फास्टनरों, शाफ्ट और भारी घटकों के लिए ALEKVS औद्योगिक थ्रेड रोलिंग मशीनें

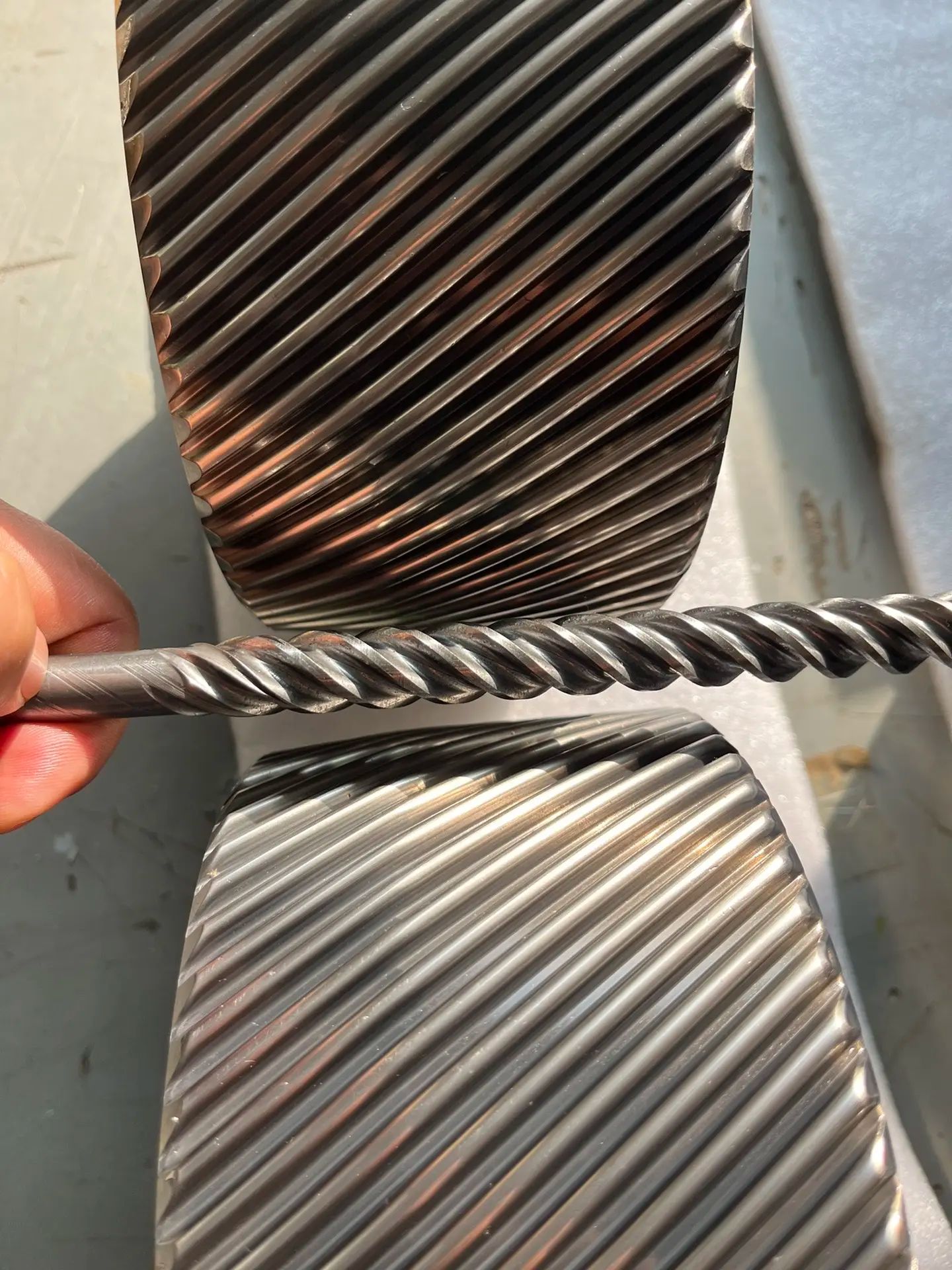

पर अलेक्सांद्र, हम इसमें विशेषज्ञ हैं बेलनाकार डाई रोलिंग तकनीक, एक ऐसी प्रक्रिया जो प्लास्टिक विरूपण के माध्यम से धागे और सटीक प्रोफाइल बनाती है—बिना किसी सामग्री को हटाए। पारंपरिक कटिंग की तुलना में, हमारी मशीनें ये प्रदान करती हैं:

