- 1.0What Is Aluminium Checker Plate?

- 2.0Pattern Types and Structural Features of Aluminium Checker Plate

- 3.0Common Manufacturing Standards and Materials for Aluminium Checker Plate

- 4.0Main Applications of Aluminium Checker Plate

- 5.0Manufacturing Processes of Aluminium Checker Plate

- 6.0Why Choose Aluminum Checker Plate?

- 7.0Surface Finishes of Aluminum Checker Plates

- 8.0Checker Plate vs. Diamond Plate — Which Is Better?

- 9.0Terminology: Checker Plate vs. Diamond Plate vs. Tread Plate

- 10.0Analysis of Safety and Anti-Slip Performance of Different Aluminum Checker Plates

1.0What Is Aluminium Checker Plate?

Aluminium checker plate—also known as diamond plate, tread plate, or checker plate—is a type of metal sheet with a raised pattern on one side. These patterns, typically in diamond, bar, or grid shapes, are rolled into the surface to provide slip resistance, protection, and a decorative finish.

Also referred to as aluminium tread plate or chequer plate, this material features a textured surface with raised lines—most commonly a five-bar pattern arranged diagonally. This design improves grip underfoot, enhances visual appeal, and adds extra strength to the sheet.

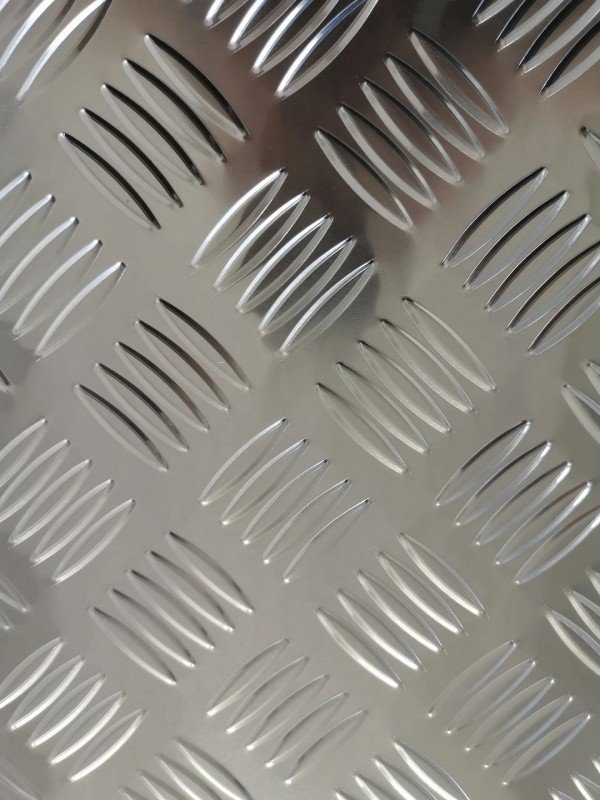

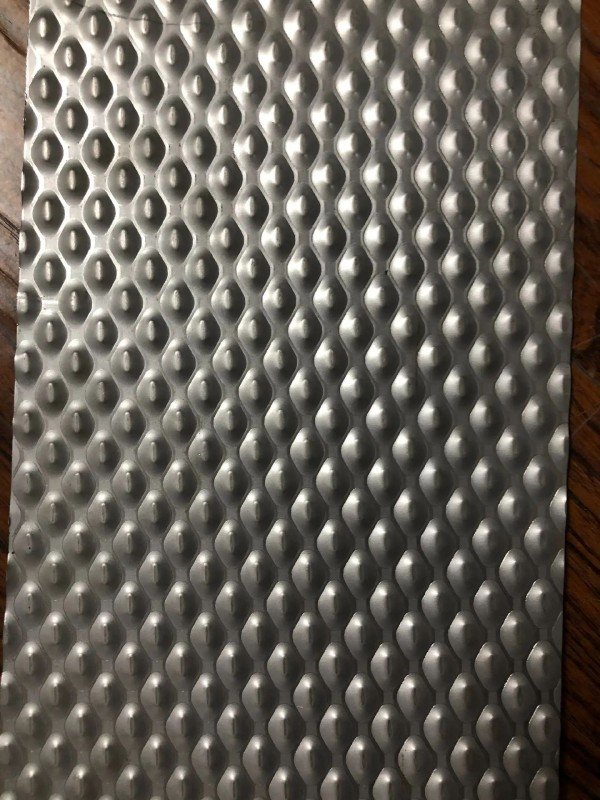

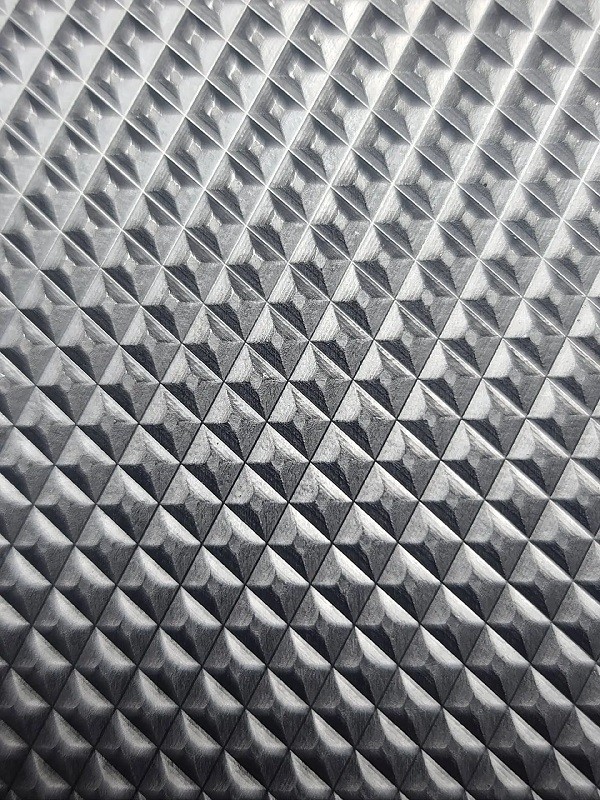

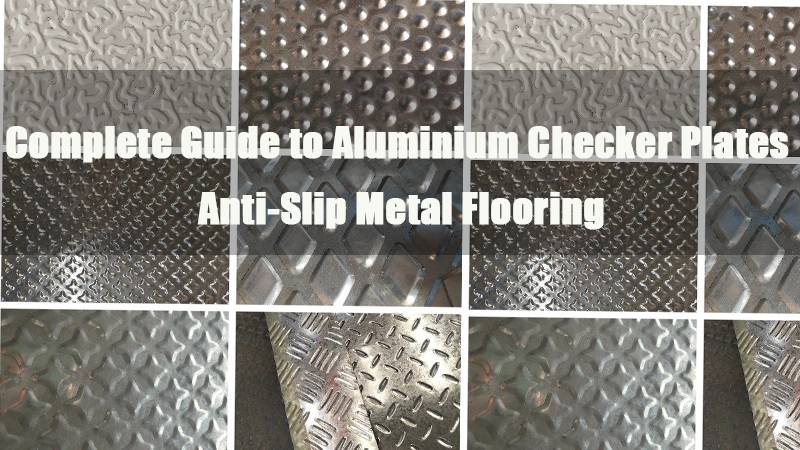

2.0Pattern Types and Structural Features of Aluminium Checker Plate

Checker plate designs are more than decorative—they provide slip resistance, impact protection, and even visual zoning. Below are common and extended pattern types, along with their structural characteristics and typical applications:

| Pattern Type | Key Features | Typical Applications |

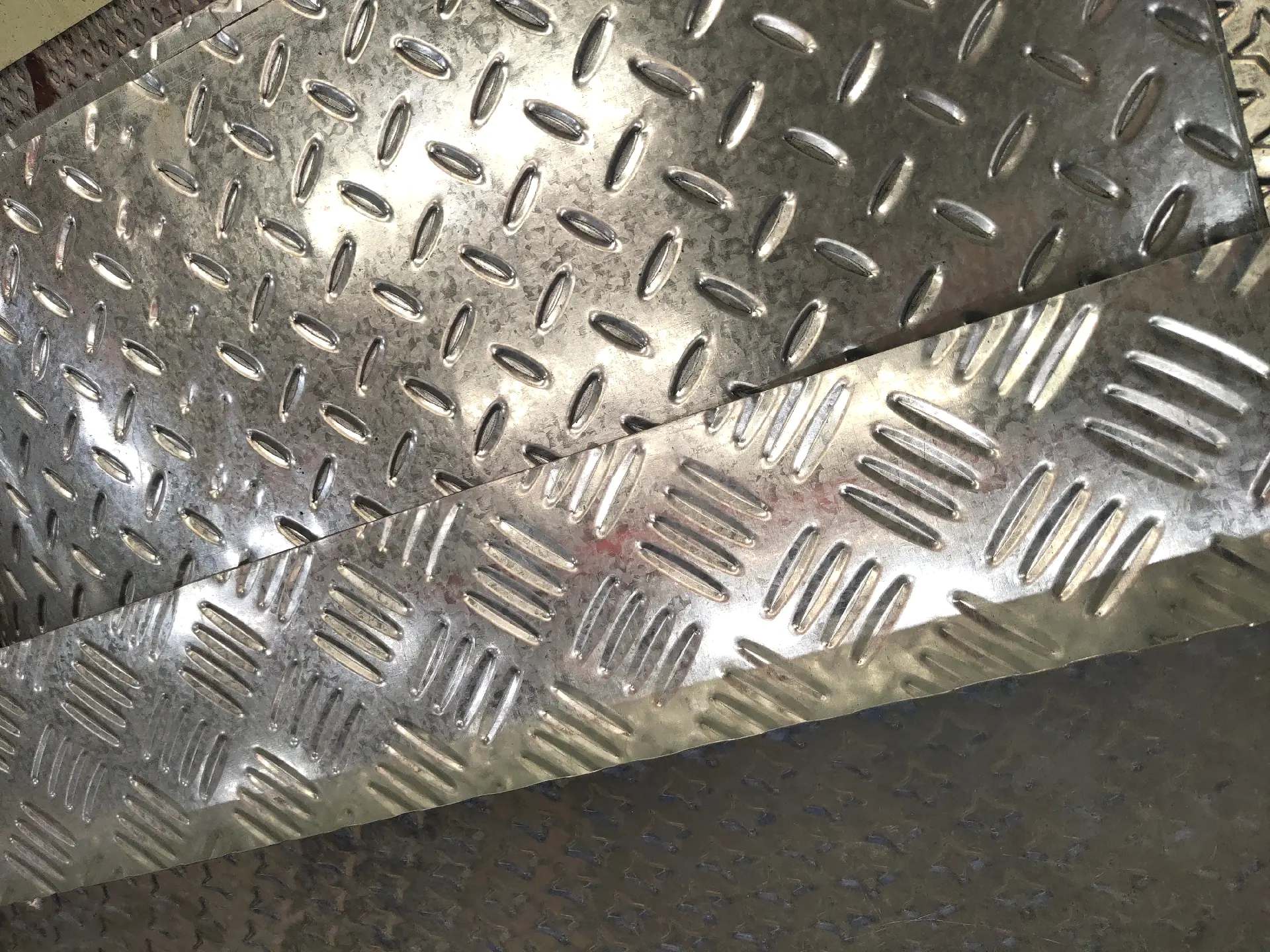

| 5-Bar | Five raised bars set diagonally for strong grip and anti-slip performance | Industrial floors, truck beds, stair treads, work platforms |

| Diamond | Single diagonal bars forming a diamond shape; decorative with moderate grip | Elevator floors, commercial areas, signage panels |

| Checker Grid | Square or rectangular bumps in a grid layout; visually clear, ideal for zoning | Parking lots, mall flooring, electrical boxes |

