Vorteile

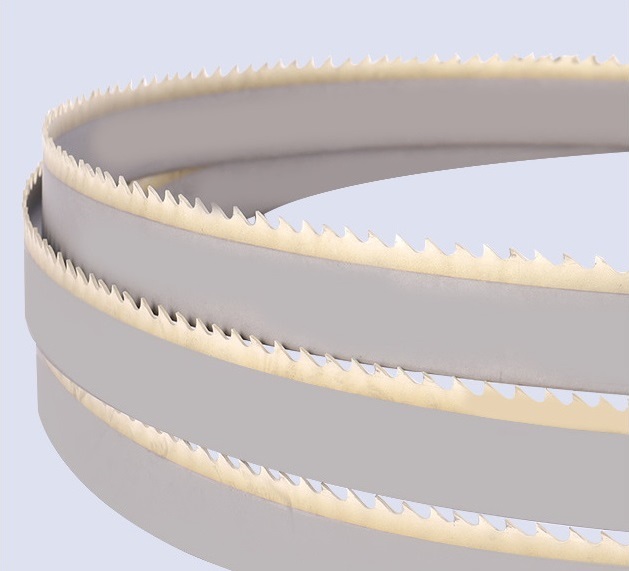

- PVD-Beschichtungstechnologie: Steigert die Schnittleistung durch 30%+ mit hoher Verschleißfestigkeit, hervorragender Wärmeisolierung und überlegener Härte. Reduziert die Schnittkosten deutlich und erhöht gleichzeitig die Arbeitseffizienz.

