- 1.0Understanding High-Volume Metal Stamping Methods

- 2.0Tooling for High-Volume Stamping: Choosing the Right Class

- 3.0Preventative Maintenance: A Must for Long-Term Success

- 4.0Quality Control for High-Volume Production

- 5.0Maximizing Throughput: Press Speeds & Capacity Planning

- 6.0Final Thoughts: Designing for Scalable Stamping Success

- 7.0One-Stop High-Volume Stamping Line Solutions

High-volume metal stamping is a highly efficient manufacturing process used to convert sheet metal into precise, repeatable parts at scale. It’s the go-to solution for industries that demand speed, consistency, and cost-effectiveness—such as automotive, appliances, construction, and electronics.

1.0Understanding High-Volume Metal Stamping Methods

Although metal stamping is straightforward in principle, there are several specialized techniques tailored for different production goals. Two of the most common processes for high-volume manufacturing are progressive die stamping and transfer die stamping. Both offer high speed and throughput, but each has its advantages.

1.1Progressive Die Stamping

Progressive die stamping feeds a continuous strip of metal through a series of stations, with each station performing a specific operation. The part is gradually formed and finally separated from the strip at the last station.

Ideal for: Washers, brackets, clips, and parts with multiple features.

Advantages:

- Fast, continuous production

- High repeatability and dimensional accuracy

- Low unit cost for large volumes

- Less material waste

- Efficient material utilization

- Can produce multiple parts per stroke (if geometry allows)

Key Difference: In progressive stamping, the part remains attached to the metal strip throughout the entire process. In contrast, transfer die stamping separates the part earlier and moves it independently.

1.2Transfer Die Stamping

Transfer die stamping uses a mechanical transfer system to move individual parts between different tooling stations. This allows for more complex forming operations, as the parts are detached from the strip early.

Ideal for: Frames, shells, structural components, or deep-drawn parts.

Advantages:

- Greater flexibility for intricate, multi-dimensional designs

- Faster cycle times (compared to manual transfer)

