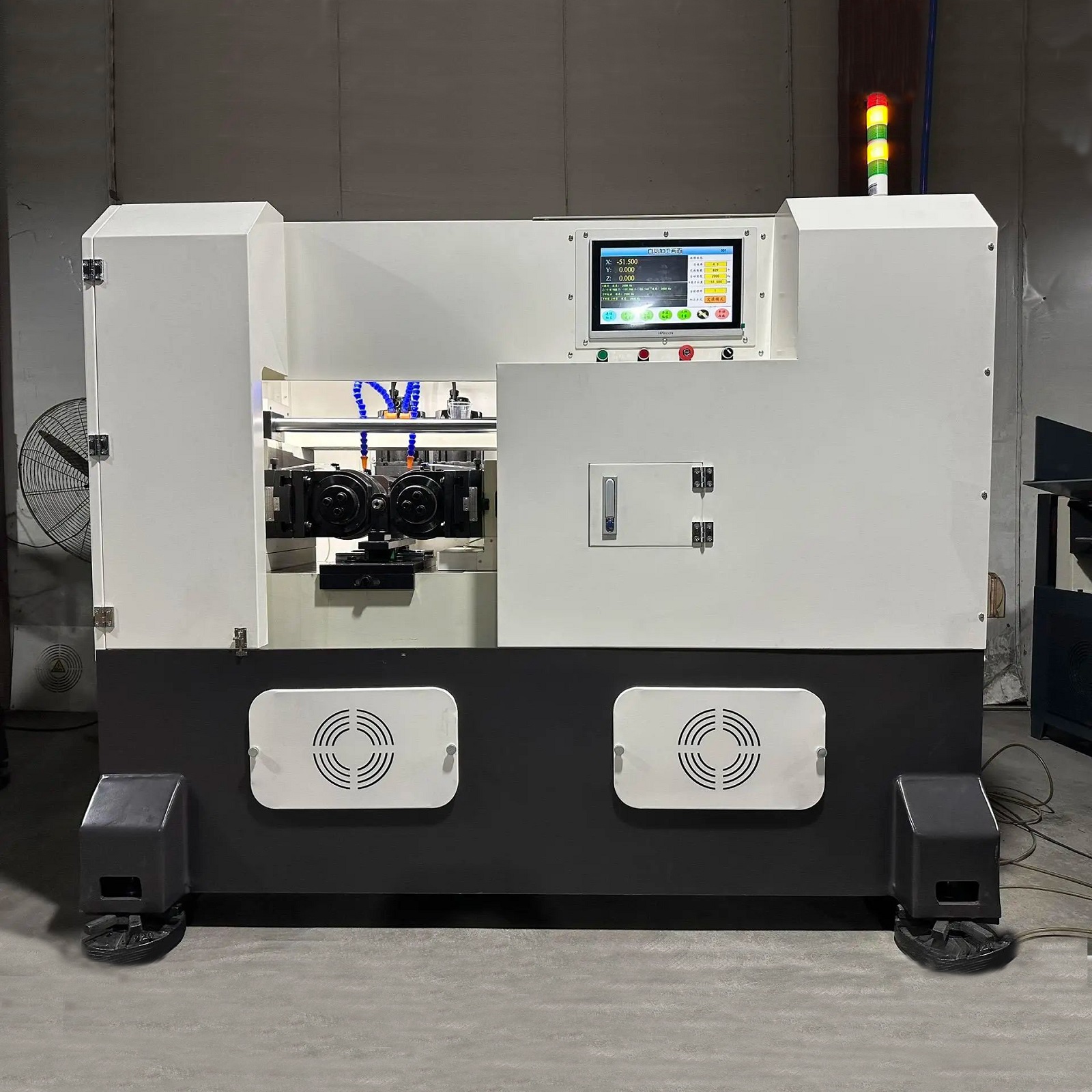

Die CNC-Präzisionsgewindewalzmaschine AEK-25NC ermöglicht schnelles und hochpräzises Gewindewalzen für Standard-, Schnecken-, Trapez- und Sondergewinde.

