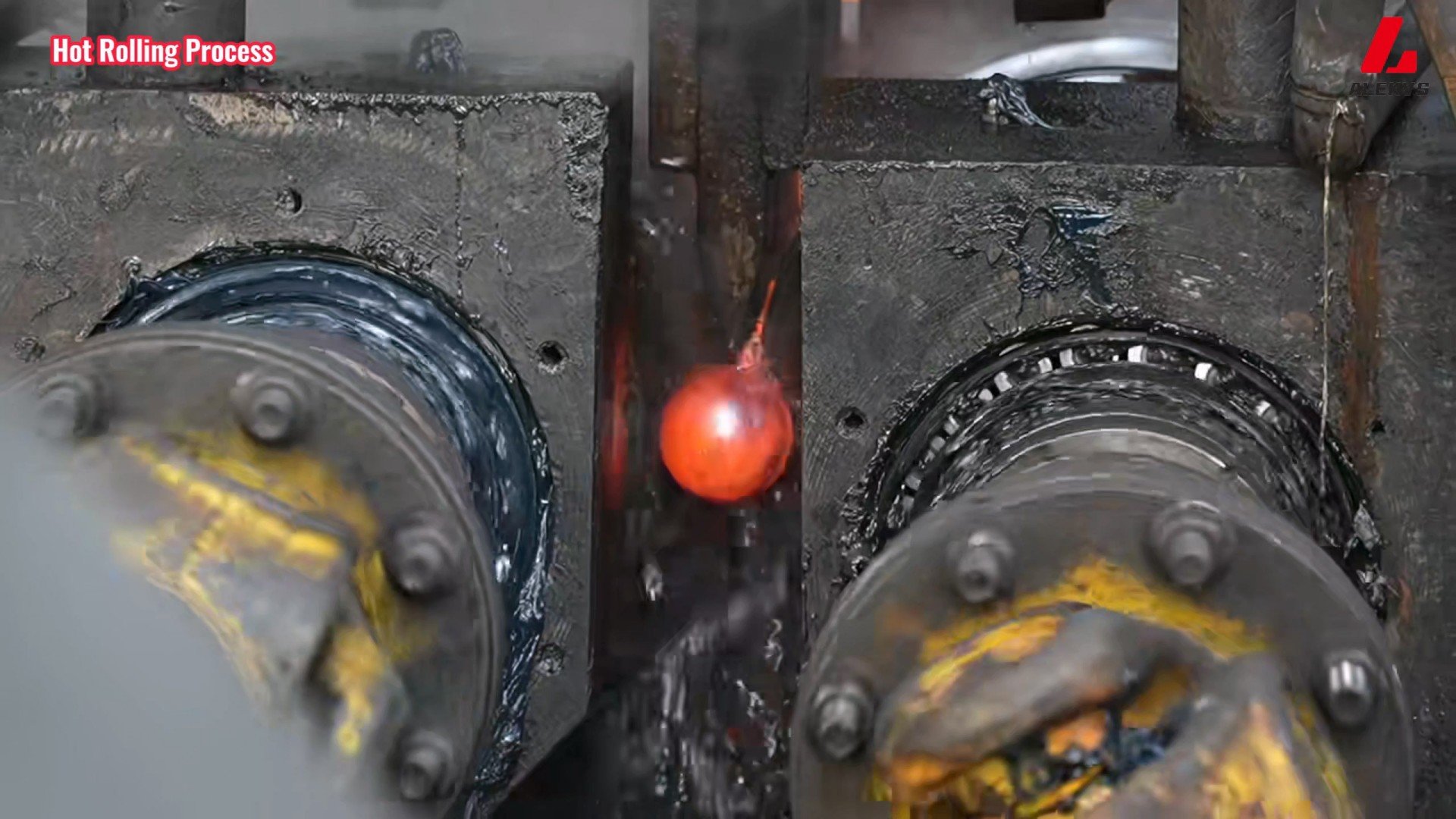

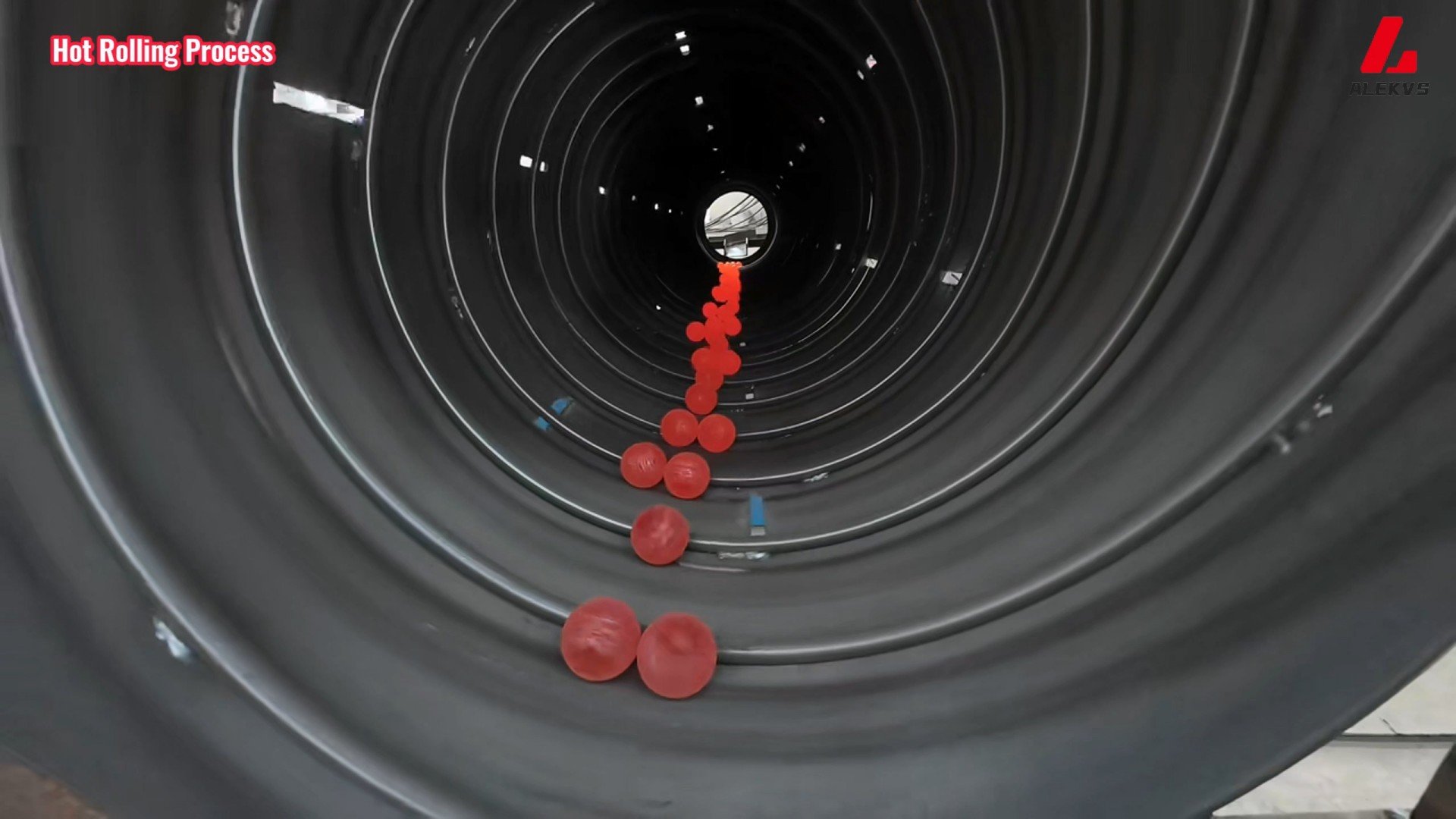

Hot Forming (Hot Heading or Hot Rolling)

For larger or harder steel balls, hot forming is commonly used. In this method, steel slugs are heated to a temperature typically between 900°C and 1200°C until the material becomes sufficiently plastic. The heated slugs are then forged or rolled between forming dies to create spherical blanks.

Hot forming is suitable for high-carbon or alloy steels that are difficult to deform at room temperature. It also allows for the economical production of larger-diameter balls. However, the hot-formed balls usually require additional grinding and heat treatment to achieve the desired precision and surface finish. This method is often used for producing grinding media, industrial machinery components, and other applications where ultra-tight tolerances are not required.