- 10 गुना अधिक तेज़ उत्पादन दक्षता

- 20% तक सामग्री की बचत

- बेहतर यांत्रिक गुण और सतह परिष्करण

- सख्त सहनशीलता के साथ उच्च पुनरावृत्ति

- टिकाऊ विनिर्माण के लिए शून्य सामग्री अपशिष्ट

हमारी उत्पाद श्रृंखला में विभिन्न प्रकार के उत्पाद शामिल हैं धागा रोलिंग समाधान, शामिल:

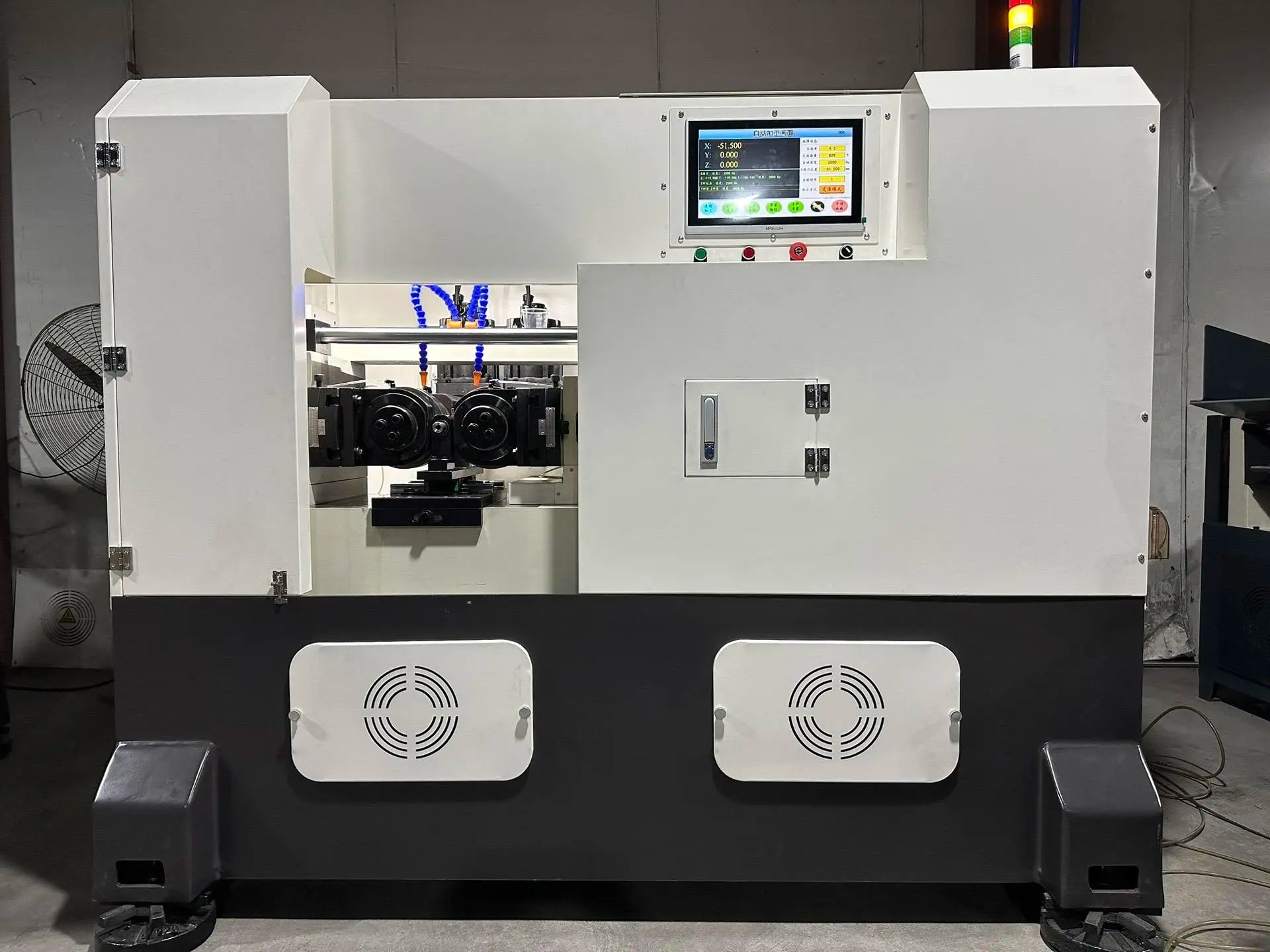

- सीएनसी 3-डाई थ्रेड रोलिंग मशीनें- उच्च परिशुद्धता और बड़े व्यास वाले भागों के लिए

- स्वचालित सीएनसी स्क्रू थ्रेड रोलिंग मशीनें- तेज़, स्वचालित स्क्रू और फास्टनर उत्पादन के लिए

