Product Overview

Product Advantages

- Integrated multi-process design reduces clamping and mold-change time, enhancing production efficiency.

- Combination of precision transmission and intelligent control ensures machining accuracy and product consistency.

- Supports multiple materials and pipe specifications, reducing investment costs and increasing production flexibility.

- Standardized operation and advanced safety configurations make it suitable for industrial-scale manufacturing environments.

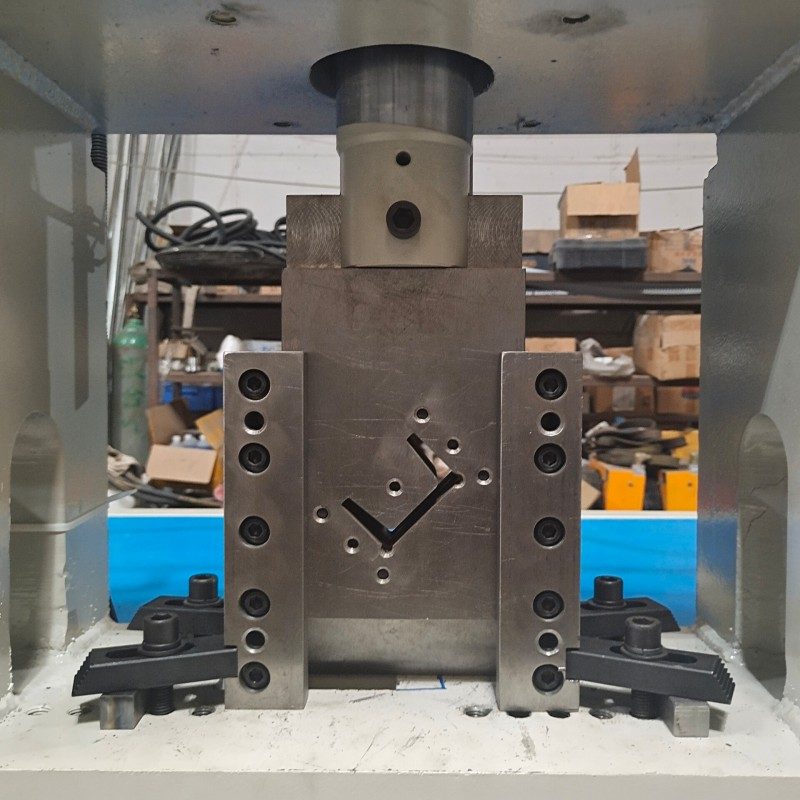

Core Structure and Functions

Multi-station Collaborative Design: 4 independent stations with flexible configuration (typical: positioning & clamping, rough/fine punching, hole-edge trimming); complete multiple processes with one clamping, reducing mold changes and workpiece transfers.

- Precision Drive & Control: Servo drive + precision ball screw, hole positioning accuracy ±0.1 mm; PLC-based intelligent linkage control synchronizes station movements, minimizes human error, and ensures stable mass production quality.

- Compatibility Scope: Suitable for round, square, rectangular, and customized pipes; compatible with stainless steel, aluminum alloy, carbon steel, etc.; standard punching diameter Φ3–Φ50 mm, customizable sizes available.

- Operation & Safety Configuration: Touchscreen interface storing 100+ sets of processing parameters for fast product changeovers; built-in fault alarm, emergency stop device, and protective enclosure ensuring safe, reliable operation with minimal manual intervention.

Application

This machine is widely used in industries such as construction materials (guardrails, photovoltaic brackets, scaffolding), automotive manufacturing (chassis tube components), furniture hardware (frames, door and window fittings), and mechanical fabrication (agricultural machinery parts, instrument tube assemblies).

It is an ideal solution for mass-production pipe punching and corner-cutting applications.

Please fill out this form to submit a request for quote. One of our team members will review the details and be in touch within 12 business hours.