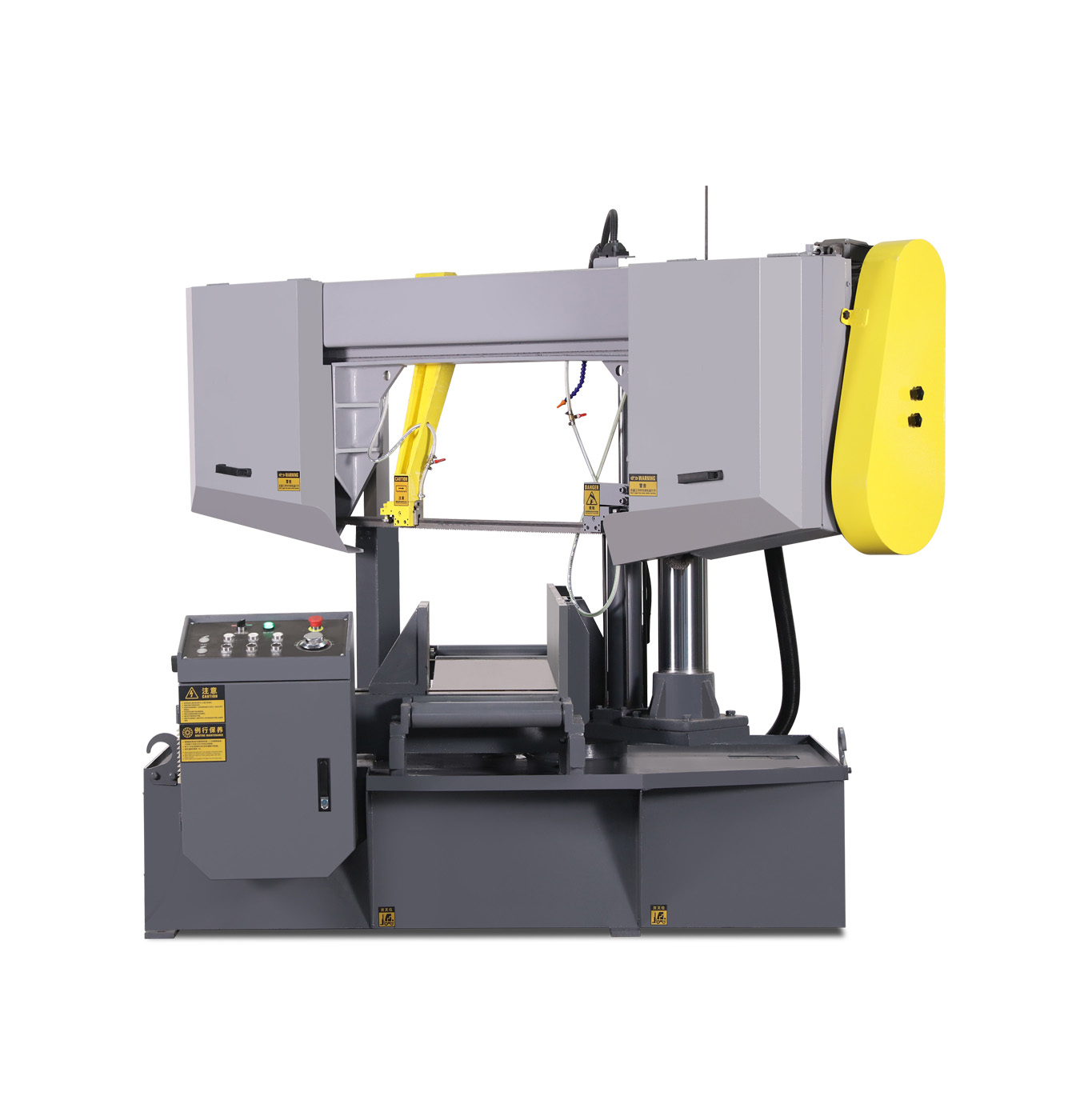

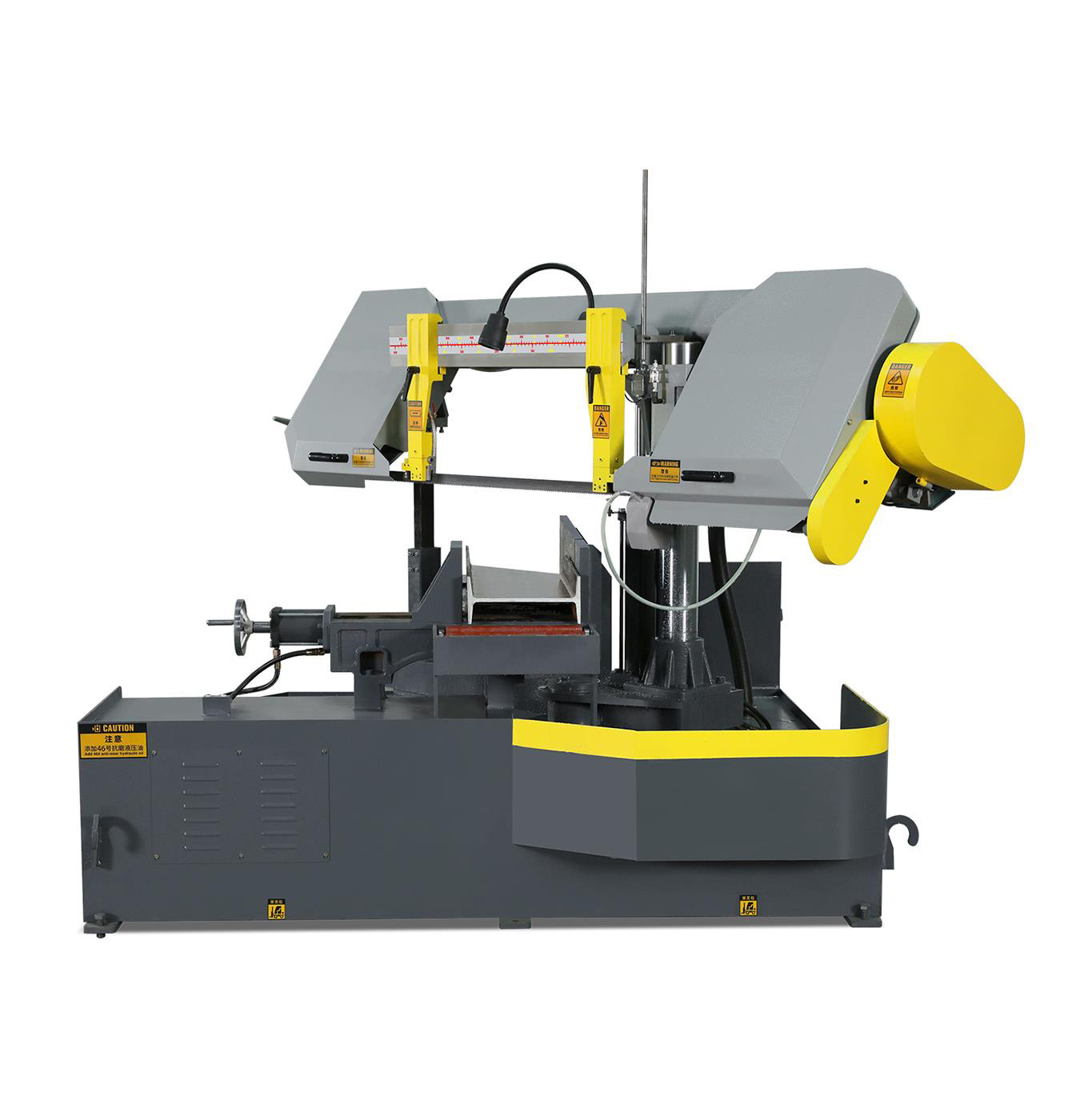

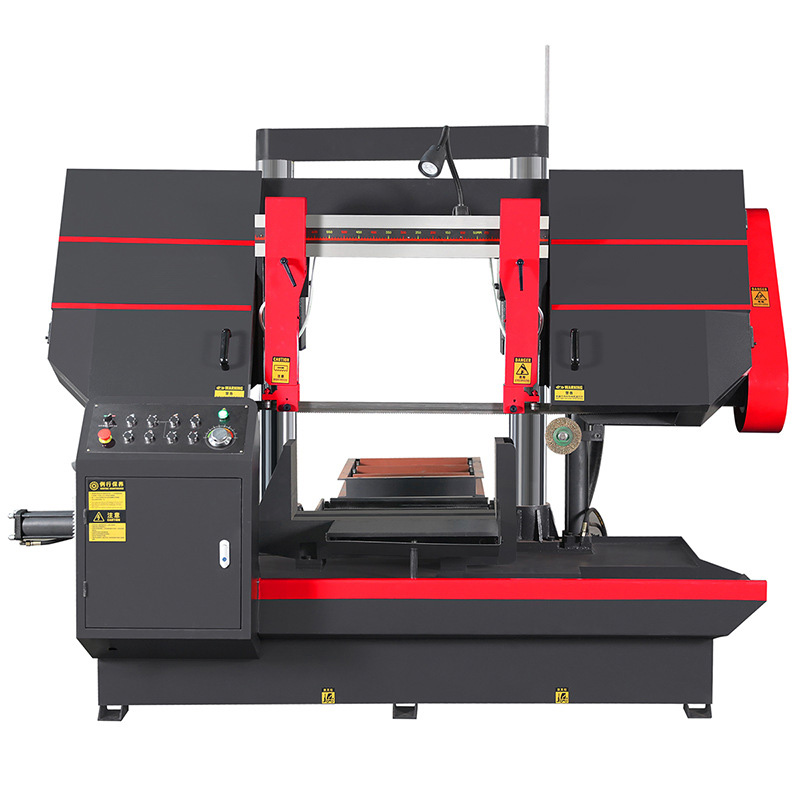