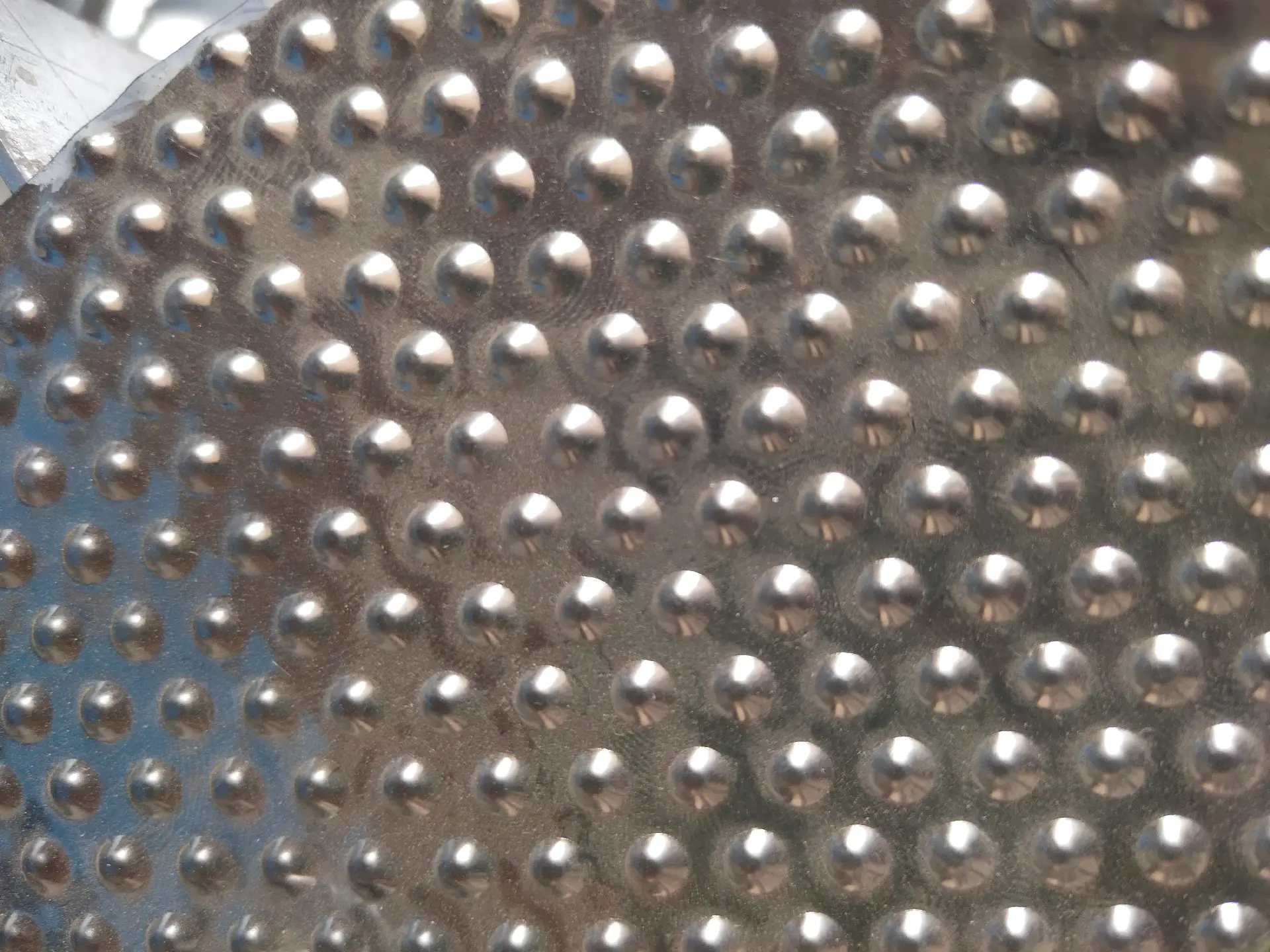

| Lentil | Rounded, dome-like bumps with smooth edges for even pressure distribution | Machinery surfaces, floor coverings, work platforms |

