- 1.0¿Qué es una cizalla eléctrica para chapa metálica?

- 2.0Cómo operar una cizalla eléctrica de chapa metálica: guía paso a paso

- 3.0Por qué son importantes los sistemas de soporte de chapa en el corte de chapa metálica

- 4.0Comprensión de la entrega frontal en cizallas eléctricas

- 5.0Paso a paso: Cómo funciona el corte frontal

- 6.0Entrega trasera en cizallas eléctricas de chapa metálica

- 7.0Beneficios de la descarga trasera para el corte de chapa metálica de gran volumen

- 8.0Entrega frontal vs. entrega trasera: ¿Qué sistema de soporte de sábanas debería elegir?

- 9.0Mejores prácticas para usar una cizalla eléctrica de chapa metálica de manera eficiente

En la fabricación moderna de metales, un cizalla eléctrica de chapa metálica Es una herramienta crucial para un corte preciso y eficiente. Sin embargo, para maximizar su rendimiento y optimizar la producción, es importante elegir la herramienta correcta. sistema de soporte de láminas es igualmente importante.

Este artículo lo explica todo, desde los conceptos básicos de las cizallas eléctricas hasta las diferencias clave entre entrega frontal y entrega trasera sistemas y proporciona las mejores prácticas que mejoran el flujo de trabajo de corte y la eficiencia del operador.

1.0¿Qué es una cizalla eléctrica para chapa metálica?

Una cizalla eléctrica para chapa metálica es un dispositivo de corte motorizado que se utiliza para cortar láminas y placas metálicas con alta precisión. Estas máquinas utilizan un motor eléctrico para accionar una cuchilla que corta el metal en línea recta. En comparación con las cizallas manuales o hidráulicas, las cizallas eléctricas ofrecen una velocidad de corte constante, controles programables y mayor precisión, ideales para los talleres de fabricación modernos.

2.0Cómo operar una cizalla eléctrica de chapa metálica: guía paso a paso

El funcionamiento eficiente de un cizalla eléctrica de chapa metálica Es crucial para un corte preciso y un flujo de trabajo fluido. Siga estos pasos esenciales:

- Cargar la placa de metal

Coloque la lámina sobre la mesa de corte. Utilice mesas extensibles o brazos de soporte para reducir el esfuerzo, especialmente con láminas grandes. - Posicionar la hoja

Las barras de soporte de la placa levantan ligeramente la placa, lo que hace que sea más fácil deslizarla y alinearla con precisión contra el tope trasero. - Mejorar la visibilidad

Las luces de la cuchilla opcionales iluminan la línea de corte para un posicionamiento preciso. - Empezar a cortar

Utilice el pedal para activar el dispositivo de sujeción e iniciar el corte. La cuchilla regresa automáticamente después de cortar. - Descarga de material

Los soportes neumáticos se inclinan hacia abajo para deslizar suavemente la pieza cortada dentro de la bandeja o del carro en blanco. - Reiniciar para el siguiente corte

Los soportes de las láminas se elevan, listos para la siguiente placa. Las piezas cortadas se apilan para facilitar su transporte.

3.0Por qué son importantes los sistemas de soporte de chapa en el corte de chapa metálica

El sistema de soporte de chapa garantiza que la placa metálica se sujete, se posicione y se descargue correctamente durante el corte. Un buen sistema de soporte reduce la fatiga del operador, previene daños al material y mejora la precisión del corte. Sin un soporte adecuado, incluso la mejor cizalla eléctrica puede ofrecer resultados inconsistentes o ralentizar la producción debido a retrasos en la manipulación del material.