3.3Step 3: Flash Removal (Flashing Process)

The raw balls have a small ridge or excess material known as flash. This is removed using two metal plates:

The balls are rolled between cast-iron plates that rotate in opposite directions

Or, one plate rotates while the other stays stationary

This operation removes flash and improves roundness, but the balls are still not yet hardened or dimensionally precise.

3.4Step 4: Soft Grinding (Optional Step)

In some factories, a soft grinding process follows flashing. It uses an abrasive grinding wheel to fine-tune the shape while the steel is still soft. This step prepares the ball for heat treatment by improving uniformity.

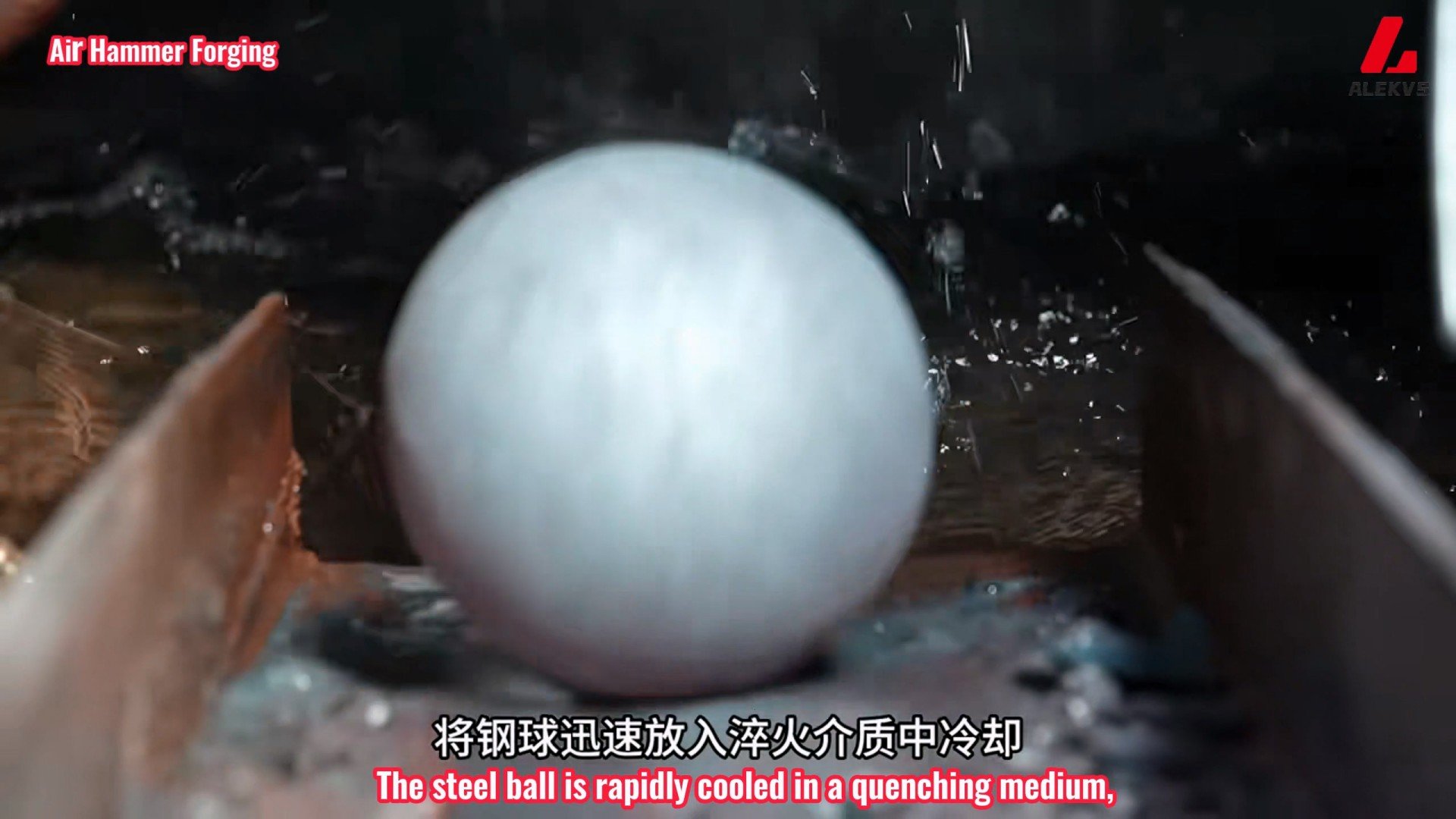

3.5Step 5: Heat Treating for Hardness and Strength

Steel balls are now heat-treated to harden and strengthen them.

