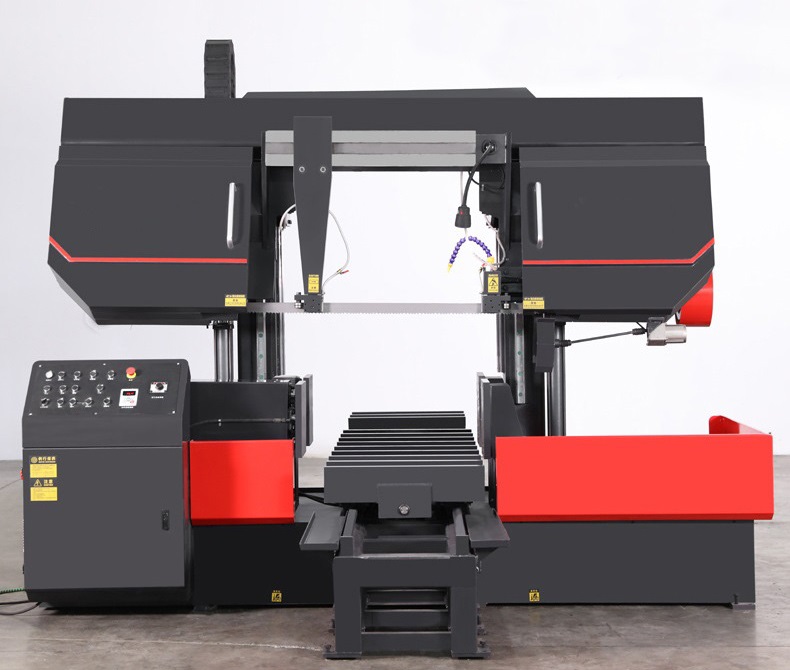

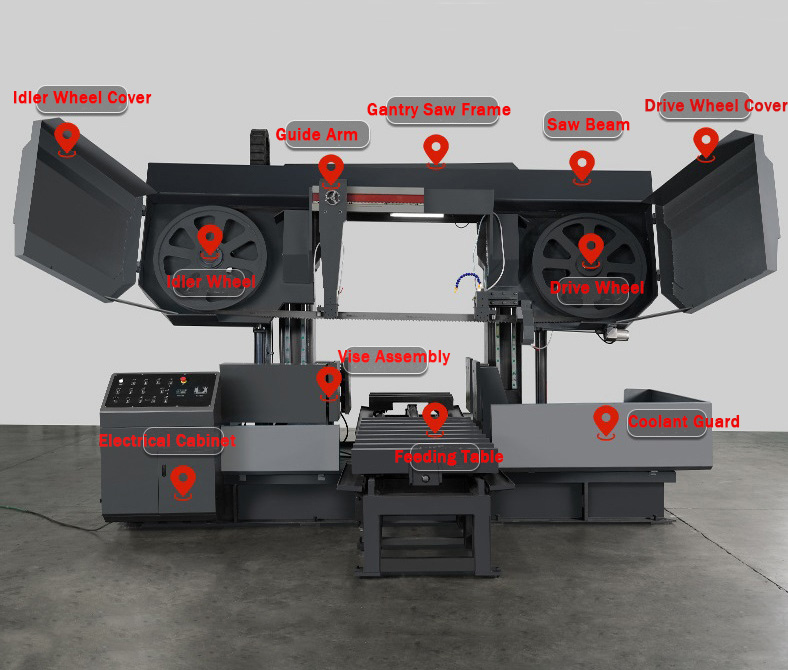

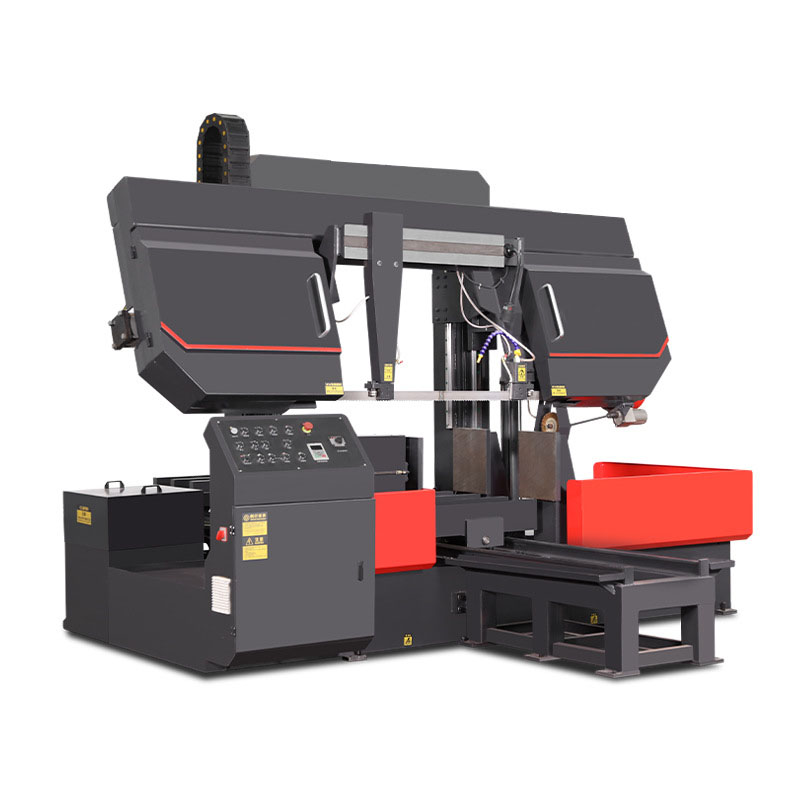

