ALEKVS Color Coating Line | High-Performance Coil Coating System

What Is a Color Coating Line?

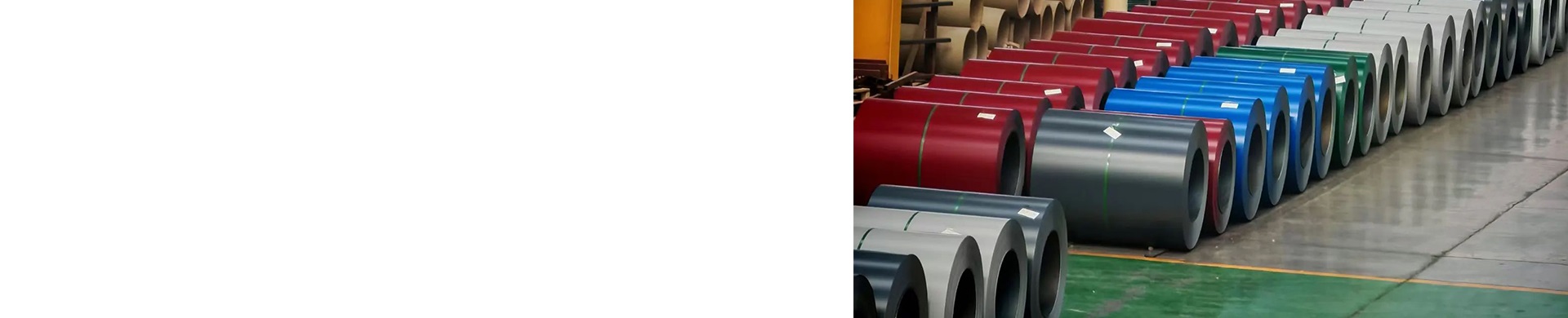

A Color Coating Line (CCL) is an advanced continuous processing system designed to apply organic coatings—such as polyester, SMP, HDP, or PVDF—on metal coil surfaces. Typically used on galvanized steel (GI), galvalume (GL), or aluminum coils, this line enables uniform, durable, and decorative color coatings, transforming raw metal into value-added pre-painted steel products (PPGI/PPGL).

At ALEKVS, we provide high-efficiency, automated Color Coating Lines engineered for precision, energy savings, and consistent quality—making us your trusted partner in premium coil coating technology.