1.0What is Metal Spinning?

Metal Spinning Technology at a Glance

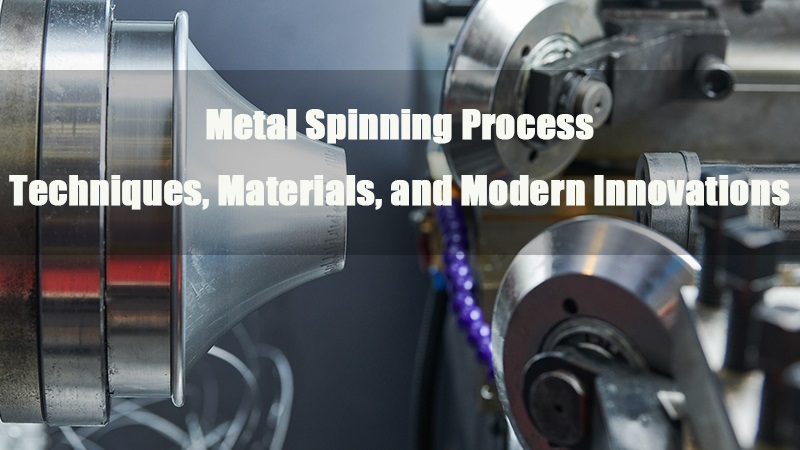

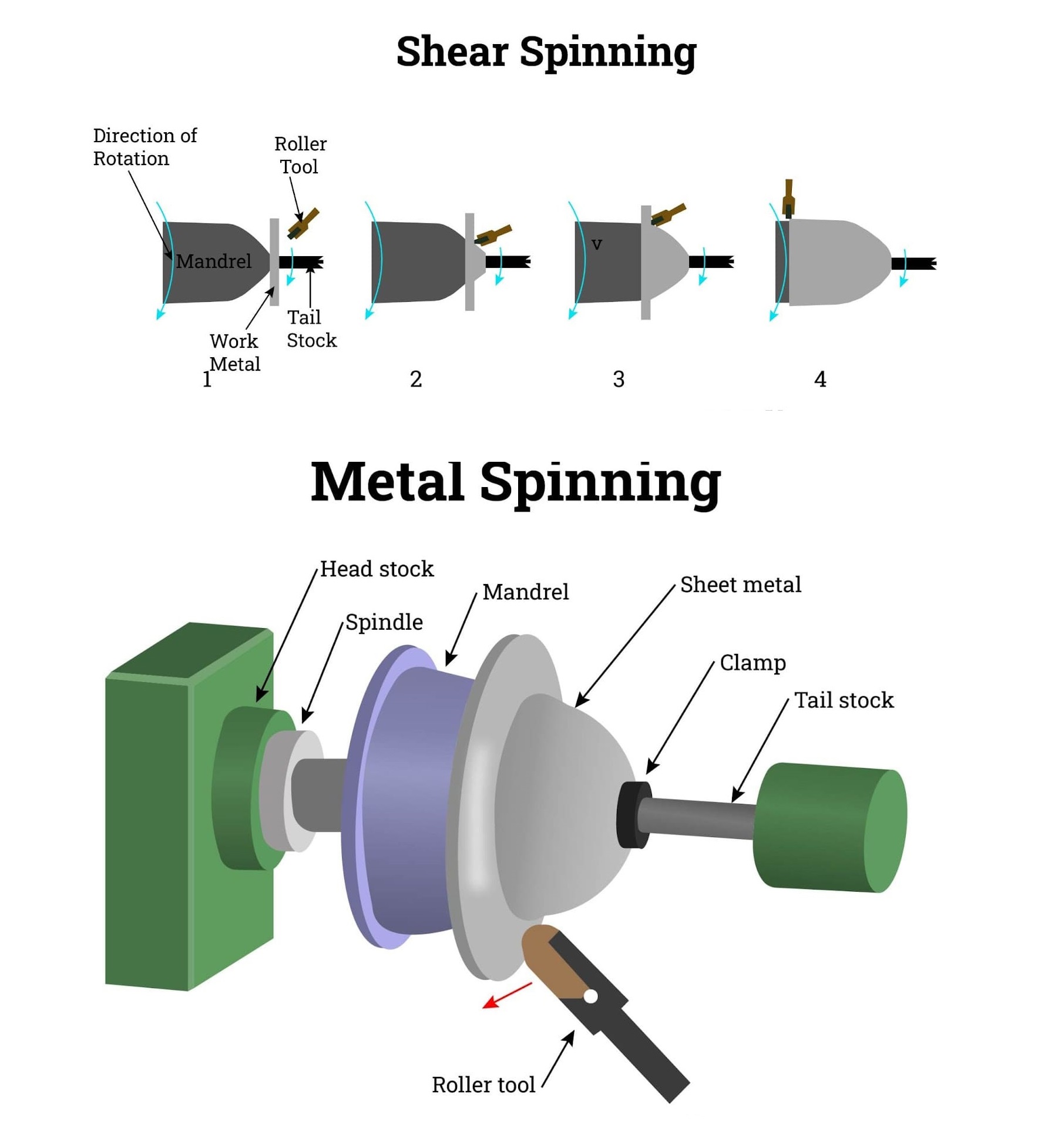

Metal spinning involves forming a metal disk (workpiece) over a shaped mandrel (block) mounted on a lathe. As the lathe rotates at hig5h speed, pressure is applied—typically using levered tools (called “spoons”)—to shape the metal over the mandrel. This process reduces the workpiece’s diameter and alters its thickness or shape to match the mandrel.

1.1Key Forming Techniques

- Standard Spinning: Metal forms over a single-piece mandrel.

- Necking/Reducing: Used to create narrowed sections. It can be done:

- With no mandrel (“spinning on air”)– suitable when surface finish isn’t critical.

- With an eccentric or removable mandrel– for more precise shapes.

