Automation-Ready · Customized Tube Bending Solutions

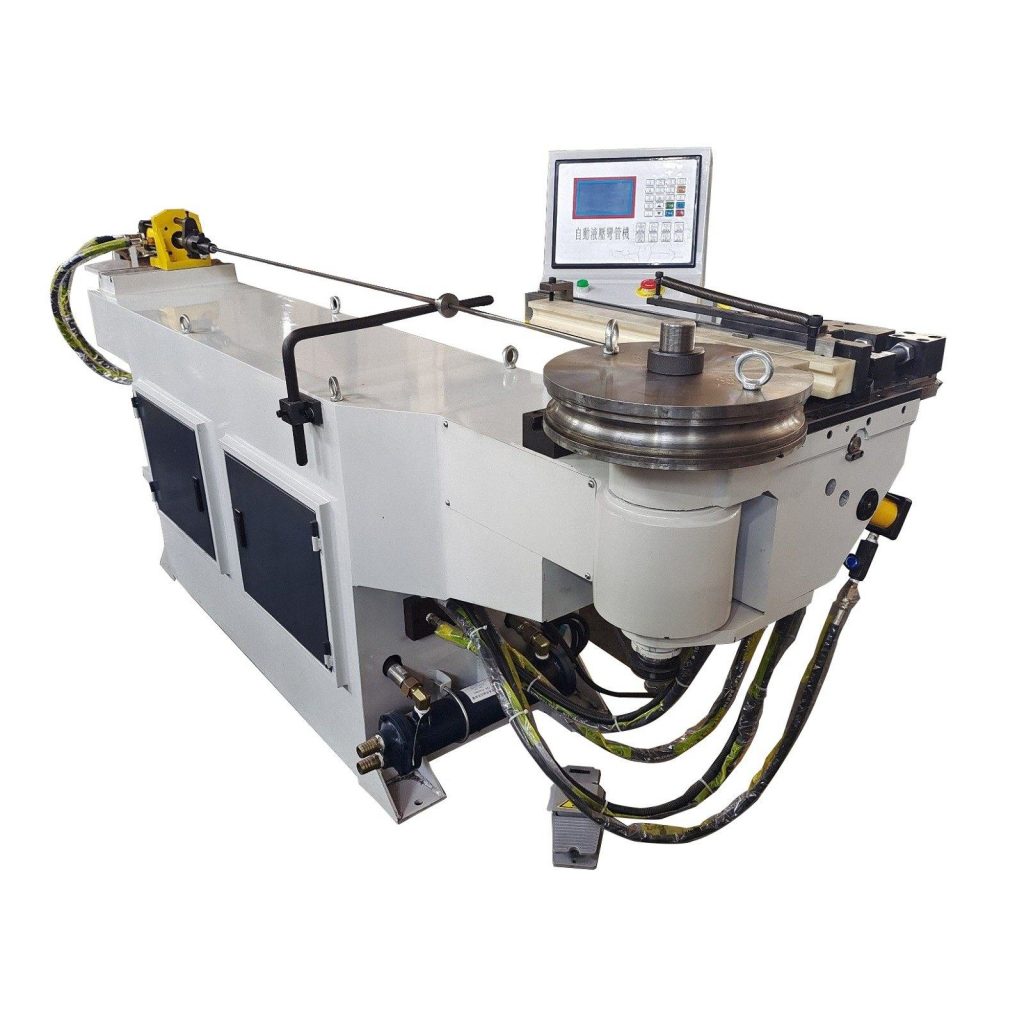

The AEK-DB CNC Series Double-Head Tube Bending Machines are designed with comprehensive automation interfaces, enabling seamless integration into automated tube bending production lines. The system supports robotic loading and unloading, automatic feeding systems, and finished-part discharge and stacking solutions, allowing flexible configuration based on production capacity and process requirements.

- Automatic loading and precise positioning

- Fully automated bending operations

- Automatic part unloading and stacking after bending

- Multi-station continuous, high-throughput production

By implementing an automated production line, manual labor requirements are significantly reduced, labor costs are lowered, and overall productivity, bending accuracy, and product consistency are greatly improved. This makes the system especially suitable for long-term, stable mass production projects.

