- 1.0What Are the Core Technical Differences Between Horizontal and Vertical Band Saws?

- 2.0How Horizontal Band Saws Are Used in Industrial Cutting Applications

- 3.0When to Choose a Vertical Band Saw: Key Application Scenarios

- 4.0Types of Metal Bandsaws

- 5.0Horizontal vs Vertical Band Saw Performance: Accuracy, Efficiency, and Material Utilization

- 6.0Cutting Accuracy:

- 7.0Operation and Maintenance: Horizontal Band Saw vs Vertical Band Saw

- 8.0How to Select the Right Bandsaw for Industrial Applications

- 9.0Case Studies: Horizontal and Vertical Band Saw Selection in Real Production

- 10.0Conclusion: Horizontal vs Vertical Band Saw – How to Make the Right Choice

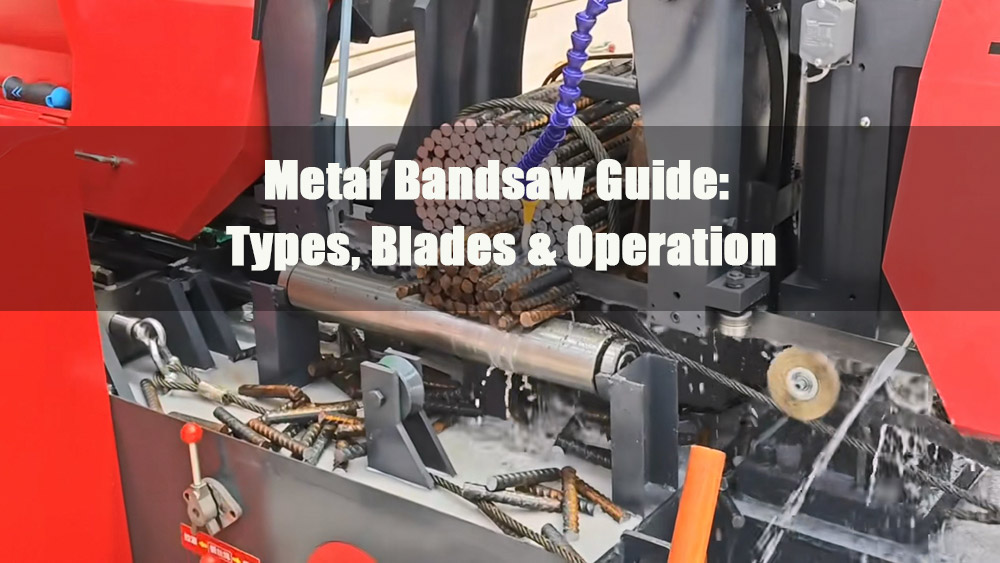

Choosing the right bandsaw is essential for efficient and precise metal cutting. Horizontal and vertical band saws serve different purposes—batch cutting versus complex contour shaping. This guide explains their differences, applications, and selection tips to help you optimize productivity and material use.

1.0What Are the Core Technical Differences Between Horizontal and Vertical Band Saws?

The fundamental differences between horizontal and vertical band saws lie in the arrangement of the saw blade, the motion of the workpiece, and the machine structure. These differences directly determine their respective application boundaries. The core distinctions can be summarized as follows:

| Comparison Dimension | Horizontal Band Saw | Vertical Band Saw |

| Blade Arrangement & Feeding | Blade arranged horizontally or at an angle, feeding along the Z-axis, perpendicular to the workpiece axis | Blade arranged vertically, moving along X/Y directions, workpiece must be moved to achieve feeding |

| Workpiece Clamping | Hydraulic / servo clamping, workpiece fixed, saw frame moves | Workpiece pushed manually or fed via worktable |

| Typical Cutting Method | Batch linear cutting, fixed-length blanking | Complex contour cutting, mold blanking |

| Precision Control | Hydraulic and CNC systems ensure cutting straightness | Relies on operator skill, flexible for curve cutting |

| Automation Level | Configurable with CNC, automatic feeding, and blanking devices | Low automation level, high manual involvement |

2.0How Horizontal Band Saws Are Used in Industrial Cutting Applications

Core Positioning: Efficient carrier for batch rough machining

Horizontal band saws are mainly used for raw material preprocessing (batch linear blanking), cutting long-sized materials into fixed-length blanks. They are not suitable for irregular shapes or small-batch complex workpieces. Instead, they provide the basic workpieces for subsequent turning, milling, and grinding processes.

Typical Applications:

- Standard parts plants cutting Φ50–200 mm 45# steel bars or alloy structural steel bars into fixed-length cylindrical blanks.

- Steel structure companies cutting 8–50 mm thick Q235/Q355 steel plates for welded structural components.

