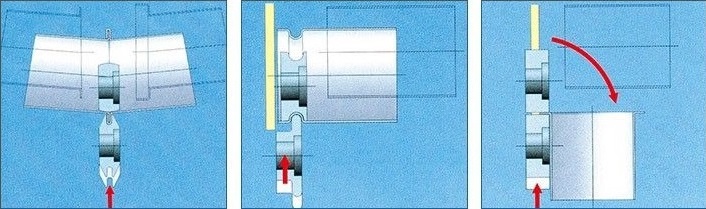

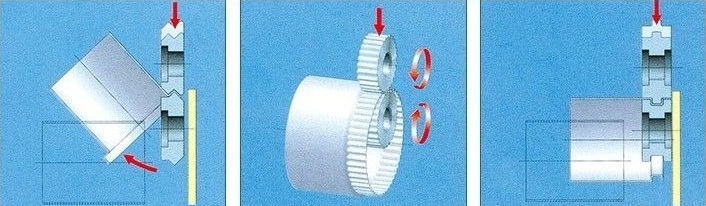

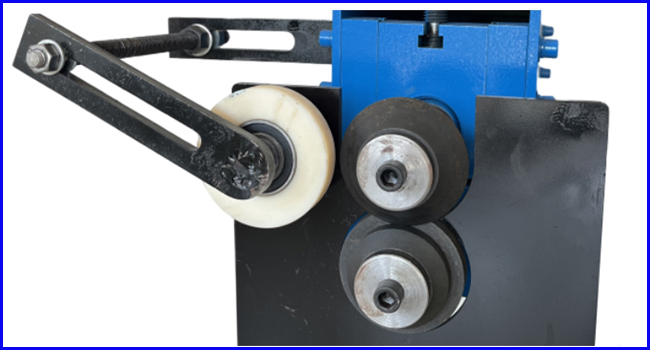

The Electric Bead Rolling Machine for HVAC Duct is widely used in the HVAC duct fabrication industry for flanging and beading with special rollers. It can also process various workpieces using specialized rolling wheels, such as leveling metal sheets, shearing, and corrugating plates.