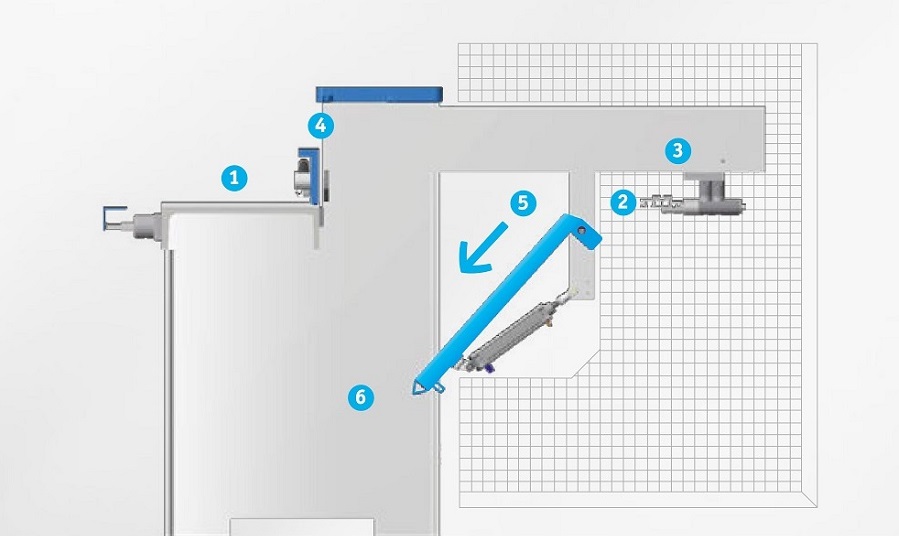

4.0Comprensión de la entrega frontal en cizallas eléctricas

En un sistema de entrega frontalTodos los procesos (carga de láminas, posicionamiento, corte y descarga) se realizan desde la parte frontal de la máquina. Esta configuración es ideal para talleres compactos o producción de lotes pequeños donde el espacio es limitado y un solo operador gestiona todo el proceso.

Las características típicas incluyen topes traseros manuales o motorizados (0–750 mm), mesas extensibles o brazos de soporte e iluminación de hoja opcional para ayudar con la alineación visual.

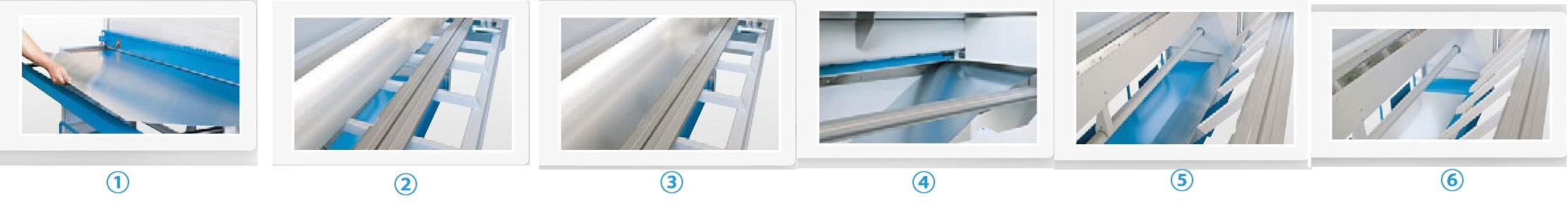

5.0Paso a paso: Cómo funciona el corte frontal

- Cargando: El El operador coloca la chapa sobre la mesa, ayudado por brazos de soporte que reducen el esfuerzo.

- Posicionamiento: Las barras de soporte elevan ligeramente la hoja, lo que permite un deslizamiento fácil y una alineación precisa contra el tope trasero.

- Alineación visual: Las luces de la cuchilla iluminan la línea de corte para mayor precisión.

- Corte: Mediante un pedal, el operador activa el sistema automático de sujeción y la cuchilla de corte.

- Descargar: Los soportes neumáticos para láminas se inclinan hacia abajo y las piezas cortadas se deslizan suavemente hacia una bandeja o un carro vacío.

- Reiniciar: Los soportes y la cuchilla vuelven a la posición inicial para el siguiente corte.