Machine Types

- Hydraulic Double-Head Tube Bending Machine

Large-diameter and thick-walled tubes; suitable for seamless steel pipes and heavy-duty aluminum profiles; simple operation; small- to medium-batch production. - CNC Double-Head Tube Bending Machine

CNC programmable control; complex and 3D bending; high precision; program storage; high-volume and complex tube processing.

Applicable Materials & Processing Range

Supported materials include:

- Carbon steel tubes

- Stainless steel tubes

- Aluminum tubes/aluminum profiles

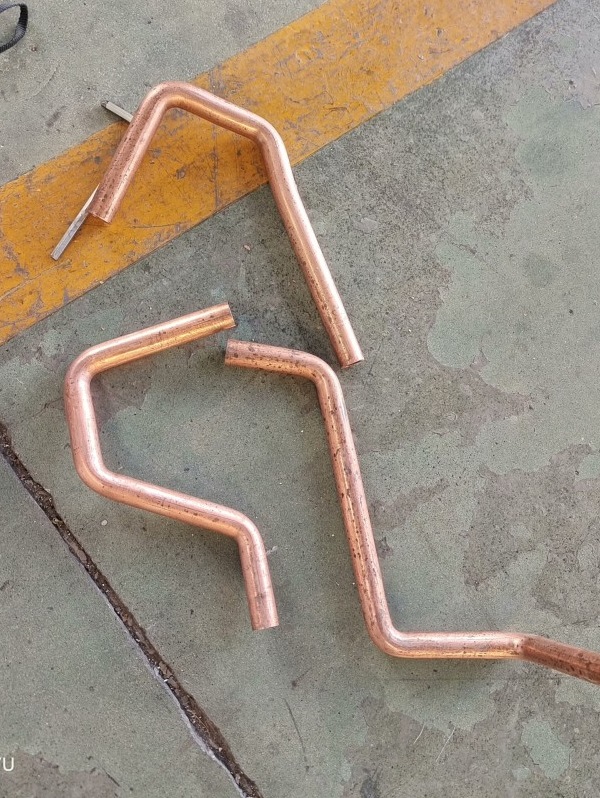

- Copper tubes

Tube diameter range, wall thickness, and bending capacity can be customized according to machine configuration and customer requirements.

Typical Application Industries

The AEK-DB CNC Series Double-Head Tube Bending Machines are widely used in industries with high demands for efficiency and consistency, including but not limited to:

- Automotive and Motorcycle Components

(Exhaust systems, bumpers, seat frames) - Fitness Equipment and Sports Apparatus

- Metal Furniture Tube Components

(Chair frames, bed frames) - Industrial Equipment and Laboratory Piping Systems

- Aluminum Profile Structures and Custom Equipment Manufacturing

Core Components & Functions – Double-Head Pipe Bending Machine

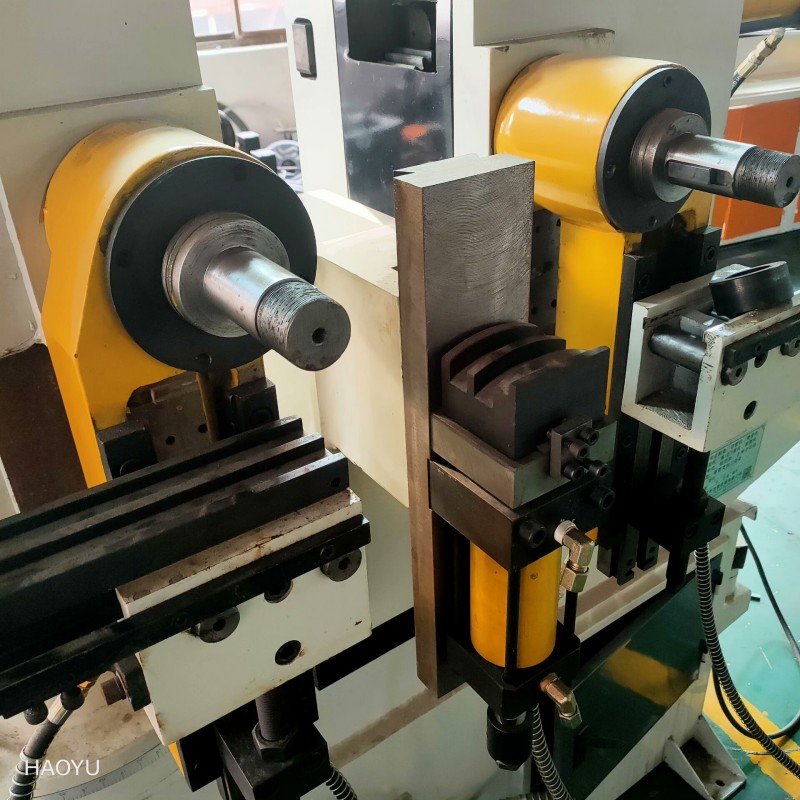

- Double-Head Bending Unit: Dual bending stations with synchronous or independent control for multi-angle and multi-radius pipe bending.

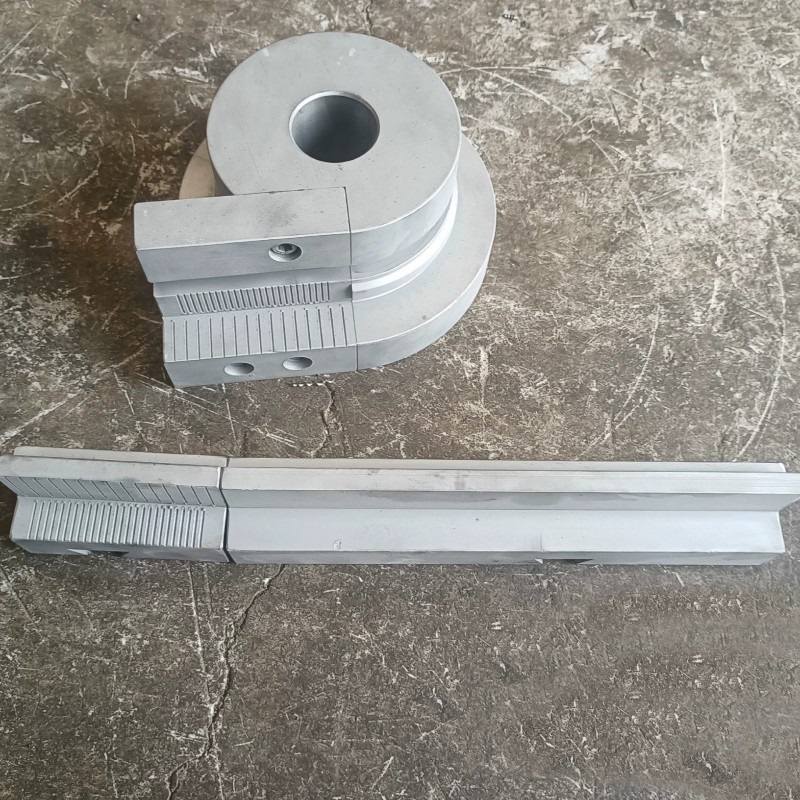

- Pipe Clamping Fixture: Hydraulic or pneumatic clamping to secure the pipe during bending and prevent slipping.

- Bending Die Set: Forms the bending radius and controls pipe shape and surface quality during bending.

- Material Feeding System: Servo-driven feeding system for precise length positioning and continuous multi-bend operations.

- Control System: PLC-based control for parameter input, program storage, and synchronous or independent dual-head operation.

- Hydraulic Power Unit: Provides adjustable hydraulic pressure for bending and clamping functions.

- Frame & Support Structure: Rigid machine frame to support dual-head bending loads and ensure operational stability.

- Auxiliary Positioning Components: Assists pipe guiding and length positioning during loading and bending.

Please fill out this form to submit a request for quote. One of our team members will review the details and be in touch within 12 business hours.