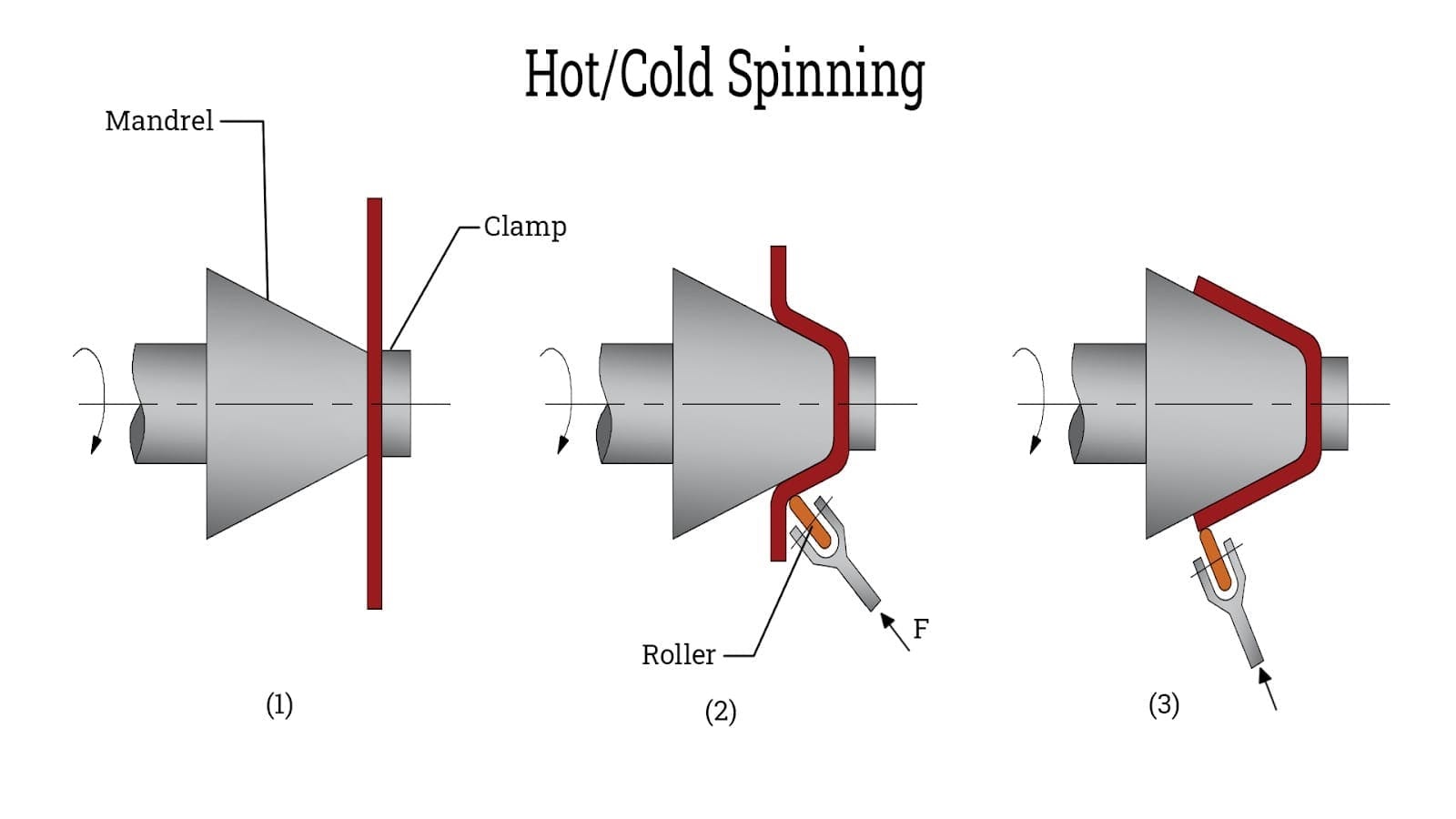

- Hot Spinning: Heat is applied during spinning to soften the material, enabling easier forming of tight or seamless shoulders.

- Ice or Low-Melting Mold Spinning: For complex or one-off shapes, the mandrel is melted away after forming.

| Feature | Hand Spinning | CNC Spinning |

| Best for | – Prototypes and small production runs – Soft, ductile metals (e.g., O-tempered aluminum, light-gauge stainless steel) – Semi-precious or precious metals | – High-volume, repeatable production – Hard-to-spin or less ductile metals |

| Advantages | – Cost-effective for low volumes – High flexibility and manual control – No extensive setup or programming required | – High precision and consistency – Automated process handles complex geometries – Reduced labor and faster turnaround for large batches |

1.2Hand Spinning vs. CNC Spinning

| Feature | Hand Spinning | CNC Spinning |

|---|---|---|

| High Level of Individual Craftsmanship | ✨ | ❌ |

| High Quantity | ❌ | ✅ |

