- 1.0What is a Lead Screw? Principle, Structure, and Basic Definition

- 2.0How Are Lead Screws Manufactured? Core Equipment and Processes

- 3.0Common Lead Screw Thread Types: Acme, Square, Buttress, and Others

- 4.0Advantages and Disadvantages of Lead Screws: Balancing Cost, Performance, and Application

- 5.0Frequently Asked Questions About Lead Screws: Bending, Back-Driving, and Lubrication

- 6.0Material Selection for Lead Screws: From Carbon Steel to Plastics

- 7.0Lead Screws vs. Ball Screws: Choosing the Right Linear Motion Component

- 8.0How to Select the Right Lead Screw? Key Parameters and Selection Tips

- 9.0Conclusion

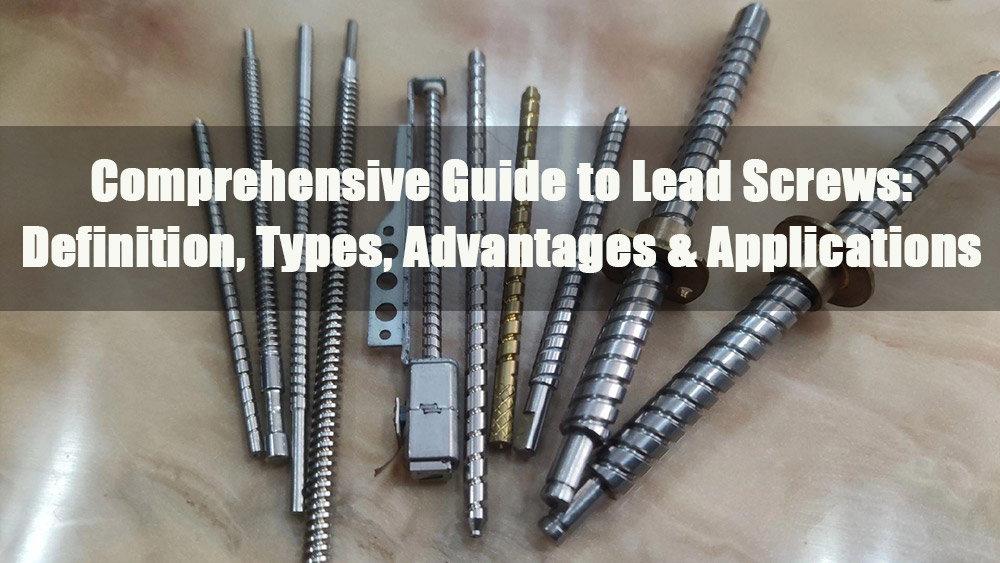

In the field of mechanical transmission and linear motion control, lead screws play a critical role as a core component for converting rotary motion into linear motion.

They are widely used across industrial automation, robotics, medical devices, and even household appliances. From precise positioning in CNC machines to smooth operation in home automation systems, lead screws are indispensable in both high-tech and everyday applications.

1.0What is a Lead Screw? Principle, Structure, and Basic Definition

A lead screw (also known as a power screw) is a mechanical device that converts rotary motion into linear motion through direct thread engagement. Its primary function is to transform torque into axial thrust or pull, without relying on recirculating ball bearings. Instead, motion is transmitted through direct thread contact between the screw shaft and nut.

Main components include:

- Screw shaft: Cylindrical rod with continuous threads or grooves, typically made from carbon steel, stainless steel, or aluminum. For special applications, titanium, ceramics, or engineering plastics may be used.

- Threads: The helical interface between the screw shaft and nut. Its geometry (such as angle and profile) directly affects efficiency, load capacity, and accuracy.

- Nut: The counterpart to the screw shaft threads. Connected to the load, the nut translates rotational input into linear motion by restricting its own rotation (or the screw’s rotation).

Working modes:

- Fixed shaft, rotating nut: A motor or manual drive rotates the nut along a fixed screw shaft, converting torque into linear displacement.