- Pipe processing plants cutting Φ30–150 mm stainless steel tubes or seamless steel pipes for pipeline projects or component assembly.

Material Adaptability:

- Hardness:Suitable for medium-to-high strength materials (HRC ≥30), such as 45# steel, 20CrMnTi, 304/316 stainless steel, and tool steels. High-power drive systems ensure stable cutting and reduce blade wear.

- Form:Specializes in processing ≥3 m long bars/pipes, ≥20 mm thick plates, and heavy solid workpieces with diameters ≥150 mm. Automatic feeding systems greatly improve batch processing efficiency.

3.0When to Choose a Vertical Band Saw: Key Application Scenarios

Core Positioning: Flexible solution for precision shaping

Vertical band saws focus on complex contours and small-batch machining. They are suitable for cutting curves, arcs, irregular holes, or local corrections. However, for steels with hardness ≥ HRC 30, they are only effective for small parts or thin plates, with relatively low processing efficiency.

Typical Applications:

- Mold factories cutting 6–20 mm thick Cr12MoV mold steel for arc notches or U-shaped grooves.

- Hardware manufacturers processing 3–10 mm aluminum alloy plates or plastic plates into irregular-shaped parts.

- Maintenance workshops trimming gear blanks, bearing housings, or other semifinished products to correct dimensional deviations.

- Craft workshops cutting wood, acrylic, or composite materials for customized shaping.

Material Adaptability:

- Hardness:Best suited for low-hardness materials (HRC < 30), such as aluminum, copper, plastics, or wood. For steels with hardness ≥30, only small parts can be processed using high-speed steel or carbide blades.

- Form:Well-suited for ≤10 mm thin plates, thin tubes, and semifinished parts with holes or irregular shapes. The flexible worktable helps prevent damage to already processed surfaces.

4.0Types of Metal Bandsaws

Metal bandsaws can be categorized based on blade orientation, automation level, and intended application. Here is a detailed list:

Horizontal Bandsaws

- Manual Horizontal Bandsaw: Hand-operated, suitable for small-batch cutting or workshop repairs.

- Semi-Automatic Horizontal Bandsaw: Features automatic clamping and feeding, ideal for medium-volume production.

- CNC Horizontal Bandsaw: Fully automated with servo feeding, length setting, and high-precision straight cutting for large-scale industrial production.

- Manual Vertical Bandsaw: Flexible for cutting curves, arcs, and irregular shapes, suitable for small-batch or custom workpieces.

- CNC Vertical Bandsaw: Equipped with CNC control, rotary worktables, and automated feeding for high-precision contour cutting.

Specialized Bandsaws

- Double-Column Bandsaw: Designed for heavy-duty cutting of thick steel bars and large solid workpieces.

- Portable Bandsaw: Compact and mobile, suitable for on-site cutting of pipes, tubes, and structural steel.

Automatic CNC Cutting Lines: Integrated systems combining multiple bandsaws with automatic feeding, cutting, and unloading for mass production.

5.0Horizontal vs Vertical Band Saw Performance: Accuracy, Efficiency, and Material Utilization

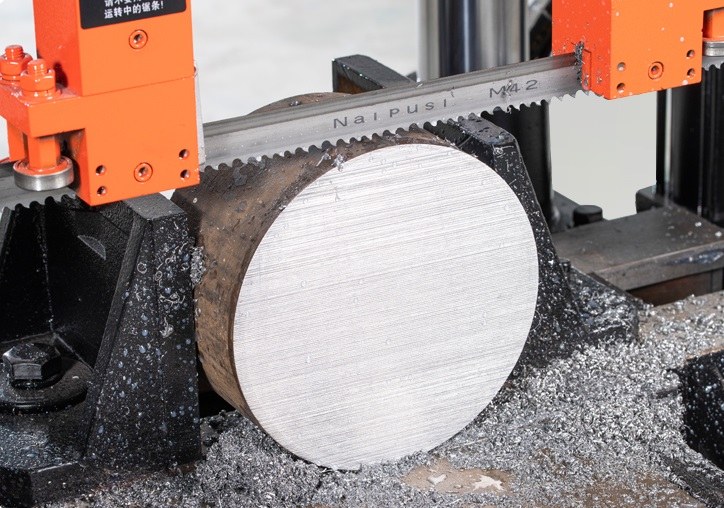

6.0Cutting Accuracy:

- Horizontal Band Saw:High precision in straight cuts; length error controllable within ±0.1–0.3 mm, up to ±0.5 mm for large-diameter or thick plates. Meets dimensional requirements for batch blanks but cannot achieve precision control for curves or irregular shapes.

