In modern metalworking, rolling is a critically important forming process. It is not only widely used in steel production, but also plays a central role in the processing of various metals such as aluminum, copper, and titanium. This article provides a brief overview of the definition of metal rolling, its historical development, and its core role in industrial manufacturing.

1.0What Is Metal Rolling?

In metallurgical engineering, rolling—also known as roll forming or calendering—is the process of shaping metal ingots by passing them between rotating rolls. When the temperature of the metal exceeds its recrystallization point during the operation, the process is referred to as hot rolling; otherwise, it is known as cold rolling.

Rolling is a metal deformation technique that uses one or more pairs of rotating rolls to apply compressive force to the material, reducing its thickness or altering its cross-sectional shape. It is typically applied to long workpieces such as plates, bars, and strips.

Recommended reading:What is Hot Rolled Coil (HRC)?

1.1A Brief History of the Process

Rolling technology originated in Europe in the late 1500s, initially used for processing precious metals. With the advent of the Industrial Revolution, rolling quickly became the dominant method in the steel industry. In the 20th century, the emergence of modern rolling mills further enhanced production capacity and precision, paving the way for automation and intelligent manufacturing in the rolling process.

1.2The Industrial Role of Rolling

Among all metal forming techniques, rolling holds a dominant position. According to industry statistics, approximately 90% of all metal materials undergo rolling at some stage of their production. It is the primary method for converting metal cast ingots into usable products such as steel plates, strips, and bars.

1.3Hot Rolling: The First Step in Metal Rolling

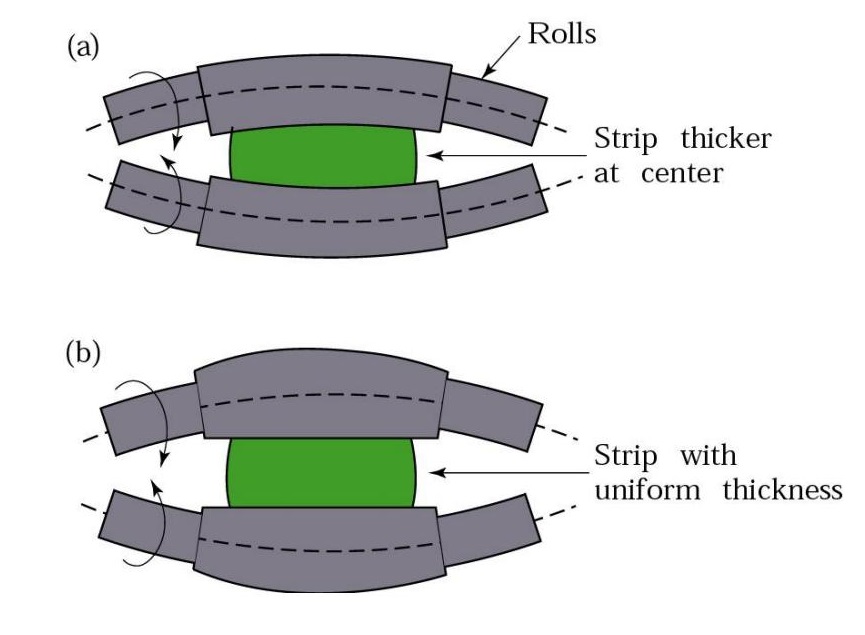

In practical production, the rolling process typically begins with hot rolling. Conducted above the metal’s recrystallization temperature, hot rolling crushes and refines the coarse grains inside the material, enhancing its mechanical properties, density, and workability.

Through hot rolling, the brittle and porous cast structure is transformed into a dense, forged microstructure. This step lays a solid foundation for subsequent processes such as cold rolling, heat treatment, or precision machining.

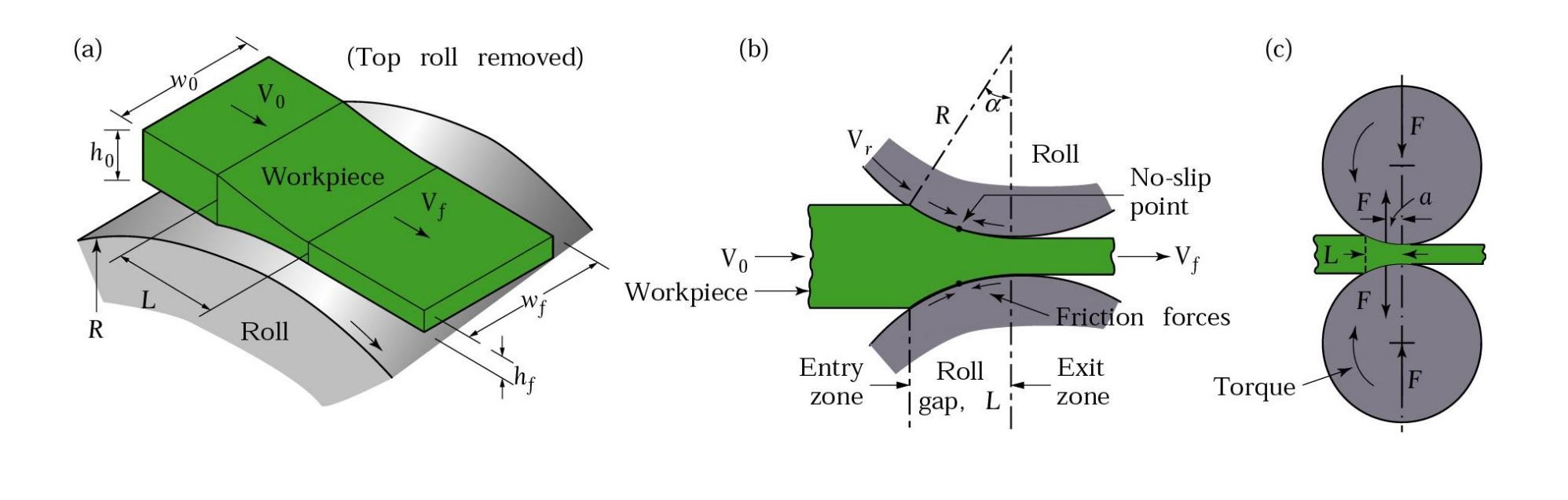

2.0Flat Rolling: The Most Fundamental Rolling Process

In metal rolling operations, flat rolling is the most commonly used and fundamental form. It is primarily applied to reduce the thickness of metal slabs while slightly increasing their width. Due to the uniform compressive force exerted by the rotating upper and lower rolls, this process is also commonly referred to as plain rolling.