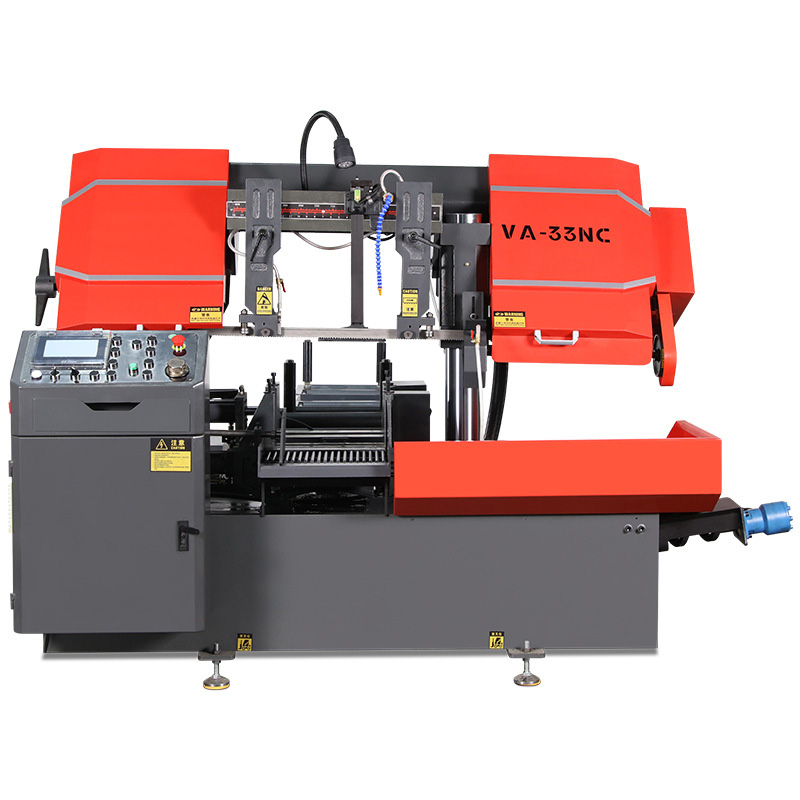

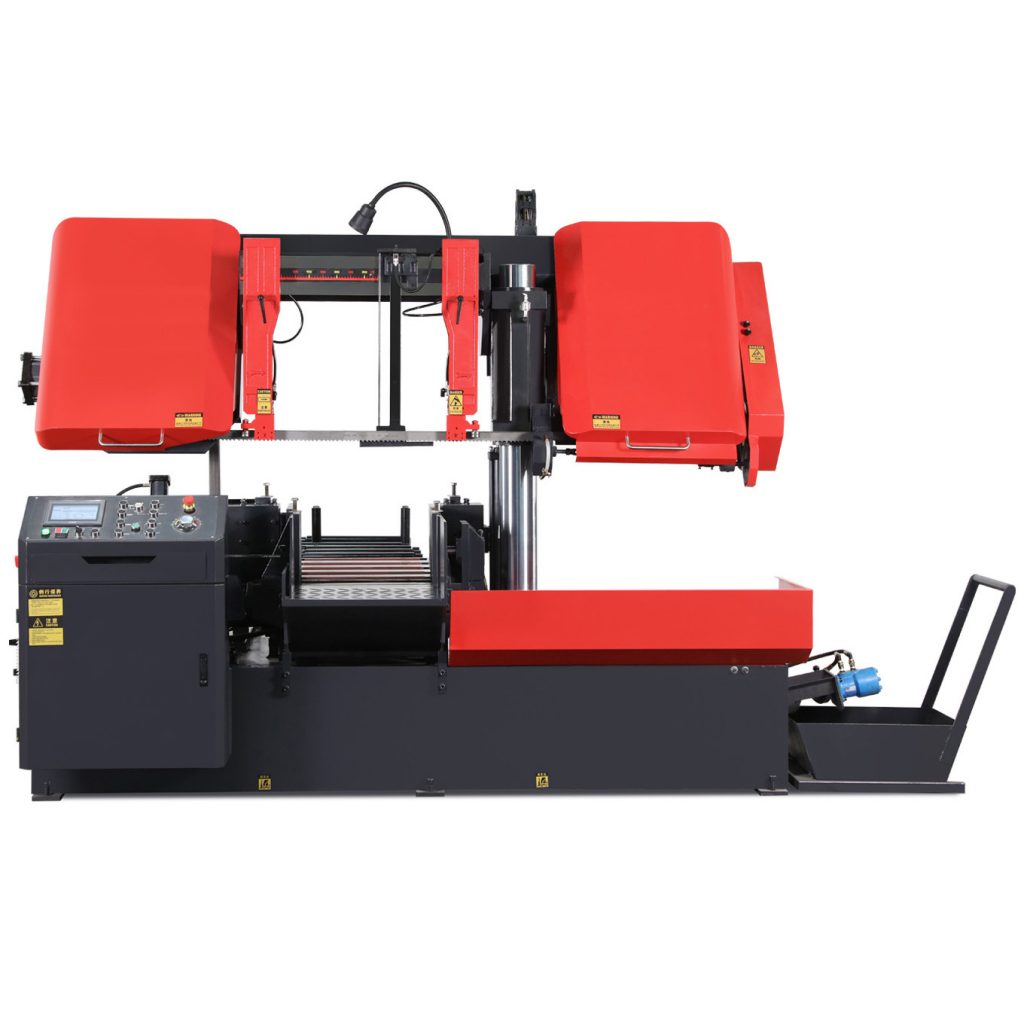

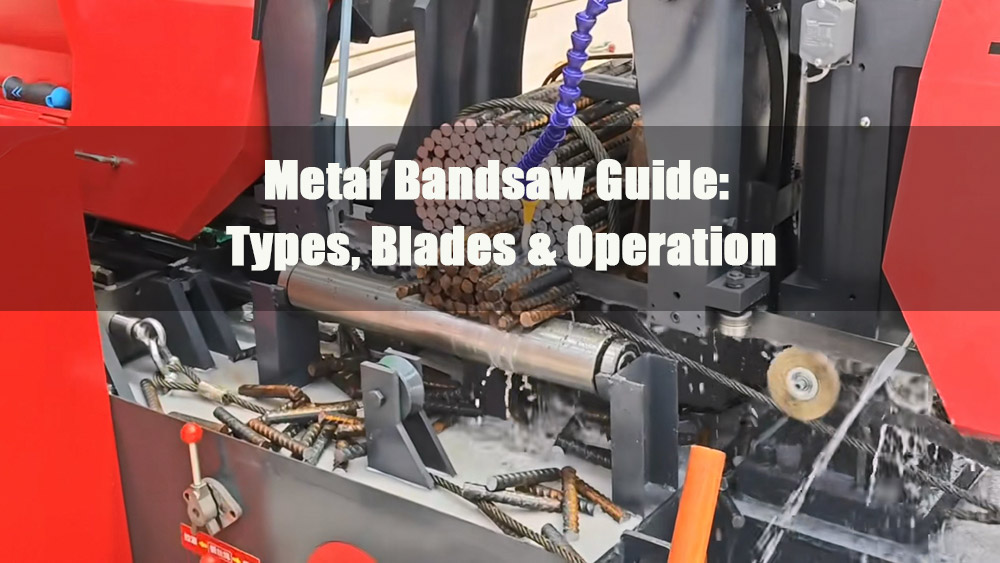

Sierra de cinta horizontal con corte giratorio de 0 a 60 grados

Características principales

- Tope de material ajustable– Garantiza longitudes de corte consistentes y precisas para piezas de trabajo repetidas.

- Sistema de control dual automático/manual– Cambio flexible entre corte totalmente automatizado y operación manual.