- Vertical Band Saw:Curve/arc error within ±0.05–0.2 mm (±0.05–0.1 mm with CNC or rotary tables). Straight-cut accuracy is slightly lower; manual feeding yields ±0.1–0.3 mm, CNC models can improve to ±0.08 mm.

Processing Efficiency:

- Horizontal Band Saw:High efficiency with automatic feeding and continuous cutting. For example, Φ80 mm 45# steel bars, 60–100 pieces per hour. Ideal for large-scale standardized production.

- Vertical Band Saw:Low efficiency for single-piece machining. Manual operation yields 5–15 pieces per hour. CNC models improve efficiency but remain less efficient than horizontal machines.

Material Utilization:

- Horizontal Band Saw:Kerf loss is only 0.5–1 mm with almost no corner scraps; material utilization >98%.

- Vertical Band Saw:Complex contour cutting often produces corner scraps; utilization ~90–95%. Optimization techniques like nesting path layout can reduce waste.

7.0Operation and Maintenance: Horizontal Band Saw vs Vertical Band Saw

Operational Complexity:

- Horizontal Band Saw:Simple operation; machine automatically completes clamping, cutting, and unloading. Beginners can master basics in 1–2 days.

- Vertical Band Saw:Requires manual control of workpiece and blade tension; guide block adjustments rely heavily on experience. Beginners need 1–2 weeks of training. CNC models reduce difficulty but require programming skills.

Safety Risks:

- Horizontal Band Saw:Lower risk; workpiece clamped hydraulically, blade shielded, hands kept away. Emergency stop system (≤0.5s) prevents accidents.

- Vertical Band Saw:Higher risk; manual feeding brings hands near the blade. Misalignment can lead to jamming or blade breakage. Protective systems are essential.

Maintenance and Costs:

- Horizontal Band Saw:Focus on hydraulic clamping system and feed guide rails. Annual maintenance ~3–5% of total equipment cost.

- Vertical Band Saw:More frequent maintenance for blade guides, rails, and tension systems. Annual maintenance ~5–8% of total equipment cost.

8.0How to Select the Right Bandsaw for Industrial Applications

Step 1: Define Core Processing Needs (Functional Positioning)

- Batch cutting of blanks (fixed-length, no complex contours): choose horizontal band saw.

- Precision shaping (curves, irregular profiles, corrective trimming): choose vertical band saw.

Step 2: Match Production Scale and Material Properties (Scenario Validation)

- Large-scale production (≥50 pieces/day, HRC ≥30, long bars, thick plates, heavy parts): horizontal band saw preferred.

- Small-batch production (≤20 pieces/day, HRC <30, thin plates, soft materials, irregular parts): vertical band saw preferred.

Step 3: Refine Accuracy and Efficiency Requirements (Configuration Optimization)

- High straight-cut accuracy ≤0.1 mm: high-precision horizontal with servo feeding.

- High contour accuracy ≤0.08 mm: vertical with CNC and servo-driven worktable.

- Cost-sensitive: manual vertical or basic horizontal.

- Efficiency priority: CNC horizontal with automatic loading/unloading.

9.0Case Studies: Horizontal and Vertical Band Saw Selection in Real Production

Case 1: Batch Rough Cutting

- Automotive parts manufacturer processes 800 pieces/day of Φ60×70 mm 20CrMnTi steel bars.

- Requirement: unmanned continuous cutting.

- Solution: CNC horizontal band saw with servo feeding and automatic length setting.

- Result: 60 pieces/hour production capacity.

Case 2: Precision Shaping

- Mold component manufacturer cuts 30 pieces/week of 10 mm Cr12MoV mold steel plates with R5 arc notch.

- Solution: CNC vertical band saw with rotary worktable.

- Result: contour accuracy ±0.05 mm.

Case 3: Small-Batch, Multi-Material Cutting

- Repair workshop cuts Φ50 mm stainless steel pipes and plastic sheet parts.

- Solution: manual vertical band saw.

- Result: balances hard/soft material processing with cost control.

10.0Conclusion: Horizontal vs Vertical Band Saw – How to Make the Right Choice

Horizontal and vertical band saws are not about superiority but functional adaptation based on material hardness, workpiece dimensions, and production volume.

Horizontal Band Saw:

- Strength: batch rough cutting, high efficiency, stability.

- Best for medium-to-high-strength materials, long/heavy workpieces, standardized blanks.

- Primary choice for large-scale production enterprises.

Vertical Band Saw:

- Strength: flexible, precision shaping.

- Best for complex contours, small-batch, multi-variety workpieces.

- Essential for mold manufacturers, repair shops, custom production.

Selection Principle:

- Evaluate equipment from:

- Core processing needs

- Production scale

- Material properties

- Precision and efficiency requirements

Goal: Maximize utilization, reduce costs, and improve overall manufacturing efficiency.