- Austenitizing: Balls are heated to around 1,500°F (815°C) to form austenite.

- Quenching: Balls are rapidly cooled in an oil bath to form hard martensitic structures.

- Tempering: Balls are reheated to 325°F (160°C) to relieve internal stress and reduce brittleness.

This results in through-hardened steel balls with high wear resistance and fatigue strength.

3.6Step 6: Descaling (Removing Oxide Layer)

3.7Step 7: Precision Grinding of Hardened Steel Balls

This grinding step improves both roundness and dimensional accuracy:

- Balls are rolled between a rotating grinding wheel and a fixed steel plate

- Fine abrasives remove small amounts of material

This step brings the balls within microns of their final size.

3.8Step 8: Lapping – Superfinishing the Surface

Lapping is a precision finishing process where balls are:

- Rolled between two hardened steel plates (one fixed, one slowly rotating)

- Exposed to a fine abrasive slurry

This removes surface irregularities, achieving a mirror-like finish and tolerances down to Ra 0.01 μm and diameter variations < 0.1 μm.

3.9Step 9: Washing, Inspection, and Sizing

At this point, the steel balls are:

- Washed to remove residues from grinding and lapping

- Visually and mechanically inspected for scratches, cracks, or irregularities

- Graded and sized based on precision

3.10Steel Ball Grades and Tolerances

Steel Ball Grades and International Standards

After cleaning and visual inspection, precision steel balls are classified into grades based on tight tolerances in roundness, surface finish, and diameter variation. The following table defines these geometric tolerances according to industry standards:

| Grade | Unit | Sphericity | Lot Diameter Variation | Nominal Diameter Tolerance | Max Surface Roughness (Ra) |