- No need for post-stamping operations

- Better suited for larger or more complex geometries

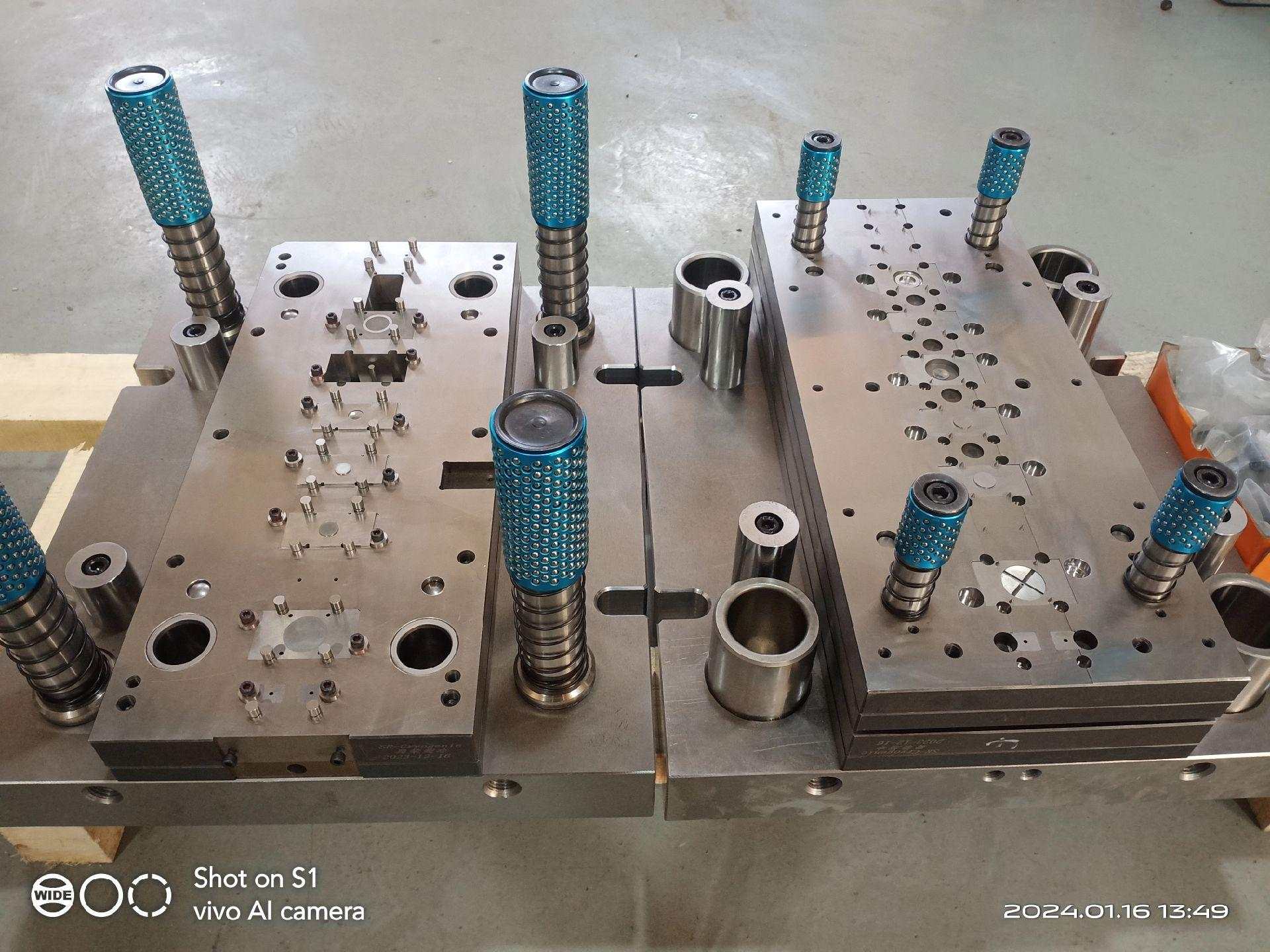

2.0Tooling for High-Volume Stamping: Choosing the Right Class

Tooling is one of the most critical factors in high-volume metal stamping. The complexity of the part, production volume, and required tolerances will determine what level of tooling is necessary.

Class A Tooling for Demanding Applications

For long-run, high-volume production—typically in the millions of parts—a Class A progressive die is recommended.

Key Features:

- Replaceable wear components (cutting inserts, forming blocks)

- Guided strippers with precision ball bearing guide posts

- Hardened steel or carbide tooling for durability

Conventional progressive dies for low- to mid-volume projects may last up to 1 million parts. In comparison, Class A tooling—when maintained properly—can exceed that significantly.

Carbide Inserts for Long-Run Efficiency

Carbide cutting and forming inserts are commonly used in high-volume dies because they last significantly longer than standard tool steels.

Considerations:

- Carbide must be processed carefully to avoid binder degradation

- Special coatings (e.g., TiN, TiCN) can further extend service life

- Progressive dies can be designed to produce multiple parts per stroke, increasing throughput

3.0Preventative Maintenance: A Must for Long-Term Success

Even the best tooling requires regular maintenance. A proactive maintenance strategy ensures consistency and extends tool life.

Best Practices:

- Keep critical spares (shims, inserts, springs) in stock

- Log every maintenance session and correlate with inspection data

- Perform periodic sharpening or insert replacement based on usage—typically every 50,000 to 100,000 strokes

Tool Storage: Protect valuable tools from corrosion, moisture, and physical damage. Fire-safe, climate-controlled environments are ideal.

4.0Quality Control for High-Volume Production

The higher the production volume, the more critical it is to have rigorous inspection protocols. Many industries require:

- FAIR (First Article Inspection Report)

- PPAP (Production Part Approval Process)

- CPK process capability analysis

- Lot traceability—from raw material to final product

Other common practices include:

- Gage R&R validation for inspection equipment

- In-process inspection plans tied to press operations

- Sample retention across each production and subcontracting stage

Your supplier should support your internal standards and help mitigate the risk of nonconforming parts.

5.0Maximizing Throughput: Press Speeds & Capacity Planning

Press speed plays a significant role in production output. Short-stroke, high-speed presses (up to 600 strokes per minute) can drastically boost efficiency—but only if the part and die design allow it.

Factors affecting press speed:

- Material strength and thickness

- Part complexity

- Tooling layout and station design

For mission-critical programs, it’s wise to have backup tooling approved on multiple presses. This ensures flexibility if a press or tool requires downtime.

6.0Final Thoughts: Designing for Scalable Stamping Success

Achieving success in high-volume stamping is about more than just machinery. It’s a balance of part design, tooling strategy, process stability, and continuous quality assurance.

Whether you’re launching a new product or scaling an existing one, partnering with an experienced metal stamping supplier can help you:

- Optimize your part design for manufacturability

- Select the best stamping method

- Reduce costs without compromising performance

- Maintain reliable production schedules

7.0One-Stop High-Volume Stamping Line Solutions

We provide complete solutions for high-volume metal stamping production lines. From equipment selection to tooling and automation, our team delivers turnkey systems tailored to your production goals.

Our stamping line solutions include:

- High-speed stamping presses (mechanical and servo), from 60 to 600 tons

- In-house design and manufacturing of Class A progressive and transfer dies

- Coil feeding systems: straighteners, uncoilers, servo roll feeders

- Automated part transfer systems between stations or presses

- Integrated inline inspection and process monitoring systems

- Spare parts kits and preventative maintenance support

- Support for pilot runs, PPAP, CPK, and quality validation

Whether you’re launching a new high-volume project or scaling an existing one, we offer reliable, efficient, and scalable production line solutions to meet your manufacturing needs.