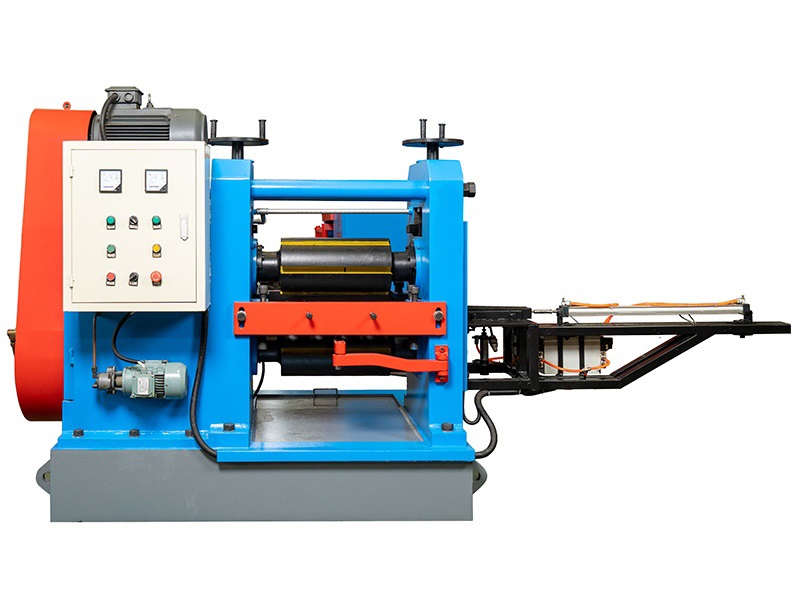

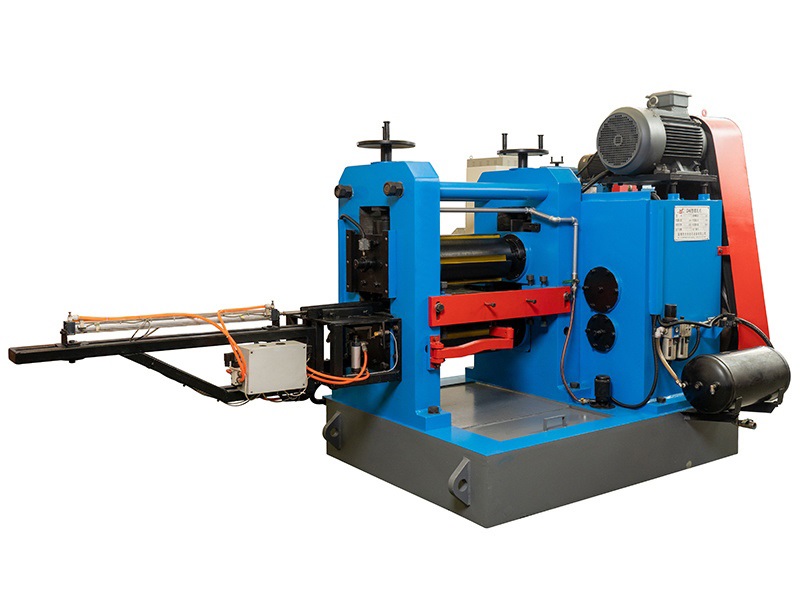

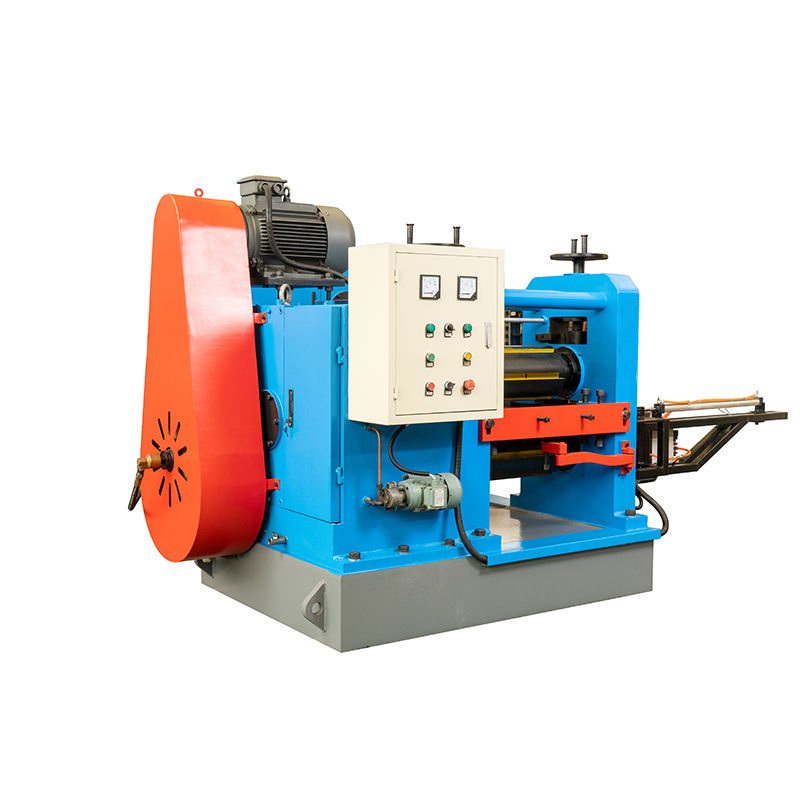

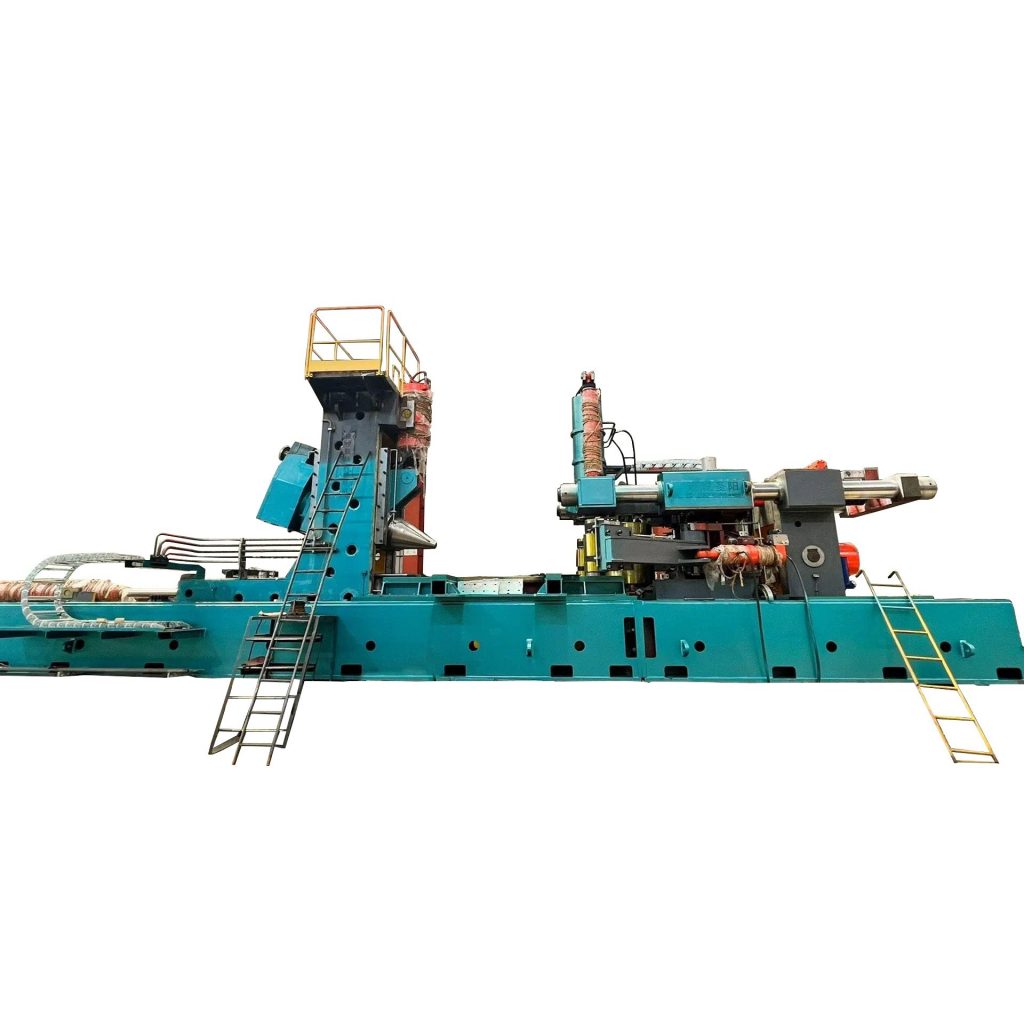

Key Features of ALEKVS Cross Wedge Rolling Machines

- One-piece forming with high efficiency and long die service life, designed for mass and automated forging production.

- Equipped with a guide plate system to prevent skewing, ensuring dimensional accuracy and stable rolling performance.

- Adjustable in radial, axial, phase, and flaring directions, enabling precise process control.

- Integrated automatic feeding system with seamless upstream and downstream equipment connection for enhanced production line efficiency.

Comparison with Traditional Roll Forging Machines

- Conventional roll forging: Material flows mostly along the length direction, suitable for shaft elongation and plate rolling.

- Cross wedge rolling (CWR): Delivers higher productivity, improved material utilization, longer die life, and is particularly effective for large-scale production of shaft-type forgings.

Application

Application Value

- Material savings: Achieves up to 80% material utilization, significantly reducing raw material, labor, and energy costs.

- Full automation: Equipped with automatic feeding and rolling systems, supporting integration into intelligent production lines.

- High productivity: Each rolling cycle can produce two forgings in just a few seconds, ideal for large-scale manufacturing.

- High precision: Continuous grain flow along the product profile, refined microstructure, and improved mechanical properties.

Process Flow

Round steel cutting → Heating → Rolling → Normalizing → Shot blasting → Straightening → Finished cutting.

Through precision rolling dies, billets are formed closer to final shapes, minimizing machining allowance and reducing overall manufacturing cost.

