- 1.0Definition and Core Characteristics of Forging

- 2.0Classification by Forging Temperature

- 3.0Classification by Die Constraint

- 4.0Classification by Equipment and Operation

- 5.0Auxiliary Processes in Forging

- 6.0Selection of Metals for Forging

- 7.0Common Forging Defects and Their Causes

- 8.0Frequently Asked Questions (FAQ)

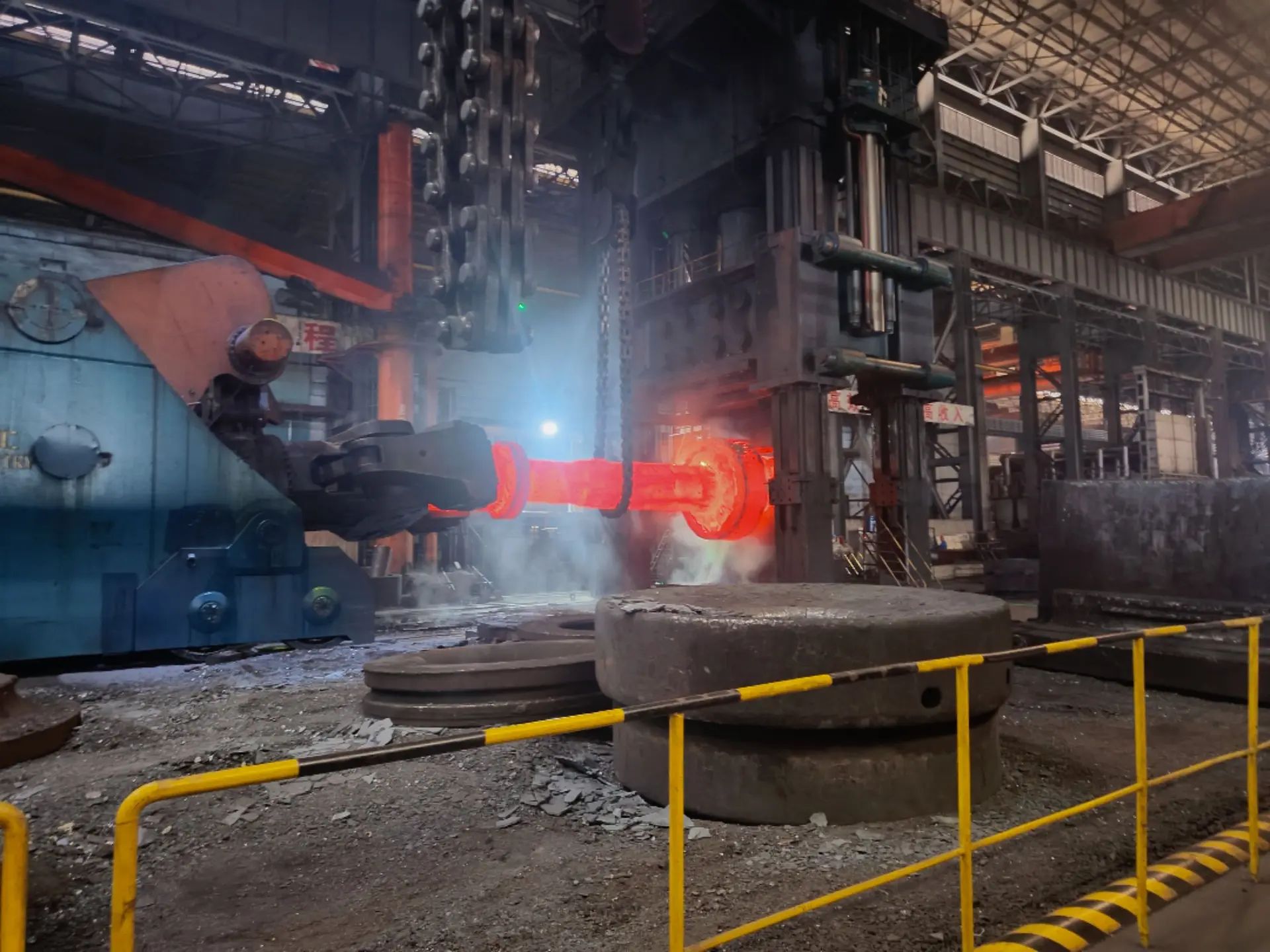

1.0Definition and Core Characteristics of Forging

Forging is a manufacturing process involving the shaping of metal using localized compressive forces. The blows are delivered with a hammer (often a power hammer) or a die. Forging is often classified according to the temperature at which it is performed: cold forging (a type of cold working), warm forging, or hot forging (a type of hot working). For the latter two, the metal is heated, usually in a forge. Forged parts can range in weight from less than a kilogram to hundreds of metric tons. Forging has been done by smiths for millennia; the traditional products were kitchenware, hardware, hand tools, edged weapons, cymbals, and jewellery.

Since the Industrial Revolution, forged parts are widely used in mechanisms and machines wherever a component requires high strength; such forgings usually require further processing (such as machining) to achieve a finished part. Today, forging is a major worldwide industry.

2.0Classification by Forging Temperature

The primary basis for temperature classification is the recrystallization temperature of the metal—the critical point at which atoms rearrange to form new grains. Based on this, forging can be divided into hot forging, warm forging, and cold forging.

2.1Hot Forging

- Temperature Range: For steel, typically 950–1260°C (varies with different metals and alloys).

- Key Features:

- Excellent metal plasticity, good formability, and low forming force.

- Work hardening is offset by recrystallization, resulting in low internal stress.

- May produce oxide scale, leading to lower surface finish and dimensional accuracy.