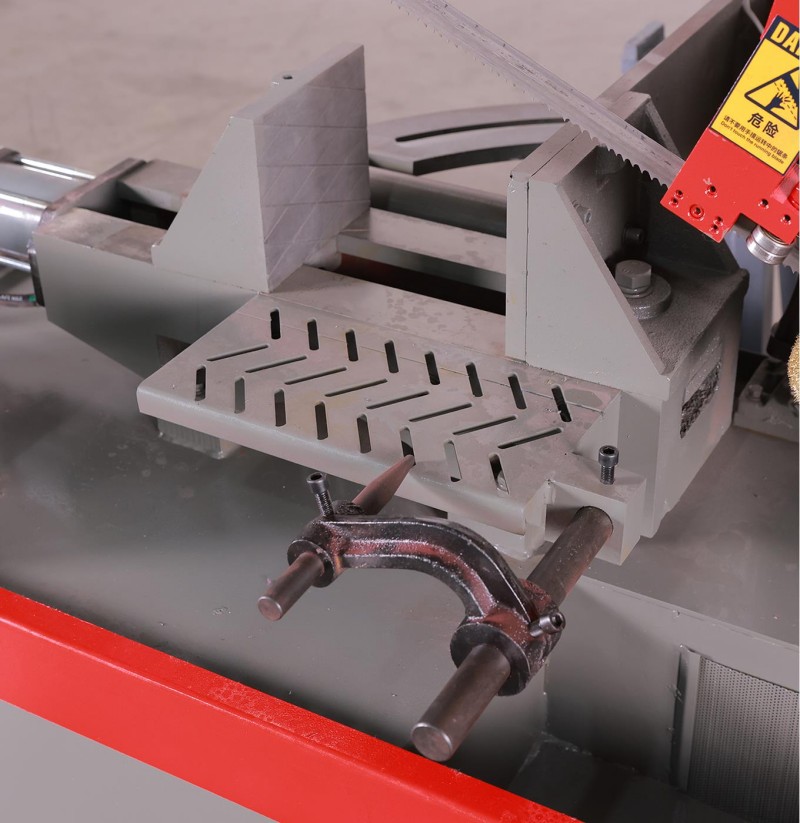

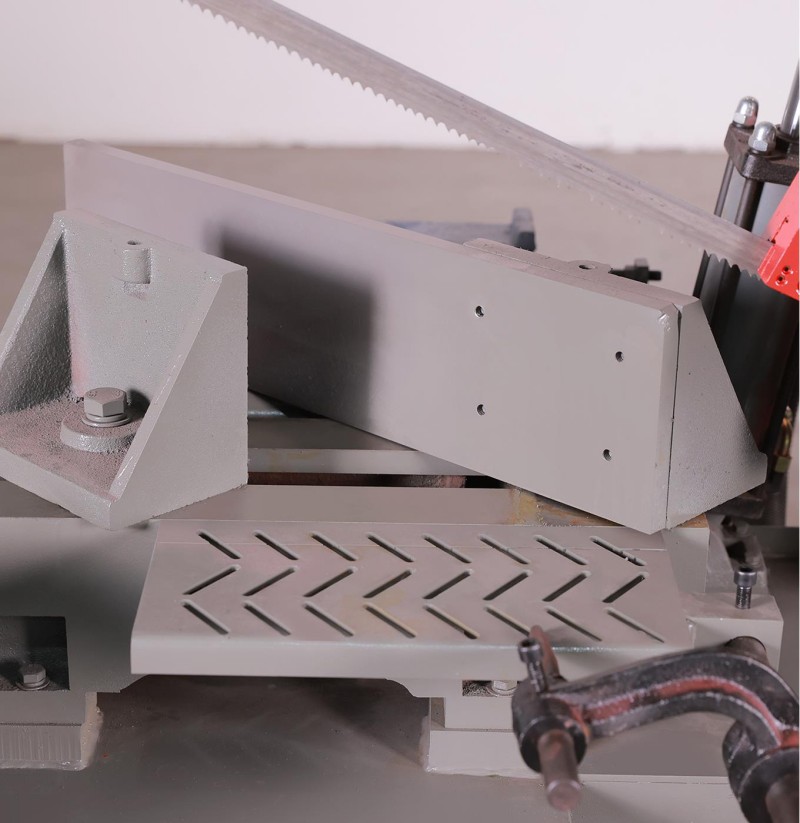

- Abrazadera de tornillo de banco hidráulica– Proporciona una sujeción estable de la pieza de trabajo durante cortes en ángulo de hasta 60°.

- Velocidad de cuchilla variable– Velocidad ajustable electrónicamente para un corte óptimo de diferentes materiales y espesores.

- Motor de alta potencia– El motor trifásico garantiza un corte suave y eficiente de metales ferrosos y no ferrosos.

- Mesa de alimentación asistida por rodillos– Los rodillos incorporados facilitan la alimentación suave del material y reducen el esfuerzo del operador.

- Tensado hidráulico de cuchillas– El tensor hidráulico de un toque con manómetro evita el apriete excesivo y la rotura de la cuchilla.

- Sistema de refrigeración estándar– Mantiene la temperatura de la hoja y de la pieza de trabajo, prolongando la vida útil de la hoja.