Upgraded version- Electric Bead Roller Machine

Product Features & Advantages

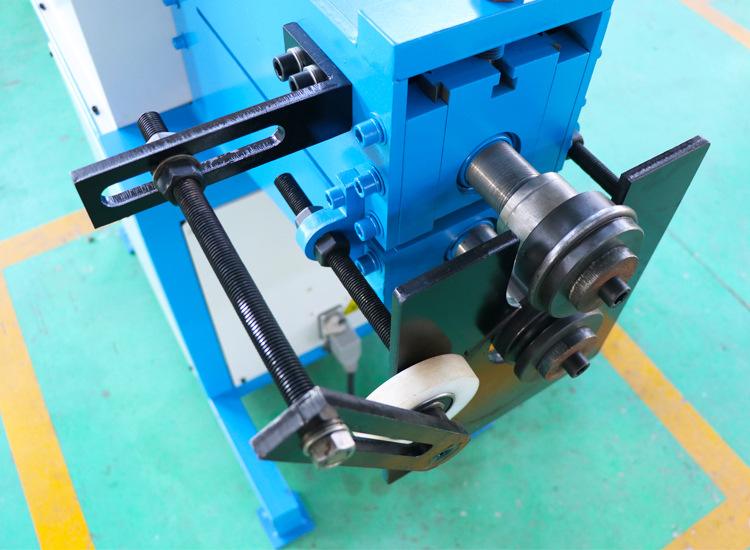

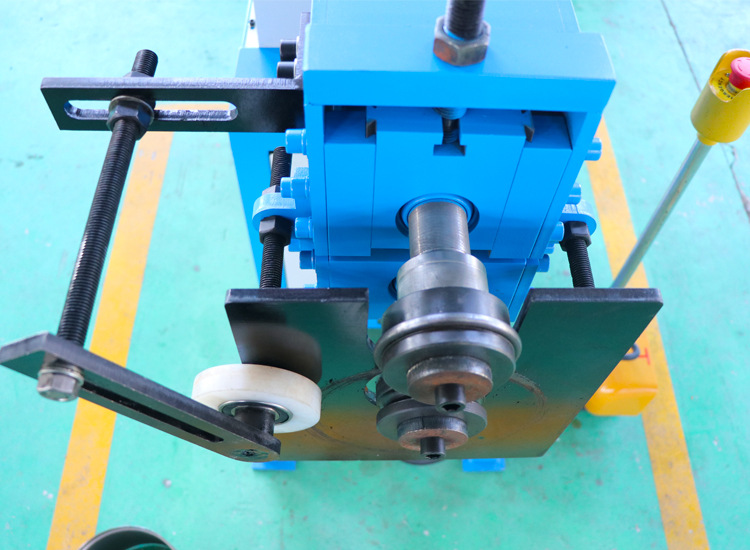

- Gear: Full-body quenching treatment for high hardness, wear resistance, and long service life.

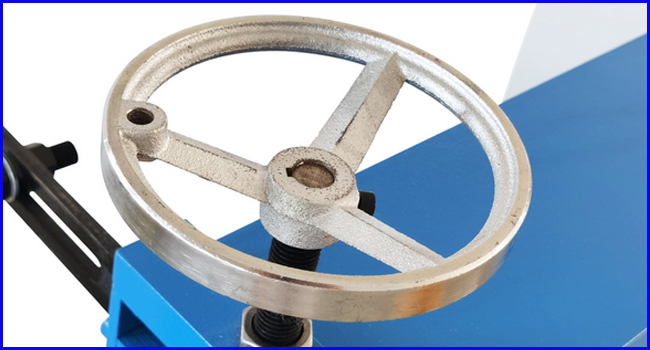

- Screw Handwheel: Adjustable for depth control, making operation simple and efficient.

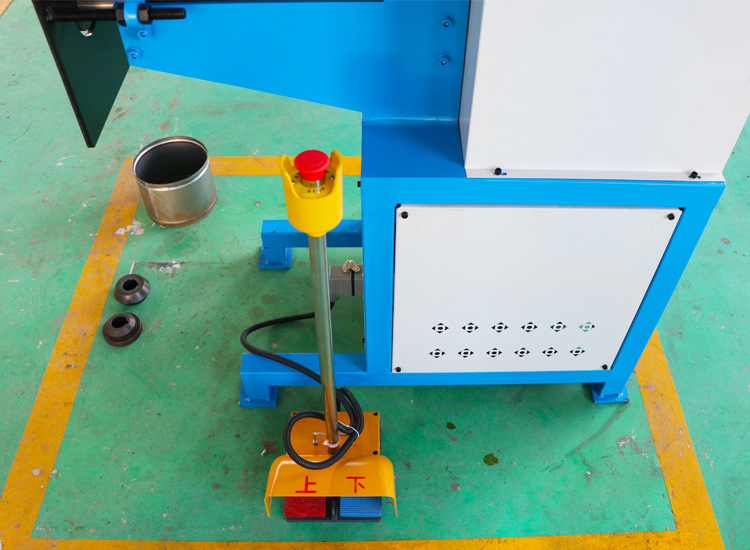

- Heat Dissipation Window: Facilitates heat dissipation, reduces motor temperature, and enhances machine longevity.