| Use of Machines to Aid Production | ❌ | ✅ |

| Bell-shaped, Spherical, and Tubular Forms Designed and Created Quickly | ✅ | ✅ |

| Most Precise for Part Production | ❌ | ✅ |

| Effective for Creating Prototypes (Rapid Part Production) | ✅ | ✅ |

| Produce Minimum Amount of Wasted Material | ❌ | ✅ |

| Faster Process Compared to Other Machining Methods (e.g., Stamping) | ❌ | ✅ |

1.3Metal Spinning: A Bridge Between Craftsmanship and Automation

Metal spinning sits at the intersection of traditional craftsmanship and modern automation. It offers the flexibility of manual artistry and the efficiency of CNC-controlled production. While high-volume parts benefit from automation, hand spinning remains essential for intricate, decorative, and custom components. Combining both methods allows manufacturers to balance efficiency with quality.

1.4The Metal Spinning Process

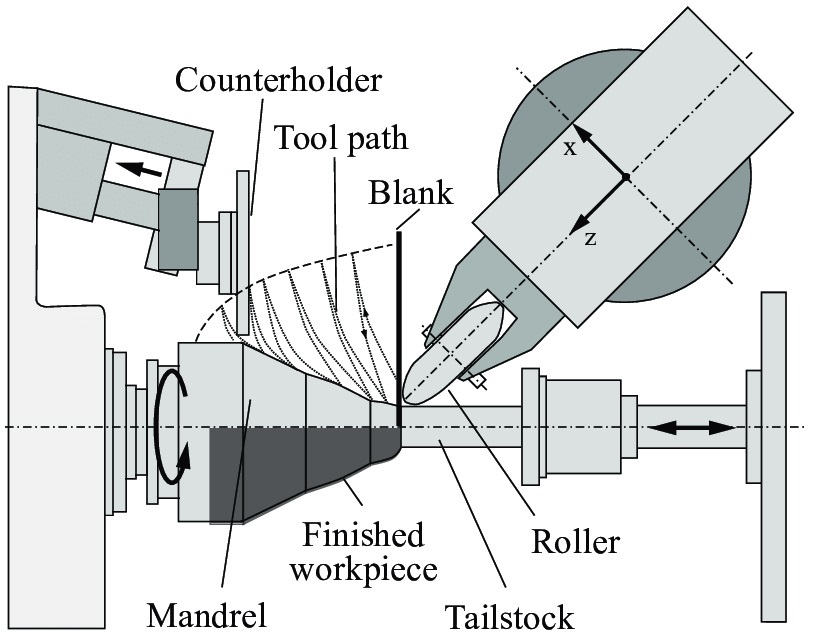

- Setup: A mandrel is mounted to the lathe’s headstock, and the metal blank is secured using a pressure pad on the tailstock.