| Round Dot | Small, evenly spaced dots; best for light-duty use with visual appeal | Interior panels, cabinet backs, elevator interiors |

| Orange Peel | Slightly wrinkled surface resembling citrus skin; subtle anti-slip effect | Wall cladding, home panels, light equipment enclosures |

| 2-Bar | Two thick parallel bars for a simple, strong and durable structure | Vehicle steps, mobile platforms, elevator thresholds |

| 3-Bar | Balanced option between 2-bar and 5-bar in grip and cost | Medium-duty floors, warehouse ramps |

| Petal Pattern | Floral-like raised shapes with strong visual impact | Architectural decoration, showroom floors, public walls |

| Custom Design | Tailor-made logos, numbering or textures per request | Branded spaces, specialty equipment, premium interiors |

Raised Pattern Technical Specs (Customizable)

| Parameter | Typical Range |

| Pattern spacing | Usually 25–50 mm |

| Raised height | 0.5–1.5 mm (depending on sheet thickness) |

| Base material thickness | Commonly 1.0–6.0 mm |

| Alloy temper options | H14, H22, H32, and others |

Quick Tips for Pattern Selection:

- Load-Bearing Strength: Use 5-Bar or 6061 alloy for platforms and truck floors.

- Slip Resistance: Prioritize 5-Bar or Lentil patterns in industrial environments.

- Visual Zoning: Grid patterns work well for spatial division and guidance.

- Aesthetic Appeal: Orange peel, round dot, or custom designs enhance interior design.

3.0Common Manufacturing Standards and Materials for Aluminium Checker Plate

Aluminium checker plate is produced in accordance with several international and regional standards that ensure quality in terms of mechanical properties, dimensional tolerances, and alloy composition.

3.1Major Standards Include:

- ASTM B209– Standard specification for aluminium and aluminium-alloy sheet and plate

- EN 485-2– Mechanical properties and tolerances for aluminium and aluminium-alloy sheet

- GB/T 3880– Chinese standard for aluminium and aluminium-alloy sheet and strip

- GB/T 15015– Technical conditions for cold-rolled aluminium sheets and strips

- GB/T 5237– Technical conditions for hot-rolled aluminium plates

- ASTM A666– Stainless steel sheet standard (referenced for slip-resistant applications)

- ISO 6361– Aluminium and aluminium-alloy hot-rolled sheet standard

- JIS H4000– Japanese standard for aluminium alloy sheet and strip

3.2Common Aluminium Alloys for Checker Plate

| Alloy Type | Key Features | Typical Applications |

| 1060 (Pure Aluminium) | Cost-effective, soft, good conductivity, easy to fabricate, low strength | Interior decoration, toolbox covers, elevator walls, signage panels |

| 3003 (Al-Mn Alloy) | Slightly stronger than 1060, excellent rust resistance, good weldability | Vehicle steps, warehouse flooring, refrigerated truck lining, kitchen walls |

| 5052 (Al-Mg Alloy) | High strength, excellent corrosion resistance (salt fog), good weldability | Marine decks, outdoor platforms, coastal equipment, stair treads |

| 5754 (Al-Mg Alloy) | Similar to 5052 but with higher strength and improved abrasion resistance | Railway floors, military flooring, utility vehicle steps, airport walkways |

| 6061 (Al-Mg-Si Alloy) | Heat-treatable, impact and wear resistant, excellent mechanical properties | Heavy-duty flooring, vehicle bases, structural platforms, tool stands |

| 6063 (Al-Mg-Si Alloy) | Smooth finish, great for anodizing, aesthetically pleasing | Curtain walls, decorative panels, window trims |

| 5083 (Al-Mg-Mn Alloy) | Extremely high strength and corrosion resistance, suitable for extreme conditions | Ship structures, military vehicles, heavy equipment bases |

