- 1.0Comprensión de la capacidad de corte según los estándares de acero dulce

- 2.0Factores clave que influyen en la fuerza de corte

- 3.0El papel del ángulo de ataque en el corte de metales

- 4.0Cómo las propiedades del material afectan el rendimiento al corte

- 5.0Fuerza de corte y espesor del metal: ¿cuál es la relación?

- 6.0Espesor mínimo cortable por tipo de máquina

- 7.0Por qué es importante la holgura de la cuchilla al cortar chapa metálica

- 8.0Tipos de cuchillas de corte y sus aplicaciones

- 9.0Aspectos esenciales del desgaste, la inspección y el mantenimiento de los cuchillos

- 10.0Comprensión del endurecimiento por trabajo en el corte de metales

- 11.0Efectos del endurecimiento del trabajo

- 12.0Prácticas a evitar

- 13.0Capacidad de corte vs. Capacidad de cuchilla: ¿Cuál es la diferencia?

- 14.0Tabla de referencia de capacidad de corte general (extracto)

- 15.0Tabla de referencia de capacidad de corte de acero

- 16.0Características de corte opcionales que mejoran la precisión del corte

- 17.0Resumen final: Mejores prácticas para un corte seguro y eficiente

Industrial Cizallas de chapa Son esenciales para el corte de precisión de chapa metálica y placas. Para garantizar un rendimiento óptimo y una operación segura, es fundamental comprender cómo se clasifica la capacidad de corte y qué factores influyen en la eficiencia de corte. Esta guía ofrece una visión general completa de los fundamentos de la fuerza de corte, el ángulo de ataque, la selección de cuchillas, las propiedades de los materiales y las mejores prácticas de mantenimiento.

1.0Comprensión de la capacidad de corte según los estándares de acero dulce

Las capacidades de corte se basan generalmente en el espesor máximo de corte del acero dulce bajo un ángulo de ataque específico. Las propiedades mecánicas estándar del acero dulce incluyen:

| Propiedad | Valor |

| Resistencia máxima al corte | 50.000 psi |

| Resistencia máxima a la tracción (UTS) | 55.000–70.000 psi |

| Límite elástico (YS) | 35.000–50.000 psi |

| Alargamiento (en 2″) | 20–35% |

Nota: Las clasificaciones incluyen tolerancias para sobretolerancias de espesor comunes. Por ejemplo, una placa de 0,250″ puede tener hasta 0,030″ más de espesor y aun así cumplir con la capacidad nominal.

2.0Factores clave que influyen en la fuerza de corte

La fuerza de corte debe superar la fuerza necesaria para cortar el material deseado. Los principales factores que influyen son:

- Resistencia al corte del material

- Ángulo de ataque y espesor del material

- Ductilidad y endurecimiento por deformación

- Estado y espacio libre del cuchillo

- Sistemas de soporte y profundidad de la pieza trasera

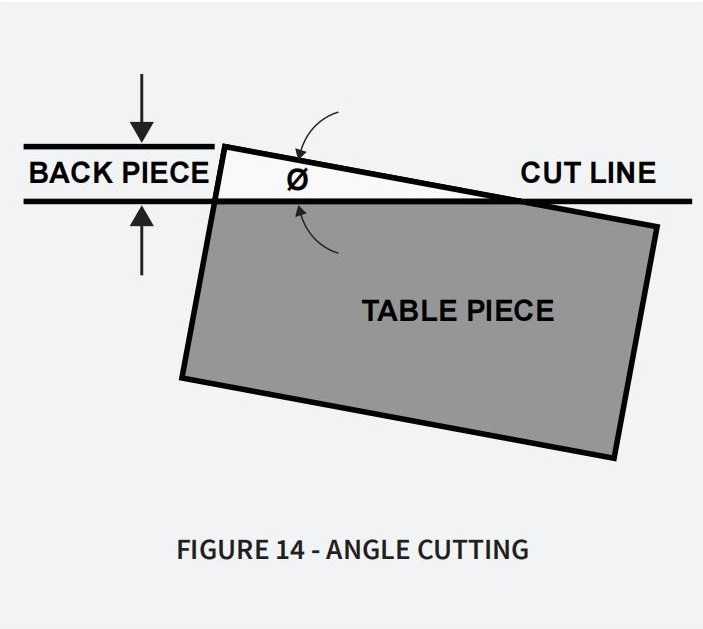

3.0El papel del ángulo de ataque en el corte de metales

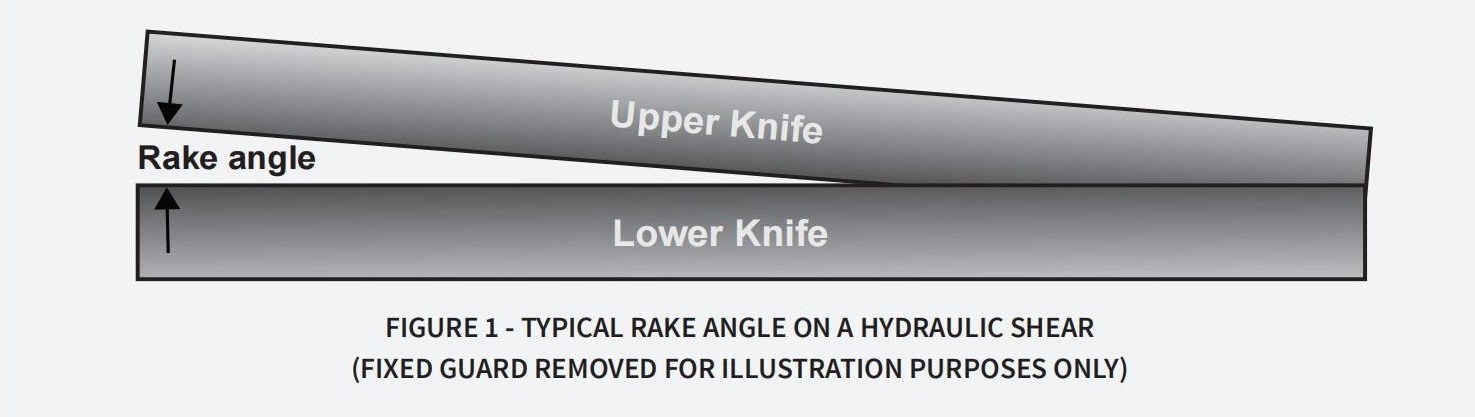

Ángulo de inclinación Es la inclinación entre las cuchillas superior e inferior. Afecta considerablemente la fuerza de corte y el comportamiento del material durante el corte.

- A rastrillo más grande ángulo reduce la fuerza requerida

- Un rastrillo excesivo puede provocar la distorsión de la pieza o un recorrido de cuchilla más largo.

3.1Ángulo de ataque en la práctica: reducción de fuerza e impacto en la calidad:

Si R₂ = 2R₁ → entonces Fuerza₂ = ½ Fuerza₁

Práctica recomendada: Utilice el ángulo de ataque mínimo que proporcione una calidad de corte aceptable sin exceder los límites de la máquina. Los ángulos de ataque más altos son especialmente beneficiosos para el acero inoxidable y los materiales de alta ductilidad.

4.0Cómo las propiedades del material afectan el rendimiento al corte

4.1Resistencia del material y su efecto sobre la capacidad de corte

Los materiales más resistentes que el acero dulce (UTS/YS más altos) requieren capacidad reducida.