- Fixed nut, rotating shaft: The nut is held in place while the screw shaft rotates, producing linear movement of the nut along the shaft’s axis.

2.0How Are Lead Screws Manufactured? Core Equipment and Processes

The manufacturing process of a lead screw directly determines its accuracy, strength, and durability. Among these, thread forming is the most critical step, and the method is chosen based on production volume and precision requirements.

2.1Thread Rolling: The Mainstream Choice for High-Volume Production

Thread rolling is the dominant cold-forming process for lead screws. It uses mechanical pressure to displace material and form threads, rather than cutting away material. This improves both surface finish and strength due to work hardening.

Key equipment includes:

- 2-Roll Thread Rolling Machine: The most common setup, using two dies to compress the cylindrical blank. Suitable for standard single- or double-start threads (e.g., trapezoidal, Acme). Offers high efficiency and low cost, ideal for medium-volume production.

- 3-Die Thread Rolling Machine: Uses three dies positioned at 120° intervals for uniform radial pressure. Produces higher precision (ISO 4H/5g), better roundness, and is capable of multi-start threads (e.g., 4-start). Often used in precision lead screws for medical or machine tool applications, as well as larger diameters.

- CNC Precision Thread Rolling Machine: Integrates CNC controls for feed, depth, and die speed. Capable of producing complex profiles (e.g., serrated or custom threads) with tight tolerances down to 0.01 mm. Essential for aerospace, semiconductor, or other high-end applications, supporting both low-volume customization and mass production.

2.2Thread Cutting: A Precision Alternative for Special Applications

For small-batch production, complex threads (deep or non-standard profiles), or hard-to-machine materials such as titanium or ceramics, thread cutting is preferred.

Whirling Thread Milling Machine: Uses a high-speed angled cutter to match the screw’s lead angle. It completes thread cutting in a single pass with excellent control over pitch, depth, and finish. Suitable for high-tolerance lead screws (IT3–IT5 grade). However, it is slower and more expensive than rolling.

2.3Secondary Processes

After thread forming, several additional steps are required:

- Surface treatment: Zinc plating for corrosion resistance on carbon steel, passivation for stainless steel, or PTFE coatings for wear resistance.

- Precision inspection: Measuring pitch diameter with thread micrometers, or lead accuracy with laser measuring devices.

- Assembly: Adjusting screw-nut clearance to ensure proper fit and performance.

The combination of these processes results in a finished lead screw with the required performance characteristics.

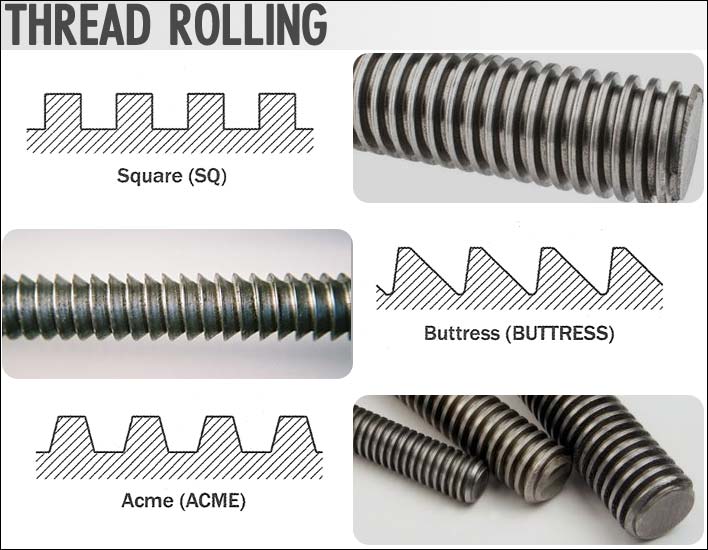

3.0Common Lead Screw Thread Types: Acme, Square, Buttress, and Others

The performance and application of a lead screw largely depend on its thread design. Different thread geometries influence efficiency, load capacity, and manufacturability. Below are the most common thread types used in industrial applications:

3.1Acme Thread (Trapezoidal Thread): The Industrial Standard

The Acme thread, with its 29° trapezoidal profile, is the most widely used lead screw thread type in industry. It features a broad thread base, which provides strong structural integrity.