The process involves several key technical parameters:

- Initial thickness: h₀

- Final thickness: h_f

- Roll-strip contact length: L

- Surface speed of rolls: V_r

- Entry velocity of the strip: V₀

- Exit velocity of the strip: V_f

During rolling, there exists a neutral point—the location along the contact arc where the velocity of the strip equals the surface speed of the rolls. This point divides the contact zone into a “forward slip region” and a “backward slip region.”

Key mathematical expressions related to flat rolling include:

Draft (thickness reduction):

h₀ − h_f

Maximum draft:

h₀ − h_f = μ²R

where μ is the coefficient of friction between the rolls and the metal

and R is the roll radius

While the primary goal of rolling is to reduce thickness, the principle of volume conservation results in a slight increase in strip width—typically around 2%. The volumetric relationship is expressed as:

h₀ × V₀ × w₀ = h_f × V_f × w_f

with the common assumption: w_f ≈ 1.02 × w₀

This approximation is crucial for understanding material flow and maintaining dimensional accuracy in rolled products.

2.1Rolling Force and Power Analysis

In flat rolling processes, rolling force is a critical parameter that influences equipment design, energy consumption, and process optimization. Under ideal conditions (neglecting friction), the rolling force can be estimated using the following formula:

F=L×w×Y_avg F = L w Y_avg

Where:

- F: Rolling force

- L: Contact length between the roll and the strip

- w: Average strip width

- Y_avg: Average true stress in the deformation zone

In industrial applications, it’s also essential to estimate the power required to drive the rolls. The rolling power can be calculated as follows:

SI units (kW):

Imperial units (hp):

Where N is the roll rotational speed in RPM.

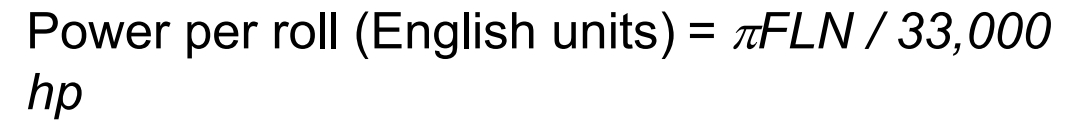

2.2Methods to Reduce Rolling Force and Roll Deformation

To reduce rolling force and minimize roll deflection, several process strategies can be employed:

- Reduce friction coefficient (e.g., lubrication)

- Use smaller-diameter rolls to decrease contact area

- Decrease the reduction per pass

- Increase rolling temperature to lower material strength

- Apply longitudinal strip tension (entry back tension and exit front tension)

- Grind roll crowns (typically center is ~0.25 mm higher than edges)

- Use simulated crown control via roll bending to induce central bulging

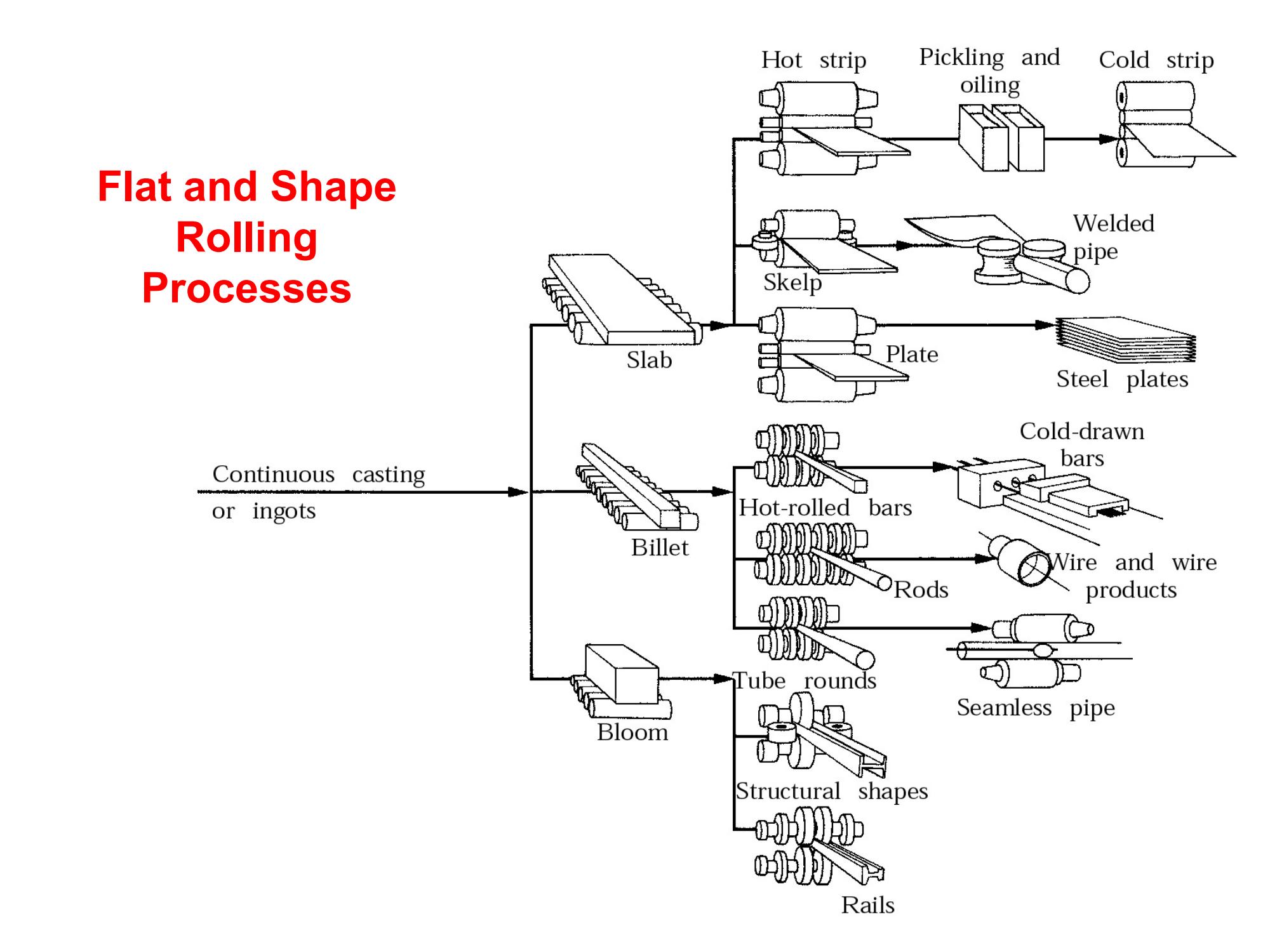

3.0Rolling Process Types

In flat rolling production, the initial stage typically involves hot rolling, transforming ingots or continuous cast billets into deformable intermediate products

- Bloom: Used for subsequent section rolling (e.g., I-beams, rails)

- Slab: Used for manufacturing plates or cold-rolled sheets

Other common rolling processes include:

- Cold Rolling: Performed at room temperature for improved dimensional accuracy and surface quality

- Pack Rolling: Simultaneous rolling of multiple metal layers for higher efficiency

- Temper Rolling: Enhances flatness and reduces residual stress in sheets

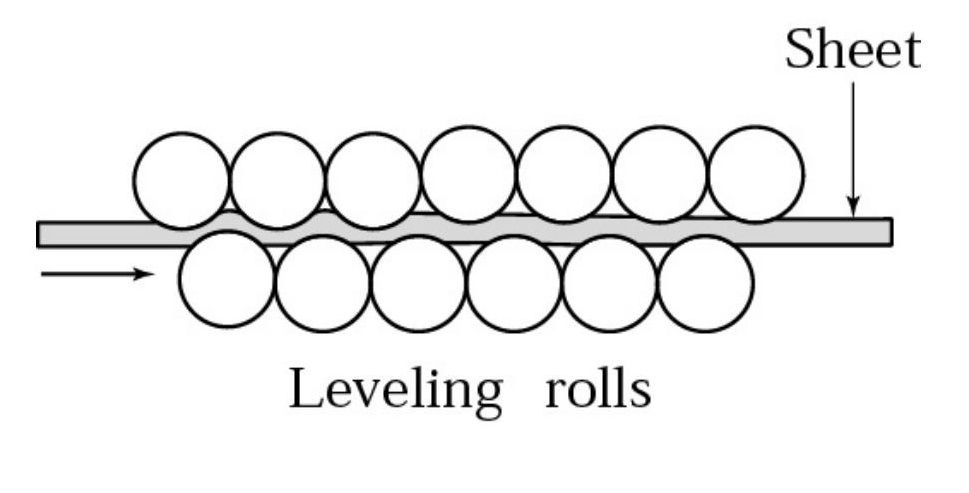

- Leveling Rolling: Dedicated to improving sheet flatness

4.0Common Rolling Defects

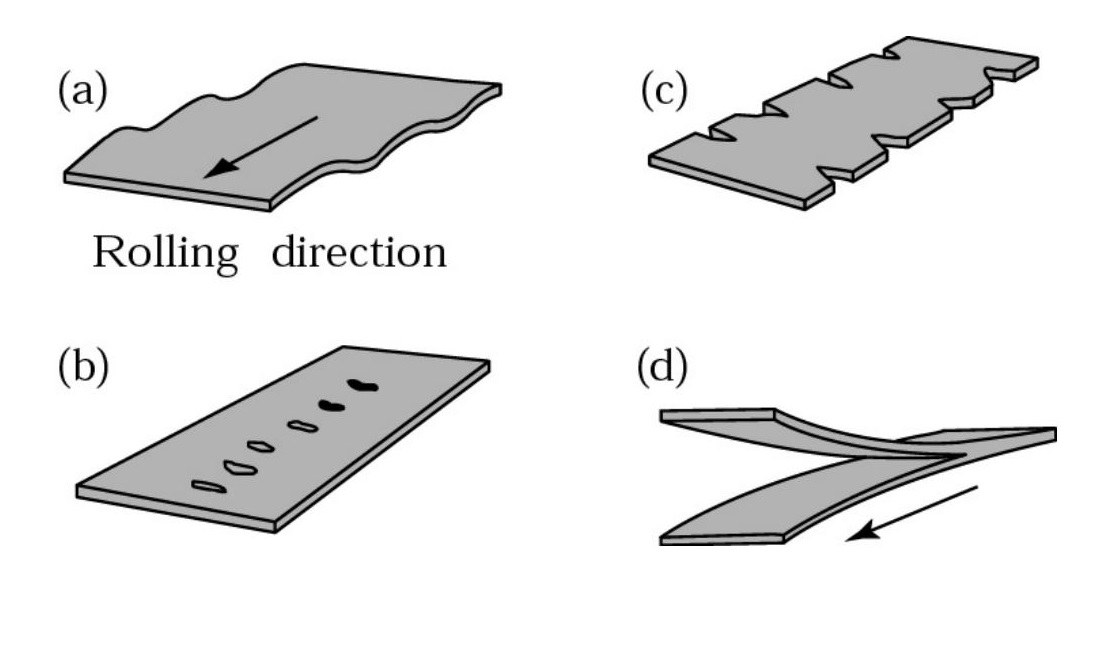

Although the flat rolling process is highly mature, several typical defects may still occur during actual production:

- Surface defects: Including scale, rust spots, scratches, pits, and cracks

- Wavy edges: Caused by excessive elongation at the strip edges due to roll elastic deformation

- Center splits: Tearing in the central part of the strip, often due to imbalanced tension control

- Edge cracks: Resulting from insufficient material ductility or stress concentration

- Alligatoring: A fracture pattern resembling an open jaw, caused by non-uniform internal structure or inconsistent deformation in the billet

These defects are often illustrated for easier identification. For example, educational materials commonly reference Figure 13.8, which shows:

(a) Wavy edges

(b) Center splits

(c) Edge cracks

(d) Alligatoring

Most rolling defects can be effectively prevented or detected early through proper control of process parameters and the use of online inspection systems.

5.0Characteristics of Rolled Products

Rolled products exhibit a range of physical and geometric properties that directly influence their subsequent processability and end-use performance:

Residual stress: Uneven plastic deformation during rolling may introduce internal stresses, affecting flatness and deformation during later processing

Thickness tolerance:

Cold-rolled sheets: High control precision, typically within ±0.1 to ±0.35 mm (approximately ±0.004 to ±0.014 inches)

Flatness tolerance:

Cold-rolled: ±15 mm/m (approx. 3/16 inch/foot)

Hot-rolled: ±55 mm/m (approx. 5/8 inch/foot)

Surface roughness:

Hot-rolled: Surface roughness comparable to sand casting

Cold-rolled: Smooth finish, suitable for electroplating, painting, and other finishing processes

Thickness designation: Commonly expressed using “Gage Number” — the smaller the number, the thicker the sheet (e.g., 10 gauge is thicker than 20 gauge)