Ausgestattet mit servogetriebenen Spindeln, CNC-gesteuerter Neigungseinstellung und starren linearen Führungen gewährleistet es eine stabile, genaue und wiederholbare Leistung.

Sein kompaktes, nicht-hydraulisches Design macht die Bedienung einfach, die Wartung leicht und die Produktion effizient, ideal für die Befestigungs-, Automobil- und Präzisionsmaschinenindustrie.

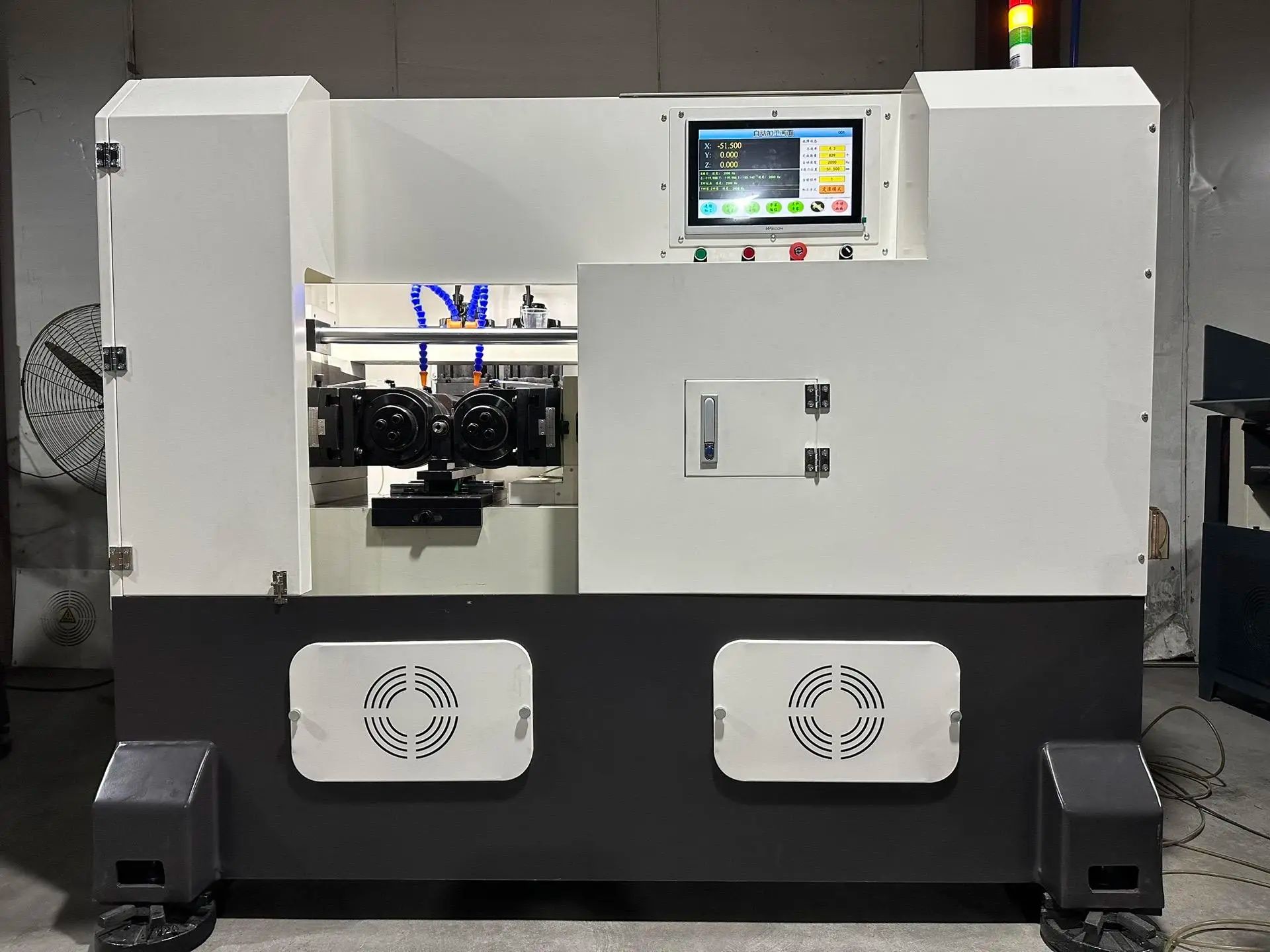

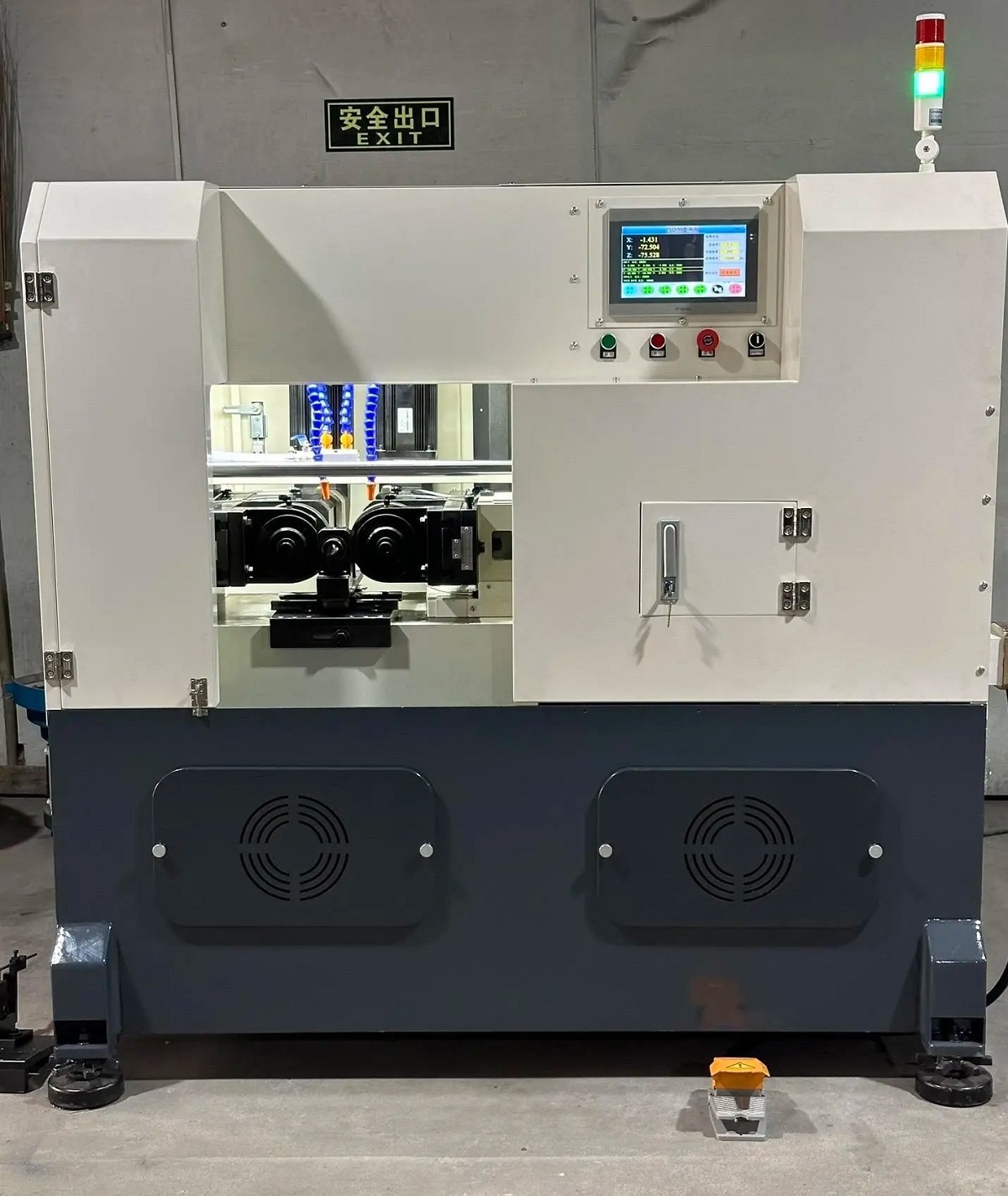

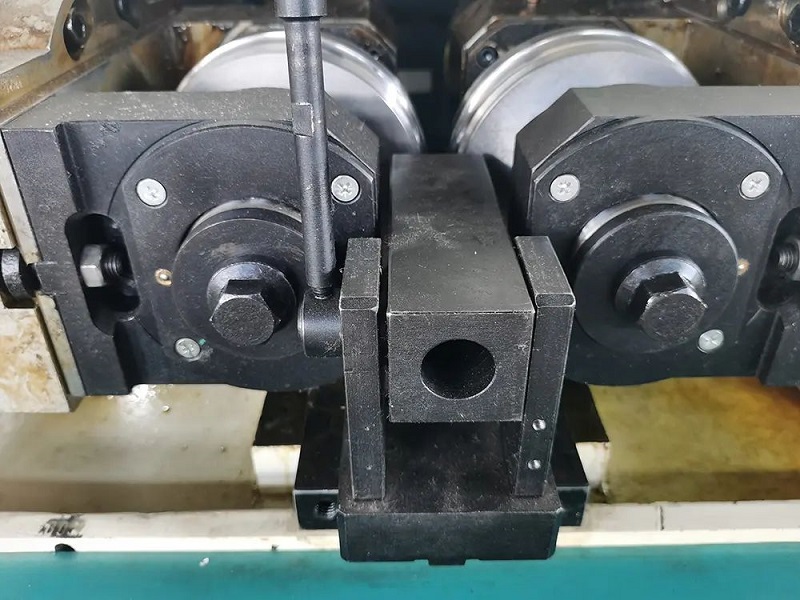

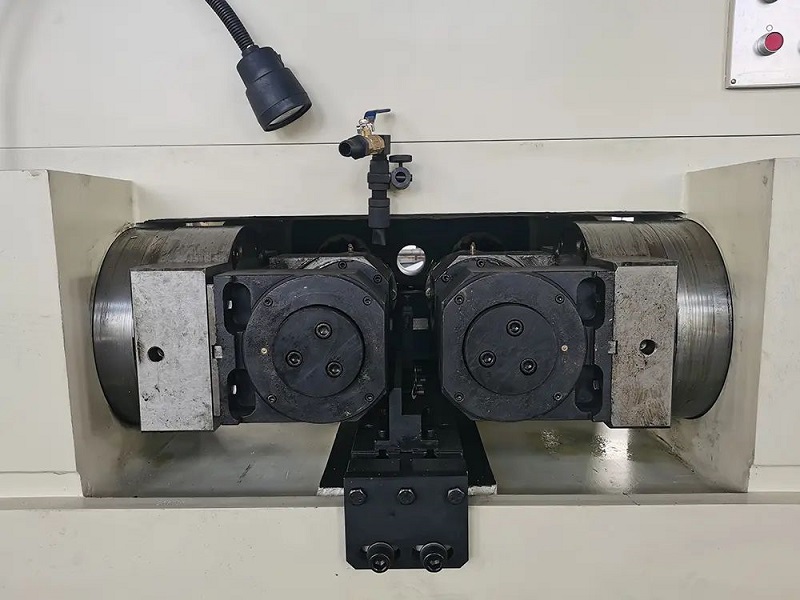

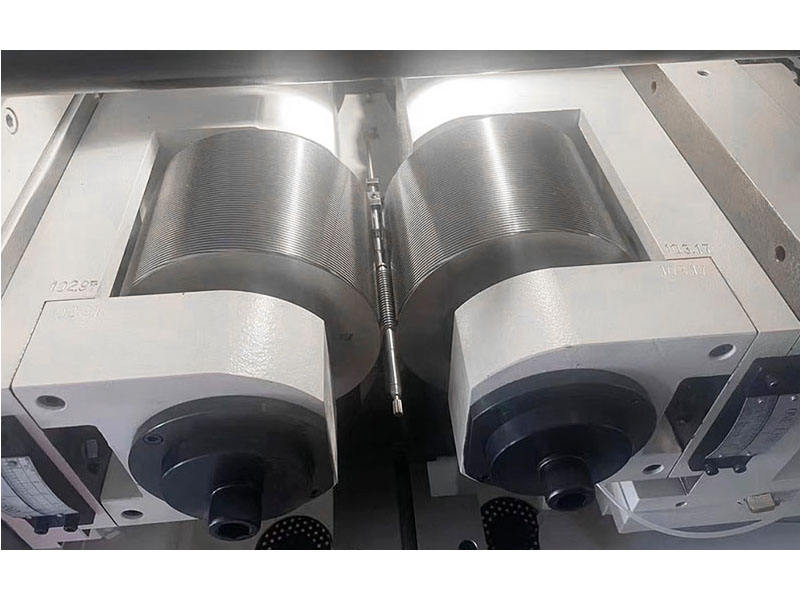

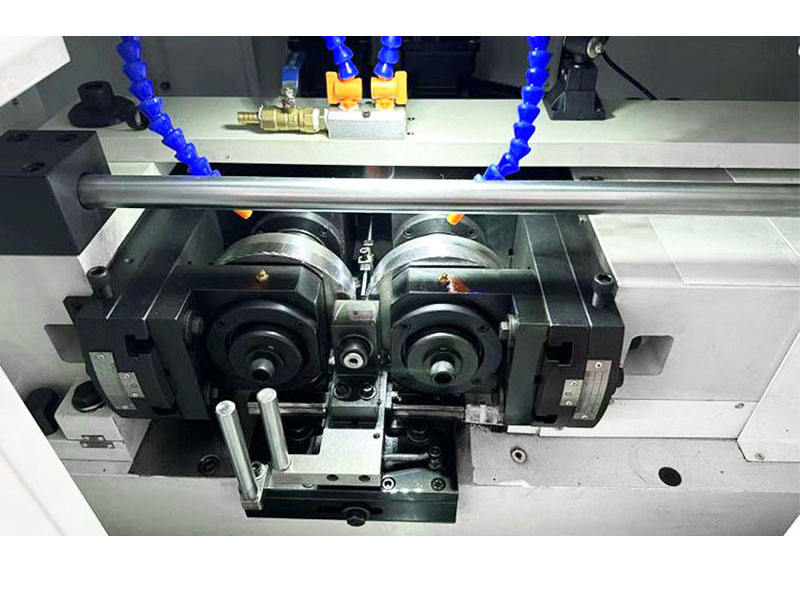

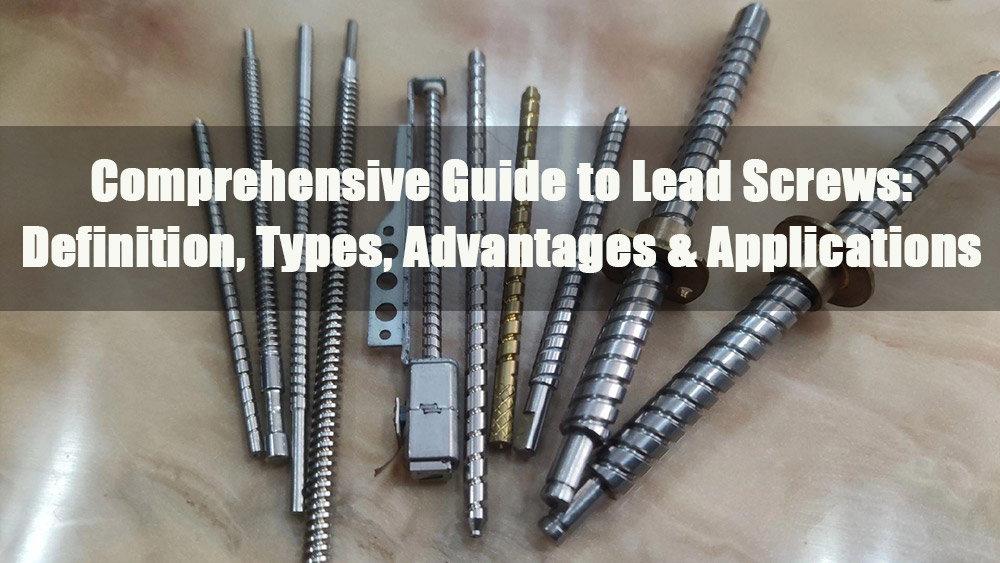