- Applications: Large forgings (e.g., shafts, hubs), rough forming of high-strength alloys. Suitable for bulk production where high precision is not required.

2.2Warm Forging

- Temperature Range: Below the recrystallization temperature but above the cold forging range. For steel, typically 650–950°C.

- Key Features:

- Minimal or no scale, better surface finish compared to hot forging.

- Dimensional accuracy between hot and cold forging, forming force lower than cold forging.

- Slightly reduced formability compared to hot forging; requires precise temperature control to prevent cracking.

- Applications: Medium-to-small precision parts such as gear blanks, where surface quality is required but extreme cold forging precision is unnecessary.

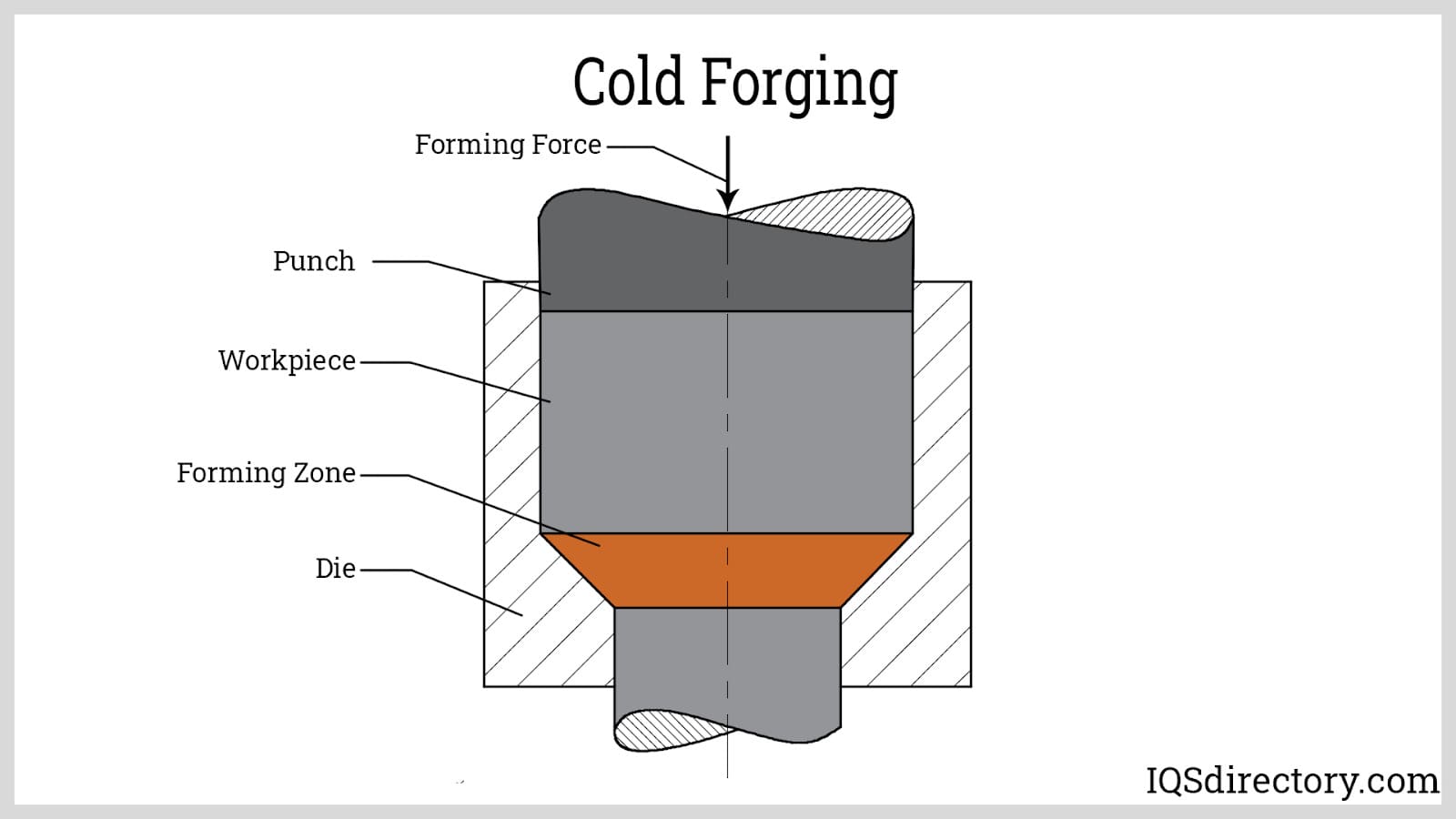

2.3Cold Forging

- Temperature Range: For steel, typically room temperature to ~150°C; aluminum and copper are cold-forged at room temperature, while 200–400°C is considered warm forging to improve ductility and reduce forming loads.

- Key Features:

- No oxidation, high surface finish, capable of achieving ±0.3 mm tolerance.

- Significant work hardening improves yield strength and fatigue resistance.

- Requires high forming force and robust equipment; limited to ductile metals such as aluminum, copper, and low-carbon steel.

- Applications: Precision fasteners (bolts, screws) and small structural components (bearing rings) where assembly tolerances must be met directly.

Recommended Reading:Cold Forging Process: Principles, Advantages, Applications, and Key Technologies

3.0Classification by Die Constraint

Forging can also be categorized according to the extent of die enclosure: open-die forging and closed-die forging.