- हाइड्रोलिक 3-रोलर्स थ्रेड रोलिंग मशीनें- भारी-भरकम, बड़े आकार के घटकों के लिए

- स्वचालित 2-रोल थ्रेड रोलिंग मशीनें- बहुमुखी और लागत-कुशल उत्पादन के लिए

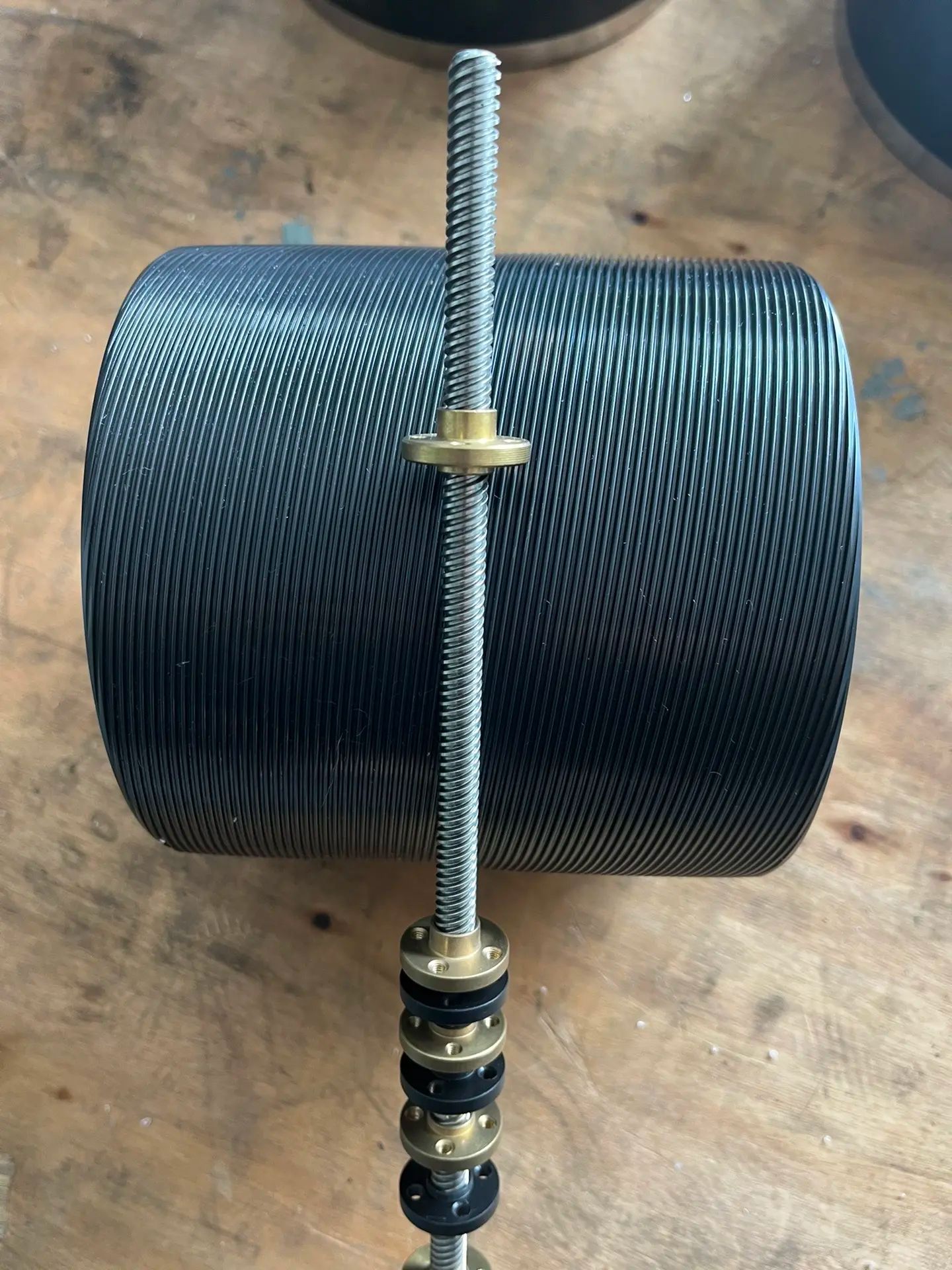

चाहे के लिए मानक फास्टनर, बॉल स्क्रू, स्प्लिन, गियर या कस्टम प्रोफाइल, ALEKVS मशीनों को यह सुनिश्चित करने के लिए इंजीनियर किया गया है परिशुद्धता, दक्षता और दीर्घकालिक विश्वसनीयता उद्योगों में.