1.0Background and Key Challenges

In hot forging production, tooling cost is a critical factor — it can account for up to 15% of the forging price. For many forging companies, tools are considered “consumables,” and frequent replacement significantly increases overall costs.

From a manufacturing perspective, tool production has long relied on EDM (Electrical Discharge Machining). More recently, high-speed cutting has become more common. While these machines can process materials with hardness up to 1600 MPa, they fail to address the fundamental issue: tool steels lose most of their mechanical strength at 700°C.

Previous attempts have focused on welding harder materials onto tool surfaces. However, these methods have not provided practical solutions. To overcome this limitation, a new approach based on explosion welding is proposed to advance forging tool technology.

2.0Drop Forging: Process and Tool Wear Issues

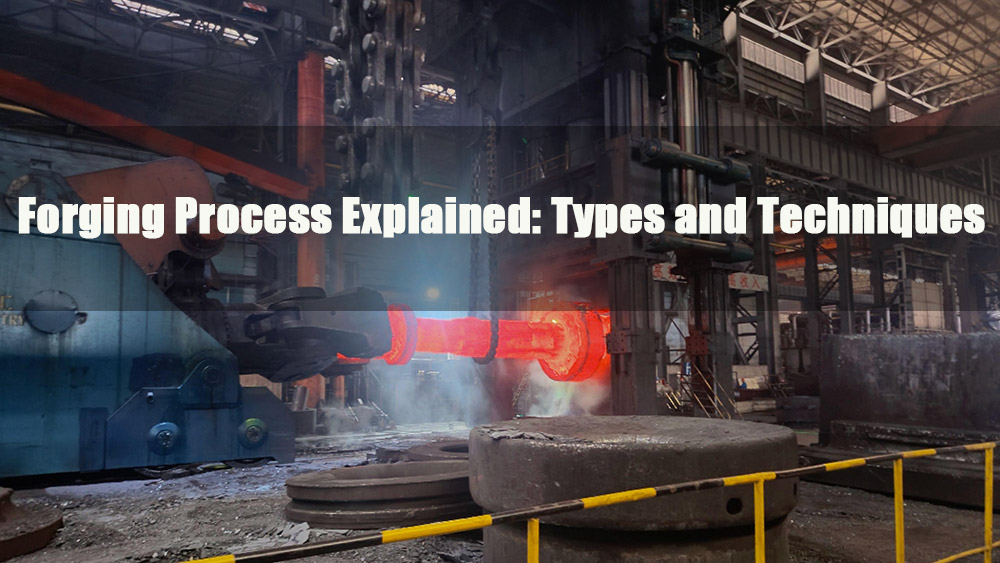

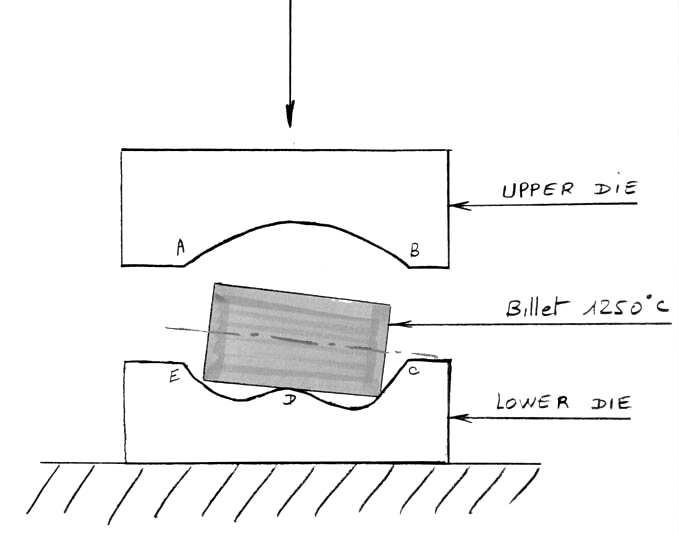

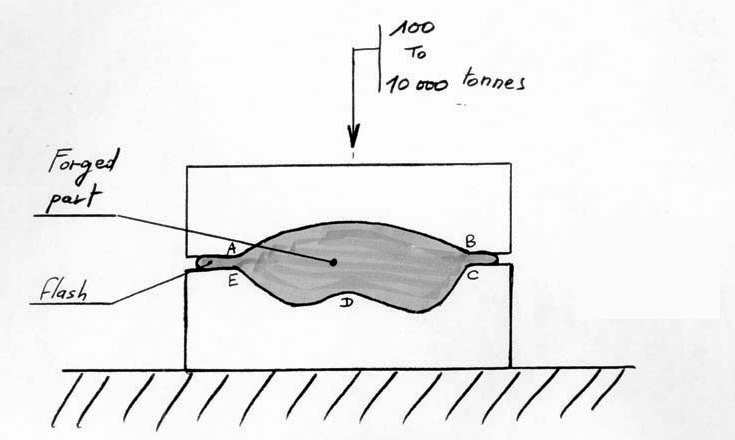

Drop forging process:

- The billet is heated to 1250°Cand placed into the lower die.

- The upper die applies force, shaping the billet into the required geometry within the cavity.

- Excess material forms flash, which is trimmed after forging.

Key causes of tool wear:

During forging, tool regions (A, B, C, D, E) are exposed to three combined stresses:

- Thermal stress: Direct contact with billets at 1250°C.

- Chemical stress: Material reactions at elevated temperatures.

- Mechanical stress: High pressure from the upper die.

A critical limitation is the performance of Z38 CDV 5 steel (a commonly used hot-work tool steel). After heat treatment, it loses much of its strength at ~600°C. In actual production, surface temperatures frequently reach 600–700°C, which falls exactly within the tool steel’s “failure zone.”