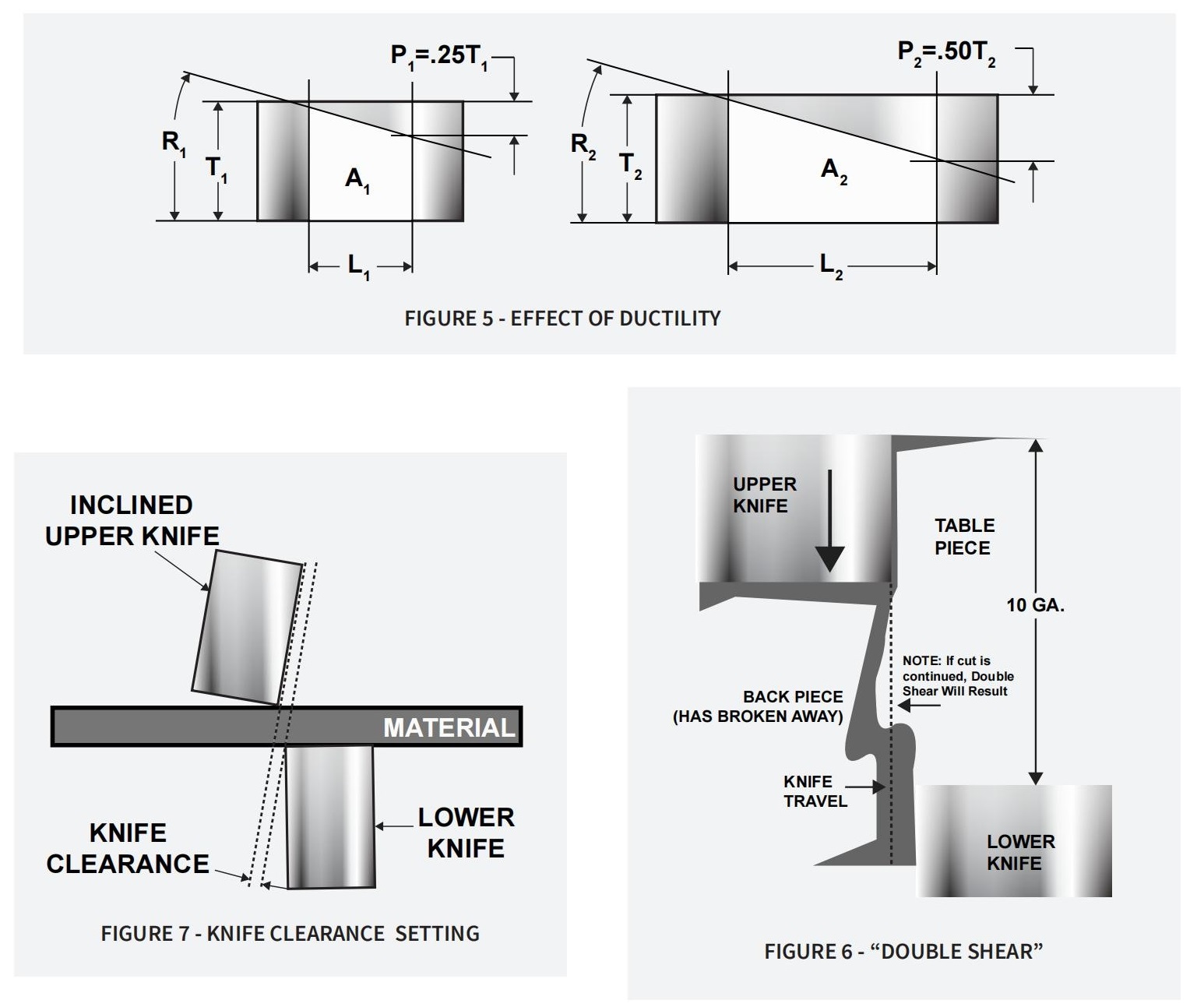

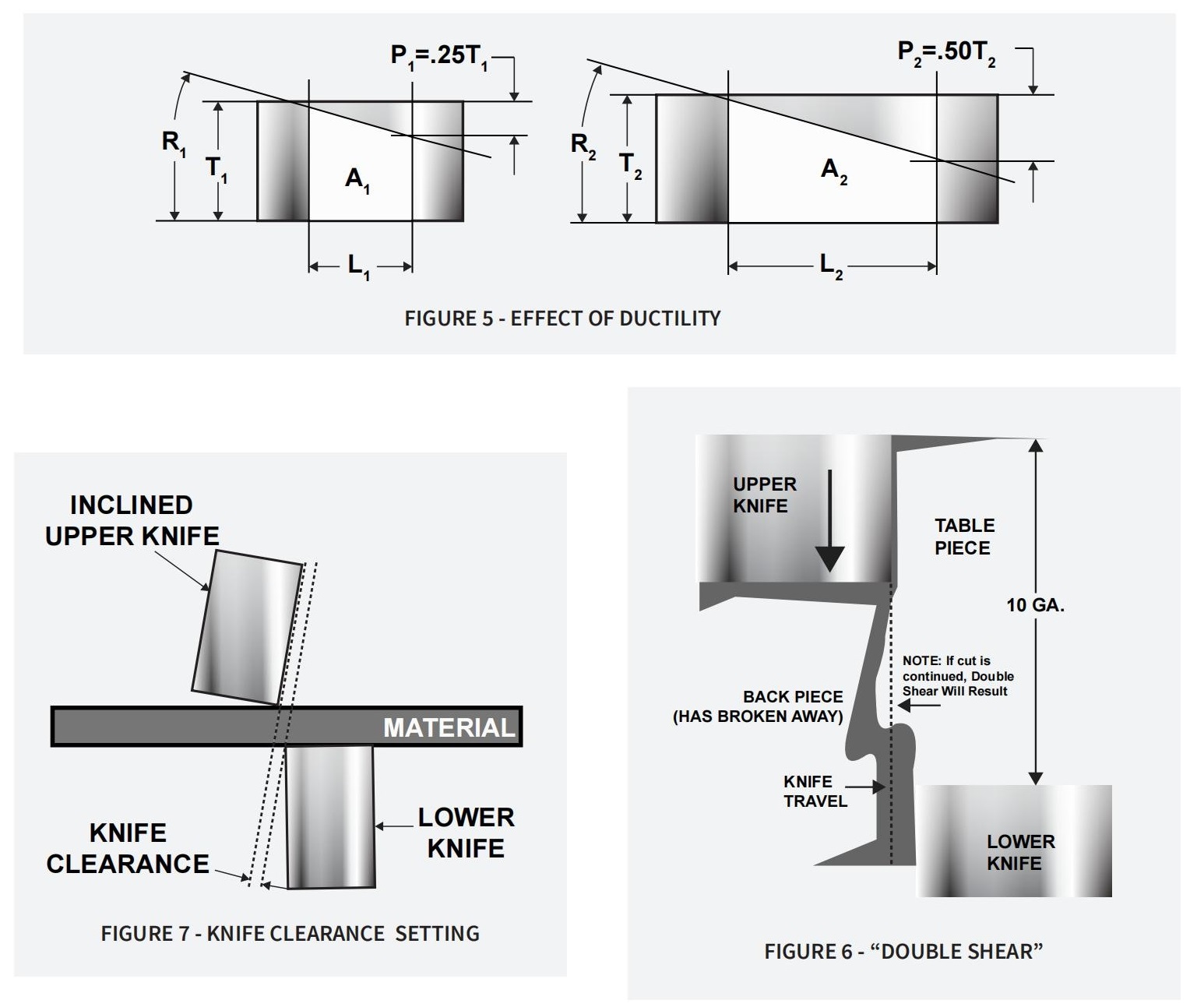

4.2Ductilidad y penetración de cuchillas en el corte de chapa metálica

Los materiales con un alargamiento superior a 35% reducen el rendimiento de corte debido a una penetración más profunda de la cuchilla.

Los ejemplos incluyen:

- Aceros al carbono 1006, 1008 y, a veces, 1010/1012

- ASTM A283 Grado A, A285 Grado A, A570 Grado 30 (cuando el alargamiento excede 35%)

5.0Fuerza de corte y espesor del metal: ¿cuál es la relación?

La fuerza de corte aumenta cuadráticamente con el espesor:

Fuerza ∝ Espesor²

→ Si T₂ = 2T₁ → Fuerza₂ = 4 × Fuerza₁

6.0Espesor mínimo cortable por tipo de máquina

Los límites mínimos dependen de la distancia entre cuchillas y el filo. Ejemplos:

| Modelo | Indicador | Pulgada | mm |

| 375 HS | 26 GA | 0.018″ | 0.45 |

| 500 HS | 22 GA | 0.030″ | 0.76 |

| 750 HS | 20 GA | 0.036″ | 0.91 |

| Serie SE | 16 GA | 0.060″ | 1.52 |

7.0Por qué es importante la holgura de la cuchilla al cortar chapa metálica

La distancia adecuada entre los cuchillos garantiza cortes limpios y consistentes.