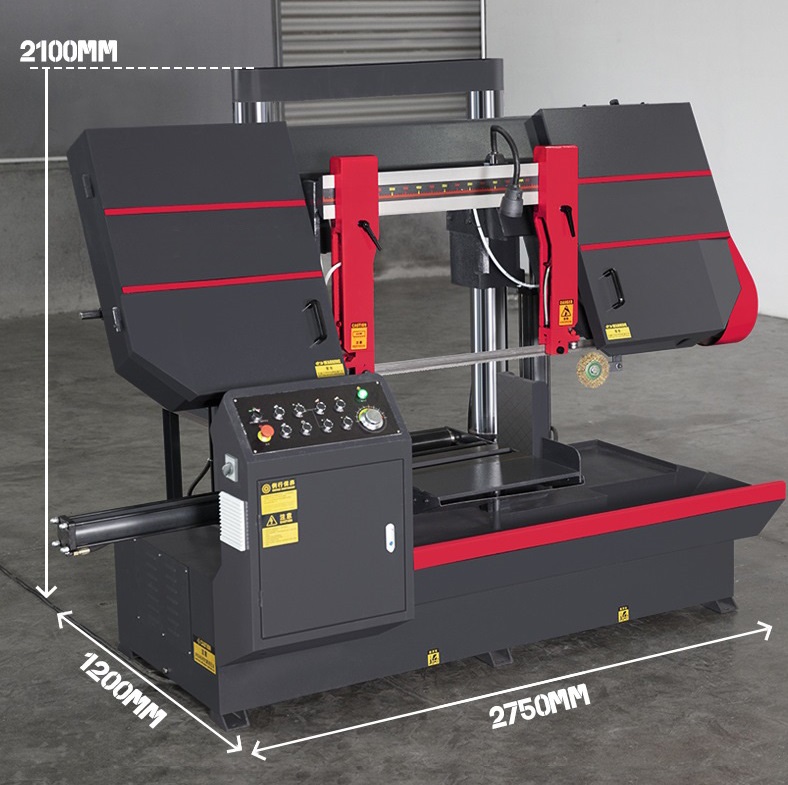

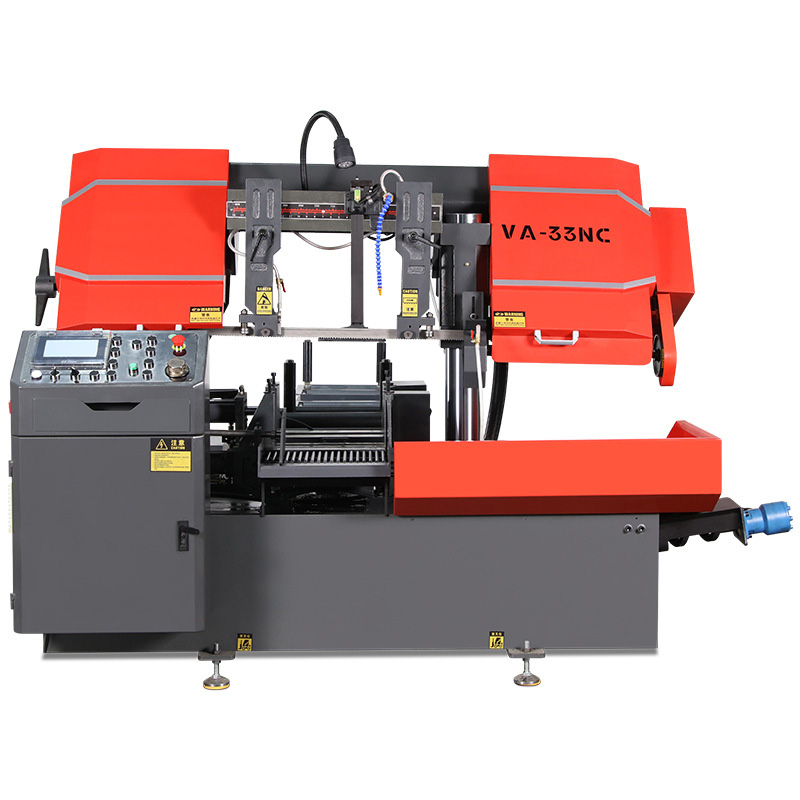

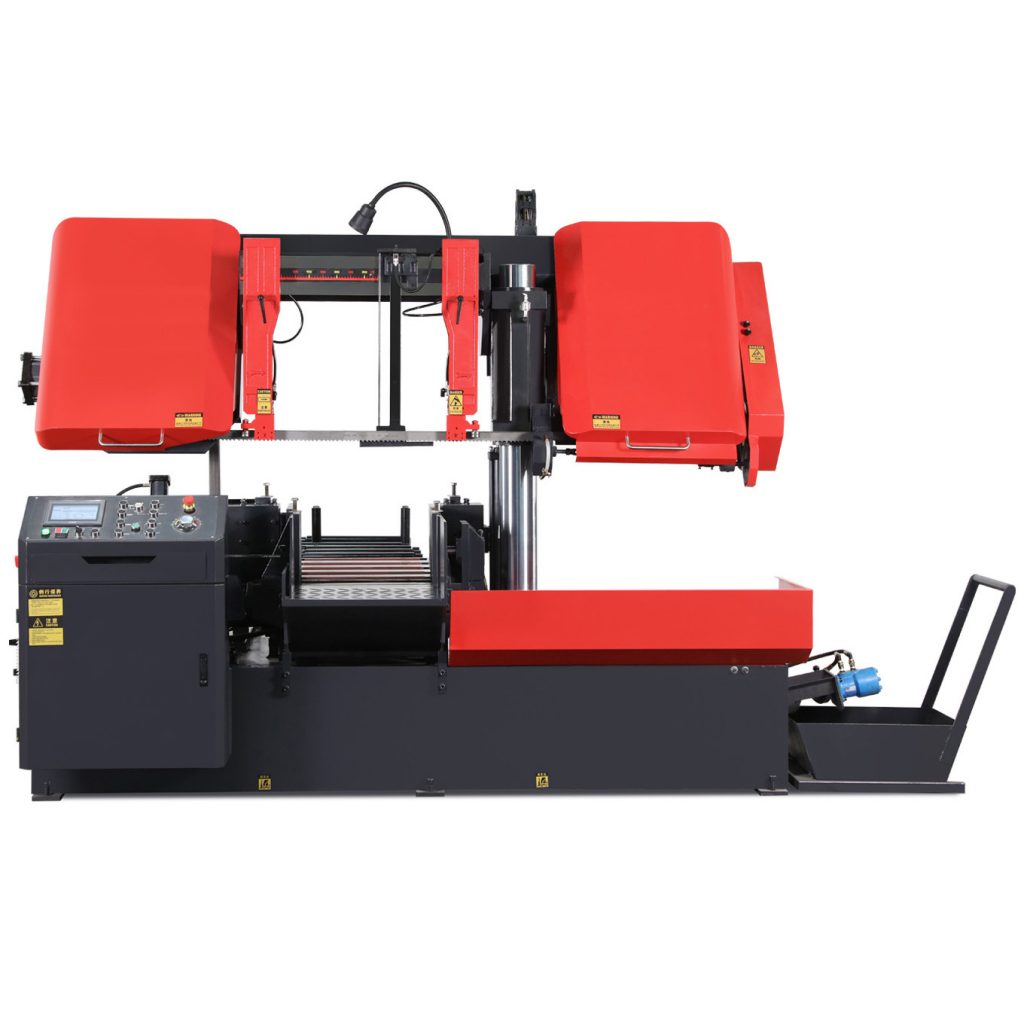

Heavy-Duty Semi-Automatic Band Saw —— AEK-VA-100SA·AEK-VA-80SA ·AEK-VA-65SA ·AEK-VA-60SA Series