Additionally, conventional tool manufacturing requires machining the full cavity into a solid steel block (before or after heat treatment). This monolithic process is extremely costly, further amplifying the economic burden.

3.0Existing Approach: Limitations of High-Temperature Alloy Welding

To mitigate tool wear, the industry has investigated high-temperature alloy cladding, aiming to create a protective surface layer that can withstand 600–700°C. Nickel- or cobalt-based alloys are typically used. Two main welding methods are applied:

- Arc welding: Alloy rods or wires are deposited onto the tool surface.

- Laser or gas welding: Alloy powders are melted and fused with the substrate.

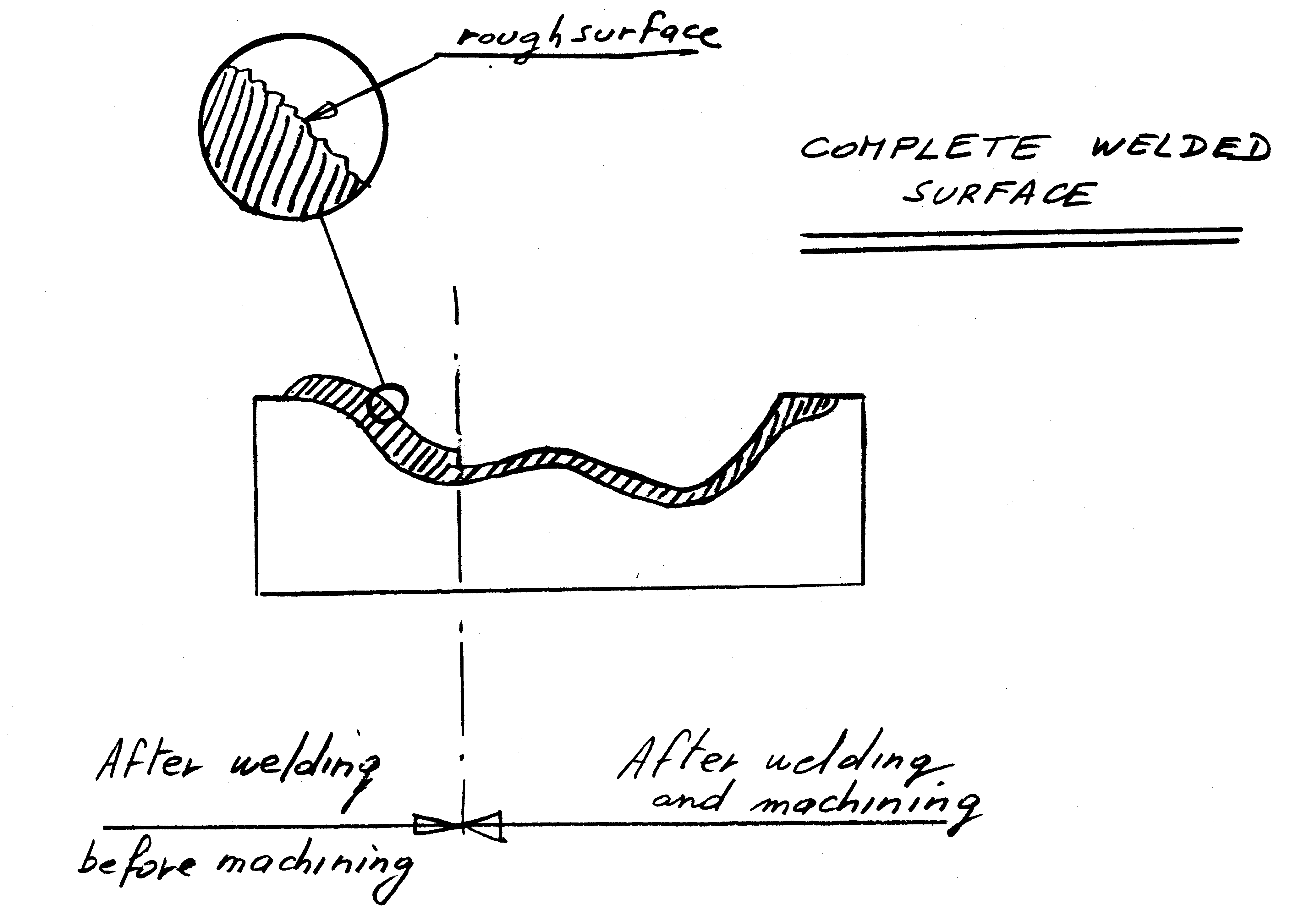

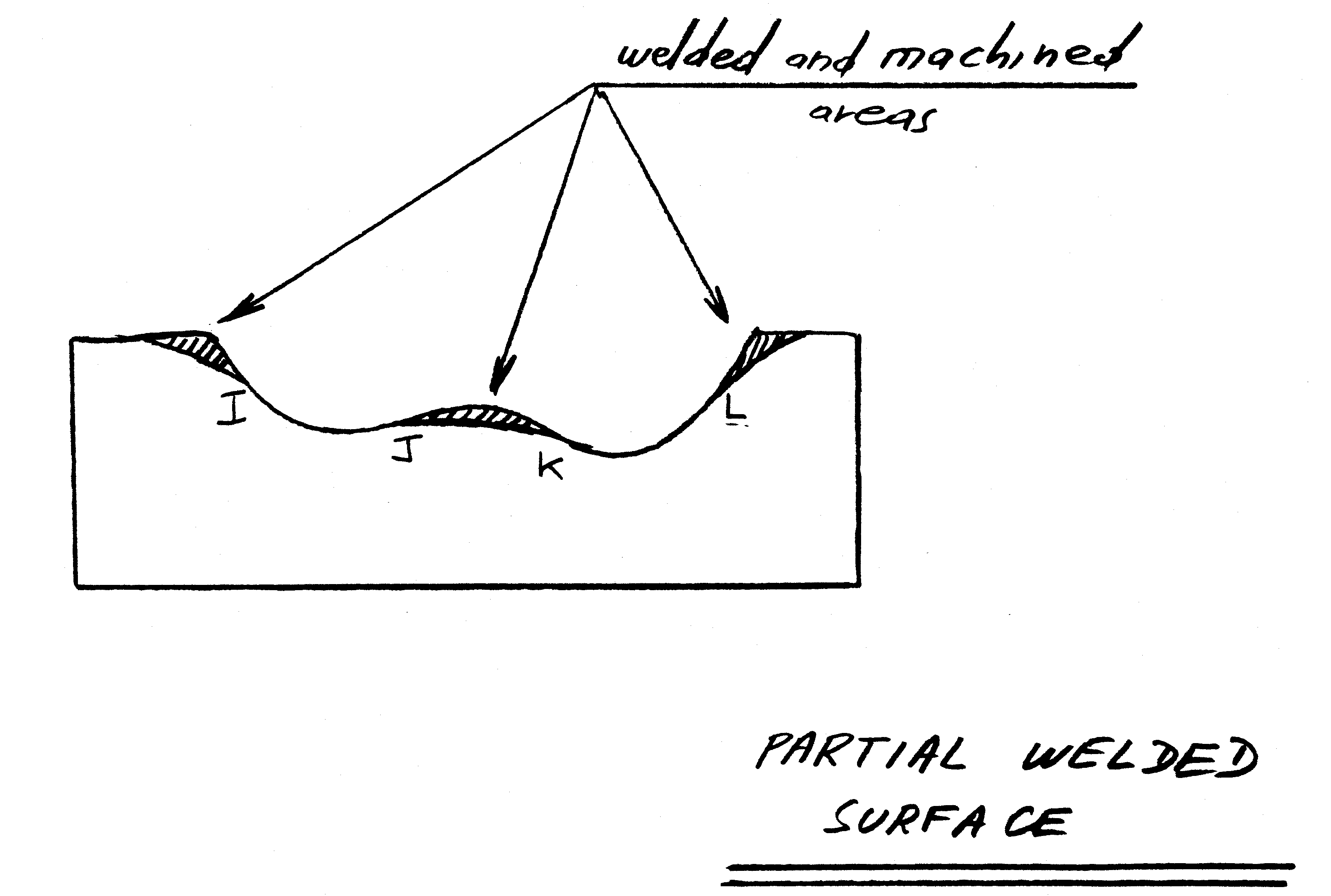

Surface coverage can be applied in two ways:

- Full-surface cladding: Coating the entire cavity.

- Localized cladding: Targeting high-wear zones.

However, this method faces two critical drawbacks:

- High post-processing cost: Welded layers are rough and inhomogeneous, requiring extensive machining to meet precision standards. This is costly and technically challenging.

- Tool steel degradation: The welding process heats the substrate, reducing its mechanical strength and accelerating wear in surrounding regions (I, J, K, L).