Maschinenfotos

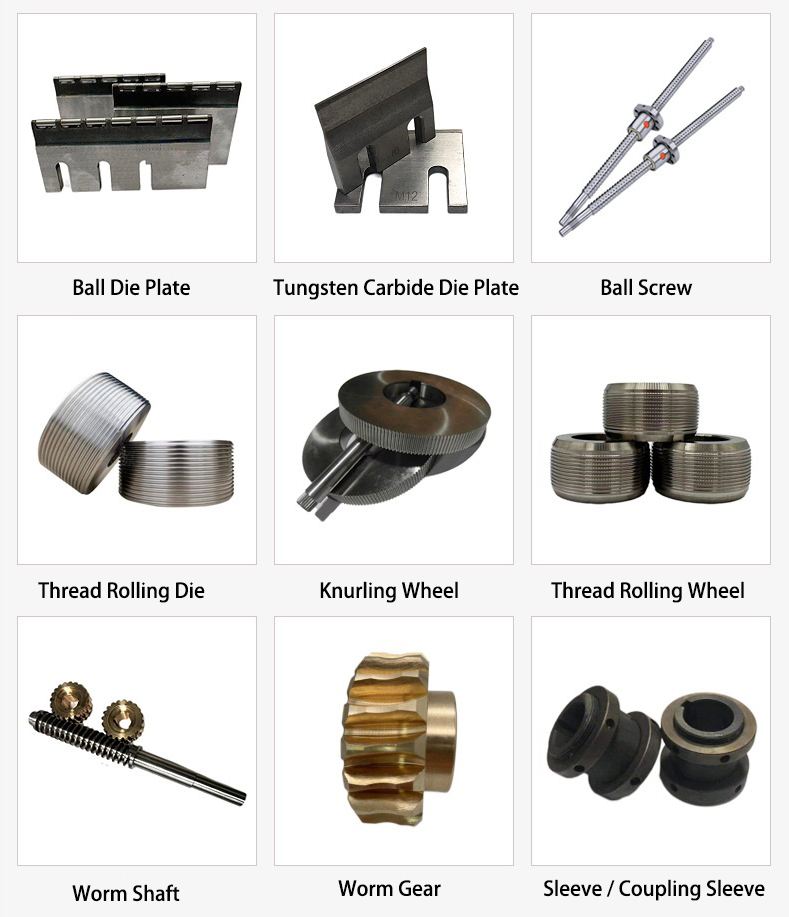

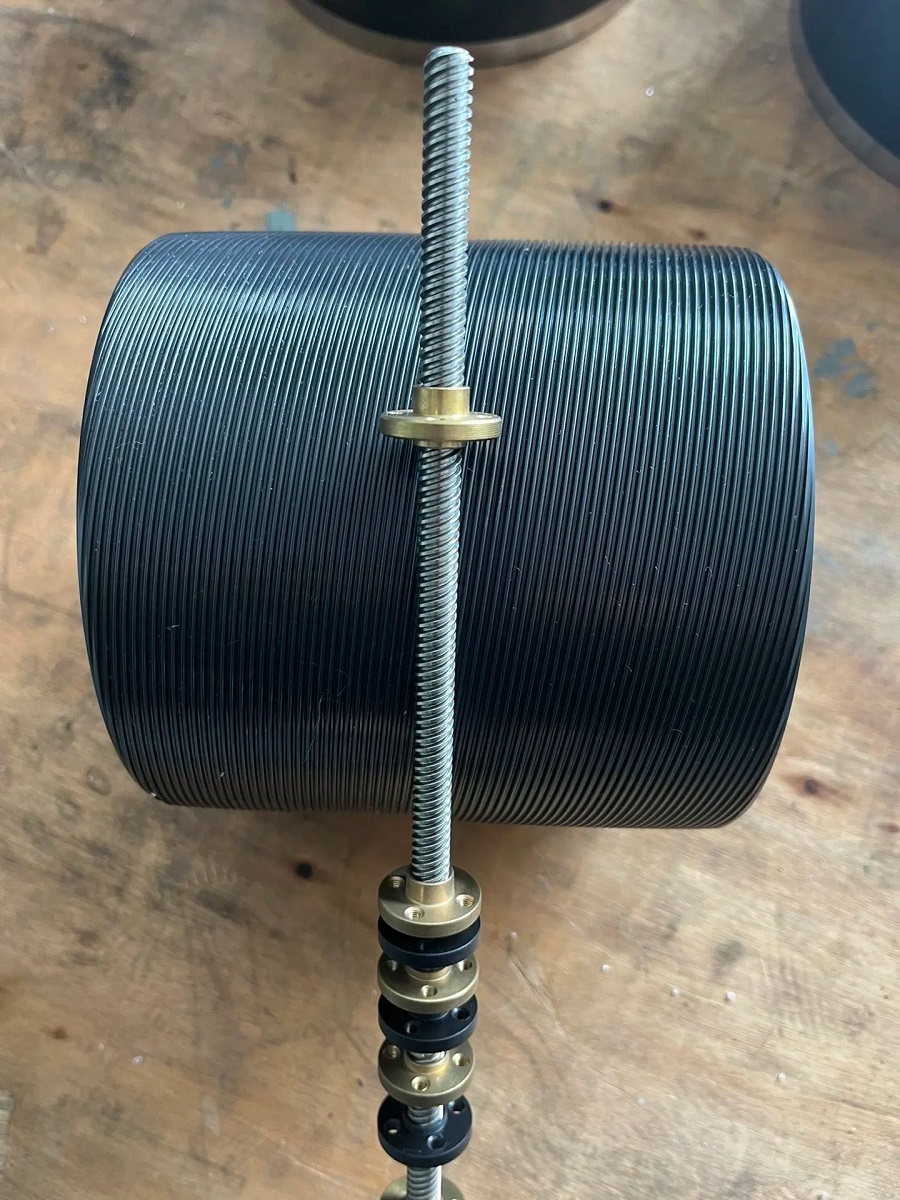

Maschinenanwendung

Hauptmerkmale

- Hohe Leistung – Servomotorantrieb liefert bis zu 30 Tonnen Walzdruck mit zwei unabhängigen Spindeln für eine abweichungsfreie Synchronsteuerung.

- Breite Anwendung – Unterstützt Einlauf- und