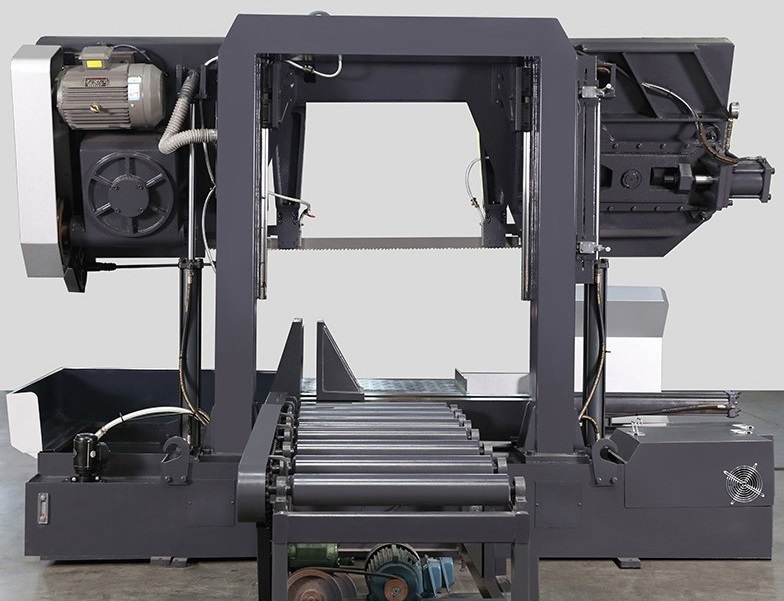

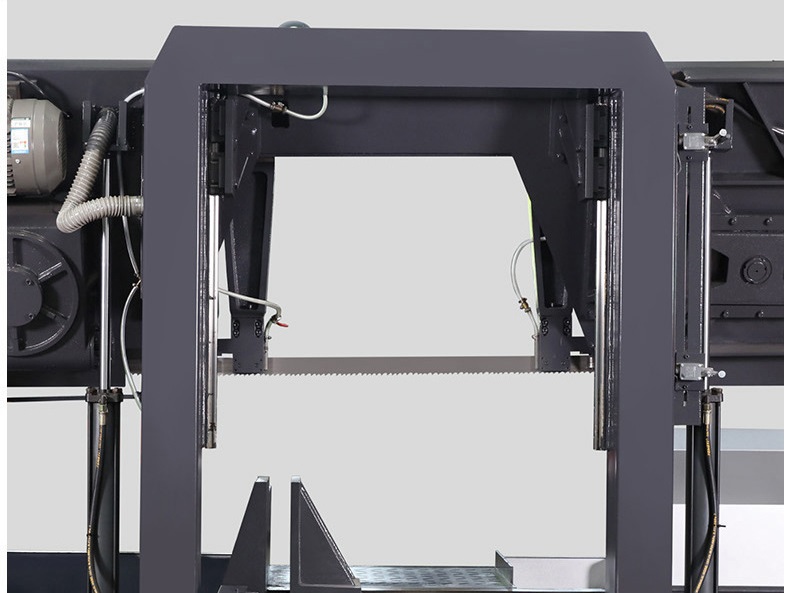

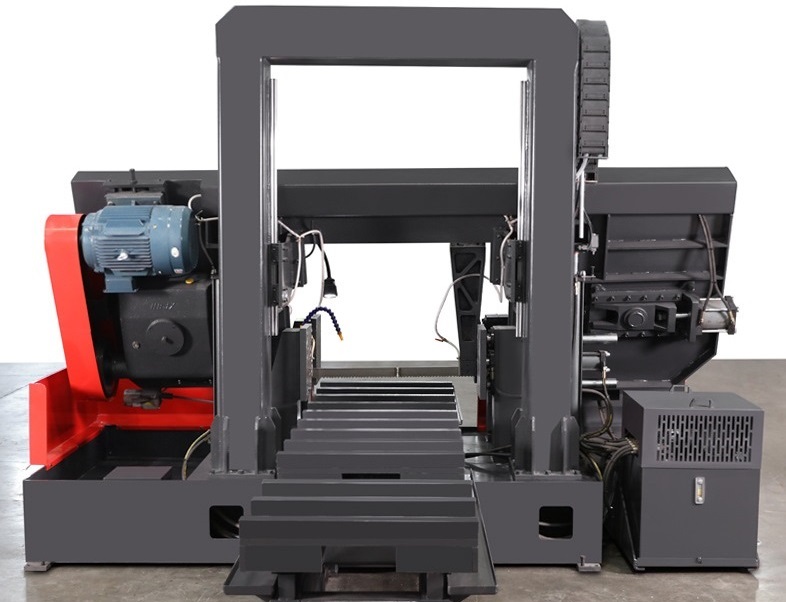

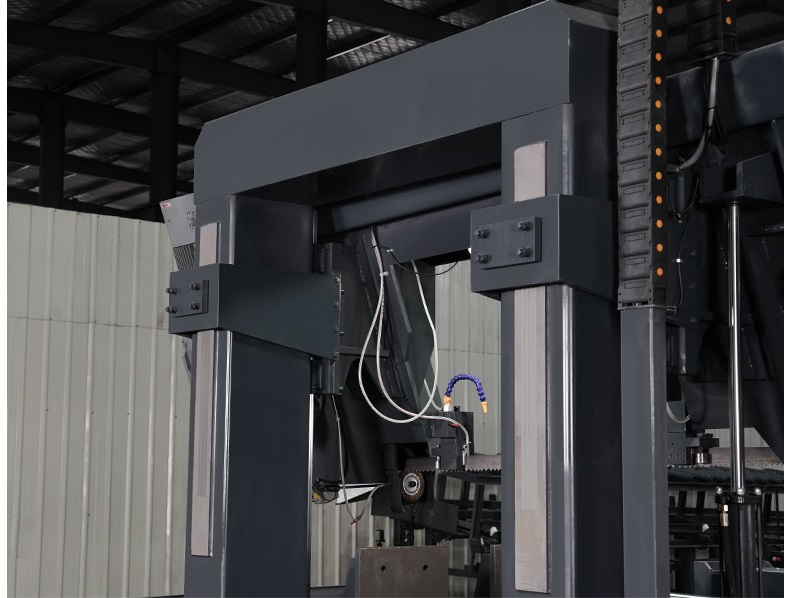

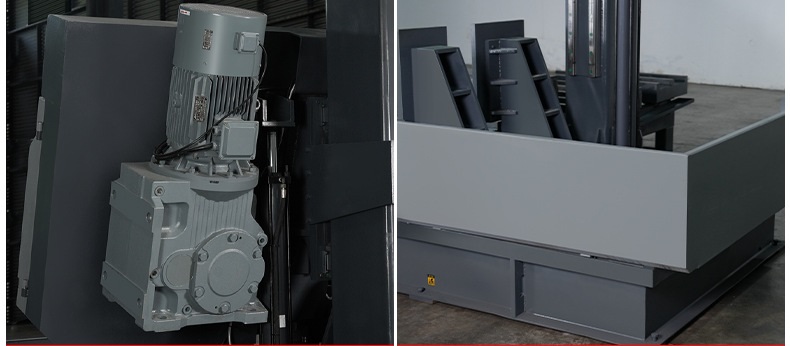

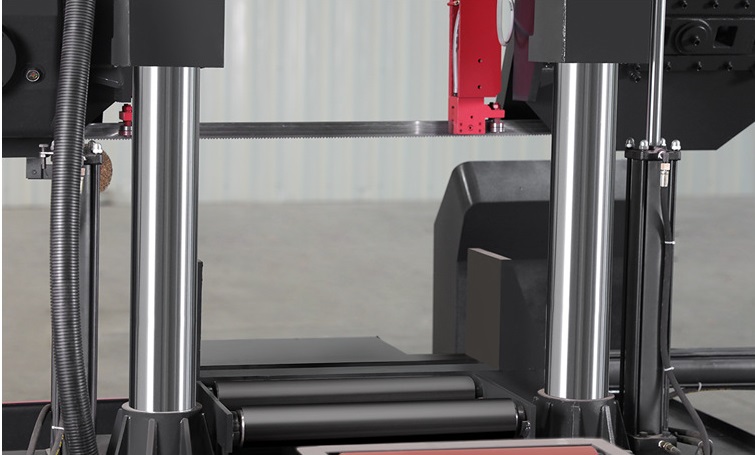