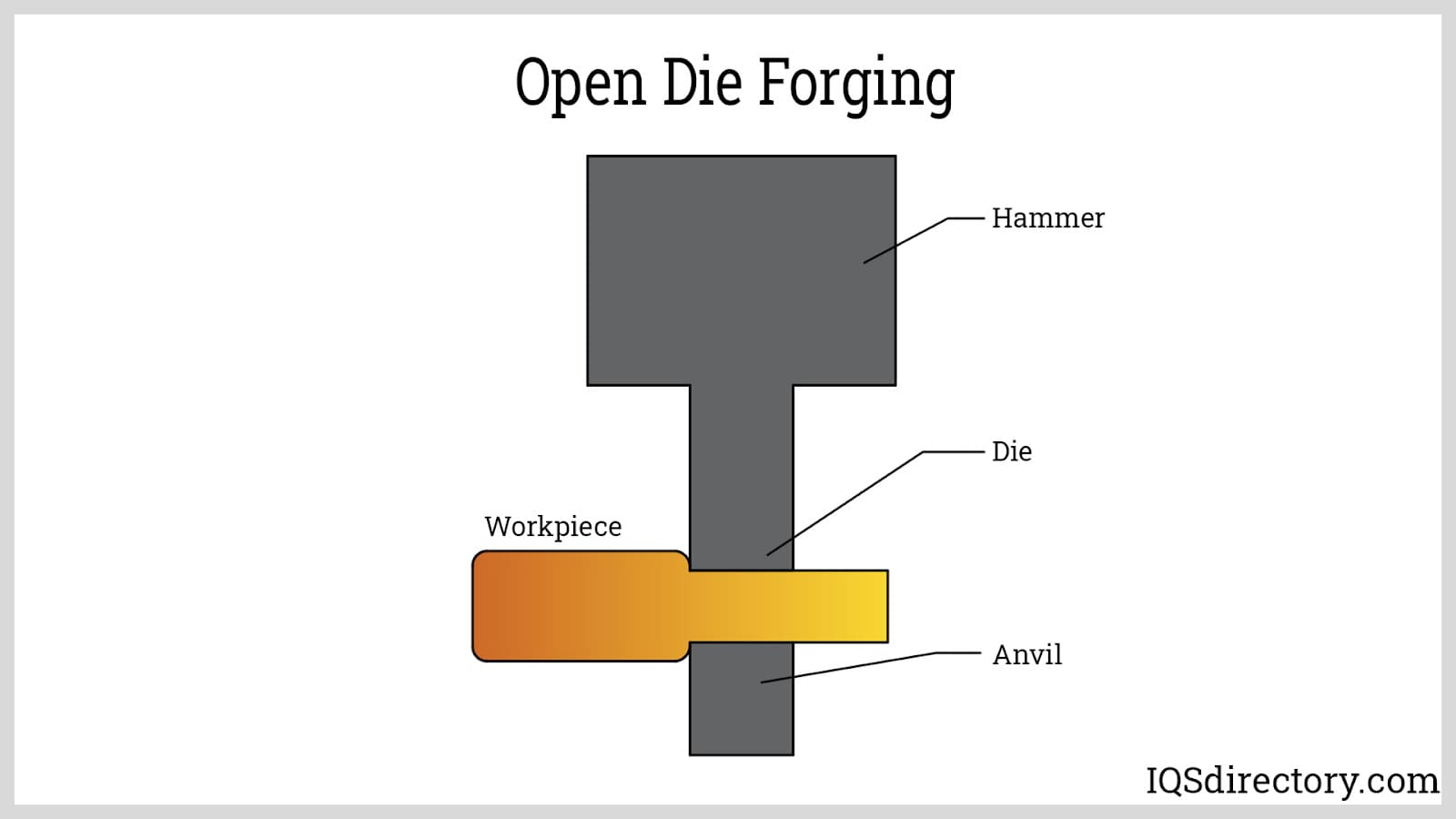

3.1Open-Die Forging (Smith Forging)

- Process Principle: Uses dies that only partially enclose the workpiece. The heated metal is shaped by repeated hammering or pressing while freely flowing outward, requiring manual repositioning.

- Advantages: Simple die structure, low cost, capable of producing large or irregular forgings. Grain flow can be oriented to enhance strength. Suitable for small-batch or customized production.

- Disadvantages: Operator-dependent, poor dimensional consistency, high machining allowance, low material utilization.

- Typical Products: Large shafts, discs, blocks, and custom industrial parts.