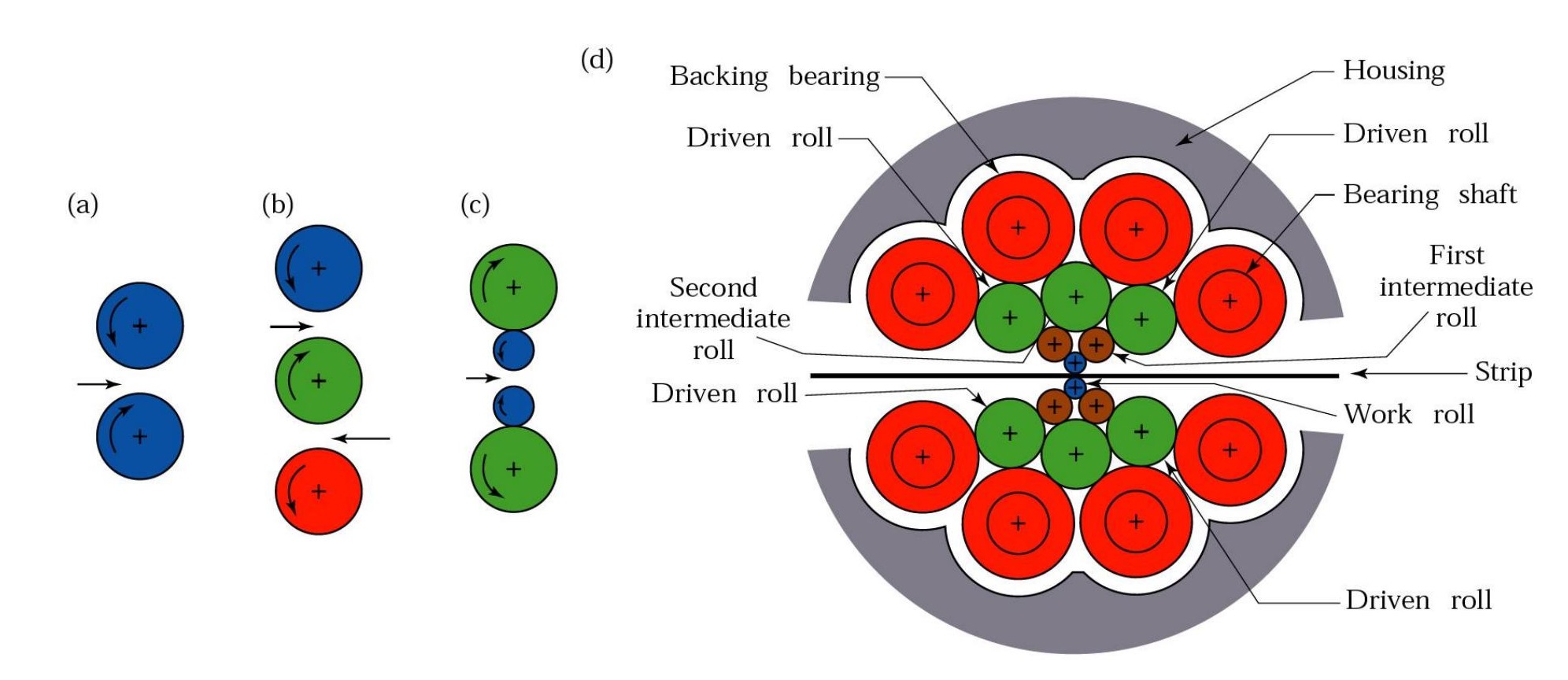

6.0Common Types of Rolling Mills

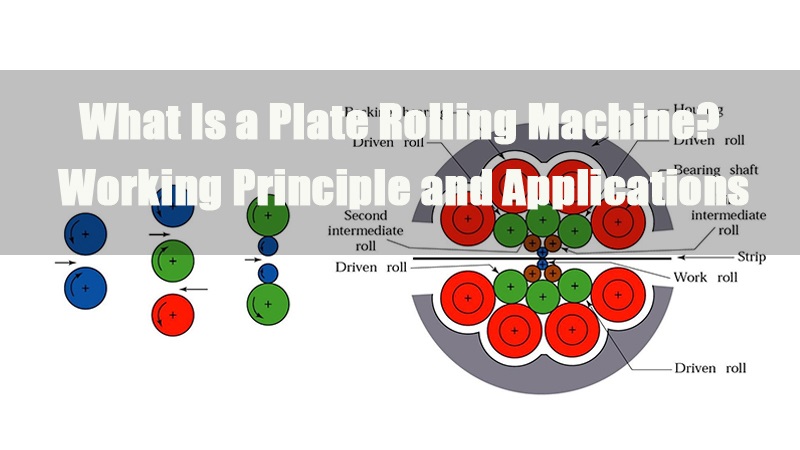

Different rolling processes require different types of rolling mill structures. The major classifications include:

- Two-High Rolling Mill: The most basic type, typically used for roughing or laboratory purposes

- Three-High Rolling Mill: Uses an upper, middle, and lower roll to alternate feed direction, improving efficiency

- Four-High Rolling Mill: Combines large backup rolls with smaller working rolls to enhance rigidity and dimensional precision

- Cluster (Sendzimir) Mill: Employs multiple backup rolls to support small-diameter working rolls, ideal for high-precision cold rolling of ultra-thin materials