| G3 | in | 0.000003 | 0.000003 | ±0.00003 | 0.5 μin |

| mm | 0.00008 | 0.00008 | ±0.0008 | 0.012 μm | |

| G5 | in | 0.000005 | 0.000005 | ±0.00005 | 0.8 μin |

| mm | 0.00013 | 0.00013 | ±0.0013 | 0.02 μm | |

| G10 | in | 0.00001 | 0.00001 | ±0.0001 | 1.0 μin |

| mm | 0.00025 | 0.00025 | ±0.0013 | 0.025 μm | |

| G25 | in | 0.000025 | 0.000025 | ±0.0001 | 2.0 μin |

| mm | 0.0006 | 0.0006 | ±0.0025 | 0.051 μm | |

| G50 | in | 0.00005 | 0.00005 | ±0.0003 | 3.0 μin |

| mm | 0.0012 | 0.0012 | ±0.0051 | 0.076 μm | |

| G100 | in | 0.0001 | 0.0001 | ±0.0005 | 5.0 μin |

| mm | 0.0025 | 0.0025 | ±0.0127 | 0.127 μm | |

| G200 | in | 0.0002 | 0.0002 | ±0.001 | 8.0 μin |

| mm | 0.005 | 0.005 | ±0.025 | 0.203 μm | |

| G1000 | in | 0.001 | 0.001 | ±0.005 | — |

| mm | 0.025 | 0.025 | ±0.127 | — |

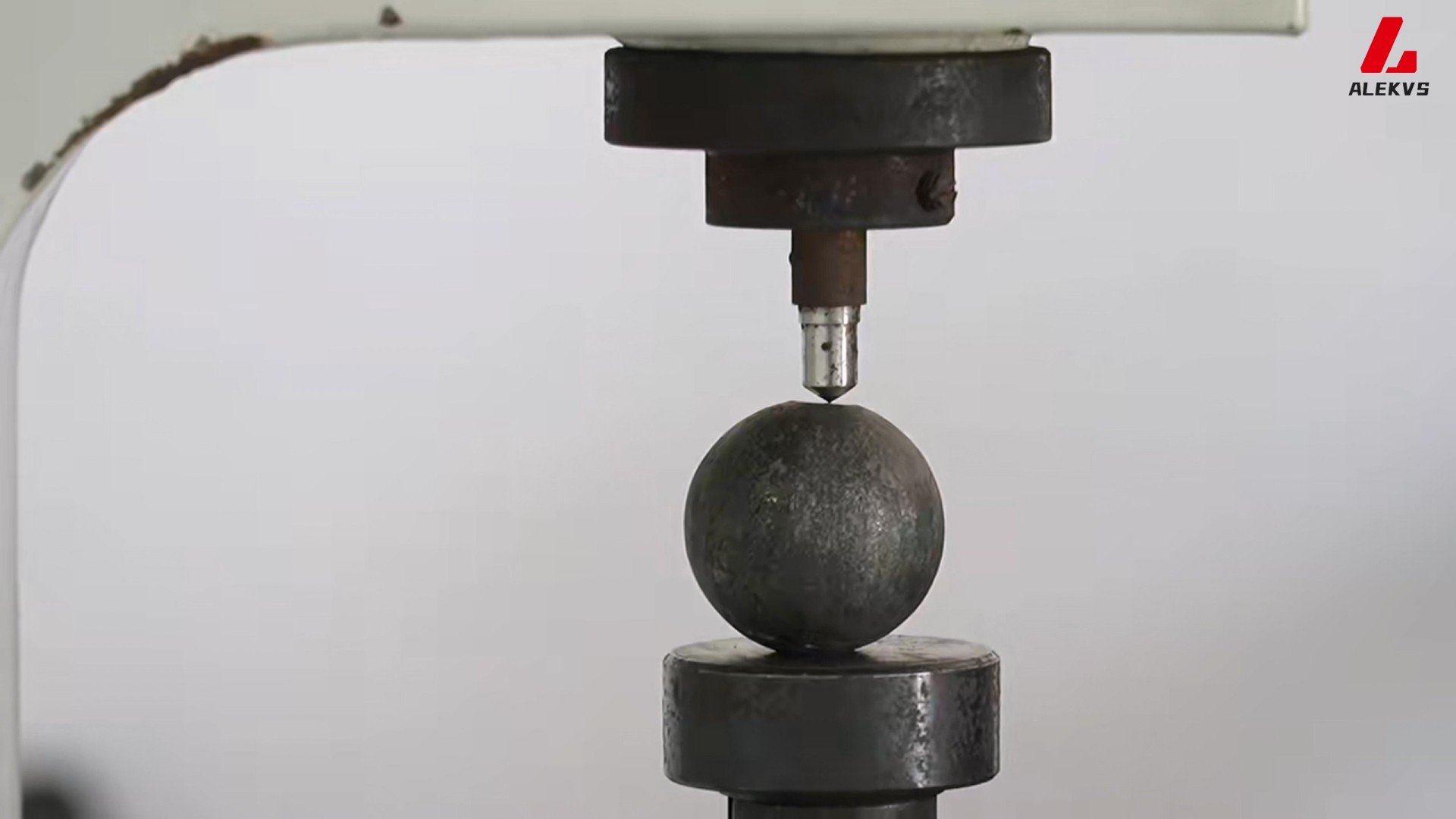

4.0Recommended Video: How Steel Balls Are Made

For a better understanding of the manufacturing process, this video provides a step-by-step look at how steel balls are formed, heat-treated, and finished. Watching it will help you visualize the production methods discussed in this article, including both cold heading and hot forming techniques.

5.0Applicable International Standards for Steel Balls

Steel balls for rolling-element bearings must comply with global precision standards. These include:

- ABMA STD 10A– Metal Balls for Unground Bearings and Other Uses

- ASTM F2215– Specification for Ferrous and Nonferrous Balls in Bearings and Valves

- DIN 5401– Balls for Rolling Bearings and General Industrial Use

- ISO 3290-1– Rolling Bearings — Balls — Part 1: Steel Balls

- JIS B 1501(JSA) – Rolling Bearings — Balls

6.0Quality Control in Every Stage

To ensure reliability, steel ball production includes:

- Raw material testing for composition and mechanical integrity

- In-process inspections at every step (shape, size, hardness)

- Non-destructive testing(e.g., eddy current inspection) for cracks or flaws

- Destructive testing on sample batches (e.g., hardness testing, microstructure analysis)

7.0Modern Innovations in Steel Ball Manufacturing

The industry continues to evolve with:

- Automation and robotics for faster, consistent production

- Machine vision and AI-based quality control

- Advanced heat-treatment ovens with real-time monitoring

- New coating technologies(e.g., anti-corrosion, self-lubricating films)

- Hybrid materials like ceramic-coated steel or silicon nitride alternatives

8.0Frequently Asked Questions (FAQ)

Q1: What materials are used to make steel bearing balls?