- Advantages: Easier to manufacture compared to other thread forms (multi-point tooling can be used), high wear resistance, suitable for medium to heavy loads, and compensating nuts can offset wear, extending service life.

- Limitations: Lower efficiency than square threads, with slightly higher friction losses.

- Applications: Bench vises, clamps, valve stems, precision actuators, lathes, and other general industrial equipment. Ideal where cost-effectiveness and durability are equally important.

Note: Metric trapezoidal threads (30° profile) are similar in principle to Acme threads but follow ISO standards. They are common in Europe and widely applied in CNC machinery and robotics.

3.2Square Thread: The High-Efficiency Choice

Square threads feature thread flanks perpendicular to the screw axis, forming a 90° angle. The reduced contact area minimizes frictional losses.

- Advantages: Highest efficiency among thread types. Provides greater load capacity at the same size, or reduces motor requirements for the same load. Generates no radial pressure, making it suitable for precision motion transfer.

- Limitations: Difficult to manufacture (requires single-point cutting), higher cost, reduced root strength, and limited load capacity.

- Applications: Screw jacks, precision machine tools, and vises where high efficiency and accuracy are required but extreme axial loads are not.

3.3Buttress Thread: Designed for One-Way Heavy Loads

The buttress thread (asymmetrical trapezoidal profile) is optimized for high axial loads in one direction. Its load-bearing flank has a shallow 7° angle, while the opposite flank is steeper at 45°, ensuring strong shear resistance.

- Advantages: Efficiency comparable to square threads, nearly twice the strength of square threads, capable of withstanding extreme unidirectional forces.

- Limitations: Poor performance under reverse loads; unsuitable for bidirectional motion.

- Applications: Large screw presses, heavy-duty lifting jacks, vertical actuators, and injection molding machines where unidirectional power transmission is required.

3.4Metric Trapezoidal Thread (Tr): International Standard

The metric trapezoidal thread shares the same working principle as Acme threads but features a 30° flank angle and conforms to ISO metric standards, making it widely adopted in international machinery.

- Advantages: High degree of standardization, compatibility with global components, and well-defined manufacturing/testing guidelines.

- Limitations: Slightly lower load capacity compared to Acme threads, but sufficient for most industrial needs.

- Applications: CNC machines, industrial robots, laboratory equipment, and general-purpose power transmission systems.