- Core Technology: Principles and Advantages of Explosion Welding

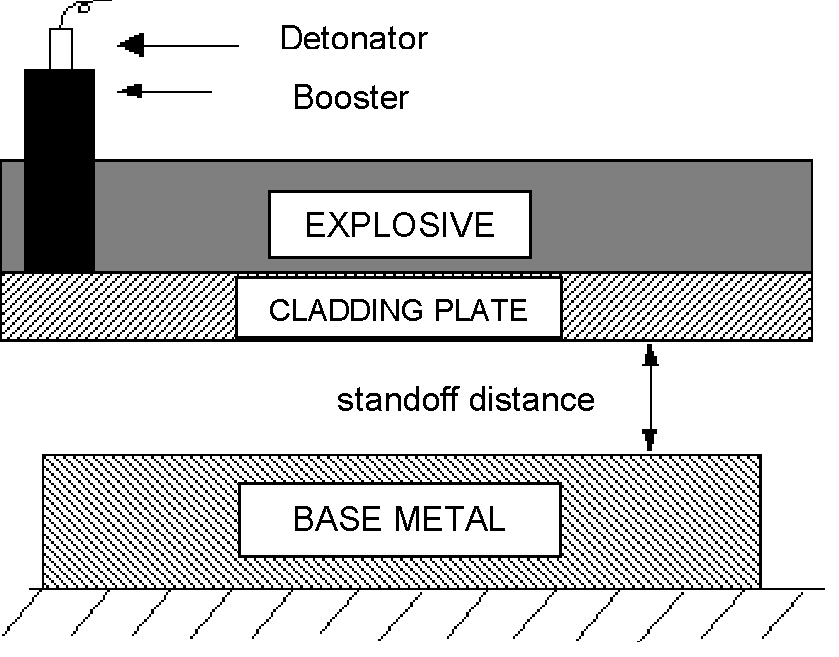

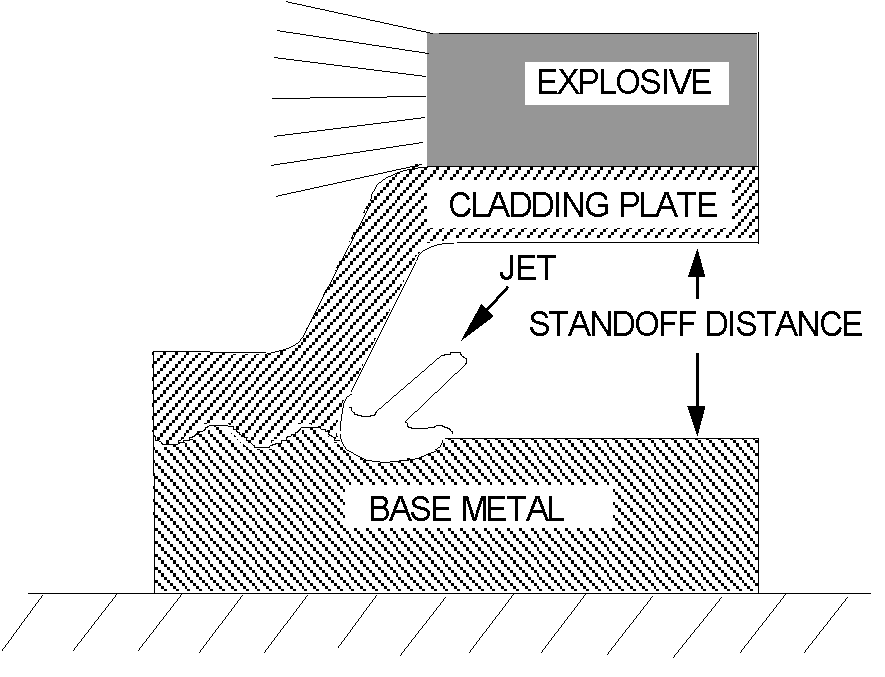

Basic principle:

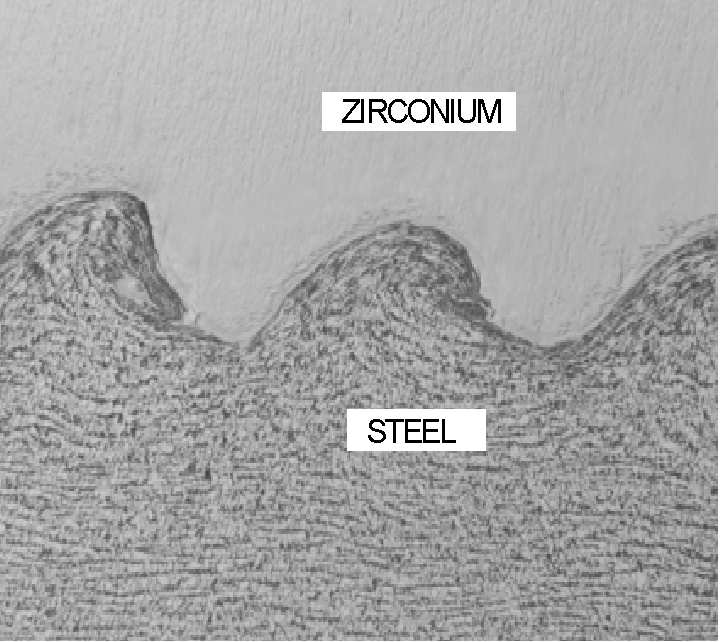

Explosion welding (also known as cladding technology) is a solid-state bonding process that does not require heating. The method involves propelling a cladding plate (e.g., high-temperature alloy) onto a base plate (e.g., tool steel) using explosive energy. Under high-velocity impact, the metals bond at the atomic level.

Throughout the process, neither the base material nor the cladding layer is heated. As long as the cladding material has low yield strength and high ductility, a wide range of metal combinations can be joined.

Application background:

Explosion welding has been widely used in industries such as chemical processing and shipbuilding. Its advantages — large bonding area, high strength, and no heat damage — make it highly promising for hot forging tool applications.