Heavy-Duty Hydraulic Horizontal Band Saw-Structure Photos

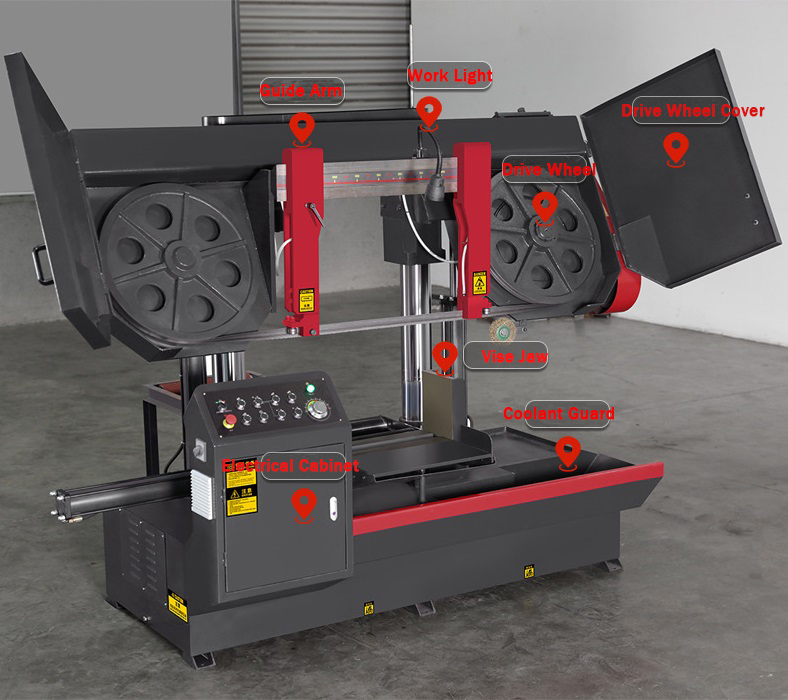

Key Features

- Powerful Drive– Main motor up to 15 kW; selected models equipped with 5.5 kW 6-pole copper motors for high torque and continuous heavy-duty cutting.

