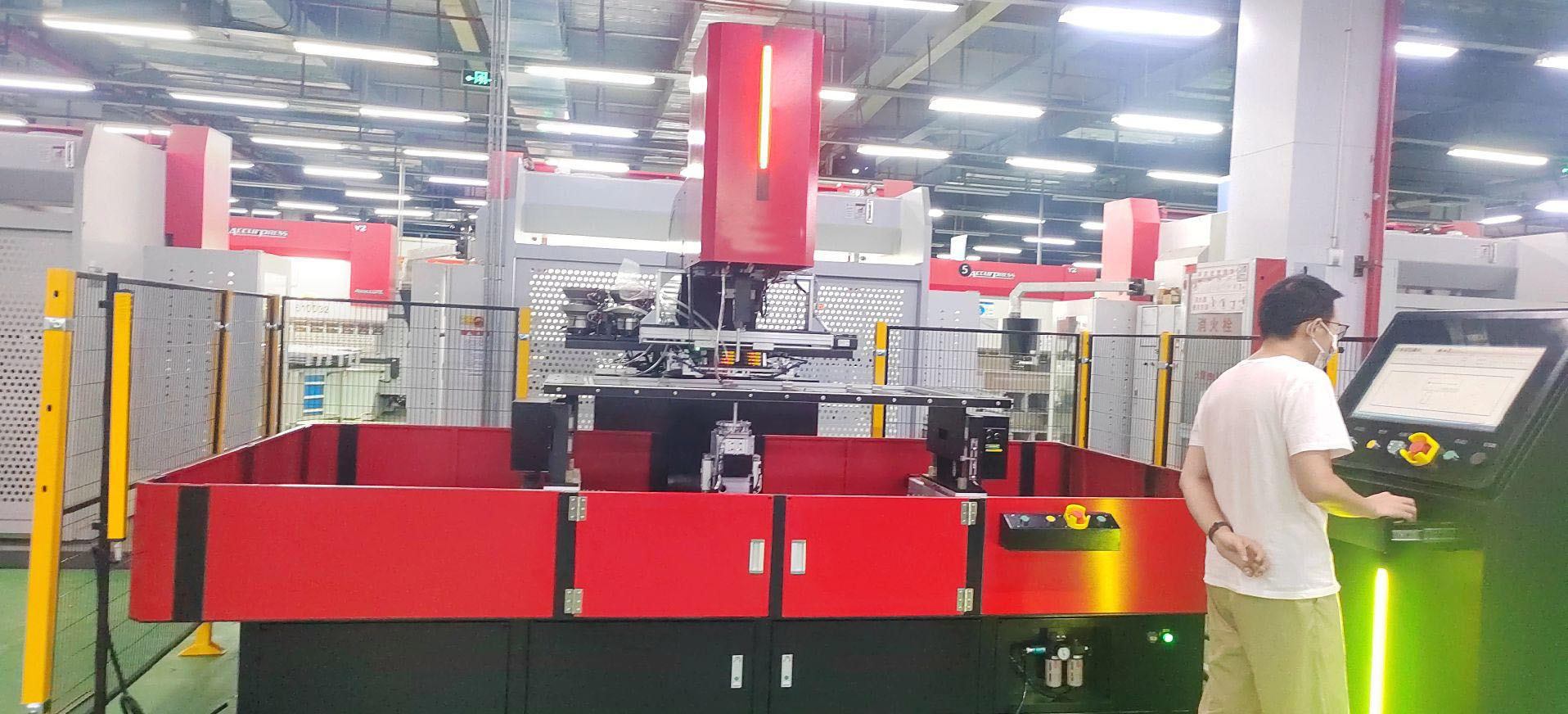

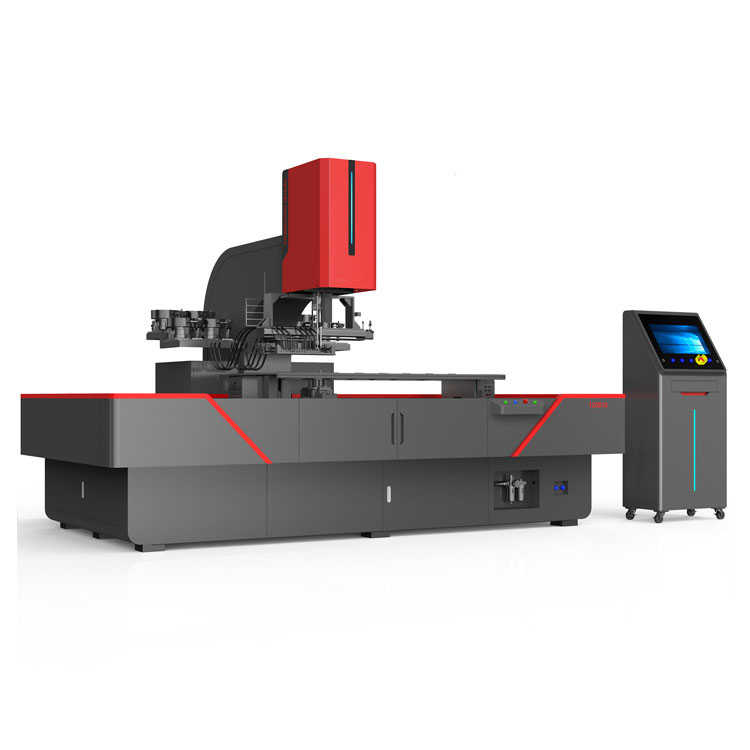

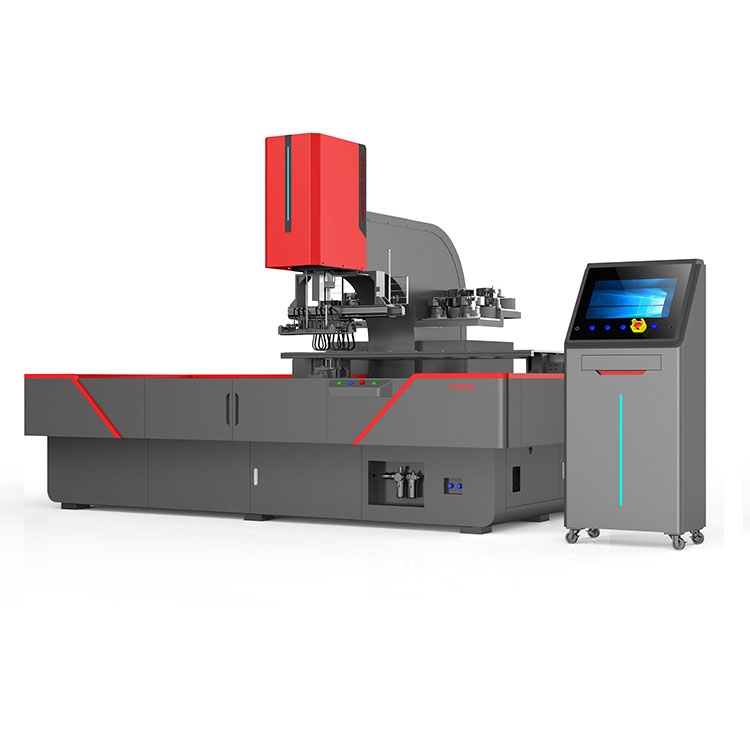

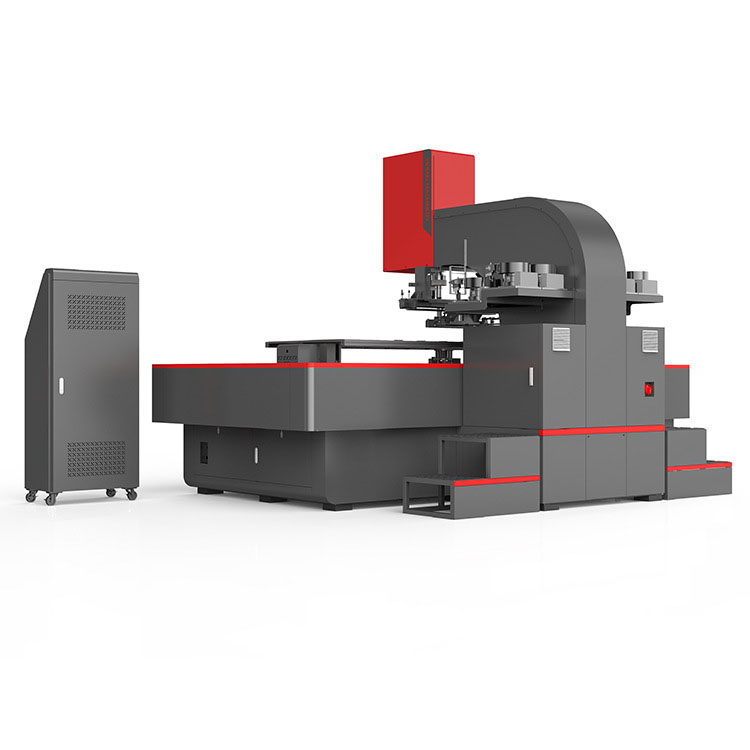

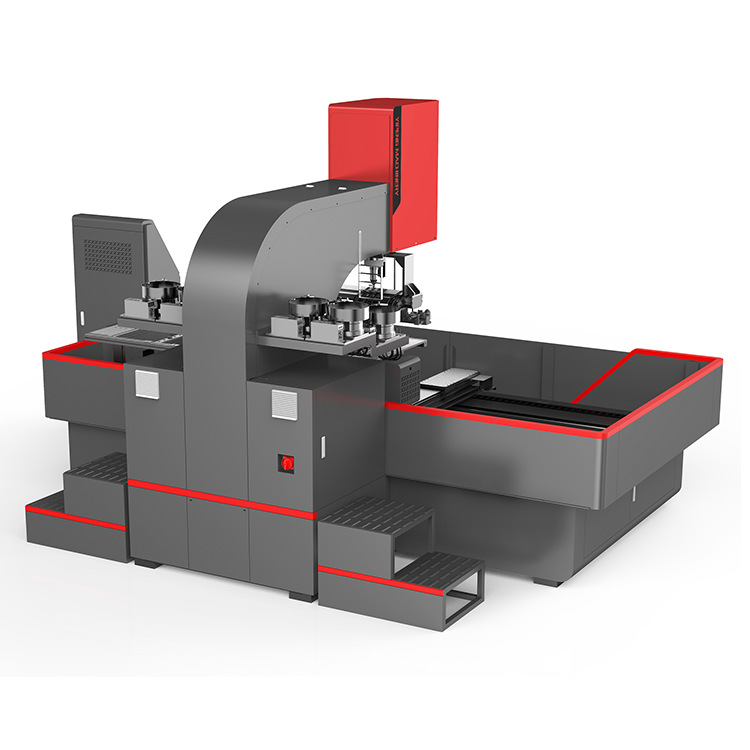

Servo-Driven Fastener Insertion System

Key Features & Advantages

- Multi-Station Automatic Feeding

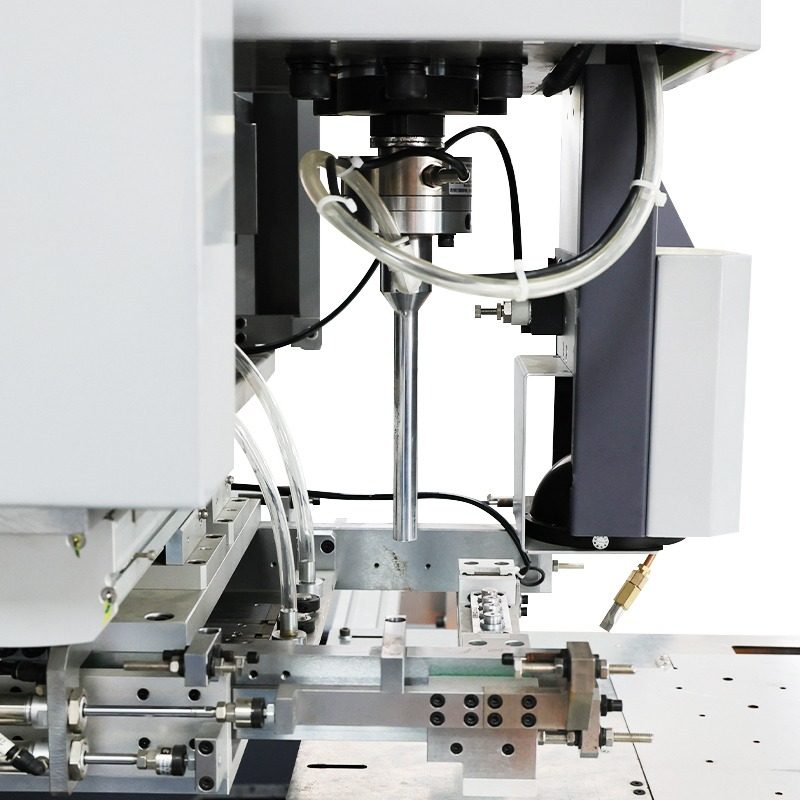

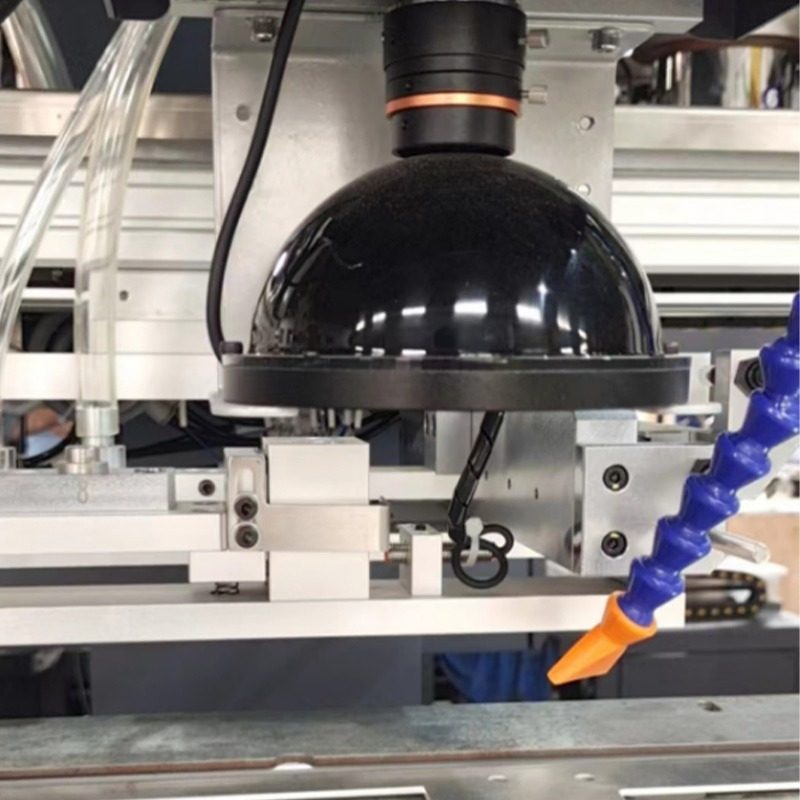

Supports up to 8 fastener types without manual changeover, improving efficiency and flexibility. - CCD Vision Positioning & Compensation

High-precision vision system ensures accurate alignment and error-free riveting. - Smart Servo Pressure Monitoring

Real-time pressure–time tracking guarantees consistent riveting quality. - Automatic Die Exchange System

Fully automated upper and lower die change for different fastener types. - CAD Drawing Import & Graphical Programming

Enables quick setup and easy offline programming through CAD data import. - MES System Integration

Connects seamlessly with production management systems for data traceability and automation. - Error-Proof Detection System

Automatically detects and prevents missed, double, or incorrect riveting. - Customizable Worktable & Dual-Side Operation

Flexible design supports workpieces up to 800 × 600 mm (32″ × 24″), with optional larger sizes. - High Efficiency & Energy Saving

One unit replaces up to 8 semi-automatic machines, cutting labor by 80–90%and energy use by up to 70%. - Flexible Configuration

Custom setups available to meet specific production requirements.