4.0Main Applications of Aluminium Checker Plate

4.1Industrial and Construction Use

- Factory and Warehouse Flooring:

Provides a durable, anti-slip surface ideal for heavy-duty environments—helps ensure worker safety. - Stair Treads and Walkways:

Used in industrial buildings and public facilities to reduce the risk of slipping on stairs and pedestrian paths. - Wall Panels, Facades, and Corner Protection:

Protects walls and columns from mechanical damage while adding a sleek industrial aesthetic. - Equipment Protective Covering:

Serves as outer casing or guard panels for machinery, enhancing durability and impact resistance. - Architectural Landscaping Material:

Adds a functional yet decorative touch to urban public spaces, improving both aesthetics and utility.

4.2Transportation Sector

- Vehicle Steps and Tailgates:

Commonly used on trucks, trailers, and cargo vans to improve grip and withstand wear. - Body Protection Components:

Includes hoods, fenders, sills, bumpers, mudguards, door panels, and side walls—offering added protection and durability. - Loading Ramps and Wheelchair Accessways:

Suitable for logistics ramps and accessible walkways, ensuring safe passage. - Livestock Trailer Floors and Ramp Gates:

Designed for high-friction, heavy-duty usage in agricultural transport environments. - Toolbox and Cargo Bed Covers:

Protects tools and transported goods, extending the service life of transport equipment.

4.3Interior and Exterior Decoration & Protection

- Interior Design Features:

Used in furniture, countertops, and cabinetry to create a modern, metallic finish. - Commercial Displays and Door Guards:

Ideal for store displays, storefront kick plates, and door protection—offering both aesthetic appeal and damage resistance. - Hygienic Anti-Slip Flooring:

Suitable for areas requiring easy-to-clean and slip-resistant surfaces, indoors and outdoors. - Vandal-Resistant Storefront Protection:

Enhances security for commercial frontages and deters damage or vandalism.

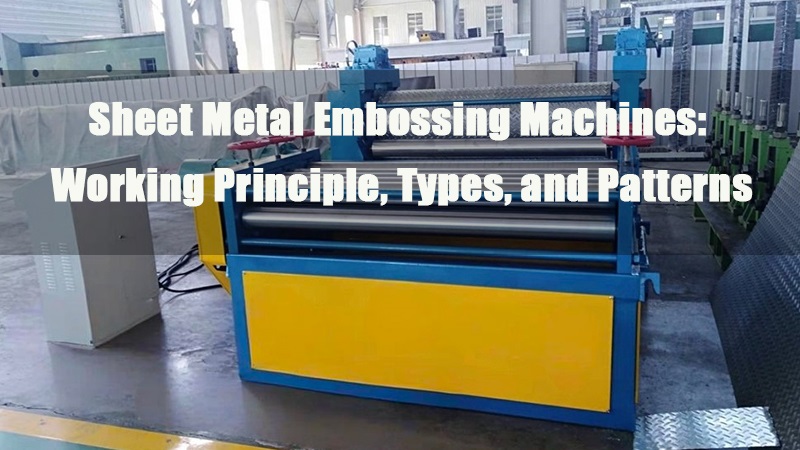

5.0Manufacturing Processes of Aluminium Checker Plate

Aluminium checker plate is produced by mechanically or physically imprinting patterned textures onto the surface of flat aluminium sheets. These patterns serve not only decorative purposes but also offer anti-slip and protective functions. The main manufacturing techniques include:

5.1Roller Embossing Process

Process Overview:

The aluminium sheet is passed through one or more pairs of patterned rollers under controlled pressure. This cold-rolling method utilizes the metal’s plasticity to imprint raised textures on one side of the sheet.