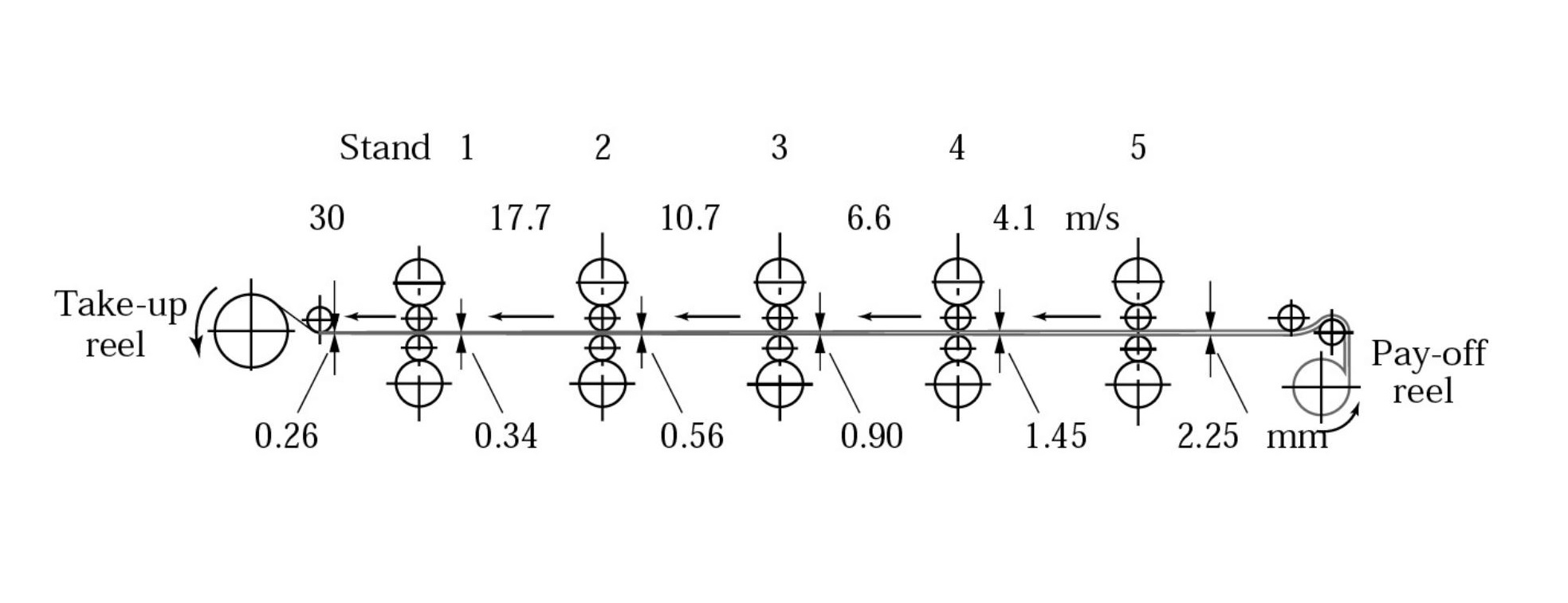

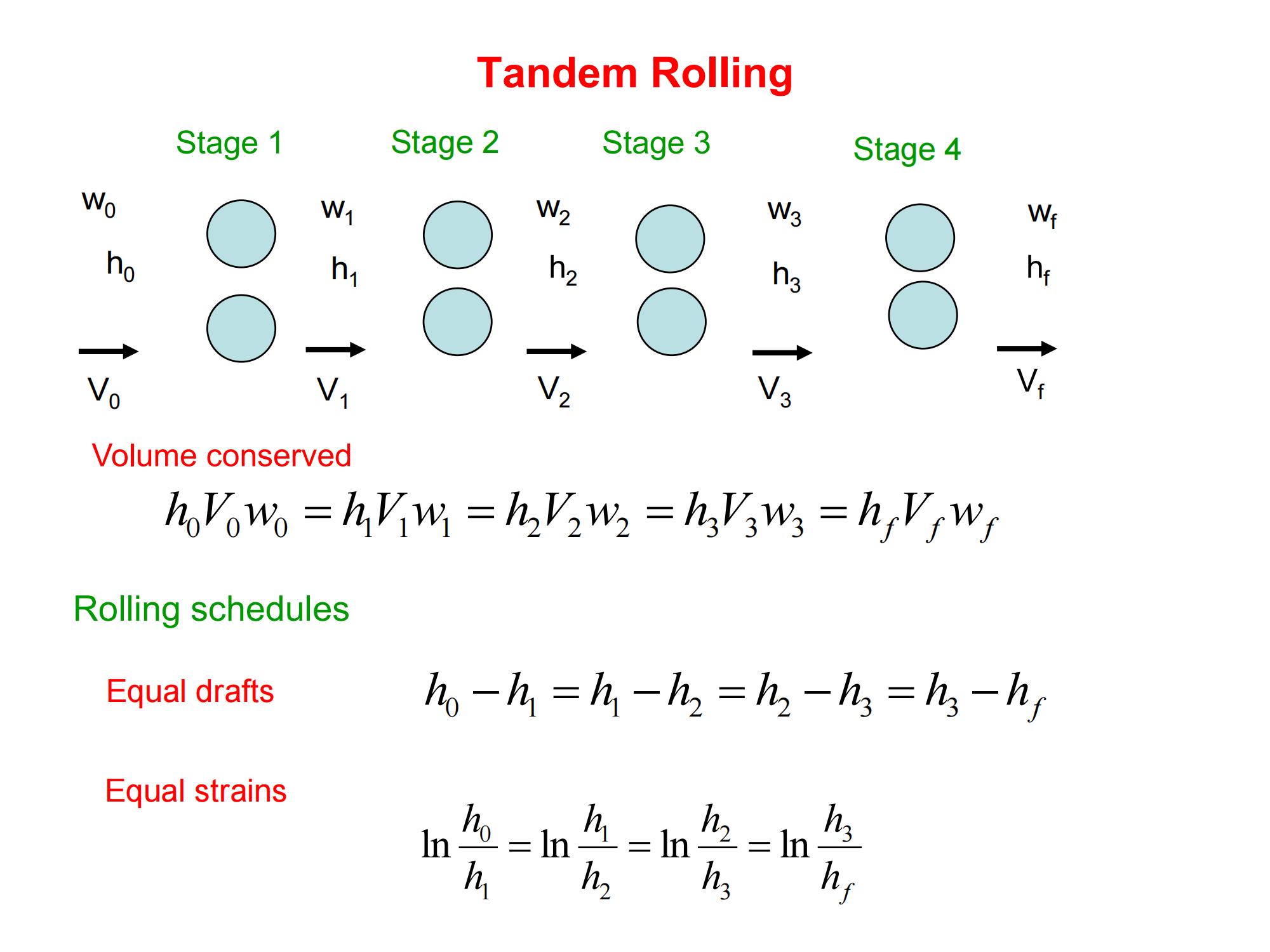

- Tandem Rolling Mill: Consists of multiple stands arranged in sequence for continuous multi-pass rolling, commonly used in large-scale cold rolling production

Rolling follows the principle of volume conservation:

h₀V₀w₀ = h₁V₁w₁ = h₂V₂w₂ = … = h_fV_fw_f

In practice, control is often achieved through equal reduction or equal strain strategies:

h₀ – h₁ = h₁ – h₂ = h₂ – h₃ = h₃ – h_f

7.0Specialized Rolling Processes

In addition to flat rolling, metal rolling includes several specialized forms to meet diverse part geometries and application requirements:

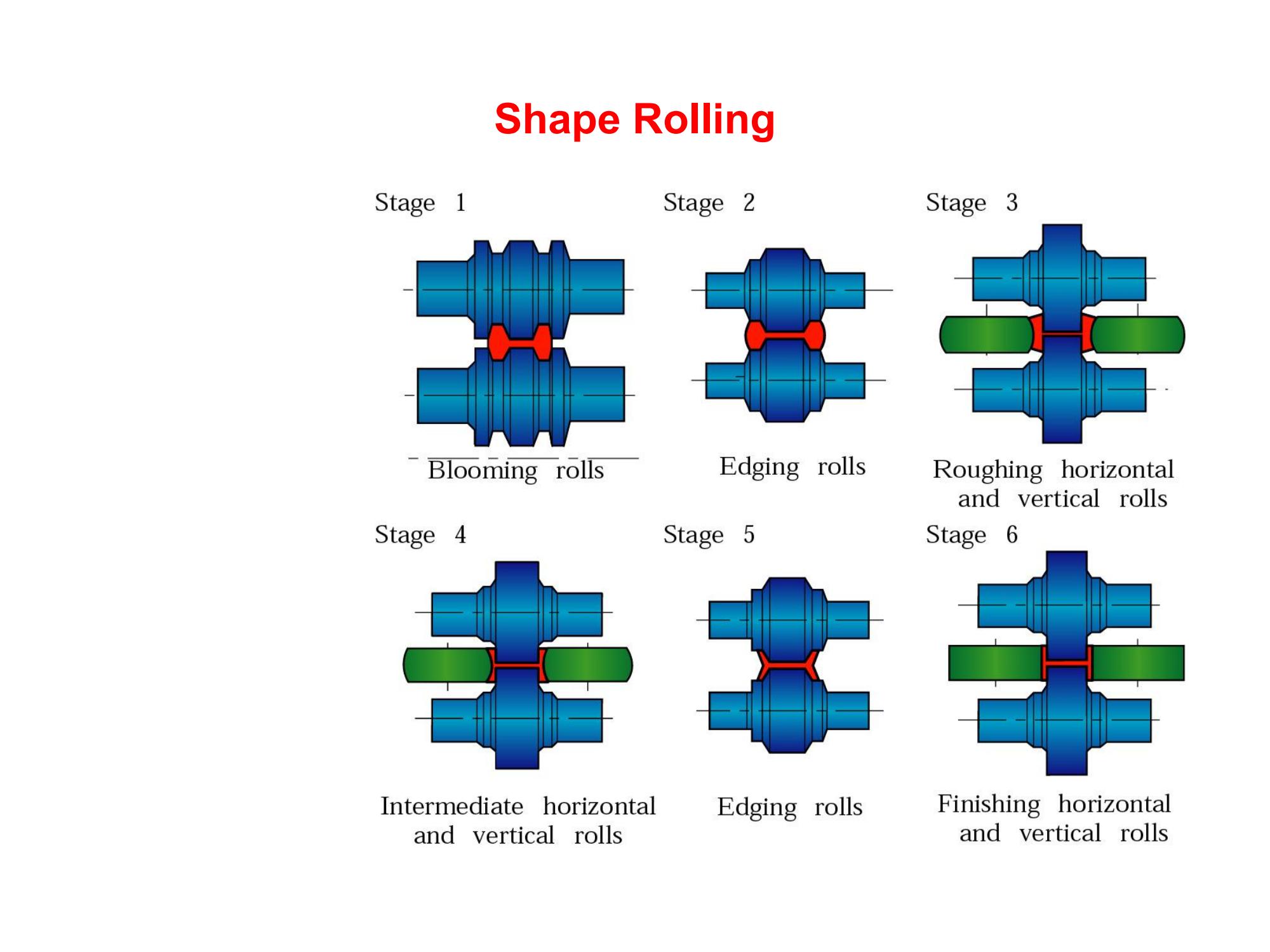

- Shape Rolling: The slab is passed through grooved rolls to form complex cross-sectional profiles such as I-beams, channel steel, and rails.

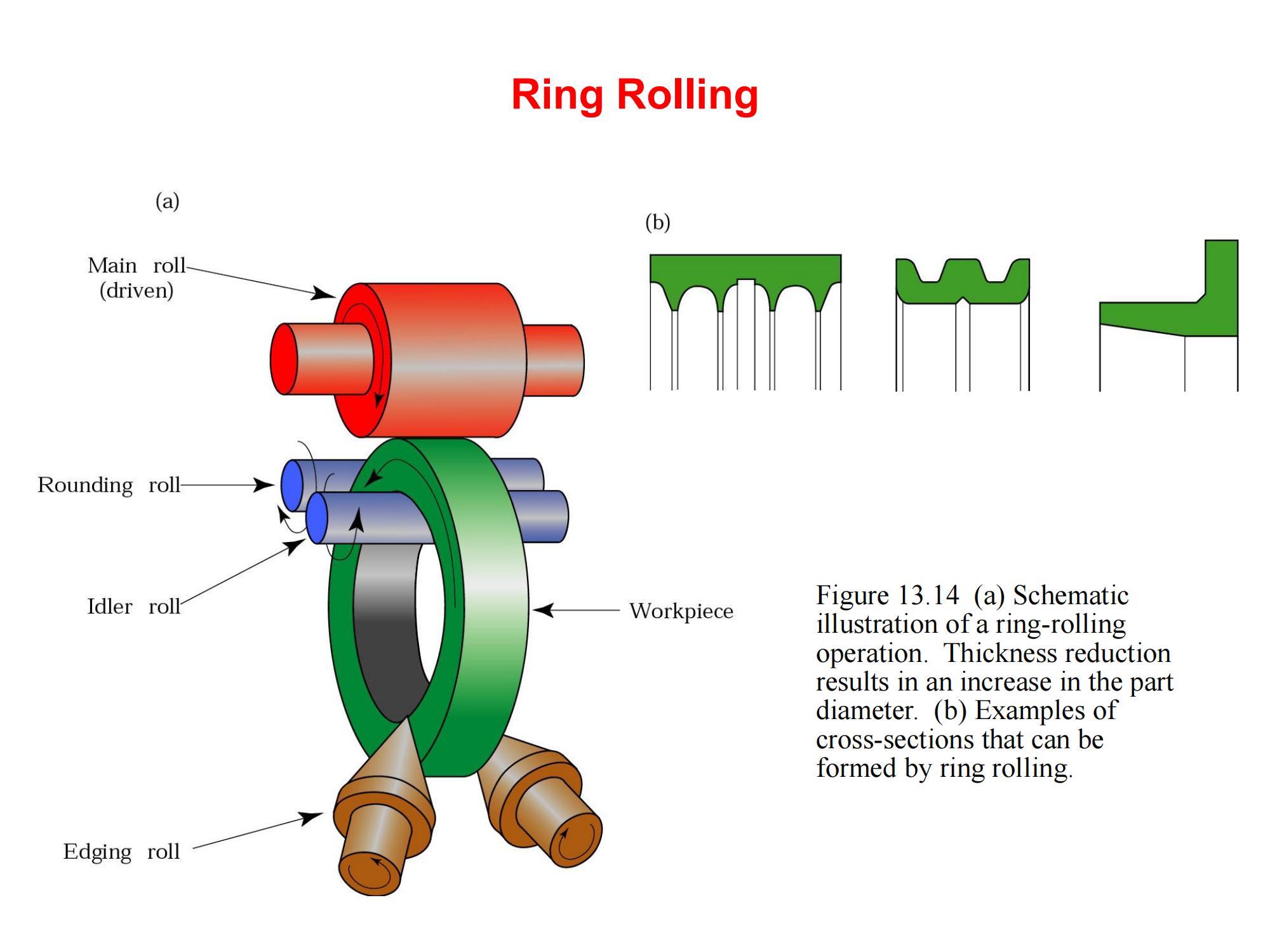

- Ring Rolling: As shown in Figure 13.14, the thickness of a ring-shaped blank is reduced to enlarge its diameter. This process is widely used for parts like gear rings and bearing races.