Chrome steel (AISI 52100) is the most common, but stainless steel, carbon steel, and special alloys are also used depending on the application.

Q2: How round are precision steel balls?

High-grade balls (e.g., G5 or G10) can deviate from a perfect sphere by less than 0.13 microns, offering extreme precision for high-performance applications.

Q3: What is the purpose of heat treating steel balls?

Heat treatment increases hardness and durability, allowing balls to withstand high loads and reduce wear in mechanical systems.

Q4: What’s the difference between grinding and lapping?

Grinding is a shaping process, while lapping is a polishing process that improves surface finish and achieves tight tolerances.

Q5: What are steel ball grades?

Steel balls are classified by grade (e.g., G5, G10, G100), which indicates precision level based on roundness, surface finish, and diameter variation.

9.0Conclusion

Though small, steel balls play a massive role in the smooth operation of the world’s machines. Their manufacturing process is a blend of metallurgical science, mechanical engineering, and modern automation—resulting in tiny components that keep engines spinning, turbines running, and technology moving forward.

Whether you’re sourcing steel balls or simply curious about industrial manufacturing, understanding this process reveals just how much precision and care goes into making something so seemingly simple.

10.0Table 1: Types of Steel Balls

Steel balls are available in a wide range of materials, sizes, and finishes, each designed to meet specific mechanical, environmental, and cost requirements. The following table summarizes the main types of steel balls, their material properties, and typical applications, helping engineers and designers select the most suitable option for their needs.

| Category | Material / Type | Key Properties | Typical Applications |

| Chrome steel | AISI 52100 | Hardness 60–67 HRC, excellent wear resistance, good dimensional stability, high load capacity | Bearings, automotive components, precision instruments |

| Stainless steel | AISI 316 | Austenitic, excellent corrosion resistance, non-magnetic | Marine environments, chemical processing equipment |

| AISI 420 | Martensitic, hardness 50–55 HRC, balance of hardness and corrosion resistance | Food processing, medical equipment | |

| AISI 440C | High-carbon martensitic, hardness 58–65 HRC, good corrosion resistance | High-performance bearings, aerospace applications | |

| Carbon steel | 1010, 1055, 1085 | Low-cost, various carbon content, lower hardness than chrome steel | Toys, low-load bearings, general industrial use |

| Specialty alloys | Tool steel (M50) | High-temperature resistance | Aerospace, high-speed machinery |

| Nickel alloys | Extreme corrosion resistance | Chemical processing, marine applications | |

| Brass & bronze | Non-sparking, decorative | Decorative fittings, special safety environments |

Size and Precision Grades

Steel balls are manufactured in various size ranges and precision grades to meet different performance requirements.

| Size Range (Diameter) | Typical Applications | Precision Grade | Tolerance Example (10 mm Ball) |

| 0.2–25.4 mm | Precision bearings, instruments | Grade 3 | ±0.08 μm |

| 0.2–25.4 mm | High-quality bearings, automotive | Grade 5 | ±0.13 μm |

| 0.2–50 mm | General industrial applications | Grade 10 | ±0.25 μm |

| 25–150 mm | Heavy-duty industrial equipment | Grade 16+ | ±0.5 μm or above |

Surface Finishes and Treatments

Surface finish and treatments significantly influence wear resistance, friction, and corrosion protection, making them critical for performance in demanding applications.

| Treatment / Finish | Purpose / Effect | Applicable Materials |

| Passivation | Enhances corrosion resistance | Stainless steel balls |

| Phosphating | Wear-resistant coating | Carbon steel balls |

| PVD – TiN (Titanium Nitride) | Increases hardness and wear resistance | Chrome steel, stainless steel |

| PVD – DLC (Diamond-Like Carbon) | Reduces friction, high wear resistance | High-performance applications |

| Surface roughness (Ra) | 0.02 μm (mirror) – 0.25 μm (standard); smoother = lower friction and noise | All materials |

| Magnetic properties | Chrome steel is ferromagnetic; AISI 316 stainless steel is non-magnetic | Depends on application needs |

