Hot Dip Galvanized Steel Coil Production Lines by ALEKVS

Hot Dip Galvanized Hot Rolled Steel Coil Production Line

The ALEKVS hot-dip galvanized hot-rolled steel coil production line is engineered for large-scale industrial manufacturing.

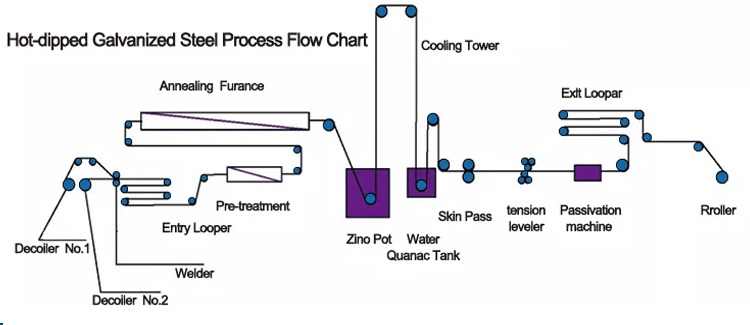

Key Features:

- Annual capacity up to 300,000 tons (customizable)

- Thickness range: 0.12–0.7 mm | Width range: 800–1250 mm

- Fully automated from raw coil to finished product

- High corrosion resistance, dimensional precision, and excellent surface finish

Applications: Construction | Automotive | Home Appliances | Pre-painted coil substrates

Hot Dip Galvanized Steel Coil Production Line for Industrial Use

Advanced Heating & Cooling:

- Equipped with Non-Oxidizing Furnace (NOF) + Radiant Tube Heater (RTH) combination

- Protective gas circulation spray cooling for precise temperature control before the zinc pot

Precision Coating: - High-precision air knives

- Online coating thickness gauge for consistent quality

Industries Served: Construction | Transportation | Energy | Appliances