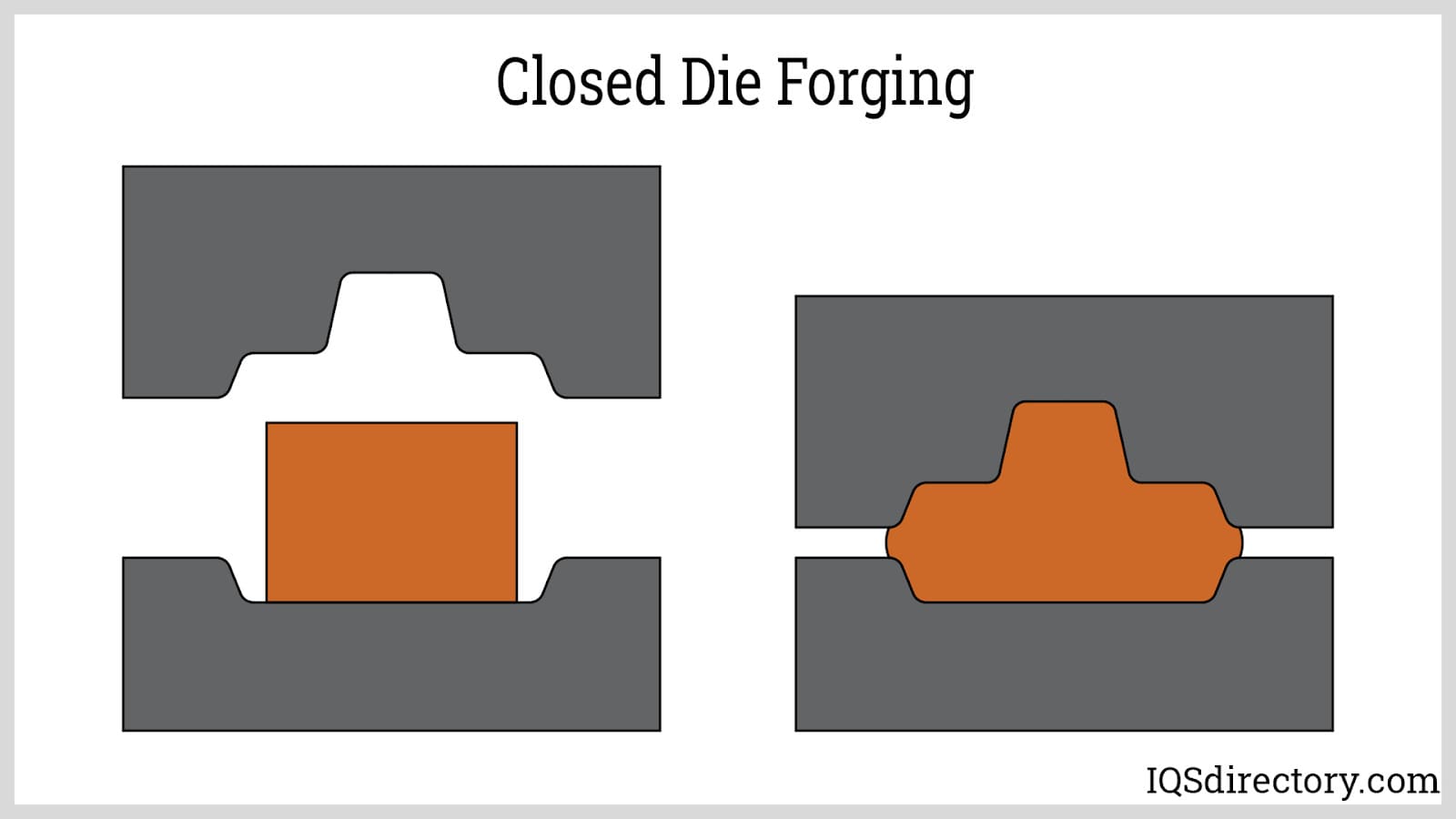

3.2Closed-Die Forging (Impression-Die Forging)

- Process Principle: Upper and lower dies form a cavity matching the part geometry. Preheated billets fill the cavity under pressure; excess material flows out as flash, later trimmed. Flashless forging encloses the cavity fully to avoid flash.

- Advantages: High dimensional accuracy, good repeatability, suitable for mass production. Grain flow aligns with part geometry, enhancing mechanical properties.

- Disadvantages: Complex die design, high tooling costs, strict billet and lubrication requirements for flashless forging. High initial investment.

- Typical Products: Automotive components (connecting rods, gears), tool parts, medium-to-small precision structures.

4.0Classification by Equipment and Operation

4.1Drop Forging

- Principle: Drop forging uses a hammer or ram, powered by steam, hydraulic, pneumatic, or electric drives, which falls onto the workpiece to deform it instantaneously. Both open-die and closed-die variations exist. Open-die forging requires manual repositioning of the workpiece, while closed-die forging allows excess material to flow as flash. Modern setups often employ a Pneumatic Forging Power Hammer to deliver controlled, high-frequency impact, improving consistency and reducing operator fatigue..

- Applications: Ideal for medium-to-small parts like shafts, farm tools, and mechanical components. Open-die drop forging can produce large or irregular shapes where grain flow direction is critical.

- Advantages & Limitations: Fast deformation, strong directional properties; however, dimensional accuracy depends on operator skill, and flash trimming is needed for closed-die forging.

4.2Press Forging

- Principle: Press forging applies slow, continuous pressure instead of impact, providing uniform metal deformation. It can be performed using open or closed dies with mechanical or hydraulic presses.

- Applications: Suitable for large or complex components, including crankshafts, connecting rods, and structural parts requiring even strain distribution.

- Advantages: Controlled deformation, improved surface finish, better detail accuracy with heated dies.

- Limitations: Slower than drop forging and higher initial equipment cost.