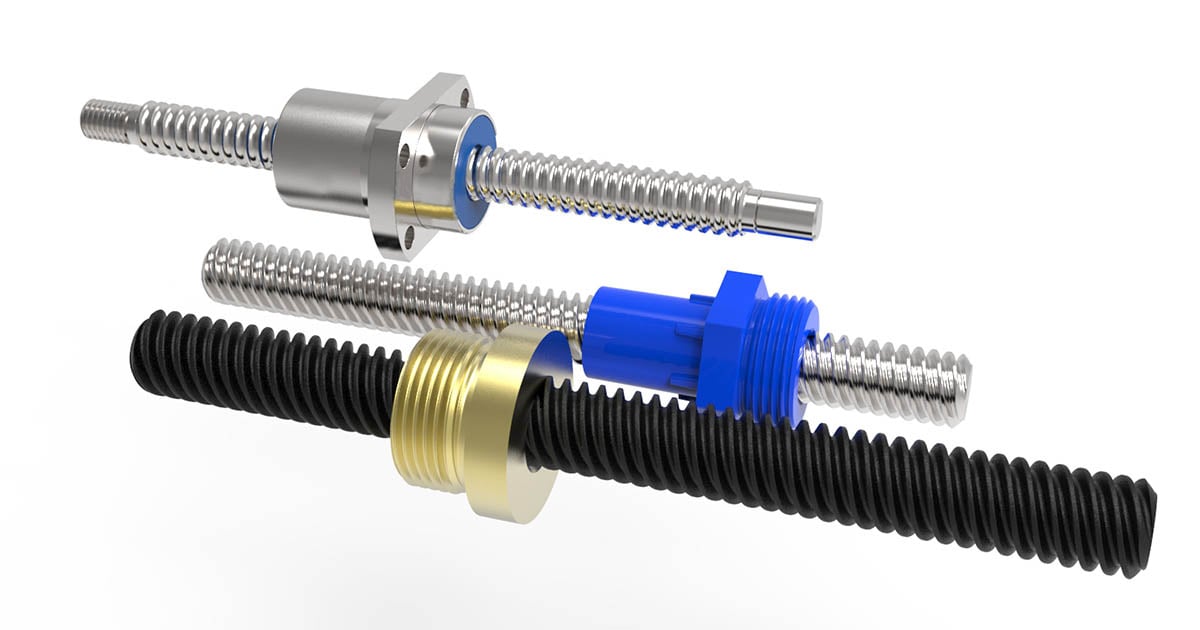

3.5Ball Screw Thread: High Precision, Low Friction

Ball screws employ a near-semicircular thread profile that allows rolling elements (balls) to circulate between the nut and screw shaft. This design converts sliding friction into rolling friction, resulting in extremely high efficiency—often above 90%.

- Advantages: Very low friction, long service life, exceptional accuracy, and capable of micrometer-level positioning.

- Limitations: Complex manufacturing process, high cost, and strict lubrication and sealing requirements.

- Applications: CNC machinery, semiconductor equipment, robotics, aerospace systems, and other applications demanding precision and repeatability.

4.0Advantages and Disadvantages of Lead Screws: Balancing Cost, Performance, and Application

4.1Key Advantages of Lead Screws

- Cost-effectiveness: Lower manufacturing costs compared to ball screws, making them ideal for budget-sensitive, light- to medium-load applications.

- Self-locking capability: Many lead screw types (e.g., trapezoidal and square threads) are inherently self-locking, holding position without additional brakes—especially beneficial in vertical systems.

- High load capacity: Within rated limits, lead screws can handle significant axial loads. Bronze-nut configurations can withstand several tons.

- Low maintenance: Simple construction with only three core parts (shaft, nut, threads). Some self-lubricating designs require no additional lubrication over their lifespan.

- Environmental resilience: Absence of rolling elements makes them less sensitive to dust or debris, suitable for harsh environments.

- Quiet and smooth operation: Sliding thread contact generates minimal vibration and noise, making them suitable for noise-sensitive applications such as medical devices or home automation.

4.2Limitations of Lead Screws

- Lower efficiency: Sliding contact results in friction losses, with efficiency typically below 40% (optimized designs may reach ~50%). Not ideal for continuous power transmission.

- Faster wear: Continuous sliding contact accelerates thread wear. Square thread nuts require periodic replacement, while trapezoidal threads can use split nuts to compensate for wear, but still face reduced lifespan.

- Speed limitations: Constrained by critical speed; exceeding this causes excessive shaft vibration. Operational speeds are usually limited to 80% of critical speed, restricting suitability for high-speed applications.

- Torque inefficiency: High friction makes them unsuitable for applications demanding very high torque transmission.

5.0Frequently Asked Questions About Lead Screws: Bending, Back-Driving, and Lubrication

5.1Can Lead Screws Bend? How to Minimize the Risk

Lead screws can bend under certain conditions, mainly influenced by length and load usage:

- Screw length: Longer screws are more prone to bending due to reduced stiffness.

- Load compliance: Using the screw within its rated load and following manufacturer guidelines (such as alignment accuracy and support method) helps prevent bending.

- Design recommendation: Always calculate the peak and continuous loads required by the actuator to ensure the screw’s load rating matches the application, reducing the risk of bending from the outset.