- Forming: Lever tools or rollers gradually form the metal by applying pressure across multiple passes until the desired shape is achieved.

- Modernization: While this was once entirely manual, many steps are now automated, improving consistency and making large-scale production more feasible.

Recommended Reading:Metal Spinning Process Guide

1.5Key Spinning Techniques

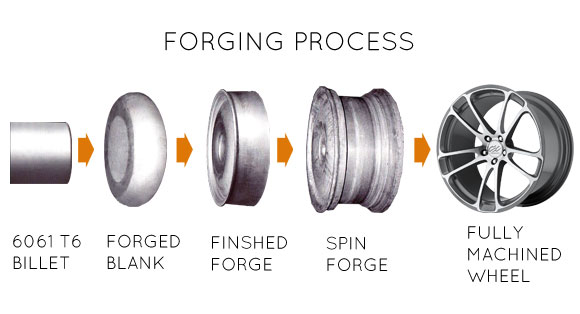

- Preforms: Rough-shaped blanks reduce forming time and cost.

- Conventional Spinning: The metal stretches over the mandrel; thinning can be controlled.

- Shear Spinning: Achieves final shape and thickness in a single pass—ideal for cones or cylinders.

- Edge Treatment: Edges can be straight, folded, or rolled to enhance function or appearance.

1.6Machines Used in Metal Spinning

- Manual Lathes: Operated by hand; suitable for blanks from 1 to 72 inches in diameter.

- Power-Assisted Lathes: Combine manual and hydraulic force; ideal for tougher materials like stainless steel.

- CNC/PNC Lathes: Fully automated; best for high-precision, high-volume production.

1.7Common Spinning Tools

- Male Tools: Replicate the inner shape of the final part; the blank is spun around the exterior.

- Female Tools: Replicate the outer shape; the blank is shaped inside the tool.

- Segmented Tools: Feature removable cores; used for parts with variable diameters and require assembly/disassembly for each use.

2.0Hand Spinning: The Art Behind Precision Metal Forming

2.1A Timeless Craft in a Modern Age

Hand spinning is a traditional metal forming technique where the operator manually controls both the rotational speed and forming pressure. Unlike brute-force forming, this process relies on the artisan’s skill and sensitivity to the metal’s grain, hardness, and behavior. The operator uses a forming tool—commonly called a spoon—to gradually shape the blank over a mandrel, while the other hand assists with lubrication or pressure adjustments.

This process demands experience and finesse. The material must be worked with, not forced, allowing for a smooth, even finish. Similar to working clay on a pottery wheel, skilled hand spinners can achieve tolerances as precise as ±0.004 inches (0.10 mm).

2.2Tools and Techniques

- Forming Tools: Common hand tools include the Sheep’s Nose for forming and the Duck’s Bill for finishing.

- Tool Support: Handles provide leverage; tools can be mounted on posts or guided with fulcrums to stabilize shaping pressure.

- Roller Tools: Many shops use long-handled tools with mounted rollers for efficiency and control.

- Sound and Feel: Operators rely on acoustic and tactile feedback to assess material fit and pressure uniformity.

2.3Materials and Applications

Hand spinning is compatible with a wide range of metals:

- Common Materials: Iron, aluminum, stainless steel, copper, and brass.

- Precious Metals: Ideal for gold, silver, and platinum due to minimal waste and high finish quality.

- Refractory Metals: Modern advancements now allow spinning of titanium, molybdenum, tantalum, and other hard or brittle alloys.

Typical applications include:

- Prototypes (e.g., beverage cans)

- Aerospace and satellite components

- Semiconductor equipment

- Parabolic antennas

- Custom or decorative parts

2.4Key Benefits of Hand Spinning

Hand spinning offers unique advantages over deep draw stamping and other forming methods.

- Low Setup Requirements: Minimal tooling changes; multiple operations possible with a single mandrel.

- Design Flexibility: Easily accommodates re-entrant profiles and near-unrestricted design geometry.

- Quick Iteration: Design modifications are low-cost and quickly implemented.

