- 1.0What Is Cast Iron and Why Is It Ideal for Cookware?

- 2.0Overview of the Manufacturing Process

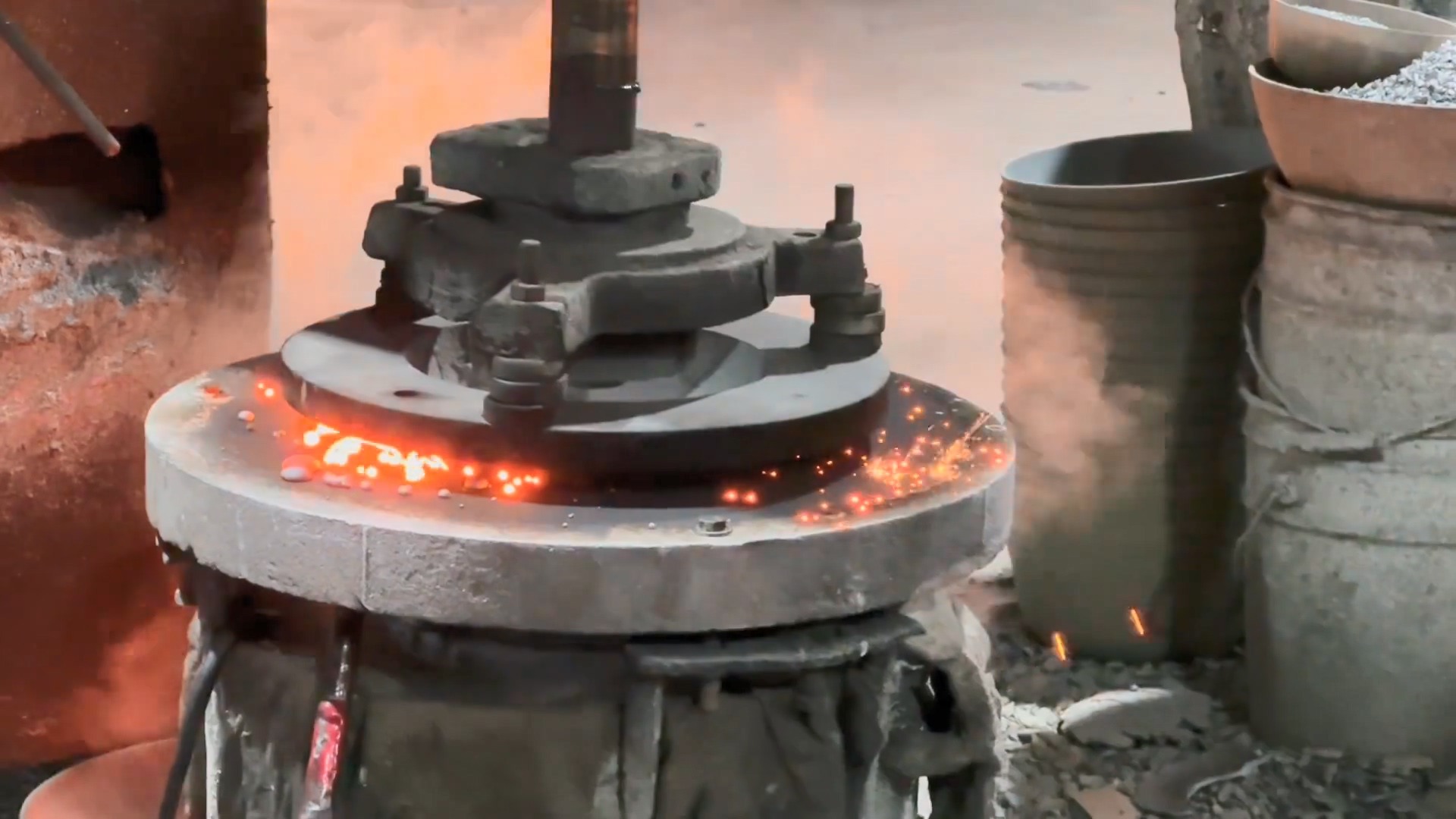

- 3.0Raw Materials & Melting

- 4.0Mold Creation & Sand Casting

- 5.0Pouring & Cooling

- 6.0Finishing & Machining

- 7.0Surface Treatment & Seasoning

- 8.0Quality Control & Packaging

- 9.0Video

- 10.0Cast Iron vs. Stainless Steel: Process & Performance Compared

- 11.0Daily Care & Usage Tips for Cast Iron Cookware

- 12.0Heat Source Compatibility

- 13.0Enameled vs. Bare Cast Iron

- 14.0First-Time Use Instructions

- 15.0Frequently Asked Questions (FAQ)