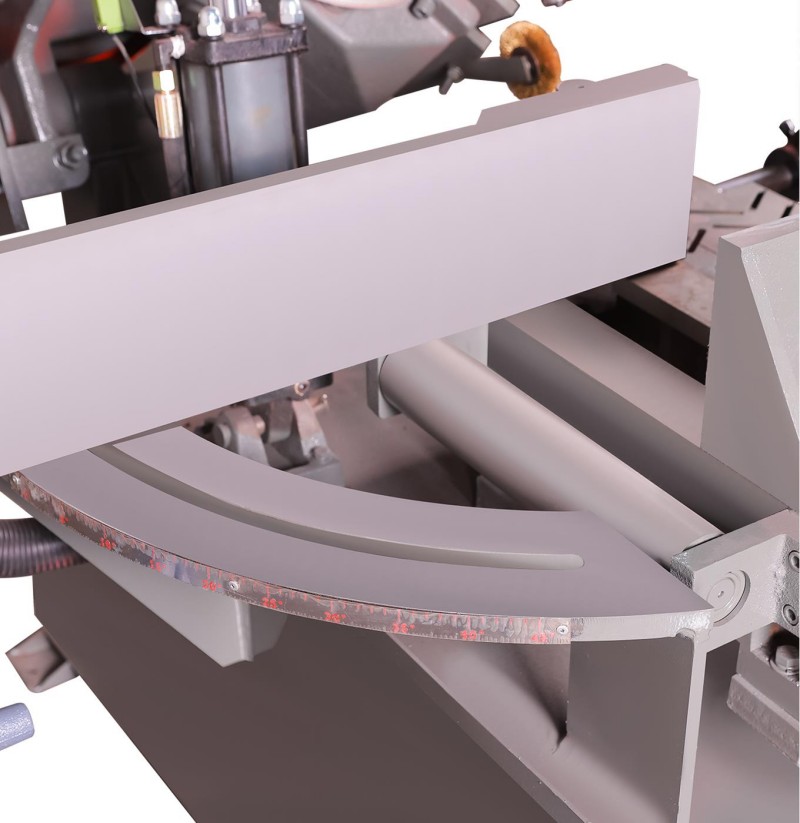

- Tornillo de banco giratorio– La prensa de ajuste rápido permite realizar cortes en ángulo de manera eficiente.

Sierra de cinta ingletadora horizontal En venta

Aplicaciones

- Fabricación de estructuras de acero:Acero angular, vigas en H, tubos cuadrados y rectangulares

- Automotriz y maquinaria pesada: Bloques de motor, componentes de chasis, bastidores estructurales

- Metalurgia general:Ejes, manguitos, bujes y otras piezas metálicas de precisión

- Fabricación industrial:Fábricas que requieren cortes angulares de alta precisión para metales ferrosos y no ferrosos

FAQ – Preguntas frecuentes

P1: ¿Qué ángulos de corte se admiten?

A1: La serie de sierras de cinta ingleteadoras horizontales AEK admite ángulos ajustables desde 0° hasta 60°, dependiendo del modelo.

P2: ¿Puedo cambiar entre funcionamiento automático y manual?

A2: Sí, todos los modelos cuentan con un sistema de control dual, lo que permite un cambio flexible entre el corte totalmente automatizado y el corte manual.

P3: ¿Qué tipos de materiales se pueden cortar?

A3: Las sierras son adecuadas para metales ferrosos (acero, acero inoxidable) y metales no ferrosos (aluminio, cobre, aleaciones).

P4: ¿Cómo se mantiene la tensión de la cuchilla?

A4: Todos los modelos cuentan con un Sistema hidráulico de tensión de cuchillas de un solo toque con manómetro, permitiendo una tensión visible y controlable para evitar roturas.

Q5: ¿Cómo se maneja el enfriamiento durante el corte?

A5: A sistema de refrigeración estándar asegura un enfriamiento continuo a través de las guías de la cuchilla, evitando el sobrecalentamiento y extendiendo la vida útil de la cuchilla.

Complete este formulario para solicitar una cotización. Un miembro de nuestro equipo revisará los detalles y se pondrá en contacto con usted en un plazo de 12 horas hábiles.