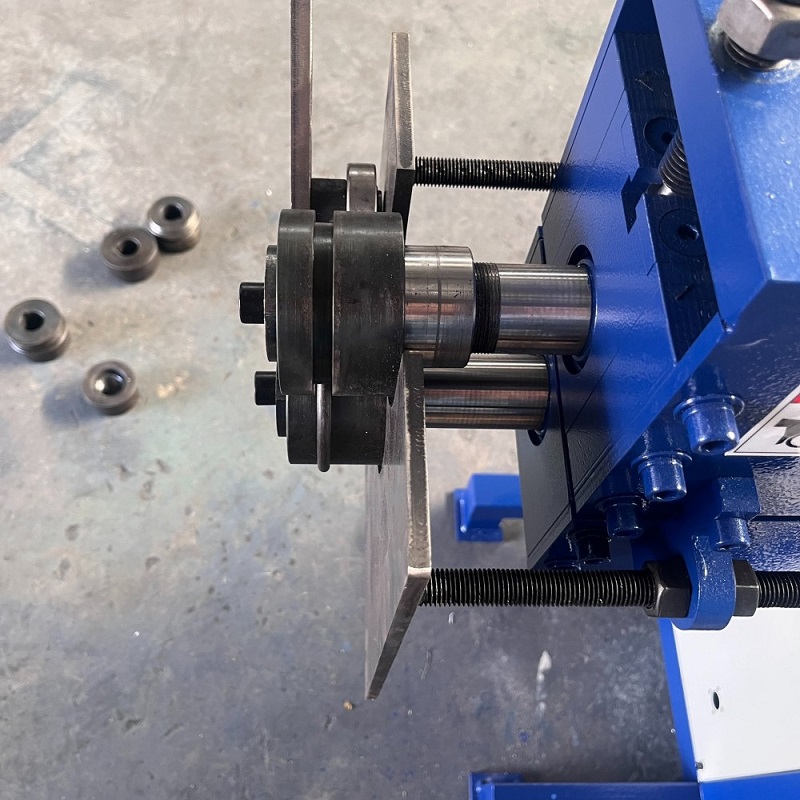

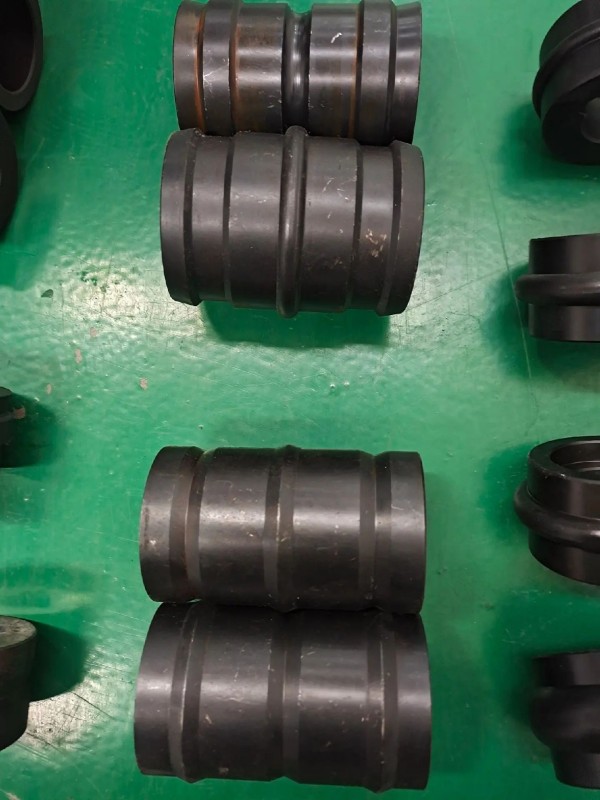

- Mold: Vacuum quenched, durable, and made of high-strength 45 steel.

- Durability: Pure copper motor coil for long life and low power consumption; A3 steel body for hardness and resistance to deformation.

- Foot Switch: Easy-to-use foot switch for convenient control during operation.

Applications and Benefits of Electric Pipe Bead Rolling Machine for HVAC Ducts

- HVAC ducts (galvanized steel, stainless steel, aluminum, etc.) – Suitable for various materials, ensuring joint strength and sealing.

- Various pipe diameters for HVAC ducts (from 3/4” to 12” or larger) – Adjustable bead depth to accommodate different pipe diameters.

- HVAC system pipes and duct connections – Enhances precision and strength of joints, ensuring secure connections and preventing leaks.

- HVAC pipes in high-load, high-temperature, or high-pressure environments – Improves sealing and pressure resistance, suitable for extreme conditions.

- Mass production of HVAC system pipes – Efficient electric drive, ideal for mass production, increasing production speed.

- Precision HVAC pipe installations – High-precision bead rolling, ensuring tight joints, ideal for precise installations.

- Custom HVAC pipe production – Offers personalized customization to meet specific design needs.

- Energy-efficient HVAC system pipes – Reduces leakage, improves system efficiency, and lowers energy consumption.

Please fill out this form to submit a request for quote. One of our team members will review the details and be in touch within 12 business hours.