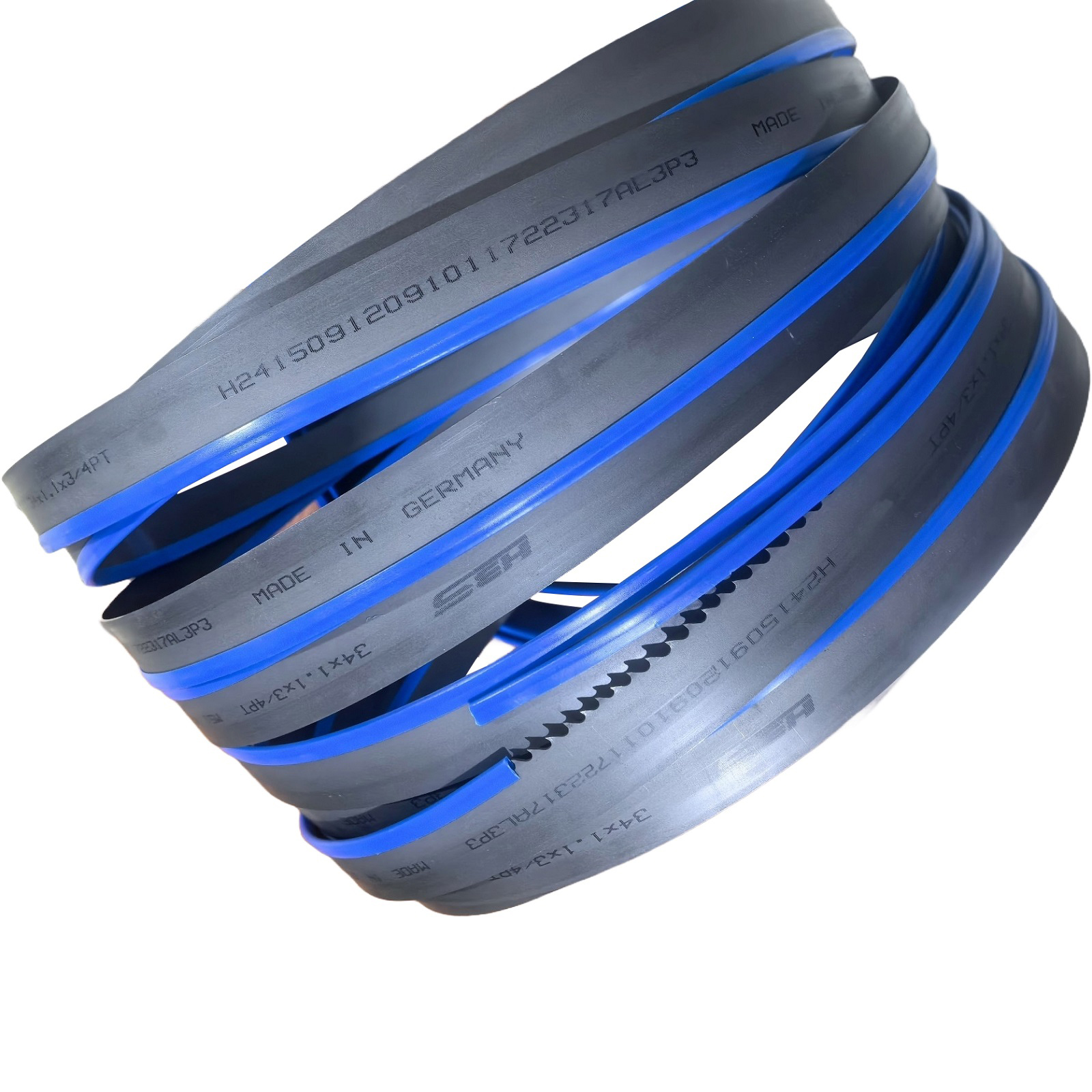

- WRC(PRO) Premium-BeschichtungUniverselles Design für vielfältige Schneidanforderungen, hohe Verschleißfestigkeit und minimales Klingenbruchrisiko. Bewältigt mühelos komplexe und anspruchsvolle Schneidaufgaben.

- Überlegen gegenüber Standard-M42-unbeschichteten KlingenDie Zahnhärte erreicht 65–67 HRC, wodurch die Schnittreibung reduziert wird. Dies gewährleistet eine höhere Stabilität und verdoppelt die Standzeit (Standard-Sägeblätter ohne Beschichtung: 3–5 Tage).

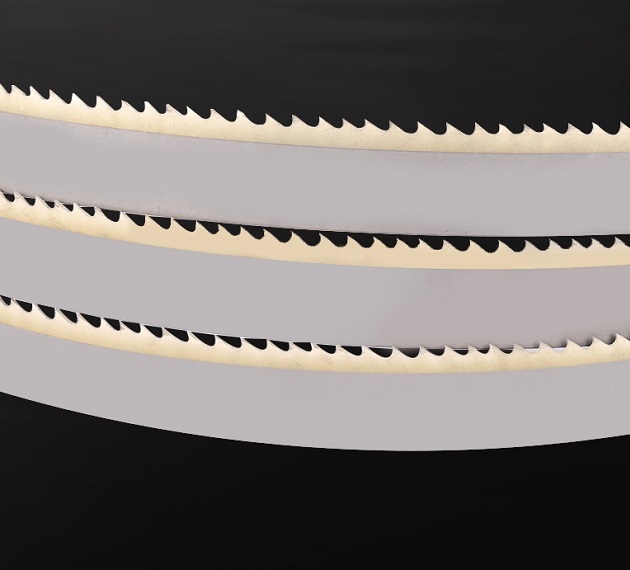

- Fortschrittliche WärmebehandlungDie integrierte Online-Fertigung mit bidirektionaler Härtung verbessert die Zahnfestigkeit, Verschleißfestigkeit und Dauerfestigkeit. Sie löst Probleme mit Klingenverbiegungen und gewährleistet einen reibungslosen Schnitt.

- Konstante Batch-Performance: Übertrifft herkömmliche Wärmebehandlungsverfahren durch längere Lebensdauer und minimale Leistungsschwankungen zwischen verschiedenen Chargen und garantiert so stabile und zuverlässige Schneidergebnisse.