Key Equipment:

- Embossing Rolling Machine: Features upper and lower rollers engraved with specific patterns.

- Drive System: Motor-powered, often with frequency control for stable speed and pressure.

- Feeding & Recoiling Units: Ensure smooth entry and exit of the sheet; finished rolls are neatly wound.

Features:

- High-speed, high-efficiency production

- Ideal for large-scale manufacturing

- Adjustable pattern depth and pressure control

5.2Cold Stamping Process

Process Overview:

Aluminium sheets are placed between dies and pressed at room temperature using hydraulic or mechanical presses to create raised or indented patterns.

Key Equipment:

- Hydraulic/Mechanical Press: Provides forming force with custom-designed dies

- Stamping Dies: Pattern-specific molds, typically made of steel or alloy

- Feeding System: Ensures accurate positioning and continuous operation

Features:

- Sharp and detailed patterns

- Suitable for deep or intricate designs

- Ideal for small to medium batch production

5.3Mechanical Embossing Process

Process Overview:

Pressure is repeatedly applied to the aluminium sheet using dies to form the desired texture. It is commonly used for sample creation or specialty orders.

Key Equipment:

- Embossing Press: Equipped with interchangeable patterned dies

- Die System: Customizable to support a wide range of patterns

Features:

- Simple operation

- Highly flexible for different patterns

- Suitable for custom samples or small-scale production

5.4Roll Forming Process

Process Overview:

The aluminium sheet continuously passes through multiple sets of roller dies, gradually forming both the pattern and complex shapes over multiple stages.

Key Equipment:

- Roll Forming Machine: Multi-stand roller system, each set responsible for part of the shape

- Control System: Adjusts speed and pressure to ensure dimensional accuracy

- Feeding & Output System: Ensures consistent material flow and clean product delivery

Features:

- High production efficiency

- Suitable for long or custom profile sheets

- Offers excellent dimensional consistency

5.5Summary Table

| Process | Key Equipment | Production Features | Best Use Cases |

| Roller Embossing | Embossing mill, patterned rollers | Fast, high-volume production | Standard patterned sheets |

| Cold Stamping | Hydraulic/mechanical press, stamping dies | Clear patterns, good for complex designs | Medium and small batches |

| Mechanical Embossing | Press, custom pattern dies | Flexible, easy to operate | Samples, diversified pattern products |

| Roll Forming | Roll forming machine, multi-roller setup | Continuous shaping, precise dimensions | Long patterned strips, special profiles |

6.0Why Choose Aluminum Checker Plate?

Advantages of Aluminum Checker Plate

Aluminum checker plate integrates multiple benefits such as strength, light weight, anti-slip properties, aesthetic appeal, and corrosion resistance, making it a truly versatile metal material. Whether used for industrial safety flooring, transport vehicle components, or architectural decorative surfaces, aluminum checker plate offers a reliable, economical, and attractive solution.

- Lightweight yet Strong

Aluminum checker plate combines low weight with high strength. It weighs about one-third of carbon steel or stainless steel of the same volume, significantly reducing handling, transportation, and installation costs. - Excellent Anti-Slip Performance

Raised patterns increase surface friction effectively preventing slips, ideal for factories, ramps, walkways, and other wet, oily, or high-traffic areas. - Highly Durable

Resistant to impact, scratching, and corrosion, it performs well under harsh conditions and boasts a long service life. - Superior Corrosion Resistance

The natural oxide layer formed on aluminum surfaces provides excellent corrosion protection. The 5754 aluminum alloy series is especially suitable for salt spray and marine environments. - Easy Processing and Attractive Finish

Can be easily cut, welded, painted, or anodized, offering a modern industrial look suitable for walls, display areas, equipment housings, and more.