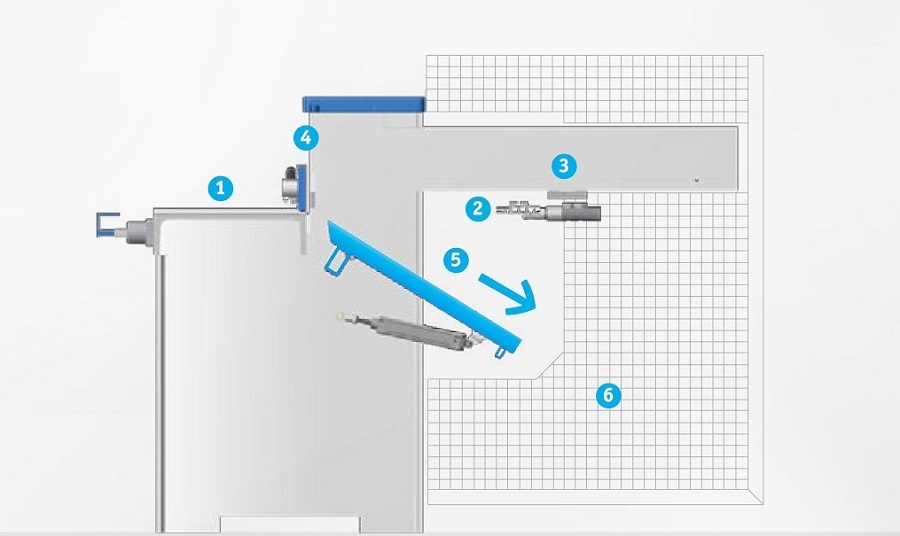

6.0Entrega trasera en cizallas eléctricas de chapa metálica

Los sistemas de entrega trasera cargan las láminas desde la parte frontal, pero descargan las piezas cortadas desde la parte trasera. Esta configuración permite la carga y descarga simultáneas, minimizando el tiempo de inactividad y aumentando la productividad. Es la opción preferida para la producción de alto volumen y para la manipulación de láminas más largas o gruesas con menor esfuerzo del operador.

7.0Beneficios de la descarga trasera para el corte de chapa metálica de gran volumen

- Flujo de trabajo paralelo: Los operadores pueden preparar la siguiente hoja mientras se retira la parte cortada de la parte trasera.

- Ergonomía mejorada: Menos levantamiento y reposicionamiento de materiales pesados.

- Tiempos de ciclo más rápidos: El flujo continuo de material reduce los tiempos de espera.

- Mejor utilización del espacio: Libera el área frontal para una carga más rápida.

8.0Entrega frontal vs. entrega trasera: ¿Qué sistema de soporte de sábanas debería elegir?

| Requisito | Sistema de entrega recomendado |

| Espacio limitado en el piso | Entrega frontal |

| Flujo de trabajo de un solo operador | Entrega frontal |

| Manipulación de hojas largas y pesadas | Entrega trasera |

| Trabajo continuo de gran volumen | Entrega trasera |

| Necesidad de una visibilidad precisa de la línea de corte | Entrega frontal con luz de cuchilla |

9.0Mejores prácticas para usar una cizalla eléctrica de chapa metálica de manera eficiente

- Siempre combina tu soporte de láminas sistema a su flujo de trabajo y al tamaño del material.

- Utilice luces de cuchilla para lograr una visibilidad precisa de la línea de corte, especialmente con materiales delgados o reflectantes.

- Mantenga la configuración adecuada del tope trasero para lograr un posicionamiento uniforme.

- Inspeccione y mantenga periódicamente los soportes neumáticos y las abrazaderas de sujeción.

- Capacitar a los operadores para que aprovechen los pedales y las funciones automáticas para minimizar el esfuerzo manual.

- Evite exceder el espesor nominal de la chapa y la capacidad de la máquina para proteger la longevidad del equipo.

Al comprender e implementar la configuración de soporte de hoja correcta para su cizalla eléctrica de chapa metálicaObtendrá ciclos más rápidos, mayor precisión y una operación más segura. Ya sea que elija la entrega frontal o trasera, optimizar el flujo de material es clave para maximizar la productividad de su taller.