Cast iron cookware has stood the test of time as a beloved kitchen essential. Known for its exceptional heat retention and even cooking performance, it remains a favorite among chefs and home cooks worldwide. But how does a raw mix of metal turn into a cooking tool that lasts a lifetime?

1.0What Is Cast Iron and Why Is It Ideal for Cookware?

Cast iron is an alloy made primarily of iron and carbon (typically 2%–4%), along with elements such as silicon. It offers high hardness, excellent wear resistance, and superior thermal properties. Due to its brittle nature, cast iron is not forged or rolled, but rather shaped through the casting process—hence the name.

Key Benefits of Cast Iron Cookware:

- Outstanding heat retention, ideal for slow-cooking and searing

- Durable and long-lasting with proper care

- Develops a natural non-stick surface over time when seasoned correctly

2.0Overview of the Manufacturing Process

Melting Raw Materials → Mold Preparation → Pouring → Cooling & Shakeout → Surface Cleaning → Finishing → Seasoning → Inspection & Packaging

3.0Raw Materials & Melting

Material Selection:

Cast iron cookware typically uses three main components:

- Pig Iron: A high-carbon raw iron source and the foundation of the melt

- Scrap Steel: Adds iron content and adjusts carbon levels

- Foundry Returns: Recycled castings and leftover material from previous batches

These ingredients are carefully measured and blended, sometimes with trace alloys, to optimize strength, hardness, and casting performance. The purity and balance of materials directly impact the quality and durability of the final product.

Melting Process:

The prepared materials are charged into a medium-frequency induction furnace and melted at temperatures typically ranging from 2100°F to 2650°F (approximately 1150°C to 1450°C), depending on the material composition and furnace capacity. A single furnace can hold up to 10 tons of molten iron. For standard batch sizes, the melting cycle typically lasts between 40 and 60 minutes, though this may vary with furnace capacity and metal load.

During this stage, impurities such as sulfur and phosphorus are reduced through refining treatments. Precision control of temperature and composition is critical to ensure metallurgical consistency—a key foundation for every quality cast iron pan.

4.0Mold Creation & Sand Casting

Mold Preparation:

The mold defines the final shape of the cookware. Most manufacturers use sand casting, where a mix of sand, clay, and water is pressed into molds using automatic molding machines. Each mold is designed to capture detailed elements such as the thickness, rim, and handle configuration.

Since each sand mold is single-use, no two castings are exactly identical—even though they share the same design.

Molding Equipment:

Modern foundries utilize high-speed automated molding lines, capable of producing up to 350–400 molds per hour. This ensures consistency in dimensions while maximizing output.

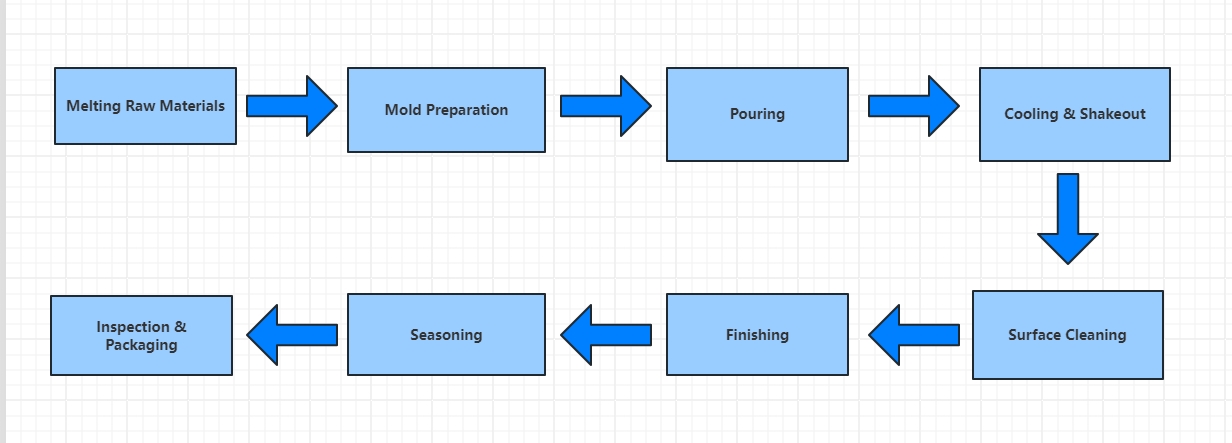

5.0Pouring & Cooling

Pouring the Iron:

Once both mold and molten iron are ready, pouring begins. Before tapping the furnace, the melt is tested for temperature and composition. Iron is then poured—either by ladle or automatic system—slowly and carefully into each mold. Flow rate and pouring technique are tightly controlled to prevent defects such as air pockets or inclusions.

Cooling and Shakeout:

After pouring, the castings cool naturally inside the molds. Cooling time varies depending on the mold size and material. Once solidified, molds are broken open in a process known as shakeout, releasing the rough casting or raw blank. At this stage, the piece has taken the shape of a pan but requires further finishing.

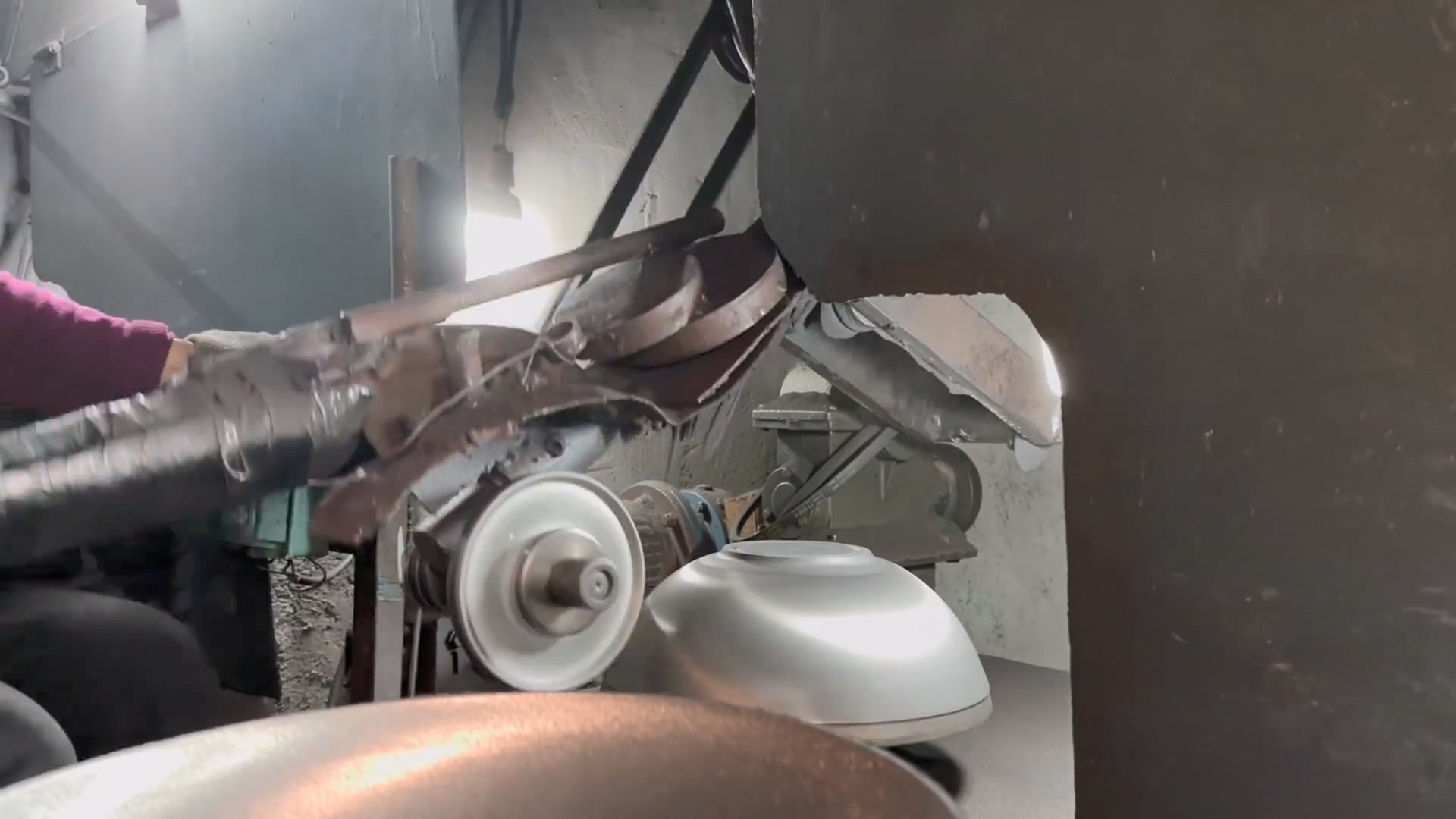

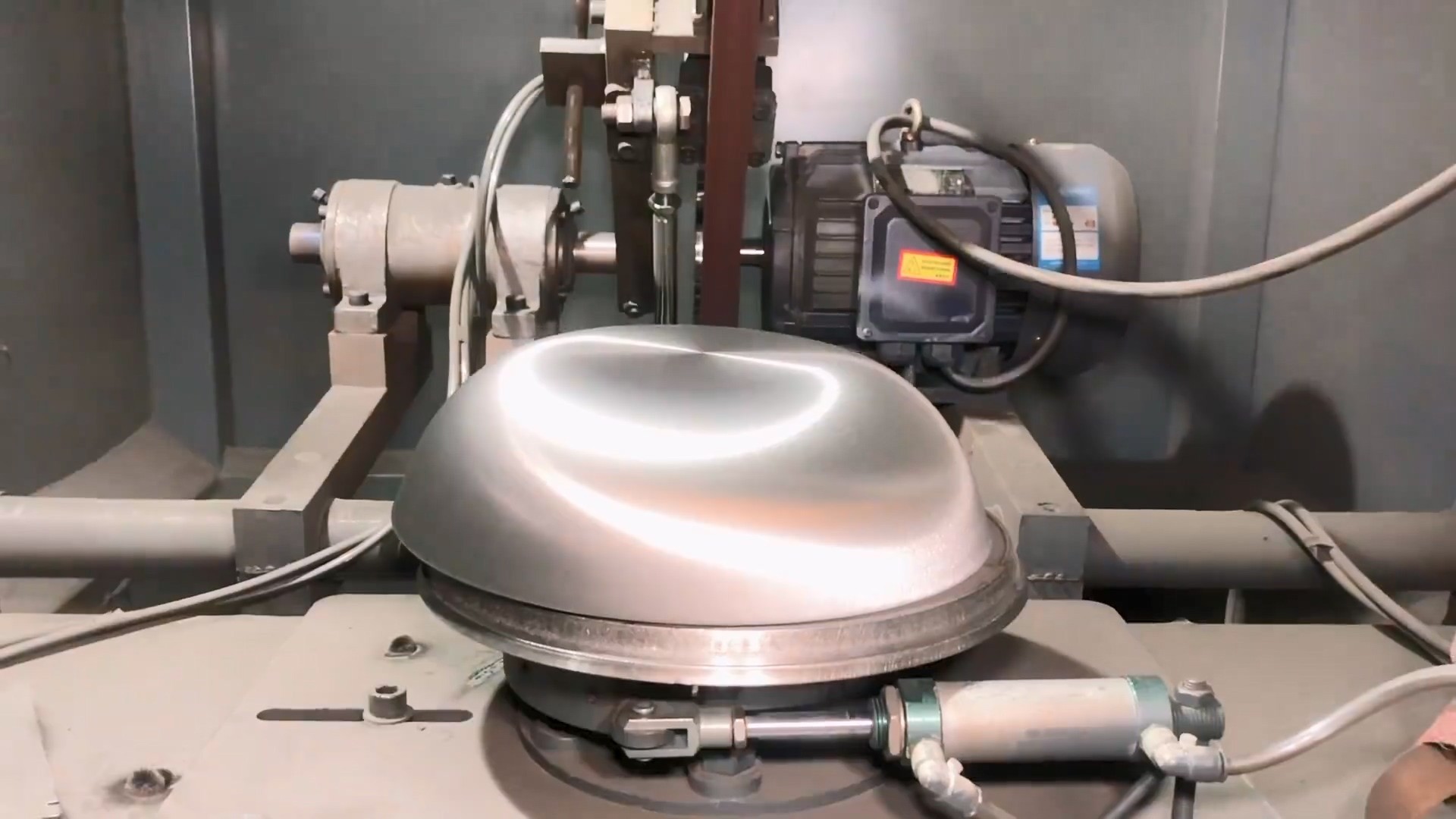

6.0Finishing & Machining

After the raw cast iron blank is removed from its mold, it is not yet ready for use. A series of post-casting treatments are necessary to ensure that each pan is safe, smooth, and functional.