7.0Surface Finishes of Aluminum Checker Plates

The surface treatment of aluminum checker plates not only enhances their functional pattern but also directly impacts their appearance, durability, and lifespan.

| Surface Finish | Characteristics and Applications |

| Mill Finish | Standard finish, bright and natural surface, ready for use without further processing |

| Anodizing | Enhances corrosion resistance and aesthetics, suitable for indoor and outdoor decorative applications |

| Powder Coating | Adds color and protective layer, ideal for applications requiring visual effects (note: may wear over time) |

| Chemical Etching | Creates textured patterns for decorative use |

| Sandblasting | Removes surface roughness to produce a uniform matte finish |

| Mechanical Embossing | Uses molds for clear patterns and smooth surfaces, commonly applied to diamond plate styles |

8.0Checker Plate vs. Diamond Plate — Which Is Better?

The choice between aluminum checker plate and diamond plate depends largely on the specific application scenario:

8.1Diamond Plate

- Deeper surface patterns with strong anti-slip properties — ideal for heavy-duty walkways, ramps, and anti-slip platforms.

- Wear-resistant and safety-focused — suitable for areas requiring high safety standards.

8.2Checker Plate

- Lower manufacturing cost — suitable for general industrial flooring, machine platforms, or decorative areas.

- Clean and attractive appearance — fits environments where both functionality and aesthetics are important.

9.0Terminology: Checker Plate vs. Diamond Plate vs. Tread Plate

| Name | Key Features | Typical Applications |

| Checker Plate | General term for metal plates with patterned surfaces (including checkerboard, five-bar patterns, etc.) | Construction, decoration, general industry |

| Diamond Plate | Surface with diamond-shaped raised patterns for increased traction | Industrial flooring, ramps, anti-slip zones |

| Tread Plate | Emphasizes “anti-slip” and “stepping” function | Stair treads, walkways, transportation facilities |

Selection Tips

Prioritize lightweight and corrosion resistance → Choose aluminum plates

Prioritize cost-effectiveness and strength → Choose steel plates

For harsh environments (humidity, corrosive conditions) or high-end decorative needs → Choose stainless steel checker plates

10.0Analysis of Safety and Anti-Slip Performance of Different Aluminum Checker Plates

10.1Functions and Types of Anti-Slip Patterns

The raised patterns on the surface of checker plates effectively increase friction and enhance grip, ensuring walking safety. Common anti-slip patterns include:

- Diamond Pattern

Provides strong grip, widely used in vehicle floors, ramps, and other places requiring high anti-slip performance. - Lentil Pattern

Balances aesthetics and anti-slip properties, commonly used in architectural decoration and indoor/outdoor interiors. - Leaf Pattern

Offers even higher friction, suitable for wet environments such as docks, chemical plants, and other special areas.

10.2Impact of Materials on Safety Performance

| Material | Anti-Slip Performance | Corrosion Resistance | Typical Application Areas |

| Aluminum | Good | Excellent | Vehicles, stairs, loading ramps |

| Stainless Steel | Excellent | Excellent | Food processing plants, marine decks, chemical equipment |

| Galvanized Steel | Average | Good | Industrial plants, workshops, heavy-duty platforms |

10.3Influence of Manufacturing Processes on Anti-Slip Effectiveness

- Cold Embossing

Produces deep and uniform patterns, suitable for areas requiring sustained high grip. - Hot Embossing

Enhances texture durability, ideal for high-pressure and frequently stepped-on environments.

10.4Wear Resistance and Weatherability

High-quality aluminum checker plates have excellent wear resistance, maintaining anti-slip performance in heavy traffic or high-frequency use areas over a long time. The natural oxide layer on aluminum and stainless steel provides corrosion protection, enabling stable performance in humid and chemically harsh environments, ensuring durability and safety.