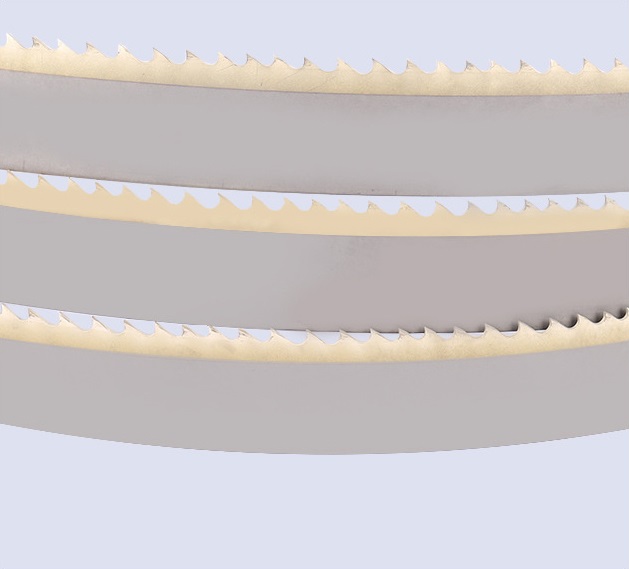

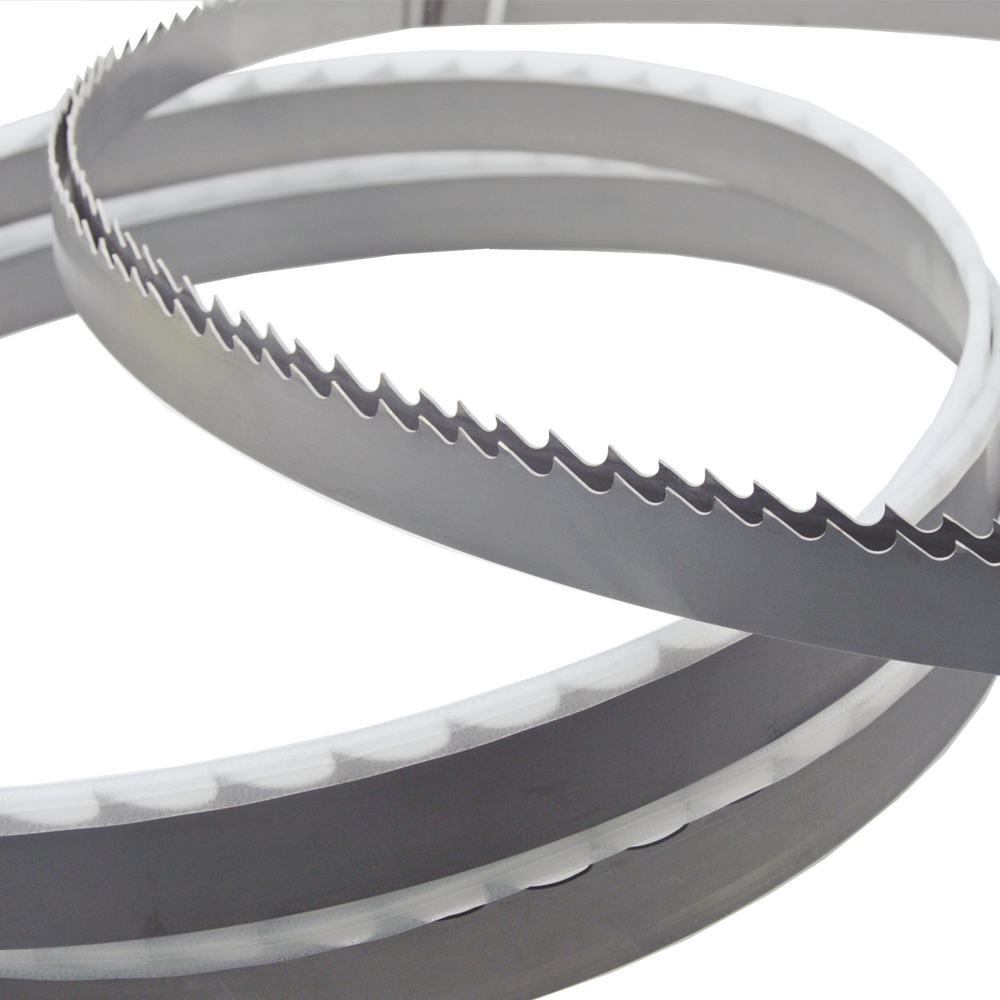

Zahngeometrie (Vielseitig für verschiedene Anwendungsfälle)