5.2Can Lead Screws Back-Drive? Efficiency as the Key Factor

Back-driving occurs when the load causes the screw to rotate, leading to unintended motion. Whether this happens depends on screw efficiency:

- Low efficiency (<40%): In most cases, back-driving does not occur under normal conditions without external vibration. This is why many lead screws are inherently self-locking.

- High efficiency (>40%): Screws with optimized thread designs or those in vibration-prone environments may experience back-driving. In such cases, an additional braking or locking mechanism is recommended.

5.3Do Lead Screws Require Lubrication? Maintenance Guidelines

Lubrication requirements vary depending on design and operating environment:

Self-lubricating screws: Some lead screws in electric actuators are pre-lubricated and require no additional lubrication throughout their service life, provided they are used within rated conditions.

Heavy-duty or harsh environments: For high-load, high-speed, or dusty/humid environments, periodic lubrication is necessary.

Avoid using contaminated grease, which accelerates wear.

Consider dry-film lubricants or reapplying a thin layer of clean grease after maintenance.

Bronze nuts: While naturally self-lubricating, bronze nuts still benefit from light grease to ensure smooth operation and extend lifespan.

6.0Material Selection for Lead Screws: From Carbon Steel to Plastics

The choice of material depends on application requirements such as load, environment, precision, and cost. Below are common materials and their characteristics:

| Material Type | Key Characteristics | Typical Applications |

| Carbon Steel | High strength, low cost, easy to machine, requires anti-rust treatment | General industrial equipment (e.g., machine tools, jacks) in dry, non-corrosive environments |

| Stainless Steel | Corrosion-resistant, rust-proof, slightly lower strength than carbon steel | Moist or corrosive environment,s such as food processing or medical devices |

| Titanium Alloy | High strength, lightweight, corrosion-resistant, expensive | Aerospace and surgical equipment requiring strength-to-weight balance and corrosion resistance |

| Aluminum | Lightweight, easy to machine, lower strength | Light-load applications such as small automation systems and household appliances |

| Bronze | Self-lubricating, wear-resistant, high load capacity | Medium to heavy-load applications, such as precision machine nuts and actuators |

| Ceramic | Very high strength, heat-resistant,low-frictionn, very costly | Extreme condition,s such as high-temperature furnaces or semiconductor equipment |

| Plastic | Lightweight, self-lubricating, quiet, limited load capacity (≤150 kg) | Light-load and noise-sensitive uses such as printers, home appliances, or medical assistive devices |

Note: In some cases, lead screws are enhanced with surface coatings (e.g., PTFE-based) to improve durability in harsh environments and reduce lubrication requirements.

6.1Applications of Lead Screws: From Industry to Everyday Linear Motion

Thanks to advantages such as cost-effectiveness, self-locking ability, and adaptability to various environments, lead screws are widely used in many fields. Whenever smooth and controlled linear motion is required, lead screws can be applied:

6.2Industrial Applications:

- Machine tools: Positioning of worktables and tool feed in lathes, CNC machines, and milling machines.

- Automation and robotics: Joint drives in industrial robots, material pushing in automated production lines.

- Heavy machinery: Force transmission in screw presses and jacks; clamping mechanisms in fixtures and vises.

- Precision manufacturing: High-accuracy positioning in 3D printers, engraving machines, and rapid prototyping systems.

6.3Consumer and Everyday Applications:

- Home equipment: Linear drives in height-adjustable desks, curtain motors, and smart locks.

- Office equipment: Paper feeding and lens positioning in printers and scanners.

- Transportation: Linear actuators for car seat adjustments and sunroof operation.

6.4Medical Applications:

- Medical imaging equipment: Patient bed positioning in X-ray, MRI, and CT scanners.

- Minimally invasive surgery: Precise micro-movements in automated surgical instruments.

- Drug delivery: Dosing mechanisms in precision medication devices.

Note: Lead screws can be manufactured with diameters as small as 0.5 mm, or even smaller, to meet miniaturization requirements in medical and other specialized fields.