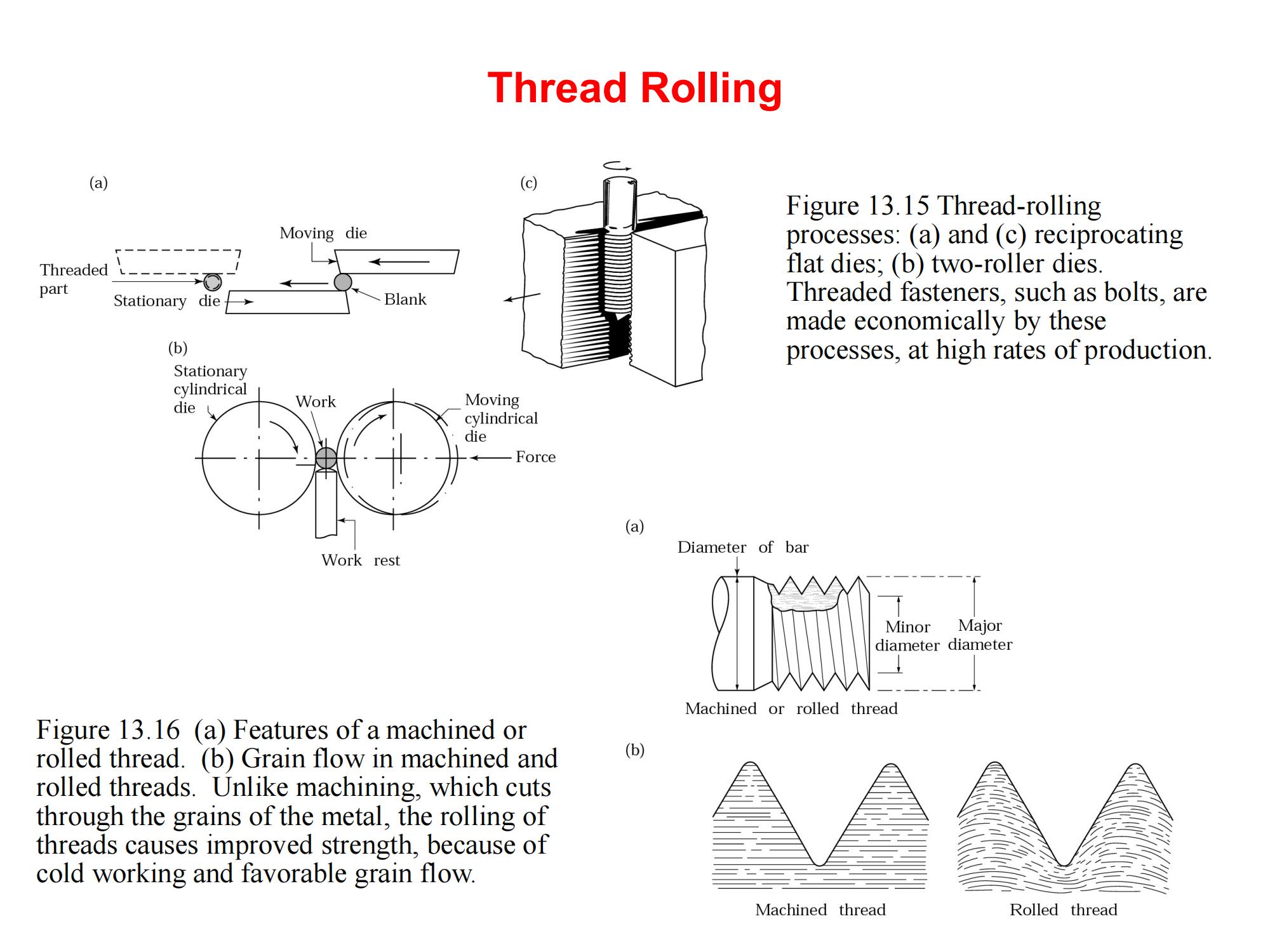

- Thread Rolling: Threaded fasteners such as bolts are formed using flat dies or rolling dies (see Figure 13.15).

Unlike cutting processes, thread rolling does not sever grain flow (see Figure 13.16), significantly enhancing the strength and fatigue life of the threads.