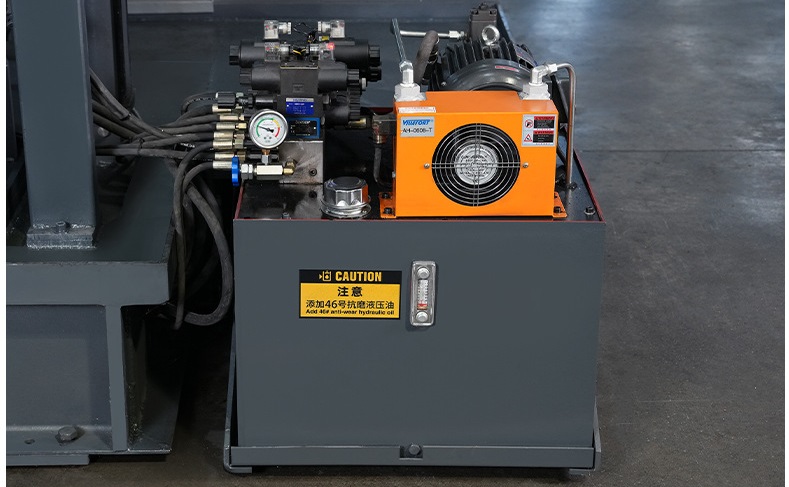

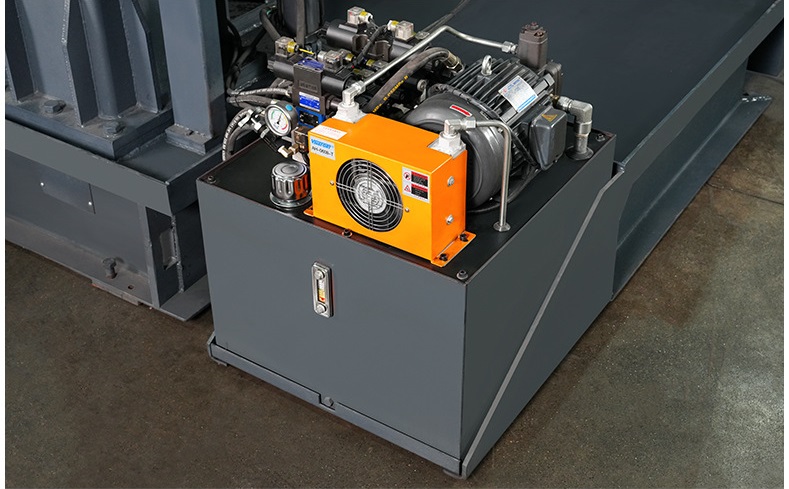

- Hydraulic Control– Full-stroke hydraulic cylinder and automatic blade tensioning ensure stability, minimizing blade breakage.

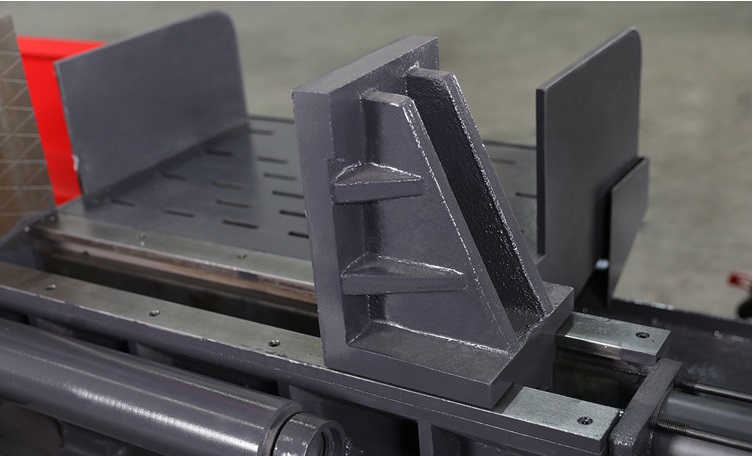

- High Cutting Accuracy– Dual-cylinder synchronized feed with reinforced vises achieves cutting tolerance within ±0.3 mm.

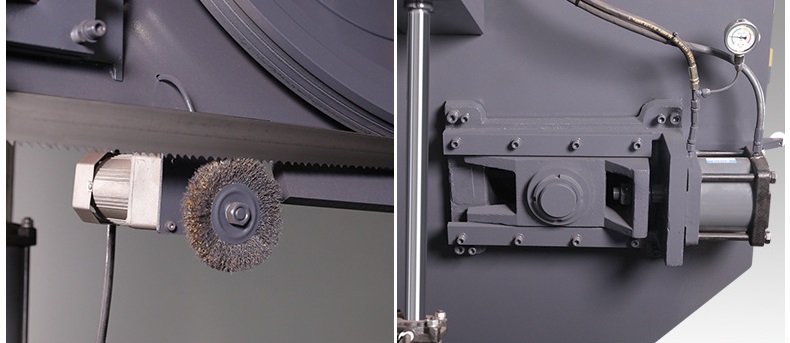

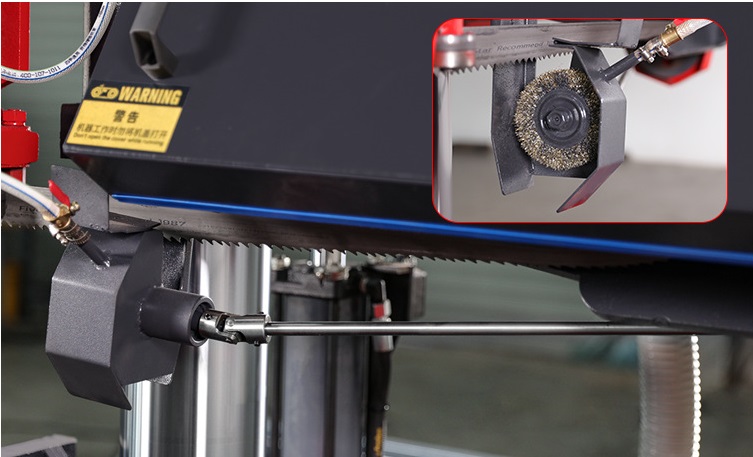

- Efficient Cooling & Chip Removal– Receiving table water-return system and wire brush link-drive ensure coolant circulation and real-time chip removal.