- Tight Tolerances: High repeatability supports precision production.

- Cost Efficiency: Tooling and production costs are significantly lower, especially for small runs (<100,000 units).

- Short Lead Times: Simplified setups and tooling reduce turnaround times.

- Prototype to Production: Ideal for one-offs, small batches, and R&D components.

- Material Savings: Virtually zero raw material waste—especially beneficial when using costly or precious metals.

- Automation Potential: While manual, the process can be partially automated for enhanced repeatability.

Despite the rise of high-speed automated forming processes, hand spinning remains a vital technique—valued for its precision, flexibility, and unmatched craftsmanship. It is both an art and a science, preserving traditional skill while adapting to modern manufacturing needs.

3.0Automated and CNC Spinning

Automated and CNC metal spinning refers to the use of powered tools—often hydraulically driven—and computer-controlled systems to shape metal workpieces with high precision and repeatability. These systems evolved from traditional manual spinning techniques through the integration of mechanical aids like tool rests and levers, leading to greater control and force application.

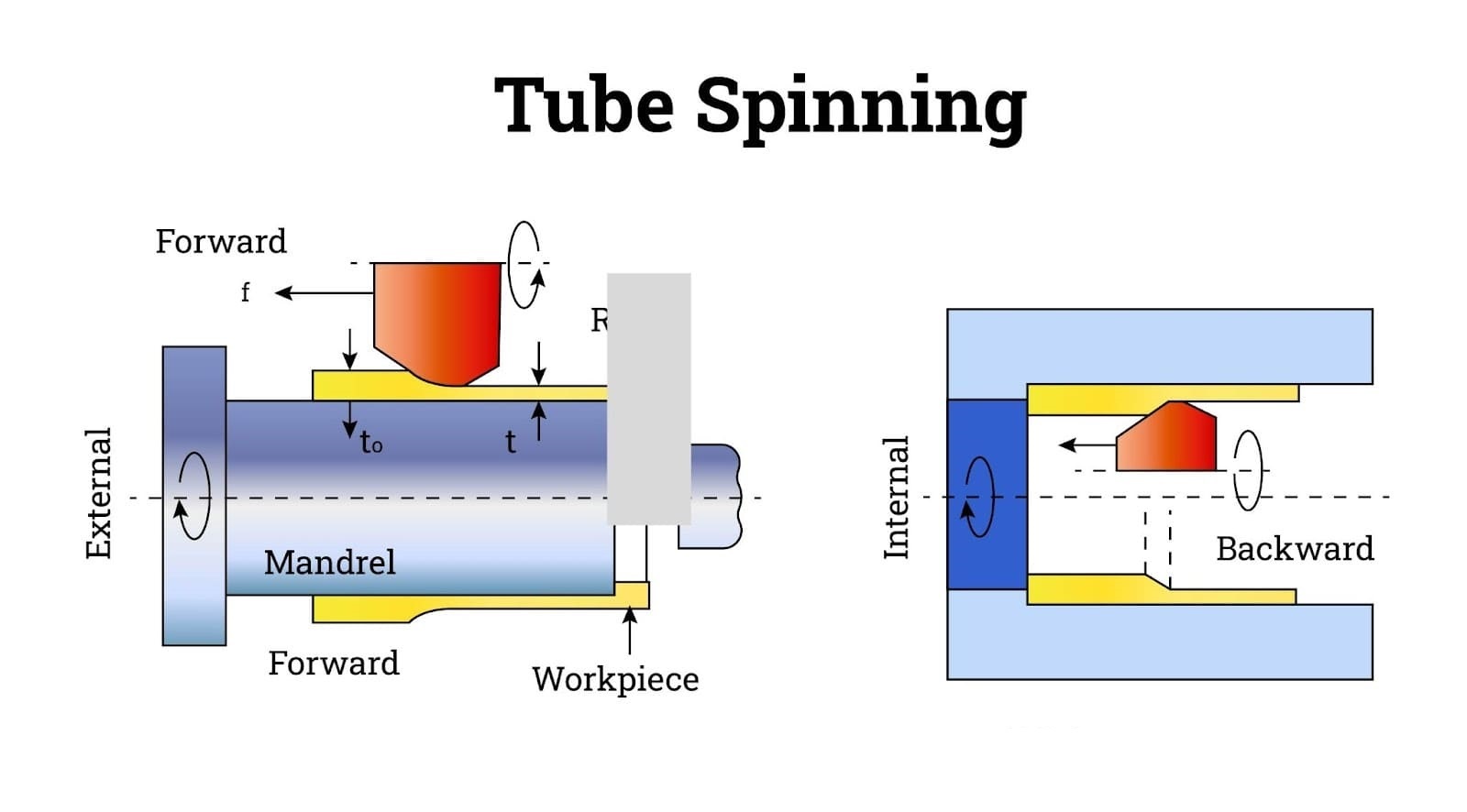

Power spinning, also known as shear spinning, involves deforming ductile metals using high shear forces—up to 3.5 MN (800,000 lbf-ft). It is commonly applied in shaping metal cones and tubes and is suitable for most metals with ductility greater than 2%.

3.1CNC Spinning Systems and Operation

CNC spinning machines operate based on pre-programmed instructions, enabling precise, repeatable forming without relying on operator skill. Once programmed, the machine:

- Automatically clamps and rotates the blank

- Applies forming forces in pre-defined sequences

- Trims and finishes edges

- Ejects the finished part

There are two main programming methods:

- Computer-Aided Machining (CAM): The operator digitally maps spinning passes to form the part.

- Programmable Numeric Control (PNC): The system records and replicates manual spinning paths.

Early automatic spinning lathes could only produce one part at a time and required significant floor space. Modern CNC systems, however, are more compact, efficient, and capable of multitasking within dedicated work centers.

3.2Advantages of CNC Spinning

- CNC spinning offers a range of operational and economic benefits:

- High repeatability and dimensional accuracy (within ~1/32″)

- Operator-independent consistency

- 24/7 operation with minimal supervision

- Fast cycle times and reduced labor cost

- Easy program transfer and update across machines

- Low tooling cost compared to deep drawing or stamping

- Short lead time with simple tooling and program changes

- Excellent for mass production, prototypes, and decorative components

3.3Applications