Performance & Application

- Easy Setup– New programs can be created in under 15 minutes.

- Unmanned Continuous Operation– Runs automatically for up to 8 hours.

- Automatic Alignment– Precisely positions workpieces on the auto-load table.

- Offline Programming– Supports CAD import and independent program editing.

Technical Capabilities (Model: AEK-518-8-C)

- Riveting Capacity: Nut ≤ M10, Bolt ≤ M8, Screw ≤ M6 (carbon steel)

- Tapping Thread: ≤ M6 (carbon steel)

- Convex Hull Forming: Up to Ø45 m

- No-Rivet Screw Joining: ≤ 4.0 mm total thickness (carbon steel)

- Pierce-Out Lock Rivet Joining: ≤ 4.0 mm total thickness (carbon steel)

Applications

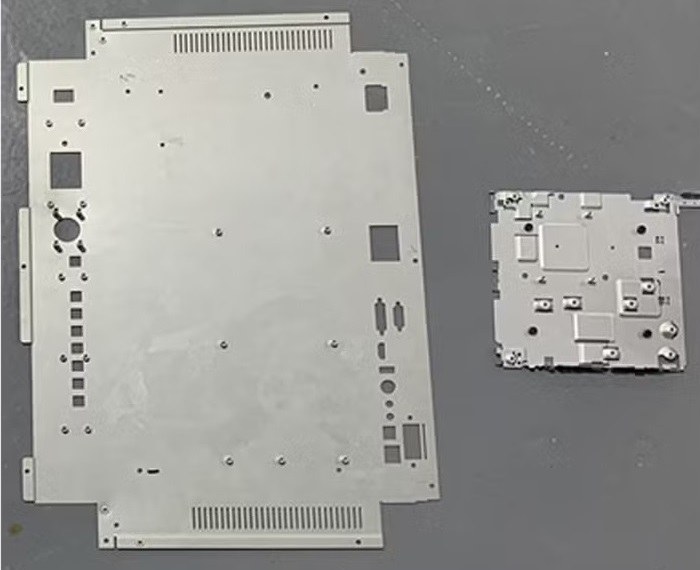

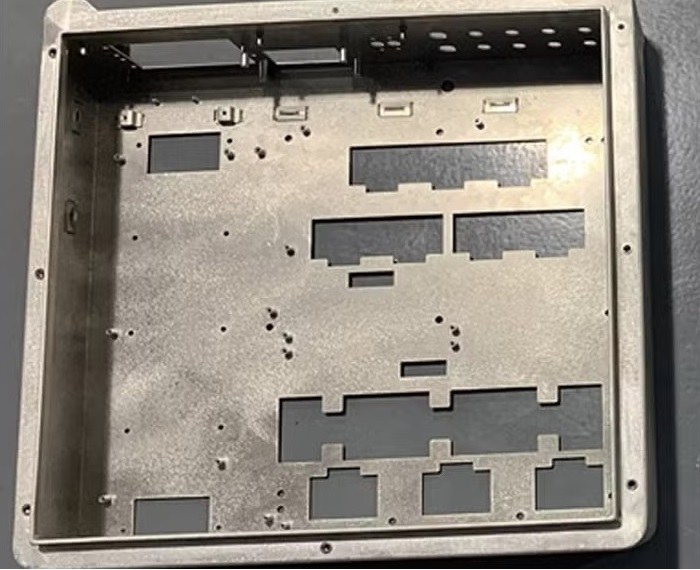

- Electrical control cabinets and switchgear panels

- Metal enclosures and sheet metal housings

- Electronic and communication equipment panels

- Server chassis and computer cases

- Battery boxes and energy storage systems

- Automotive body and structural components

- Appliance and hardware components

- New energy and precision metal fabrication products

Fully Automatic Fastener Insertion Center- Customized Solutions

Please fill out this form to submit a request for quote. One of our team members will review the details and be in touch within 12 business hours.