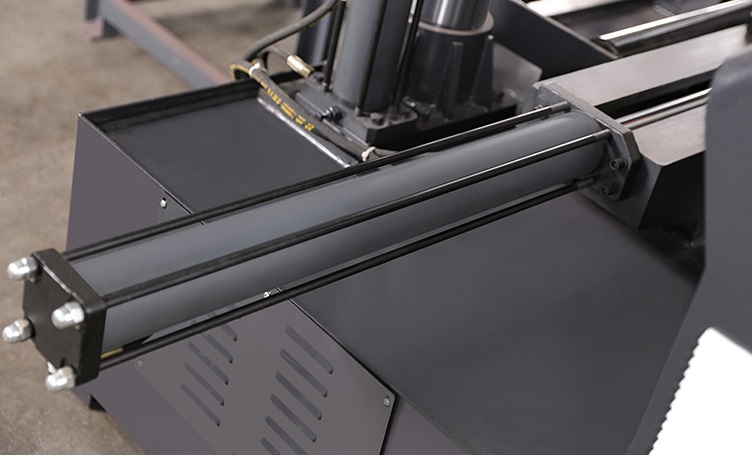

- Robust Construction– High-strength frame with large-diameter rollers for smooth handling of heavy workpieces.

Optimized Configurations

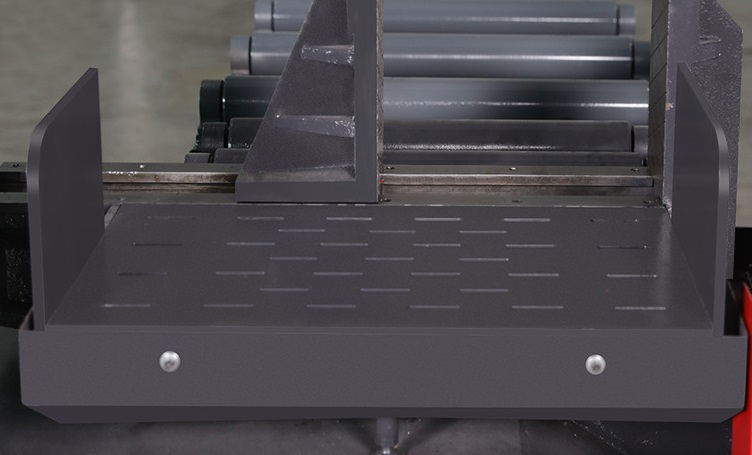

- Return water attachment for receiving table

- 87 mm diameter table rollers for stable feeding

- Bed-mounted rollers for long material handling

- Detachable raised splash guard for easy cleaning

- Side door design for easier maintenance

- Electric feed button for simple operation

- Cast iron jaws with rib reinforcement for firm clamping

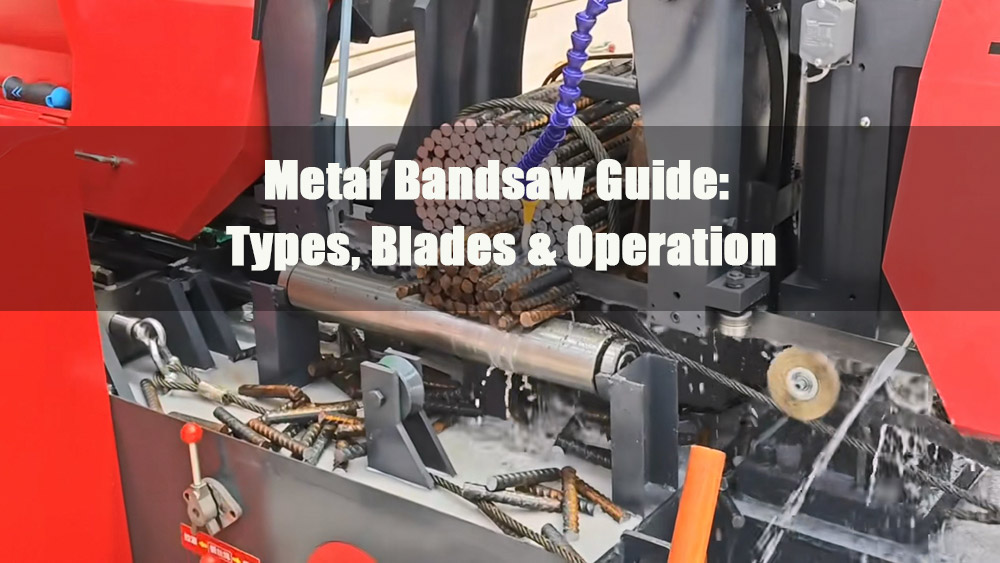

Typical Cutting Materials

- Mold Steel(Cr12, H13, P20, 718, etc.)