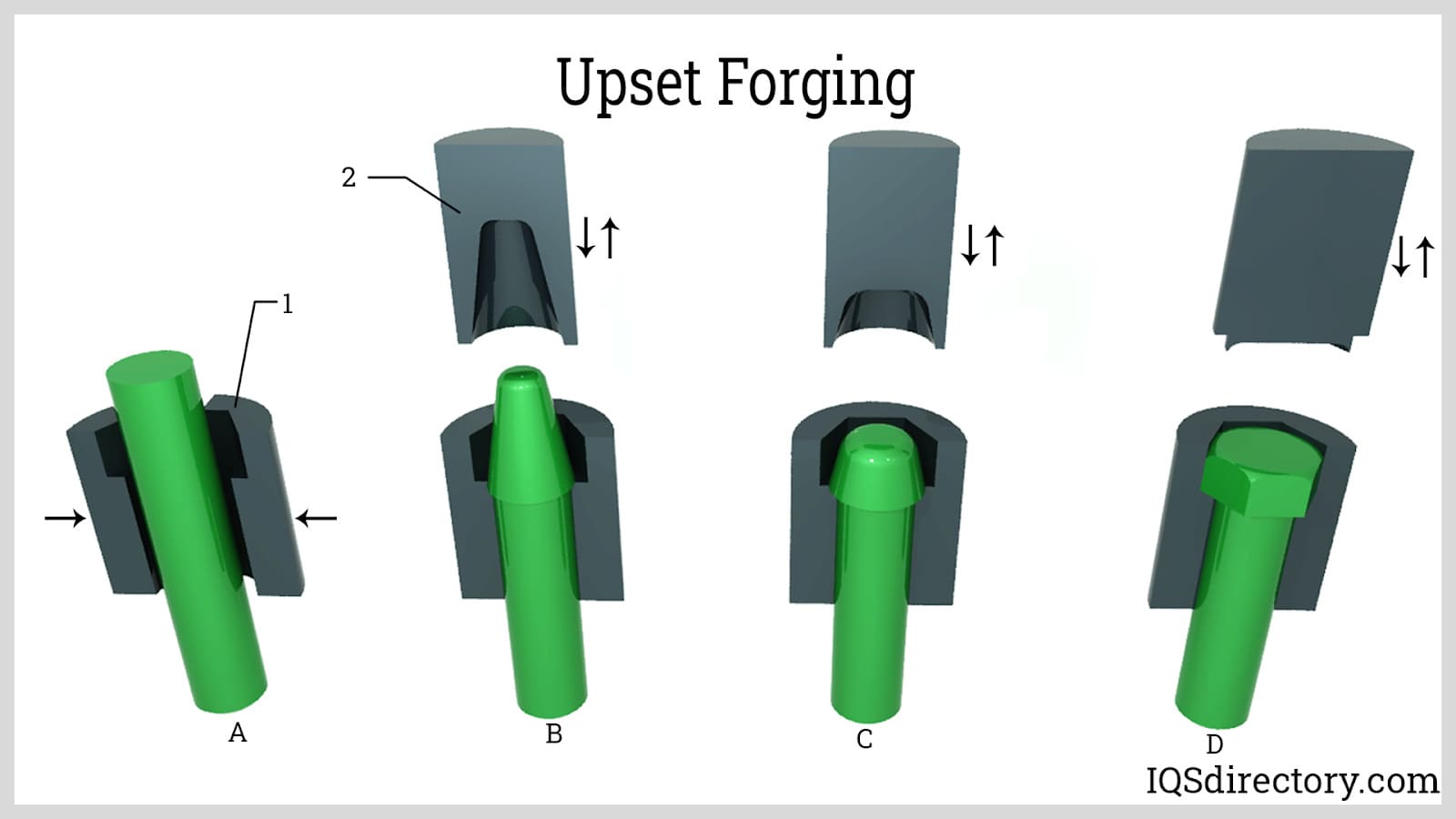

4.3Upset Forging

- Principle: In upset forging, a bar or billet is compressed axially, shortening its length while increasing diameter. Multi-cavity dies enable sequential forming of features.

- Applications: Fasteners (bolts, screws), engine valves, couplings, and other parts requiring diameter expansion. High-volume lines can produce dozens to hundreds of parts per minute.

- Note: Often integrated into automated systems for fasteners in modern production.

4.4Automatic Hot Forging

- Principle: Automated hot forging lines combine heating, descaling, shearing, and forging across multiple stations. Flashless processes minimize material waste and improve efficiency.

- Applications: High-volume production of small-to-medium symmetrical parts such as automotive components.

- Advantages & Limitations: High throughput, consistent quality; production rate and tolerances depend on part geometry. Equipment investment is multi-million dollars, and lines are typically designed for small symmetrical pieces.

Many modern CNC Roll Forging Machines are employed in automated hot forging lines to control precise deformation and ensure repeatability across large batches.