7.0Lead Screws vs. Ball Screws: Choosing the Right Linear Motion Component

Both lead screws and ball screws convert rotary motion into linear motion, but their structure and performances differ significantly. Selection should be based on application requirements:

| Comparison Factor | Lead Screw | Ball Screw |

| Core Structure | Direct sliding contact between screw and nut, no rolling elements | Nut contains circulating ball bearings, motion transmitted via rolling |

| Efficiency | Low (typically ≤40%) | High (typically 85–95%) |

| Accuracy | Moderate (suitable for general applications) | High (superior positioning and repeatability) |

| Self-Locking | Usually self-locking (when efficiency <40%) | Not self-locking (requires external brake) |

| Cost | Low (simple structure, easy to manufacture) | High (complex design, requires precision machining) |

| Noise | Low (sliding contact, quiet operation) | Higher (ball rolling generates noise) |

| Load Capacity | Medium to heavy load (bronze nuts can support several tons) | Medium to heavy load (less impact resistance) |

| Wear & Service Life | Faster wear, shorter lifespan | Slower wear, predictable life (L10 standard) |

| Typical Applications | Medium/light load, low speed, budget-sensitive, vertical motion | High-speed, high-precision, continuous duty, efficiency-critical applications |

8.0How to Select the Right Lead Screw? Key Parameters and Selection Tips

Choosing a lead screw should be based on the application requirements, with special attention to the following critical parameters to ensure that performance matches system needs:

8.1Load Capacity: Match Peak and Continuous Loads

- Peak Load: The instantaneous force during sudden acceleration or deceleration (can be up to 5 times the continuous load).

- Continuous Load: The average load (RMS value) acting on the nut over time, which directly determines the L10 service life of the screw.

- Material Guidelines: Plastic nuts typically support ≤150 kg, while bronze nuts can withstand several tons. Always select based on the actual load conditions.

8.2Speed: Operate Within the Critical Speed Range

The maximum operating speed is limited by the screw’s critical speed (exceeding this causes excessive shaft vibration and safety risks).

Recommended working speed ≤ 80% of the critical speed. Lower operating speeds help reduce heat buildup and eliminate the need for shorter duty cycles.