Cleaning and Surface Preparation:

Castings typically retain sand, flash, and remnants of the gating system. These must be removed through various finishing methods:

- Grinding: Sharp edges, seams, and casting flashes are removed using grinding wheels or precision tools.

- Polishing: The cooking surface, bottom, and exterior are polished using a Flat Belt Grinding Machine, which refines the surface finish and improves stovetop contact.

- Shot Blasting / Sand Blasting: This process removes residual sand and oxidation while texturing the surface to promote better oil adhesion during seasoning.

Precision Machining:

Key contact areas such as the base, rim, and handle holes require machining to ensure performance and stability.

- Machining the Flat Base: Improves stovetop contact and heat distribution.

- Drilling & Tapping: Prepares precise holes for handle rivets or screws.

- Edge Finishing: mooths rim transitions for better comfort and a refined look.

7.0Surface Treatment & Seasoning

Process Order Note:

Finishing and machining are performed before seasoning. This is because the protective oil layer formed during seasoning adheres best to clean, heated surfaces. Machining processes would otherwise damage or remove the coating.

Unlike stainless steel or enamel cookware, bare cast iron has no natural corrosion protection. Therefore, before leaving the factory, each piece must undergo seasoning—a crucial step that protects the surface and enhances performance.

What Is Seasoning?

Seasoning refers to applying a thin layer of vegetable oil (commonly soybean or flaxseed oil) to the cookware surface, then heating it to a high temperature until the oil polymerizes. This forms a black, semi-glossy carbonized layer that protects the iron and creates a naturally non-stick cooking surface.

Seasoning Steps:

- Clean and dry the surface thoroughly

- Apply a thin, even coat of oil (inside and out)

- Bake at high temperature—typically between 180°C and 250°C (355°F to 480°F)—though some manufacturers season at temperatures as high as 300°C (570°F) for a more durable coating.

- Maintain heat to allow oil to polymerize

- Repeat 2–3 times for a durable coating

This matte black finish is the hallmark of a well-seasoned cast iron pan and a defining visual feature that distinguishes it from other cookware types.

8.0Quality Control & Packaging

Once seasoning is complete, every piece undergoes a series of inspections to ensure it meets factory standards. Key quality checks include:

- Dimensional Accuracy: Ensures product matches design specs

- Surface Integrity: Checks for cracks, porosity, or sand inclusion

- Rust Resistance: Confirms even seasoning coverage

- Function Test: Selected units undergo real-use cooking tests

- Visual Inspection: Final manual review before packaging

Approved pans are packaged in protective boxes and plastic bags. Most include a user guide and care instructions to help customers maintain their cast iron properly.

9.0Video

10.0Cast Iron vs. Stainless Steel: Process & Performance Compared

| Feature | Cast Iron | Stainless Steel |

| Material | High-carbon gray or ductile iron; high heat retention | 18/8 or 18/10 stainless alloys; corrosion-resistant and strong |

| Forming Method | Wet sand casting; thick-walled, solid body | Stamped or deep-drawn from steel sheets; thin and uniform |

| Thermal Behavior | Heats slowly but retains heat exceptionally well | Heats quickly but loses heat faster |

| Cooking Style | Ideal for searing, braising, baking, and long simmers | Best for quick sautés, boiling, and fast-paced cooking |

| User Profile | Traditionalists and slow-cook enthusiasts | Home cooks and professionals seeking lightweight, responsive cookware |

11.0Daily Care & Usage Tips for Cast Iron Cookware

Cleaning Steps:

After cooking, allow the pan to cool slightly before cleaning. Use warm water and a soft brush or sponge. A small amount of mild dish soap may be used if necessary. After cleaning, dry the pan thoroughly with a cloth and place it over low heat until all moisture evaporates. Finish by applying a thin layer of cooking oil to seal the surface.

