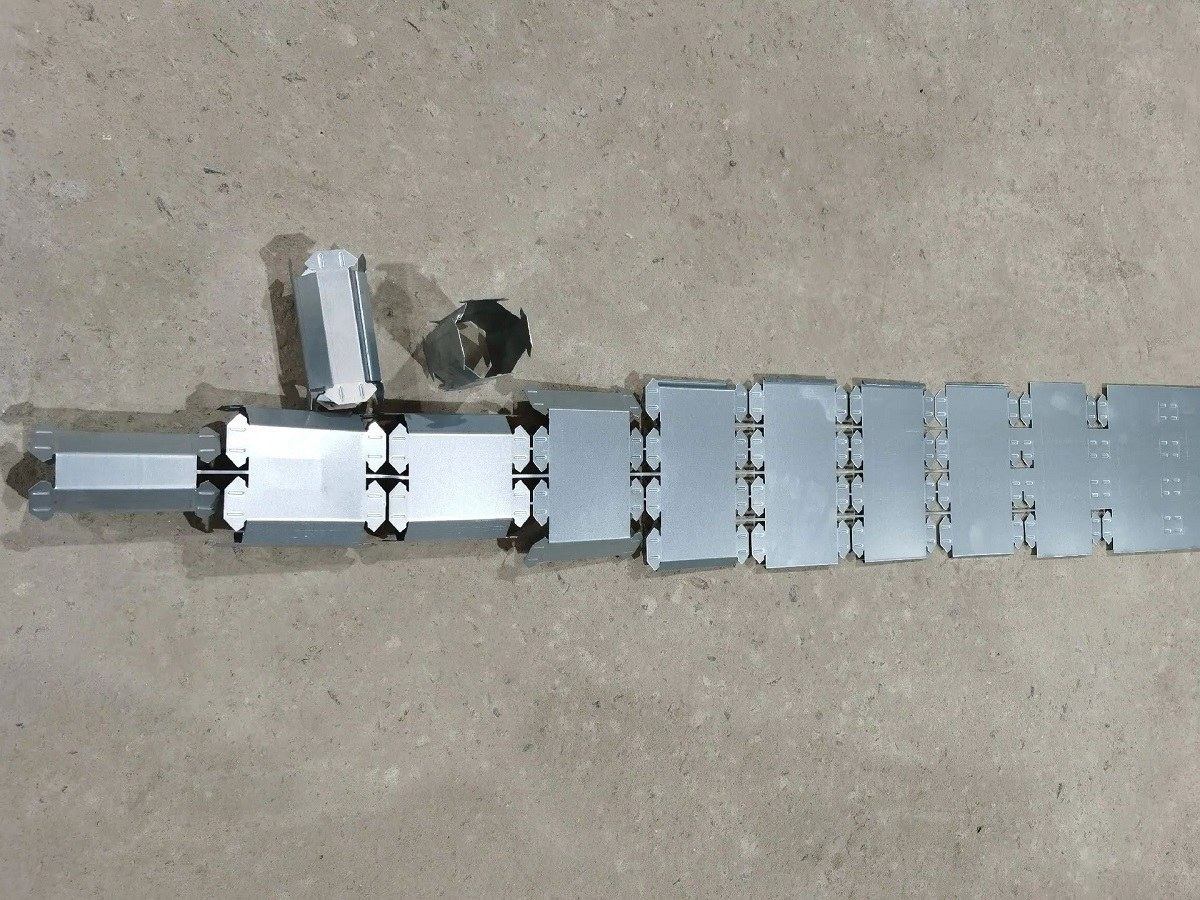

Dual Station Hydraulic Metal Tube Punching Machine Photos

Main Features

- Dual Hydraulic Workstations: Capable of handling multiple punching or notching operations simultaneously to boost productivity.

- Flexible Mold Configuration: Supports punching, notching, cutting, and pressing functions by replacing customized molds, adapting to diverse processing scenarios.

- High Precision: Gantry milling guarantees precise alignment of mold bases, with a tolerance of up to ±0.30 mm.

- Scratch-Free Surface: Specially designed molds and an auto chip-removal system prevent scratches and clear metal chips promptly.

- Durable Construction: SKD11 tempered molds, high-quality hydraulic hoses, and reliable cylinders ensure a long service life.

- Hydraulic Power System: Operates smoothly with adjustable pressure for different materials.

- User-Friendly Operation & Maintenance: Manual feeding system simplifies structure, reducing maintenance costs and operation barriers.

- Cooling System: Automatic oil cooling in the hydraulic station maintains stable performance during continuous operation.

Processing Capability

- Handles raw materials up to 3m in length, with equal or unequal spacing between holes.

- Supports various hole shapes including square, rectangular, D-shaped, oval, triangular, waist circular, and prismatic holes.

- Enables customized processing of different hole positions and distances, with data storage for recall.

- Applicable for stainless steel tubes, mild steel pipes, aluminum profiles, iron pipes, and copper tubes.

Applications

- Manufacturing of aluminum ladder profiles

- Production of steel and zinc guardrails

- Processing of iron/aluminum fences

- Manufacturing of balustrades, handrails, and railings

- Production of shelving brackets and furniture frames

For higher productivity, a 4-Workstation Pipe Hole Punching Machine is also available.

Please fill out this form to submit a request for quote. One of our team members will review the details and be in touch within 12 business hours.