4.0Implementation: Manufacturing Forging Tools with Explosion-Welded Bimetals

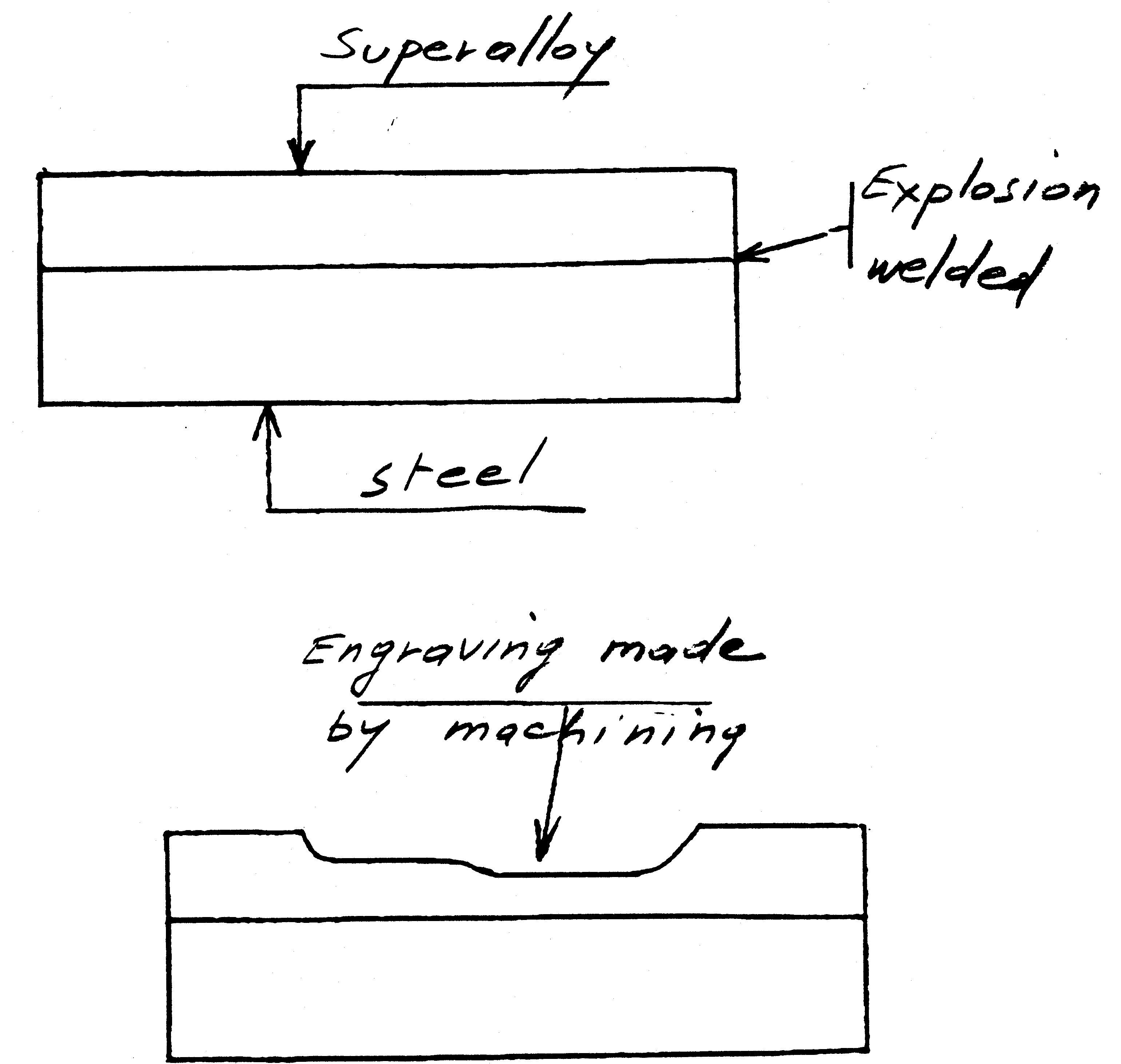

The new solution consists of two main stages: bimetal plate preparation and cavity machining.