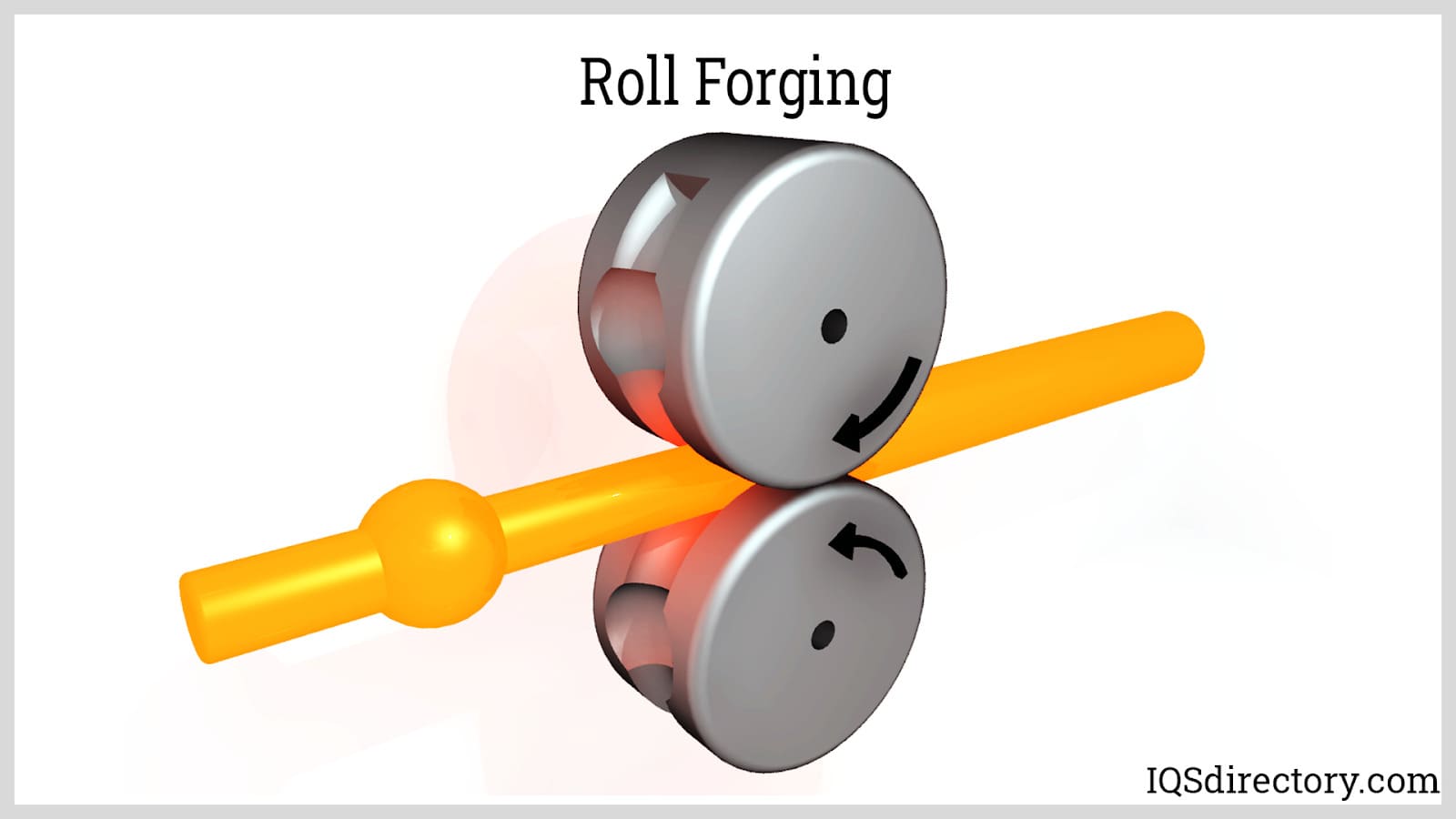

4.5Roll Forging

- Principle: Heated bars pass through grooved rolls to reduce thickness and elongate the workpiece. Multiple passes or roll changes achieve the final shape.

- Applications: Shafts, axles, springs, and tool blanks.

- Advantages: Flashless, uniform grain flow, suitable for continuous production of elongated components.

CNC Roll Forging Machines offer precise control of roll speed, gap, and billet rotation, ensuring dimensional consistency and repeatable grain flow.

4.6Ring Rolling

- Principle: Ring rolling produces seamless rings by compressing hollow billets between rolls. The inner diameter expands while wall thickness is controlled. Sizes range from small industrial rings to large wind turbine bases.

- Applications: Bearing races, flanges, large structural rings.

- Advantages & Limitations: High material efficiency, grain flow aligned circumferentially; requires preformed hollow billets.

Advanced CNC Ring Rolling Machines and Radial & Axial Ring Rolling Machines provide automated control over ring expansion, mandrel rotation, and wall thickness, allowing near-net-shape production of complex rings.