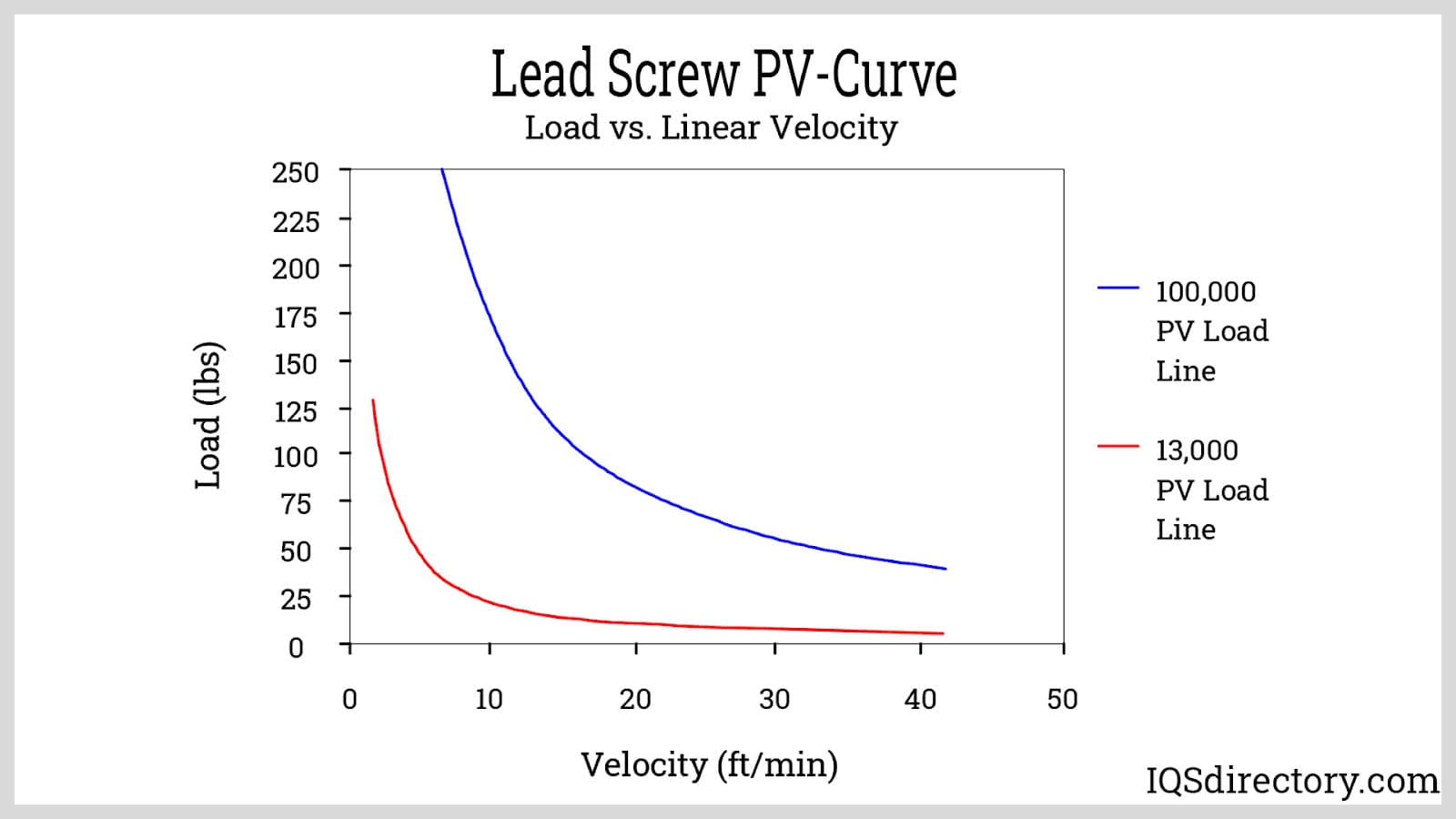

8.3Pressure-Velocity Factor (PV Value): Prevent Overheating Damage

The PV factor is the product of surface pressure × sliding velocity at the nut-screw interface, and it is critical for polymer lead screw assemblies.

Higher loads require reduced speeds to avoid frictional heat and permanent damage.

Higher speeds require reduced loads to ensure the actual PV value remains below the material’s PV limit, extending service life.

8.4Environmental Compatibility: Consider IP Rating and Materials

For harsh environments (dust, moisture, corrosion), stainless-steel screws or PTFE-coated screws are recommended, with attention to the IP rating (dust and water resistance).

For clean environments (medical, electronics), plastic or aluminum screws offer advantages in weight reduction and quiet operation.

8.5Thread Type: Match Efficiency and Load Direction

- Square threads for high-efficiency applications.

- Buttress threads for unidirectional heavy loads.

- Acme (trapezoidal) threads for general industrial use.

9.0Conclusion

- Established Technology

Lead screws are a proven linear motion solution, with performance heavily influenced by manufacturing techniques such as CNC precision thread rolling and 3-die thread rolling. - Selection Considerations

Choosing the right screw requires evaluating cost, load requirements, accuracy demands, and environmental conditions. - Best Applications

- Ideal for: medium-to-light loads, low-speed motion, vertical positioning, and cost-sensitive projects.

- Less suitable for: high-speed, high-precision, or continuous-duty applications, where ball screws or other advanced systems may be a better fit.

References

www.iqsdirectory.com/articles/ball-screw/lead-screws.html

www.progressiveautomations.com/blogs/how-to/lead-screw-questions-asked-answered

ractory.com/lead-screws/

kiwimotion.co.uk/technical-articles/ball-screws/ball-screw-vs-lead-screw/

blog.igus.ca/2021/06/03/what-is-a-lead-screw/