- Muy poco:Doble cizallamiento, rebabas, desgaste rápido

- Demasiado:Cortes imprecisos, pliegues

7.1Ajustes de espacio libre de cuchillas recomendados según el tipo de cizalla:

- Tijeras mecánicas: 7%del espesor del material

- Cizallas hidráulicas: 7–15%, ajustable con calzas de mesa

Para el acero inoxidable, mantenga un espacio libre mínimo para evitar rebabas y endurecimiento por trabajo.

8.0Tipos de cuchillas de corte y sus aplicaciones

Cómo elegir el material de cuchilla adecuado resistencia al desgaste y resistencia a los golpes.

| Tipo | Resistencia al desgaste | Resistencia a los golpes | Uso ideal |

| A | Más alto | Más bajo | Acero inoxidable/dulce fino |

| B | Alto | Bajo | Acero inoxidable ligero o aluminio |

| do | Medio | Medio | Corte de uso general |

| D | Bajo | Alto | Aplicaciones de alto impacto |

| mi | Más bajo | Más alto | Materiales abrasivos, frágiles o de alto impacto |

| S | Moderado | Muy alto | Acero inoxidable, Inconel, Hastelloy, aleaciones dúctiles |

Para cortes frecuentes de acero inoxidable (especialmente uso >50%), se recomienda el tipo S.

Para acero inoxidable de calibre ligero (≤10 GA), el tipo A puede ser suficiente.

9.0Aspectos esenciales del desgaste, la inspección y el mantenimiento de los cuchillos

Los cuchillos desafilados o dañados aumentan la fuerza de corte y pueden dañar las máquinas.

9.1Indicadores comunes de desgaste de cuchillos

- Utilización de tazas

- Zonas brillantes (indican doble cizallamiento)

- Mal acabado del borde

9.2Factores que aceleran el desgaste del cuchillo:

- Materiales cortados con llama o endurecidos

- Láminas estampadas (por ejemplo, placa de estribo)

- Despeje inadecuado

- Materiales de corte >300 BHN

9.3El impacto de la profundidad de la pieza posterior en la fuerza de corte:

- Gire y afile los cuchillos periódicamente

- Monitorizar el desgaste cerca de los brazos cuadrados

- Evite cortar placas AR >360 BHN

10.0Comprensión del endurecimiento por trabajo en el corte de metales

La profundidad de la pieza posterior es la distancia desde la hoja hasta el borde posterior del material:

- Mayor profundidad → mayor fuerza requerida

- Utilice mesas neumáticas o brazos de esquina para soportar materiales pesados o dúctiles.

11.0Efectos del endurecimiento del trabajo

Los materiales que se endurecen por deformación, como el acero inoxidable y las aleaciones de níquel, requieren mayor fuerza para cortarlos debido a la mayor dureza superficial. Para mitigar este problema, utilice cuchillas con alta resistencia a los impactos y una inclinación adecuada.

12.0Prácticas a evitar

| Práctica | Riesgo |

| Cortes de recorte < 0,125″ | Aumento de la carga, atrapamiento de material |

| Gran espacio libre para cuchillos en láminas delgadas | Limpiar en lugar de hacer cortes limpios |

| Corte multicapa | Mala calidad de corte, sobrecarga de la máquina. |

| Cortes en ángulo < 20° | Astillas, falla por corte |

13.0Capacidad de corte vs. Capacidad de cuchilla: ¿Cuál es la diferencia?

Comprender esta distinción previene fallos prematuros:

| Parámetro | Gobierna | Depende de |

| Capacidad de corte | Máquina | Espesor² × Resistencia al corte × Ángulo de ataque |

| Capacidad del cuchillo | Material del cuchillo | Espesor × Resistencia al corte (independiente del ángulo de ataque) |

Los modelos hidráulicos suelen contar con protección contra sobrecargas. Sin embargo, el bloqueo aumenta el desgaste de las cuchillas.