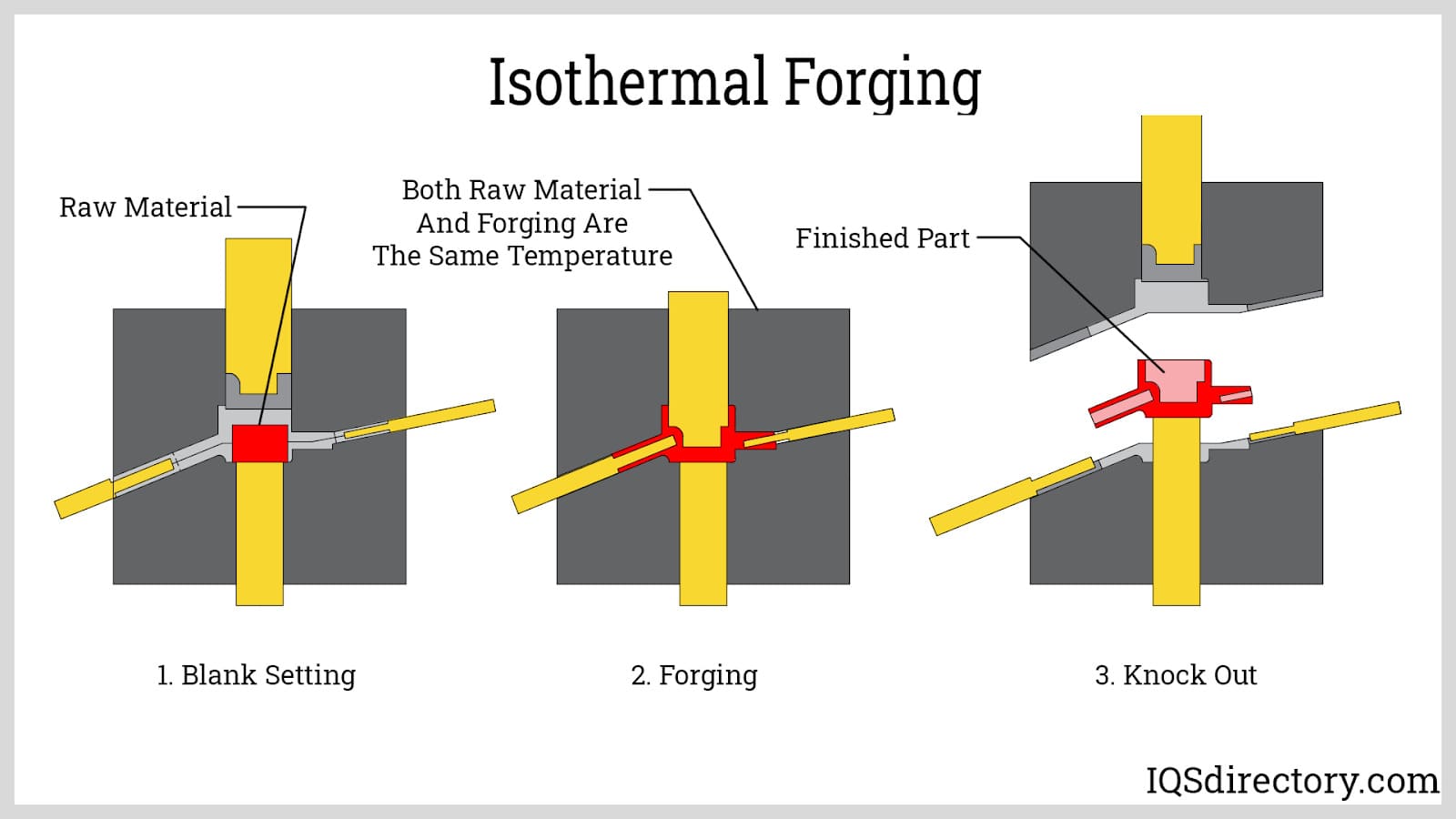

4.7Isothermal Forging

- Principle: Die and billet are maintained at nearly identical temperatures to reduce cracking and allow uniform deformation.

- Applications: Difficult-to-deform alloys, aerospace components like turbine blades.

- Advantages: Excellent microstructural control and reduced defect formation.

- Limitations: Specialized dies and precise temperature control are required; slower cycles than conventional hot forging.

4.8Induction Forging

- Principle: Electromagnetic induction rapidly and locally heats billets before forging, often combined with drop or press forging.

- Applications: Automotive and aerospace components requiring localized high-temperature deformation.

- Advantages: Efficient heating, reduced scale, consistent process; precise control over heated zones.

- Limitations: High equipment investment; limited by workpiece size and coil design.

5.0Auxiliary Processes in Forging

The final performance of a forged component depends not only on the forming operation itself but also on a series of auxiliary processes designed to optimize metallurgical quality. Key supporting techniques include annealing, tempering, and die lubrication:

Annealing:

- Purpose: Improve the ductility and machinability of the metal, relieve internal stresses generated during forging, and reduce hardness.

- Process: The forging is heated either above the recrystallization temperature (post-hot forging) or below it (pre-cold forging), held for a defined period, and then cooled in a controlled manner. Cooling rate adjustment is used to refine grain size, where fine grains improve toughness.

- Application:Post-hot forging annealing prevents cracking during subsequent machining, while pre-cold forging spheroidizing annealing refines pearlitic structures, improves ductility, and reduces forming loads.

Tempering:

- Purpose:Balance hardness and toughness of the forging, reduce brittleness after quenching, and stabilize dimensional accuracy.

- Process:The quenched forging is reheated to a temperature below the critical point (commonly 200–600 °C for steels), held for a specified duration, and then cooled. Hardness decreases and toughness increases with higher tempering temperatures.

- Application:Components subjected to impact or cyclic loading (e.g., crankshafts, gears) require tempering to achieve a combination of high strength and high toughness.

Die Lubrication:

- Function:Reduce friction between metal and dies, preventing surface defects or barrel-shaped deformation, while extending die life and facilitating proper metal flow into cavity details.

- Requirements:Hot forging requires high-temperature-resistant lubricants (e.g., graphite-based), whereas cold forging requires low-friction, easily removable lubricants (e.g., metallic soap-based).

6.0Selection of Metals for Forging

Almost all metals and alloys can be forged, but the choice of material depends on the intended application and performance requirements of the finished component. Common industrial metals and their characteristics are as follows:

| Metal / Alloy | Key Properties | Suitable Forging Processes | Typical Applications |

| Carbon and Alloy Steels | High strength, low cost, excellent hot forgeability, good heat-treatment response | Hot forging, warm forging | Automotive crankshafts, agricultural machinery parts, tools |

| Stainless Steel | Excellent corrosion resistance, high strength-to-weight ratio | Hot forging and warm forging are typical; cold forging is feasible for austenitic grades (e.g., 304/316), while martensitic or precipitation-hardening grades may require warm or hot forging | Chemical equipment components, aerospace fasteners |

| Aluminum and Aluminum Alloys | Low density, excellent ductility, outstanding cold forgeability | Cold forging, warm forging | Lightweight structural parts (e.g., automotive wheels, electronic housings) |

| Titanium and Titanium Alloys | High strength, excellent high-temperature and corrosion resistance, difficult to deform | Hot forging, isothermal forging | Aircraft engine blades, spacecraft supports |

| Copper and Brass | Excellent electrical conductivity, high ductility, smooth surface in cold forging | Cold forging, warm forging | Electrical connectors, valves, hardware components |

6.1Forgings vs. Other Manufacturing Processes

The advantages of forgings stem from solid-state plastic deformation and optimized grain structure. Their properties differ significantly from cast, welded, and machined products:

Forgings vs. Castings

| Dimension of Comparison | Forgings | Castings |

| Structural Integrity | Free of porosity and dendritic defects; grain flow follows part geometry; strength typically 20% higher than equivalent castings | Prone to gas porosity and shrinkage defects; random grain orientation; lower fatigue resistance |

| Tolerance and Complexity | Limited capability for thin walls or deep cavities; broader tolerances requiring machining | Capable of complex geometries with fine detail; often near-net-shape with minimal secondary machining |

| Material Utilization | Hot forging produces flash (10–20% material loss); cold forging/flashless forging achieves higher efficiency | Casting involves gates and risers (20–30% material loss), but near-net-shape capability is higher |

| Cost Considerations | High die cost; economical for high-volume production | Low mold cost (e.g., sand casting); more economical for low-volume runs |

Forgings vs. Welded Assemblies:

- Strength:Forgings are single-piece structures without weld seam defects (e.g., porosity, incomplete fusion), providing consistent impact and fatigue resistance. Welded assemblies have welds as “weak points” prone to crack initiation under stress concentration.