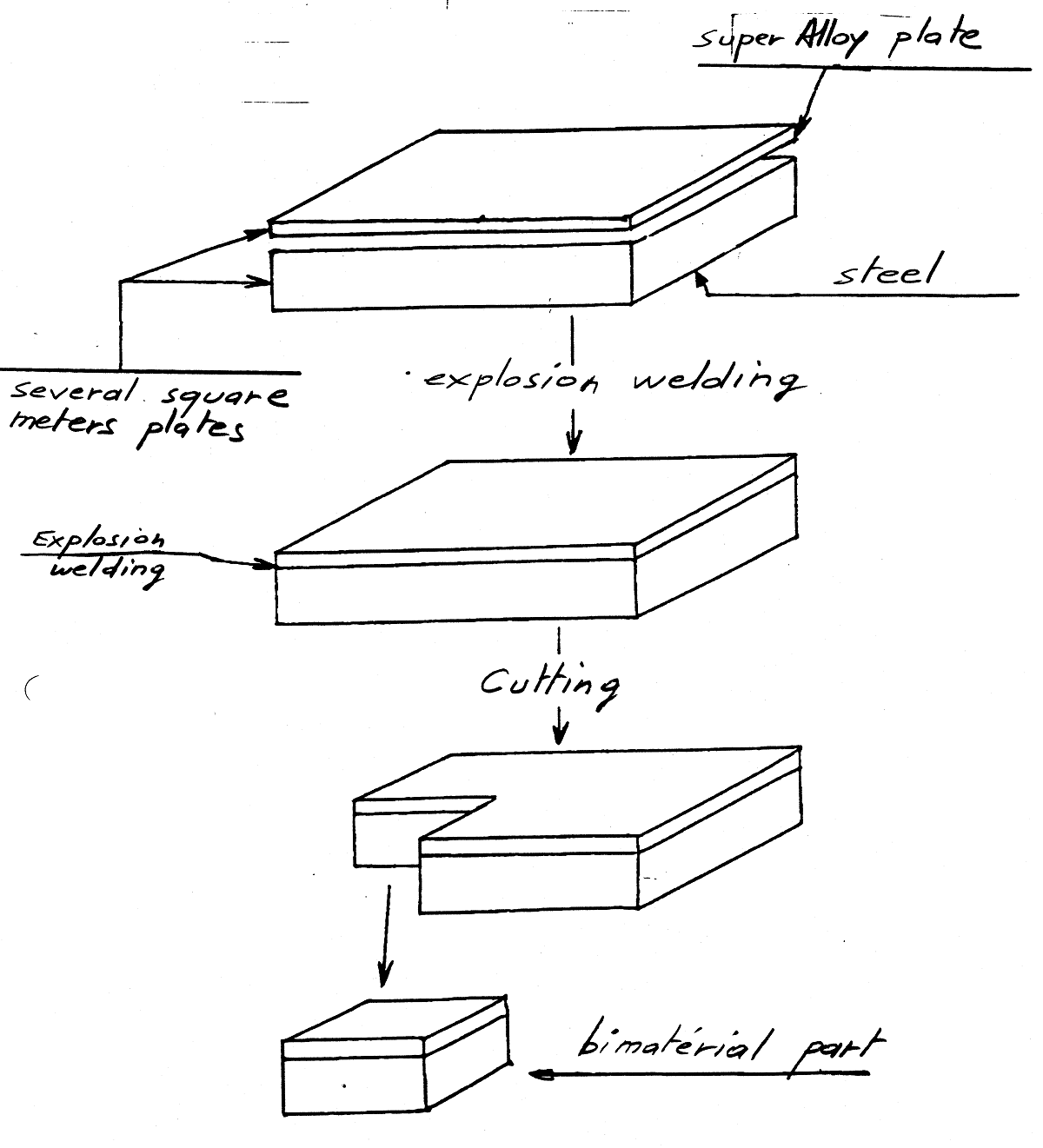

Stage 1: Preparing bimetal plates

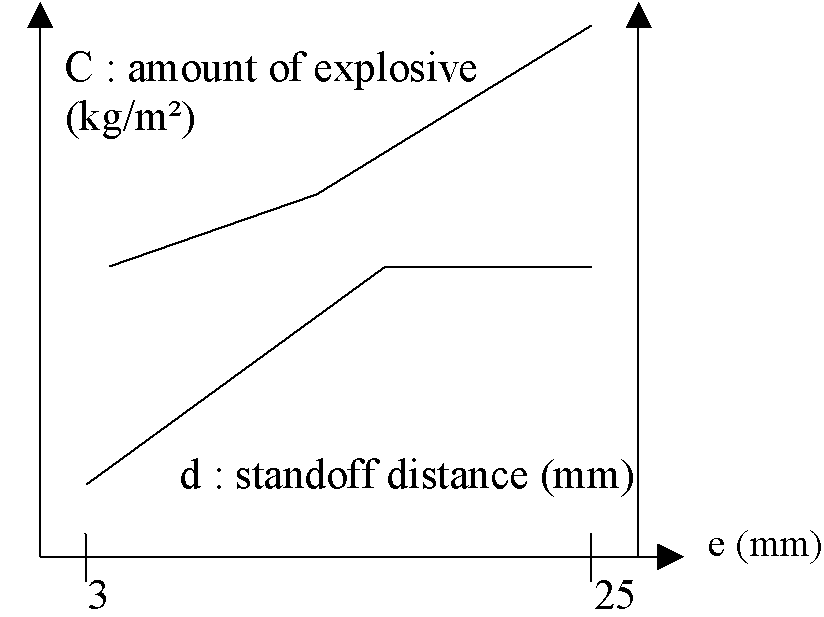

Large plates (up to several square meters) are bonded using explosion welding:

Backing plate: Tool steel selected to provide structural strength.

Cladding plate: A high-temperature alloy, several millimeters to centimeters thick, providing wear and heat resistance.

Stage 2: Machining tool cavities

Step 1: Cutting billets