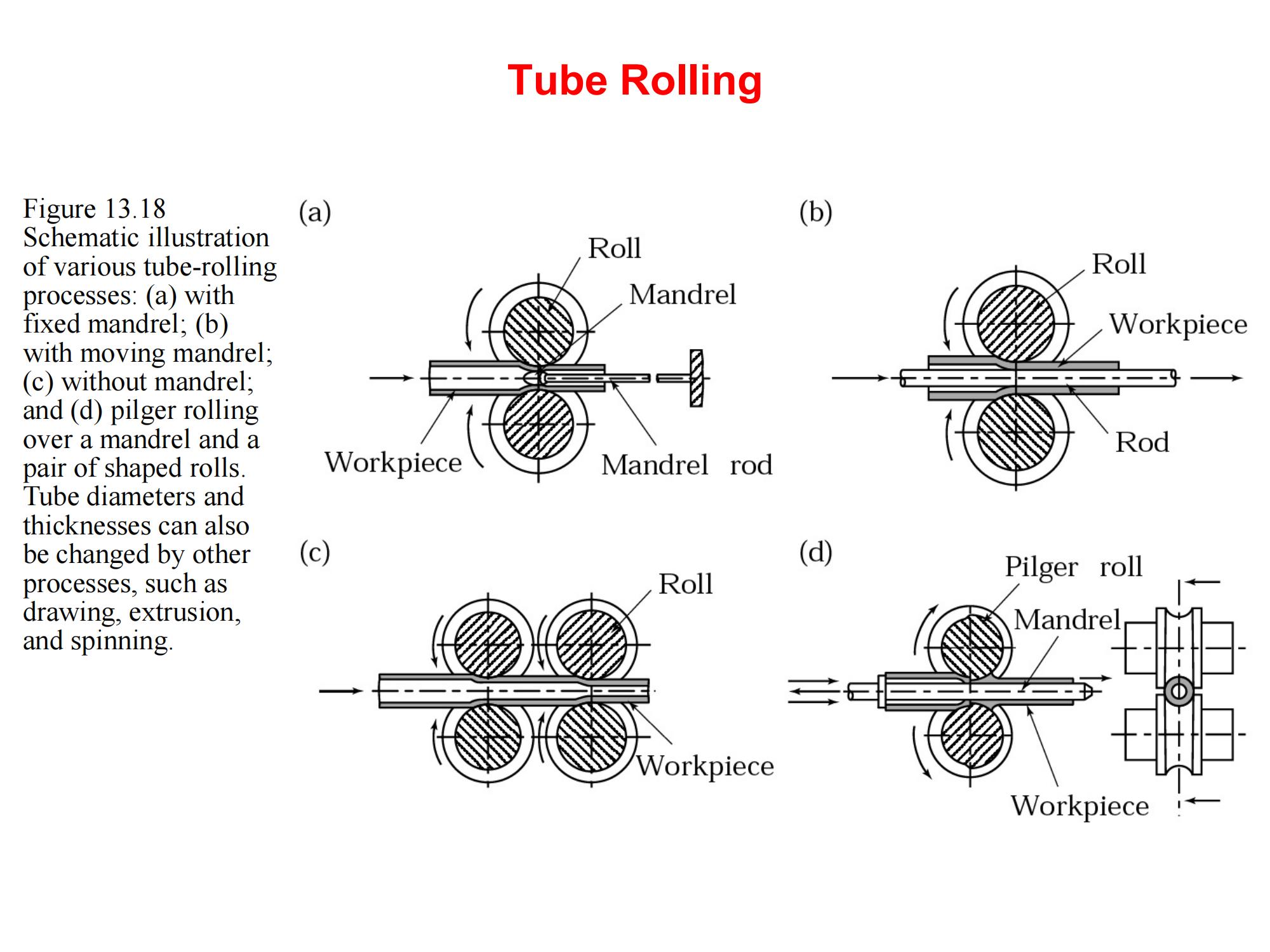

- Tube Rolling: Includes fixed mandrel, floating mandrel, plug rolling, and Pilger rolling (see Figure 13.18).

It is used to alter tube dimensions, wall thickness, and surface quality — especially effective for hard-to-machine materials like stainless steel and titanium alloys.

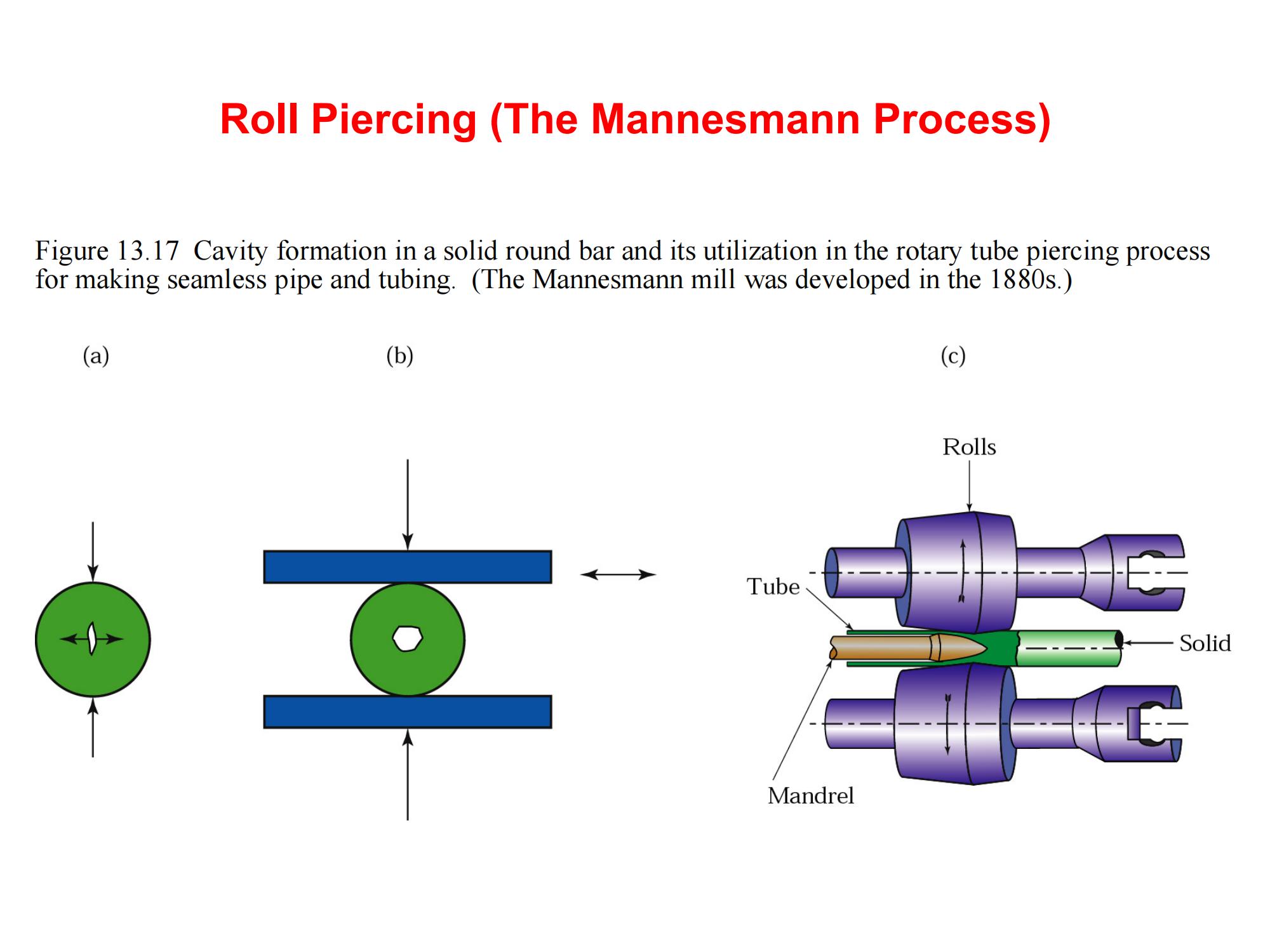

- Roll Piercing (Mannesmann Process): A solid round bar is pierced internally to produce seamless tubes. As illustrated in Figure 13.17, this method was developed in the 1880s by the Mannesmann brothers and remains the foundation of modern seamless pipe production.

8.0Conclusion

Metal rolling is not only the most widely used metal forming technique in modern manufacturing, but also a foundational process that supports high-volume, high-precision, and high-efficiency production. From hot rolling to cold finishing, from flat products to complex shapes like threads and rings, the versatility of rolling makes it indispensable in industries ranging from construction and automotive to aerospace and energy.

Understanding its principles, parameters, and potential defects is essential for engineers and manufacturers seeking to optimize material flow, ensure product quality, and reduce production costs in an increasingly automated industrial landscape.

Attached resource : PDF Rolling of Metals Process