Durchlaufwalzen für Standard-, Schnecken-, Trapez- und Sondergewinde mit flexiblen Durchmesser- und Steigungsbereichen.

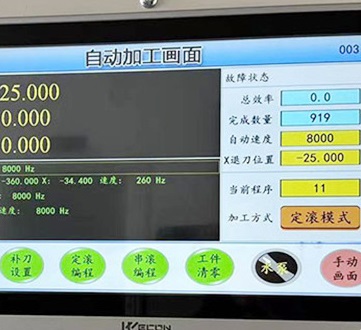

- Präzise Steuerung – CNC-gesteuerte Pitch-Verstellung mit digitaler Anzeige und gespeicherten Parametern gewährleistet Genauigkeit und einfache Wiederholvorgänge.

- Erweiterte Struktur – Servogetriebene Wellen, Linearführungen und Kugelumlaufspindeln mit großem Durchmesser garantieren hohe Steifigkeit, Stabilität und Präzision.

- Benutzerfreundlich und zuverlässig – Nichthydraulische Ausführung, stabile Bearbeitungsgenauigkeit und einfache Befehlseingaben für komplexe Walzvorgänge.

- Wartungsfreundlich – Kompaktes, langlebiges Design mit einfacher Bedienung und komfortabler Wartung.

Anpassbare CNC-Gewinderollmaschine mit austauschbaren Matrizen

Bitte füllen Sie dieses Formular aus, um eine Angebotsanfrage zu senden. Ein Mitglied unseres Teams wird die Details prüfen und sich innerhalb von 12 Geschäftsstunden bei Ihnen melden.