- Material Utilization:Forgings achieve shape through deformation with minimal scrap. Welded structures require cutting and assembling multiple pieces, leading to higher material loss.

- Production Efficiency:Forgings can be highly automated for mass production, while welded assemblies require manual or robotic welding, plus additional non-destructive testing (e.g., X-ray inspection), increasing process complexity.

Forgings vs. Machined Bar Stock:

- Grain Structure:In forgings, grain flow follows the part geometry, enhancing directional strength. Machining cuts through the grain, reducing fatigue resistance.

- Size Range:Forgings can produce components from under 1 inch to over 450 tons, whereas machining is limited by available stock sizes.

- Cost:Near-net-shape forgings reduce subsequent machining, lowering costs in mass production. Machining waste can reach 30–50% of the raw material.

7.0Common Forging Defects and Their Causes

Although forging is a mature and well-established process, defects may still occur due to design flaws, operational errors, or material-related issues. The major types of forging defects, their manifestations, and root causes are summarized as follows:

| Defect Type | Manifestation | Primary Causes |

| Voids | Internal cavities or unfilled regions within the metal | Uneven billet heating, improper die design restricting metal flow, gas entrapment |

| Cracks | Linear discontinuities on the surface or inside the forging | Insufficient temperature (poor ductility), excessive forming force, small die radii causing stress concentration |

| Laps | False seams caused by folding of the material onto itself | Inadequate material flow, improper die cavity design leading to metal backflow |

| Cold Shut (Laps/Seams) | Surface-fold defects creating weak zones | Low forging temperature (poor metal flow), inadequate die venting causing gas blockage |

| Excess Flash | Surplus material beyond the intended limits | Oversized billet, improper die closure clearance, insufficient pressure in closed-die forging |

| Surface Scratches | Irregular surface marks or indentations | Worn die surfaces, inadequate lubrication, insufficient descaling of billet causing oxide scale to embed |

| Poor Grain Structure | Coarse or uneven grain distribution | Overheating leading to grain growth, insufficient deformation causing incomplete recrystallization, uncontrolled cooling rates |

7.1Core Forging Equipment

The selection of forging equipment depends on the process type and the size of the component. Key machinery and their functions include:

- Forging Furnace: Provides the required forging temperature. Modern systems primarily use gas or electric heating. Induction furnaces, applied in automated hot forging or induction forging, enable rapid and localized heating.

- Power Hammer: The primary equipment for drop forging. Classified by power source into steam hammers, hydraulic hammers, and electric hammers. Ram weights range from about 230 kg (small-scale) to several tons (large-scale), delivering high-impact deformation force

- Press Machine: Industrial presses range from a few tons to several thousand tons; extremely large presses may reach tens of thousands of tons, but these are rare.

- Upsetting Machine: Specialized horizontal or vertical presses designed for upsetting operations. Equipped with multi-cavity split dies, these machines allow automatic workpiece transfer and continuous forming.

- Ring Rolling Mill: Dedicated equipment for ring forging, consisting of a drive roll, mandrel roll, and guide rolls. The inner diameter, outer diameter, and height of the ring are controlled by adjusting the spacing between the rolls.

- Roll Forging Machine: Comprising one or more pairs of grooved rolls. Metal is deformed by rotation of the rolls, making the system suitable for continuous forging of elongated components such as bars or shafts.

8.0Frequently Asked Questions (FAQ)

Q1: What is the main difference between drop forging and press forging?

A: Drop forging uses a hammer to apply instantaneous impact, making it suitable for small-to-medium parts with strong directional grain flow. Press forging applies slow, continuous pressure, providing uniform deformation and better control over large or complex components.

Q2: Which machines are used for high-precision shaft production?

A: Shafts and elongated components often use CNC Roll Forging Machines for precise dimensional control and consistent grain flow. For tapered or stepped shafts, a Cross Wedge Rolling Machine can preform the bar with minimal material waste before final forging.

Q3: How are seamless rings produced and which machines are used?

A: Seamless rings are produced by expanding hollow billets between rotating rolls. Small-to-medium rings typically use a CNC Ring Rolling Machine, while large rings requiring control of both diameter and height use Radial & Axial Ring Rolling Machines.

Q4: Which materials are suitable for these forging processes?

A: Common metals include carbon and alloy steels, stainless steel, aluminum, copper, and high-performance alloys such as titanium. The choice depends on part size, required mechanical properties, and compatibility with the forging process (hot, warm, or cold).

Q5: What is the difference between a CNC Roll Forging Machine and a traditional roll forging setup?

A: A CNC Roll Forging Machine offers precise control over roll speed, gap, and billet rotation, ensuring consistent dimensional accuracy and repeatable grain flow. Traditional roll forging often relies on manual adjustments and operator experience, making high-volume, high-precision production more challenging.

References

https://en.wikipedia.org/wiki/Forging

https://www.tfgusa.com/resources/metal-forging-processes-methods/

https://www.iqsdirectory.com/articles/forging.html

https://www.compass-anvil.com/forging-vs-casting