Usage Precautions:

- Avoid soaking the pan or leaving it in damp environments to prevent rust.

- Do not heat the pan empty or expose it to sudden temperature changes (e.g., adding cold water to a hot pan), as this may cause warping or cracking.

- Limit long-duration cooking of acidic or alkaline foods, which may degrade the seasoning layer.

Storage & Maintenance:

Before storing, ensure the pan is fully dry and lightly oiled. Store in a well-ventilated, dry place. If storing for an extended period, place a sheet of paper towel inside to absorb excess oil and moisture.

Check the seasoning layer regularly—if rust or sticking occurs, re-seasoning will restore its protective and non-stick qualities.

12.0Heat Source Compatibility

Cast iron cookware is known for its remarkable versatility across different cooking environments. It performs reliably on various heat sources, including:

- Gas stovetops: Provide strong, direct heat—ideal for searing and browning.

- Electric and ceramic cooktops: The heavy base ensures steady heat distribution.

- Induction cooktops: As cast iron is magnetic, it works efficiently on induction surfaces.

- Ovens and grills: Oven-safe and grill-compatible, perfect for baking, roasting, and finishing dishes.

- Open flame or campfires: Durable enough for outdoor use and open-fire cooking.

This adaptability makes cast iron a go-to choice for both indoor kitchens and outdoor adventures.

13.0Enameled vs. Bare Cast Iron

There are two main types of cast iron cookware: bare (traditional) and enameled. Each has its own benefits and use cases:

- Bare cast iron requires seasoning to develop a non-stick layer, but in return, it can withstand extremely high temperatures and is excellent for browning and crisping.

- Enameled cast iron is coated with a porcelain glaze that prevents rust and eliminates the need for seasoning. It’s easy to clean and suitable for acidic foods like tomato sauces.

While bare cast iron develops character over time, enameled pieces offer convenience with minimal maintenance. Choosing between the two depends on your cooking habits and preferences.

14.0First-Time Use Instructions

Using cast iron for the first time? Whether pre-seasoned or raw, a few steps will ensure optimal performance from the beginning:

- Rinse and dry: Wipe the pan with warm water and a soft cloth—no soap is necessary unless it’s raw, unseasoned iron.

- Heat and oil: Warm the pan on low heat, then apply a very thin layer of cooking oil to the entire surface.

- Bake to reinforce(optional): Place the oiled pan upside down in a preheated oven (200–250°C / 400–480°F) for 45–60 minutes to strengthen the seasoning.

- Avoid acidic foods for the first few uses: This helps the seasoning layer build evenly without being disrupted.

With proper care from the start, your pan will develop a durable, naturally non-stick coating that only gets better with time.

15.0Frequently Asked Questions (FAQ)

- Is cast iron cookware healthy? Can it rust or leach metal?

High-quality cast iron is safe when properly used and maintained. The seasoning layer acts as a natural barrier between food and metal, limiting iron release. If the coating is damaged or if acidic foods are cooked for long periods, some iron may leach—but this is generally within safe dietary limits. Without proper drying and oiling, the pan may rust. - How should I clean cast iron? Can I use dish soap?

Use warm water and a soft brush or sponge. Avoid harsh detergents that can strip the seasoning. Mild dish soap is okay for light cleaning, but avoid frequent use. For heavy residue, use coarse salt and heat to scrub. Always dry immediately and apply a thin layer of oil to prevent rust. - Can cast iron break if dropped? Why is it brittle?

Cast iron is strong under heat but brittle under impact. Its structure doesn’t absorb shock well, so dropping it on a hard surface may cause cracking or breakage. Handle with care to avoid damage. - What utensils are safe for cast iron pans?

Wood, bamboo, and silicone utensils are ideal. They help preserve the seasoning layer and avoid scratches. Metal utensils are safe to use, but they may wear down the surface over time. - How often should I re-season my pan? Any tips?

Frequency depends on usage. With frequent use, a stable seasoning layer typically forms after 10 to 15 cooking sessions. Re-season the pan whenever you notice food sticking, dull surfaces, or visible rust. Tips: apply oil thinly, bake at high heat, and repeat for better results.