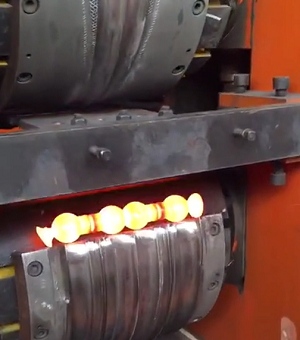

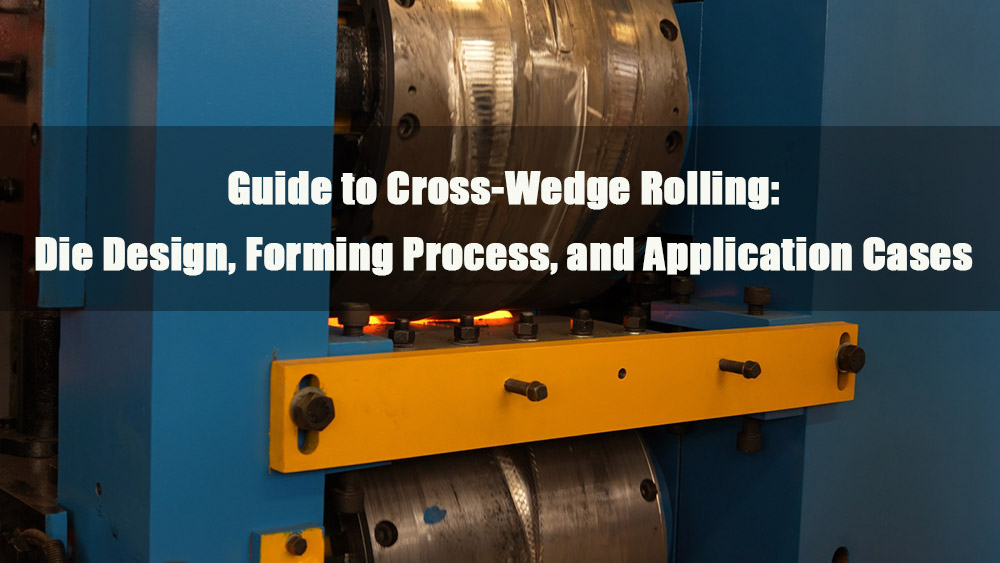

Process Principle

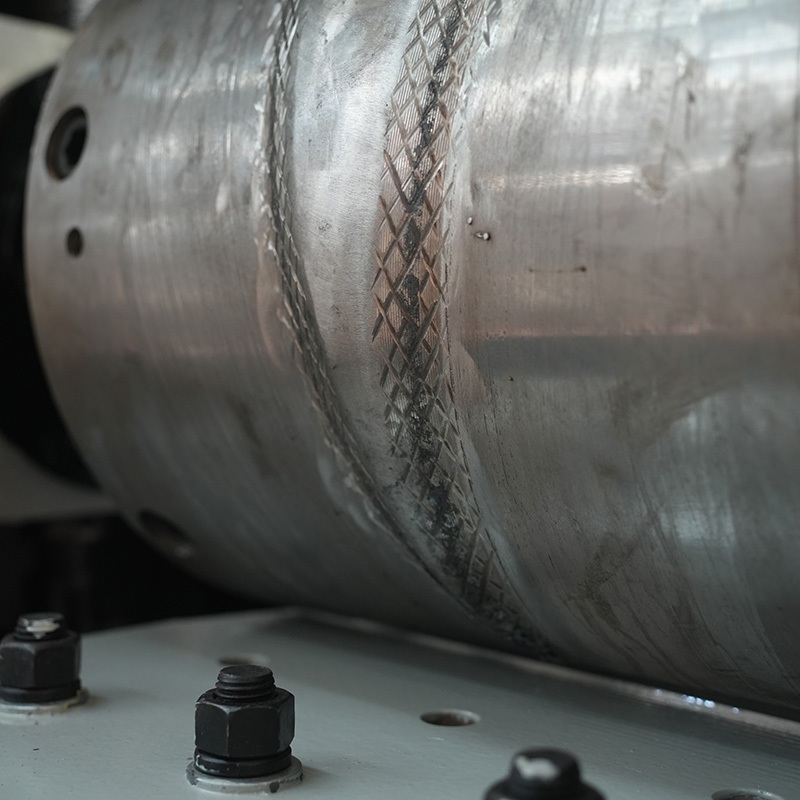

Cross Wedge Rolling (CWR) is an advanced forging technology in which cylindrical billets undergo continuous localized deformation between two rolls equipped with dies. The workpiece takes the exact shape of the die grooves as the rolls rotate in the same direction, driving the billet to deform radially under wedge compression and form into the desired shape.

Compared with traditional die forging, CWR technology offers the following advantages:

- Lower forming force and reduced friction, resulting in longer die life.

- Near-net-shape forming with 10%–30% higher material utilization.

- Simple and efficient process: one forging can be completed in just a few seconds with a single roll rotation.

- Shock-free and low-noise operation, highly suitable for mass production and automated forging lines.

Please fill out this form to submit a request for quote. One of our team members will review the details and be in touch within 12 business hours.