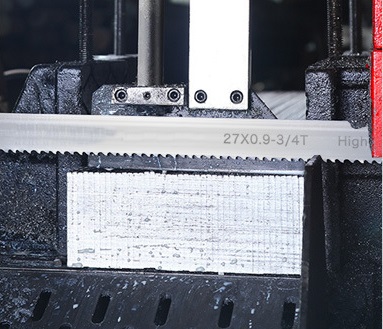

- 3/4 Anti-Pull-Zahn: Hohlrohre (Wandstärke > 10 mm)

- 2/3 Spitzzahn: Massive Werkstoffe (Durchmesser 150–500 mm)

- 4/6 Anti-Pull-Zahn: Hohlrohre (Wandstärke < 10 mm)

- 3/4 Spitzzahn: Massive Werkstoffe (Durchmesser 60–150 mm)

- 3/4 Camelback-Zahnung: Gebündelte oder hochbelastbare Materialien

- 4/6 Spitzzahn: Mittlere bis leichte Schnittlasten

Material- und Produktdetails

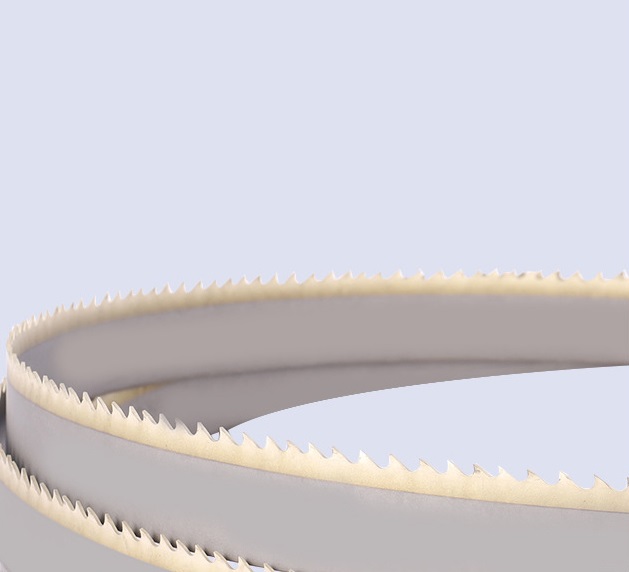

- Grundmaterial: M42 Bimetall mit hochfestem Federstahl-Trägermaterial, das Härte, Verschleißfestigkeit, Flexibilität und Dauerfestigkeit in Einklang bringt.

- Zähne & ZahnbelagDie bidirektionale Härtung schärft die Zähne für einen gleichmäßigen Spanabtransport und schmalere Schnittwege. Die PVD-Beschichtung schützt die Zähne, reduziert die Reibung und verbessert den Vorschub.

- Schutzkonstruktion: Ein 1 cm dicker, verschleißfester Zahnriegel verhindert Oxidation und Transportschäden und schützt so die Schneide vollständig.

Anwendbare Materialien

Edelstahl (304/316), Werkzeugstahl, Wälzlagerstahl, 45# Stahl, A3 Stahl, Q235 Stahl, Hohlrohre, Vollmaterialien und Bündelmaterialien.

Bitte füllen Sie dieses Formular aus, um eine Angebotsanfrage zu senden. Ein Mitglied unseres Teams wird die Details prüfen und sich innerhalb von 12 Geschäftsstunden bei Ihnen melden.