Bimetal plates are cut into smaller billets according to tool dimensions (typically a few square decimeters).

Note: While smaller plates can be directly explosion-welded, large-plate cutting is more cost-efficient.

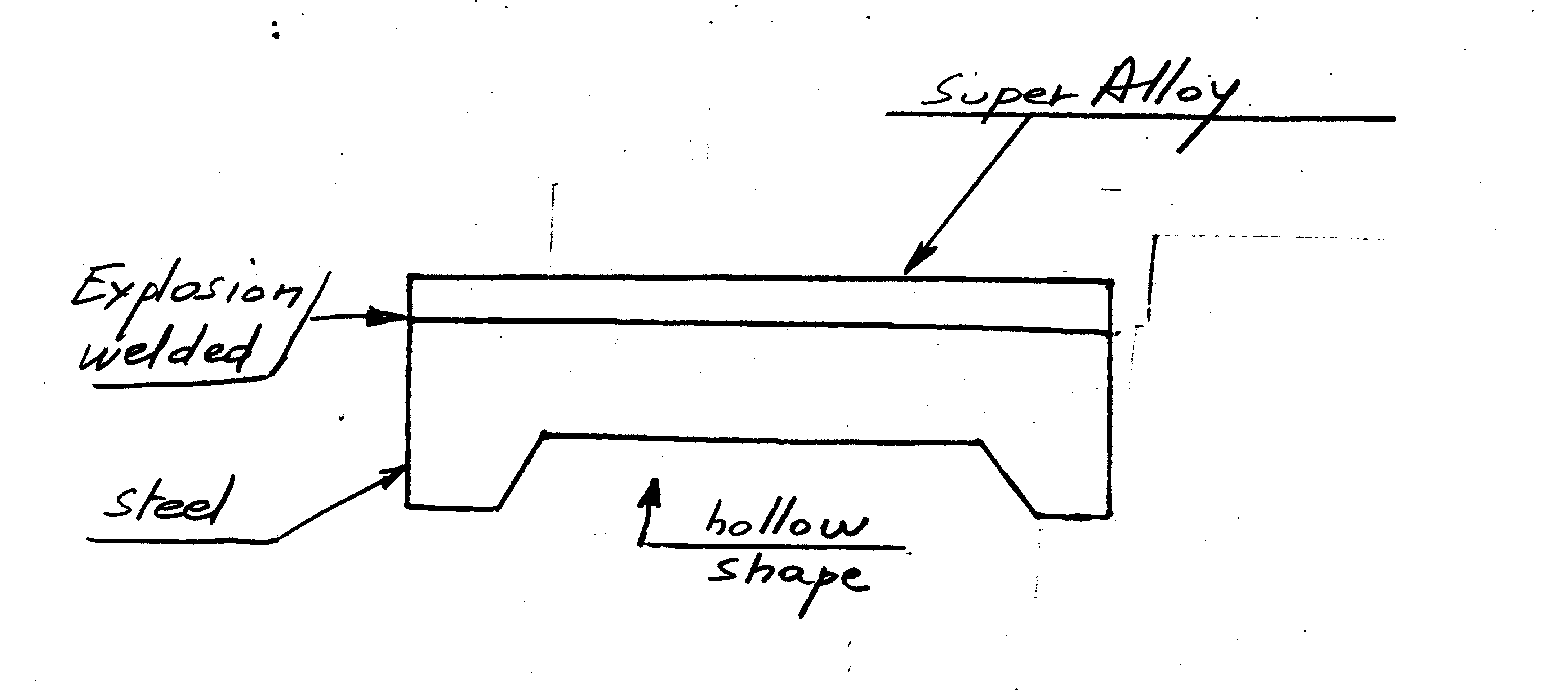

Step 2: Pre-machining recesses (optional)

A simple recess may be pre-machined into the tool steel side to control deformation during forging and reduce forming forces. This recess may partially disappear during forging and is not always required.