- CNC spinning is widely used in the manufacture of:

- Lighting fixtures (e.g., lamp shades)

- Cylindrical containers (e.g., bottles, canisters)

- Aerospace components

- Pressure vessels

- Decorative metalware

While hand spinning remains relevant for artistic and low-volume production, CNC spinning is the preferred choice for industrial manufacturing where precision, efficiency, and scalability are critical.

4.0Advantage: Hand and CNC Combo-Spinning Shops

4.1A Hybrid Approach for Maximum Flexibility

Despite the advancements in CNC metal spinning technology, hand spinning continues to play a critical role in modern metal forming shops. CNC systems offer unmatched efficiency, accuracy, and repeatability for high-volume production—especially for bell-shaped, spherical, or tubular parts—but they lack the tactile feedback and nuanced material control that experienced hand spinners possess.

Shops that combine both CNC and manual spinning capabilities enjoy a distinct competitive advantage. This hybrid approach enables them to handle a wide range of production demands—from one-off prototypes to full-scale manufacturing runs—while ensuring both cost efficiency and craftsmanship.

4.2Key Advantages of a Combined Approach

- Faster Prototyping and Iteration

Manual spinning allows rapid development of prototypes and custom shapes without the need for programming or specialized tooling. This frees up CNC equipment for longer or more complex production runs, improving overall efficiency. - Shorter Lead Times

For short-run or custom orders, hand spinning can deliver finished parts in a matter of weeks, especially when no custom tooling is required. CNC systems can then take over for longer runs, ensuring scalability - Craftsmanship for Artistic and Specialized Products

Certain parts—such as musical cymbals, decorative vases, or aerospace components with complex curvature—still require the intuitive skill of an artisan. Master spinners, with years of apprenticeship, can make minute, real-time adjustments that no current CNC system can fully replicate. - Comprehensive Production Capability

A shop proficient in CNC, manual, automated, and shear spinning can fulfill diverse customer needs:- Prototypes, low- and high-volume orders

- Tight tolerances and consistent repeatability

- Low upfront tooling costs

- Production of both standard and custom parts

4.3Broad Application and Material Compatibility

Combo-spinning shops can manufacture parts across a broad spectrum of industries and applications, including:

- Decorative and architectural components

- Medical and aerospace parts

- Industrial and precision instruments

- Tonal and aesthetic products (e.g., cymbals, lighting)

They also support a wide range of materials—from ductile metals like aluminum and copper to refractory and precious metals—with few limitations on part size.

You May Also Like:What Is Metal Spinning ? Process Types, Machines, and Applications