- Ferrous Metals(carbon steel, alloy steel, tool steel, bearing steel)

- Non-Ferrous Metals(aluminum alloy, copper alloy, brass blocks)

- Heavy-Duty Materials(large-diameter round bars, thick plates, forged billets, castings)

- Structural Steel(H-beams, square tubes, thick-walled pipes, I-beams, steel strips)

Industries of Application

- Mold Manufacturing– Cutting large mold steel blanks

- Steel Processing Centers– Batch cutting of round bars, plates, and profiles

- Heavy Machinery Manufacturing– Cutting large raw parts for heavy equipment

- Shipbuilding & Bridge Construction– Processing long and heavy structural sections

- Foundry & Forging Plants– Cutting castings and forged billets

- Metal Distribution & Supply Chains– Material cutting and preparation for delivery

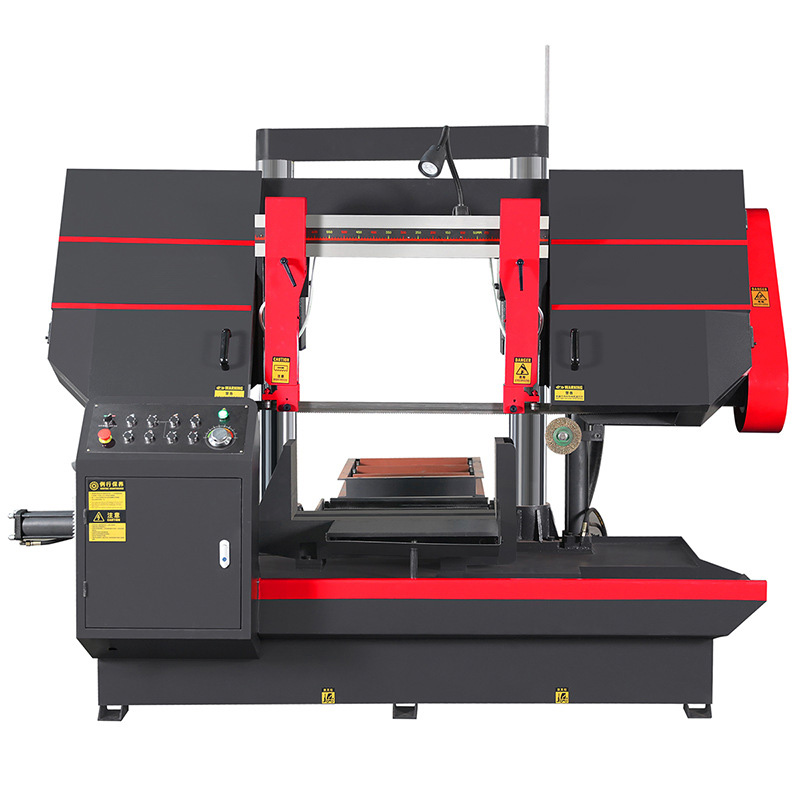

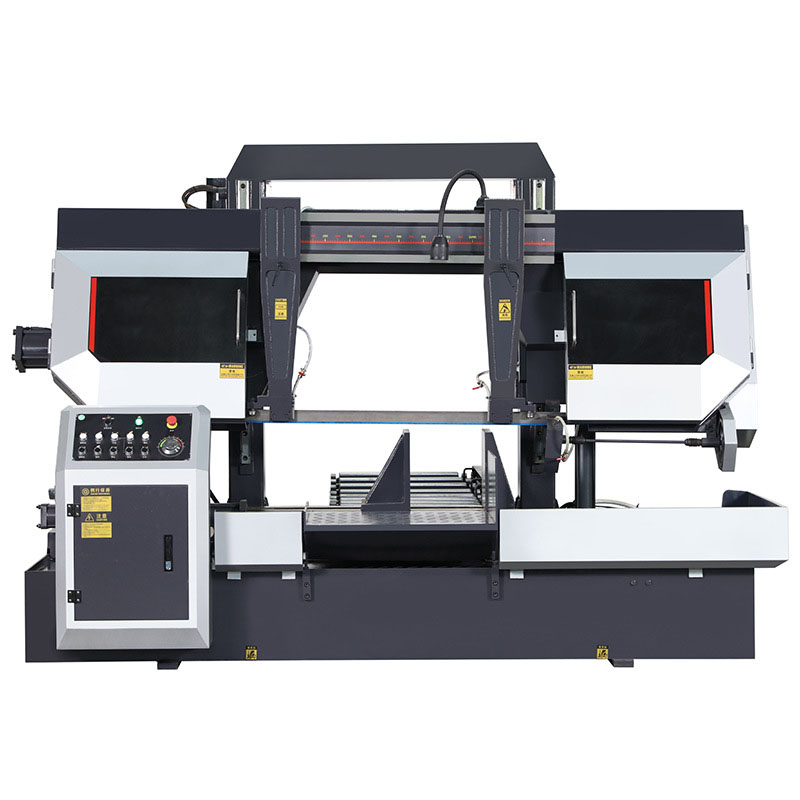

High Rigidity · Strong Power · Precision Cutting- AEK-VB-50SA & 60SA Series

Machine Detail Photos

Please fill out this form to submit a request for quote. One of our team members will review the details and be in touch within 12 business hours.