Special case: For large tools requiring significant forming forces, a thinner cladding configuration may be applied.

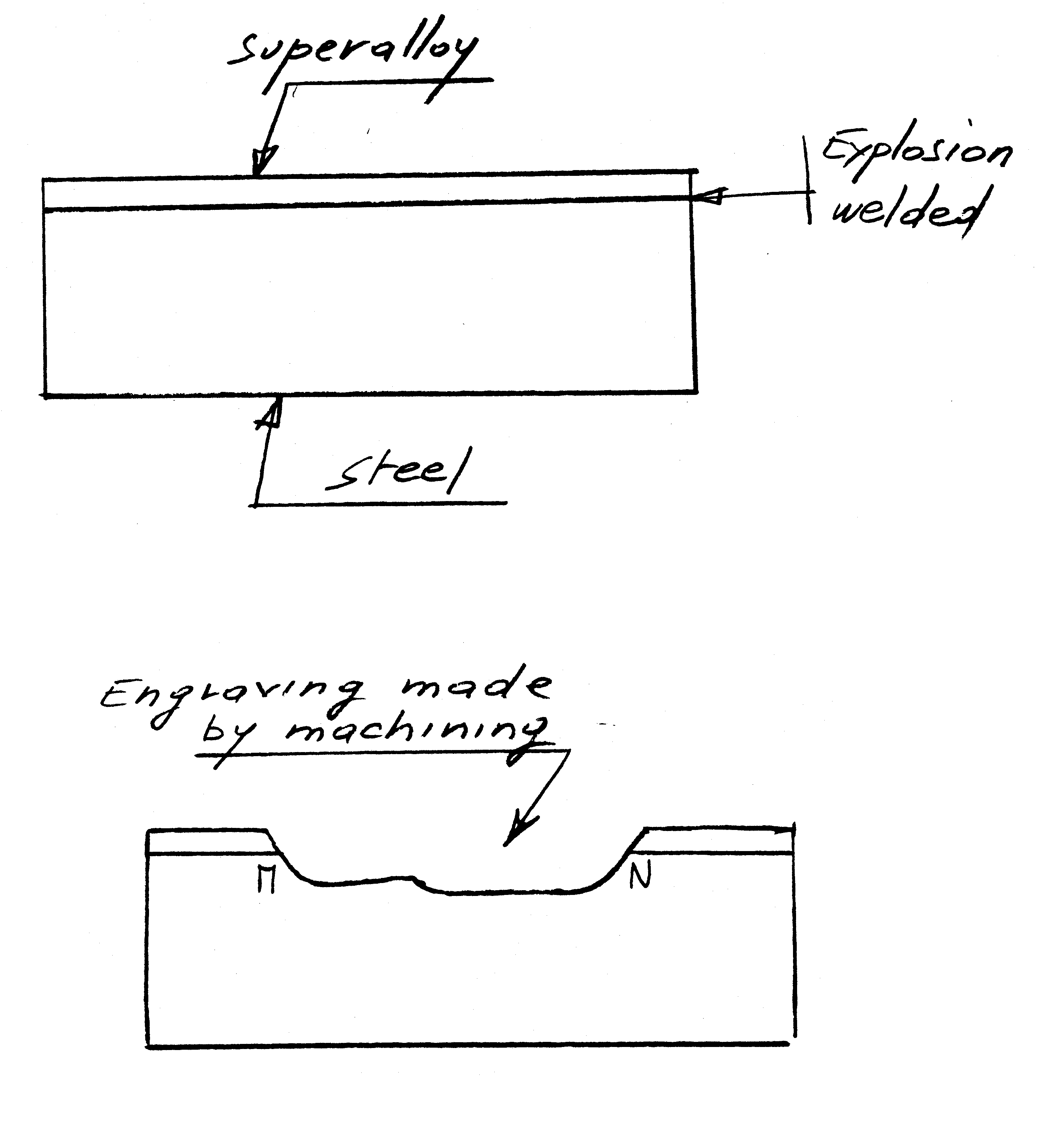

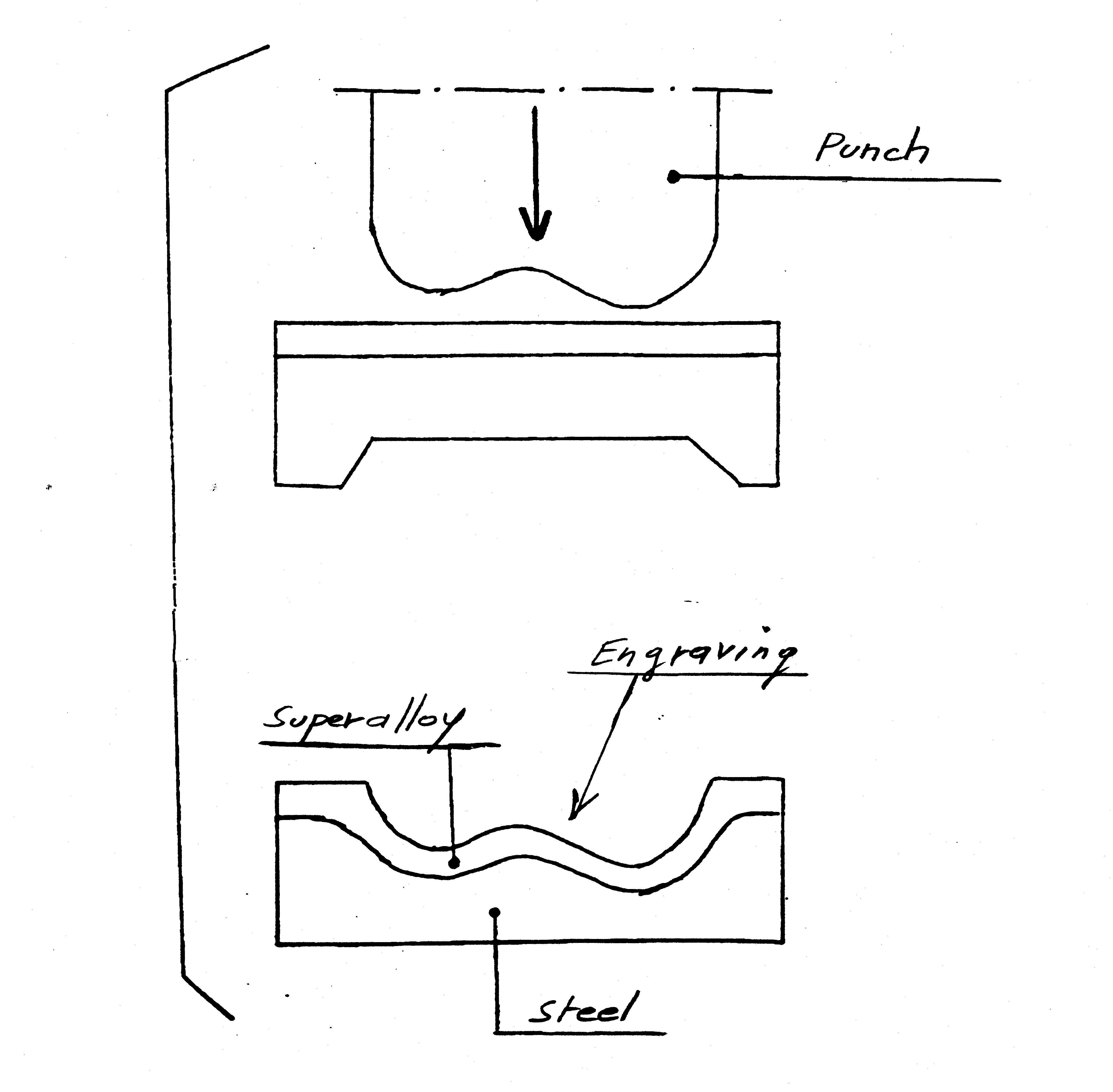

Step 3: Forging and finishing cavities

The bimetal billet (with or without recess) is heated to the desired temperature (cold, warm, or hot forging).

A punch with the required geometry is pressed from the cladding side to the target depth.

For precision requirements, the cavity can be further machined or polished. For shallow cavities, direct machining in the cladding layer is also possible.

Post-processing:

Depending on the properties of the alloy and tool steel, the forged tool undergoes specific heat treatment. External surfaces that connect to forging equipment are machined as needed to ensure proper installation.

5.0Key Advantages of the New Solution

- Significantly Extended Tool Life:

Tests show that explosion-welded bimetal tools can achieve 3–4 times the lifespanof conventional tools, greatly reducing replacement frequency. - Reduced Manufacturing Costs:

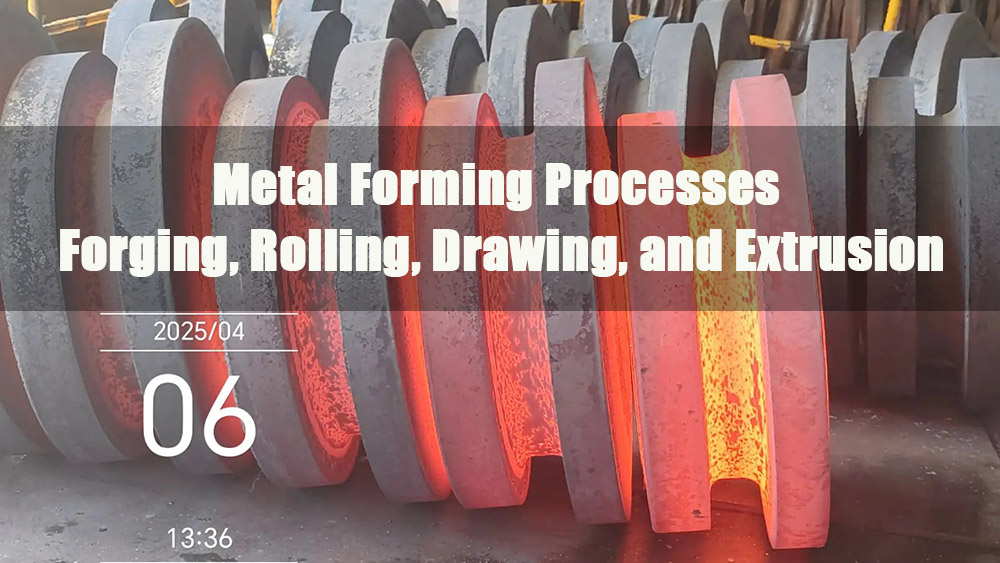

In traditional tools, costs are typically distributed as: 25% material, 65% machining, 10% heat treatment. With the new solution:

Material cost: Remains largely unchanged. The additional expense of high-temperature alloys and explosion welding can be offset by selecting more economical base steel.

Machining cost: Significantly reduced. Full-block cavity machining is avoided, simplifying com.

- Enhanced Competitiveness of Forgings:

Tooling costs typically account for 5–15% of forging price, depending on equipment type, tool geometry, and lubrication conditions. Adopting this new solution can reduce forging prices by 4% for drop forging and up to 10% for press forging.