14.0Tabla de referencia de capacidad de corte general (extracto)

| Grado ASTM | Resistencia a la tracción (ksi) | Límite elástico (ksi) | Alargamiento mínimo (% en 2″) | Espesor nominal del acero dulce | Capacidad máxima equivalente (pulgadas) |

|---|---|---|---|---|---|

| A36 | 58–80 | 36–51 | 23 | 0,188″ (aprox. calibre 7) | 0.250 / 0.375 / 0.500 / 0.625 / 0.750 |

| A514 | 110–130 | ≥110 | 18 | 0,188″ (aprox. calibre 7) | 0.281 / 0.375 / 0.500 / 0.625 / 0.750 |

| A572 Grado 50 | ≥65 | ≥50 | 21 | 0,188″ (aprox. calibre 5) | 0.344 / 0.438 / 0.562 / 0.688 / 0.875 |

Notas de uso:

Esta tabla está diseñada para estimar el espesor máximo cortable para varios grados de acero ASTM en máquinas de corte de metales, incluidas cizallas hidráulicas, cizallas mecánicas y sistemas de corte controlados por CNC.

“Capacidad máxima equivalente” refleja la clasificación de corte típica basada en acero dulce como material de referencia.

14.1Ejemplo:

- 250″ A572 Grado 65→ Requiere clasificación de corte para Acero dulce de 0,375″

- T-1 (ASTM A514)en un cizalla de 750″ → Capacidad máxima: 0.625″

15.0Tabla de referencia de capacidad de corte de acero

| Grado de acero | Resistencia a la tracción (ksi) | Límite elástico (ksi) | Alargamiento mínimo (%) | calibre 12 (0,1046″) | 10 GA (0,1345″) | 0.188″ | 0.250″ | 0.281″ | 0.375″ | 0.500″ | 0.625″ | 0.750″ | 1.000″ | 1.250″ |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| A1008 CS Tipo A/B/C | NS | 20–40 | 30 | 12 GA | 10 GA | 7 GA | 0.250 | – | – | – | – | – | – | – |

| A1008 DDS | NS | 17–29 | 38 | 14 GA | 12 GA | 10 GA | 0.250 | – | – | – | – | – | – | – |

| A1008 SS Grado 40 | 52 minutos | 40 minutos | 20 | 12 GA | 10 GA | 7 GA | 0.250 | – | – | – | – | – | – | – |

| A1008 HSLAS Grado 50 Cl. 1 | 65 minutos | 50 minutos | 20 | 13 GA | 11 GA | 8 GA | 5 GA | – | – | – | – | – | – | – |

| A1011 SS Grado 36 Tipo 2 | 58–80 | 36–51 | 21 | 12 GA | 10 GA | 7 GA | 0.250 | – | – | – | – | – | – | – |

| A1011 HSLAS Grado 70 Cl. 1 | 85 minutos | 70 minutos | 14 | 14 GA | 12 GA | 9 GA | 7 GA | – | – | – | – | – | – | – |

| A1011 HSLAS-F Grado 80 | 90 minutos | 80 minutos | 18 | 14 GA | 12 GA | 10 GA | 7 GA | 0.281 | 0.375 | 0.500 | – | – | – | – |

Notas:

Esta tabla proporciona pautas generales para el espesor cortable estimado en función de las propiedades mecánicas del material.

Los valores son nominales y deben verificarse con la capacidad de la máquina de corte específica y la configuración de la cuchilla.

Las referencias de GA (calibre) son aproximadas y pueden variar según el estándar (por ejemplo, calibre de acero de EE. UU. frente a especificación del fabricante).

El rendimiento del corte se ve afectado por el ángulo de ataque, la holgura de la cuchilla, el estado de la cuchilla y la dureza del material.

16.0Características de corte opcionales que mejoran la precisión del corte

- Calzas de mesa cautivas para un ajuste rápido de la holgura de la cuchilla

- Espacio libre para cuchillas eléctricas(modelos automatizados)

- Lámina neumática apoya para manipular materiales grandes o flexibles

- Esquina trasera apoya Para evitar la distorsión en material grueso o dúctil.

17.0Resumen final: Mejores prácticas para un corte seguro y eficiente

- Comience con el ángulo de inclinación máximo y luego redúzcalo según la calidad del corte.

- Siempre haga coincidir el tipo de cuchillo con el material y el grosor

- Controle el desgaste, mantenga el espacio libre y gire las cuchillas periódicamente

- Nunca exceda la capacidad nominal de corte o cuchilla

Al aplicar estos principios y comprender la física detrás del corte, los operadores pueden garantizar un rendimiento seguro, preciso y duradero de sus equipos de corte.