11.0Table 2: Key Properties and Specifications

The performance of steel balls depends on several critical properties, including hardness, corrosion resistance, load-bearing capacity, and dimensional accuracy. The following table provides an overview of these key specifications to assist in selecting steel balls for specific operating conditions.

| Property | Typical Values / Range | Influencing Factors | Notes |

| Hardness | 52100: 60–67 HRC; 420: 50–55 HRC; 440C: 58–65 HRC | Material, heat treatment | Higher hardness = better wear resistance and load capacity |

| Wear Resistance | Excellent in chrome steel; enhanced by PVD or nitriding | Hardness, material composition, surface finish | Tested by Taber abrasion or similar methods |

| Corrosion Resistance | 316: Excellent; 440C: Good; 52100: Limited | Alloy composition, surface treatments, environment | Use passivation, oil coating, or special coatings for extra protection |

| Load-Bearing Capacity | Higher in chrome steel; depends on size and hardness | Material hardness, diameter, lubrication | Includes static and dynamic loads; affects fatigue life |

| Fatigue Life | High in precision-grade chrome steel | Material quality, surface finish, operating conditions | Critical for high-speed or continuous operation |

| Temperature Resistance | 52100: –20°C to 120°C; 440C: –30°C to 200°C; M50: up to 315°C | Material and heat treatment | High temperature lowers hardness; low temperature may increase brittleness |

| Dimensional Accuracy | Grade 3: ±0.08 μm; Grade 5: ±0.13 μm; Grade 10: ±0.25 μm | Manufacturing process, precision grade | Critical for bearings and instruments |

| Roundness | Tighter than diameter tolerance; Grade 5 ≈ 0.13 μm | Precision manufacturing | Affects smooth operation and noise level |

| Surface Finish (Ra) | 0.02 μm (mirror) – 0.25 μm (standard) | Grinding, polishing methods | Smoother = reduced friction and noise |

| Lot Uniformity | Consistent hardness, size, and roundness within batch | Strict quality control | Important for multi-ball applications (e.g., bearings) |

12.0Table 3: Industry Standards and Certifications

Compliance with recognized standards ensures consistent quality, performance, and interchangeability of steel balls across different manufacturers and applications. The following table highlights key industry standards and certifications relevant to steel balls.

| Standard / Certification | Scope | Key Requirements | Typical Industry / Applications |

| ABMA 10-1989 | General steel balls | Grades, dimensional tolerances, surface finish; 0.397–150 mm | Bearings, general industry |

| ABMA 12.1-2001 | Instrument bearings | Stringent tolerances for high-precision balls | Aerospace instruments, precision devices |

| ABMA 12.2-2001 | Miniature & extra-small bearings | Dimensional accuracy for tiny balls | Electronics, micro-bearings |

| ISO 3290-1:2014 | Finished steel balls | Size, roundness, surface quality, test methods | Precision bearings, global applications |

| ISO 9001:2015 | Quality management system | Consistent manufacturing quality | All industries |

| ISO 14001:2015 | Environmental management | Sustainable production practices | Increasingly important across industries |

| ASTM A295 | High-carbon bearing steel | Chemical composition, heat treatment | Industrial & automotive bearings |

| ASTM A756 | Magnetic properties | Specifies steel ball magnetic characteristics | Electronics, sensors |

| ASTM F2235 | Stainless steel balls | Mechanical properties, quality requirements | Bearings, food & medical equipment |

| AS9100 | Aerospace quality management | Stringent production and documentation requirements | Aerospace and defense |

| NADCAP | Aerospace special processes | Accreditation for heat treatment, coating | Aerospace manufacturers |

| IATF 16949 | Automotive quality management | PPAP and production quality approval | Automotive bearings and components |

| ISO 13485 | Medical devices quality | Compliance with medical standards | Medical equipment |

| FDA Compliance | Regulatory approval | Required for medical-use components | Medical devices |

| MIL-STD-1835 | Military precision components | Precision locking and material standards | Defense and military applications |

| ISO 4288:1996 | Surface roughness measurement | Rules for Ra assessment | All industries requiring precise surface finish |

| ISO 6508 / ASTM E18 | Rockwell hardness testing | Hardness measurement methods | Quality control in all industries |

| ASTM E10 | Brinell hardness test | Alternative hardness measurement method | Industrial quality control |