- 1.0Core Definition and Characteristics of Cold Forging

- 2.0Working Principle of Cold Forging

- 3.0Advantages and Limitations of Cold Forging

- 4.0Eight Core Cold Forging Processes and Their Industrial Applications

- 5.0Lubricant Selection as a Critical Support Process in Cold Forging

- 6.0Typical Applications of Cold Forging

- 7.0Key Differences Between Cold Forging and Hot Forging

- 8.0Key Technologies in Cold Forging

- 9.0Cold Forging Process: Frequently Asked Questions (FAQ)

Forging is a manufacturing process in which compressive forces are applied to a solid metal workpiece, causing plastic deformation and reshaping it into the desired form. Unlike casting (pouring molten metal) or machining (removing material), forging refines the grain structure of the metal as it flows, resulting in more uniform mechanical properties and higher strength—often superior to cast or machined components of the same material.

Based on processing temperature, forging is generally divided into three categories:

- Cold Forging:Performed at room temperature up to the lower limit of the metal’s recrystallization temperature (no high-temperature heating).

- Warm Forging:Conducted above room temperature but below recrystallization (typically 300–800°C), balancing accuracy and deformation effort.

- Hot Forging:Executed above the metal’s recrystallization temperature (e.g., steel 800–1250°C, copper alloys 700–800°C).

1.0Core Definition and Characteristics of Cold Forging

Cold forging, also known as cold forming, is a precision forming process performed at room temperature or below the recrystallization threshold (e.g., steel <400°C, aluminum 100–200°C, copper 200–300°C). Under high pressure from a die set (typically 500–2000 MPa), the metal undergoes plastic flow, producing components of the required shape and size with little to no material removal. The process relies on plastic deformation at low temperatures to achieve near-net-shape results.

Key characteristics include:

- Defined Temperature Range:No high-temperature heating is required; forming is done at room or near-room temperature. Friction may raise the metal temperature slightly to 250–300°C, but this remains below recrystallization levels.

- High-Pressure Deformation:Mechanical or hydraulic presses apply axial or radial loads, forcing atoms to realign along the die cavity. The process follows the principle of volume constancy (minimal mass or volume loss).

- High Accuracy and Fine Surface Finish:Dimensional accuracy can reach IT6–IT9 (tolerances ±0.01–±0.1 mm). Surface roughness values can be as low as Ra 0.4–3.2 μm, often eliminating or minimizing the need for secondary machining such as drilling or grinding.

- High Material Utilization:Material utilization rates reach 85–95%, far exceeding traditional machining (50–70%), which significantly reduces scrap.

2.0Working Principle of Cold Forging

The essence of cold forging is the plastic flow of metals at low temperatures. The process typically involves three key stages:

- Billet Preparation:

- Raw Material:Select ductile metals such as wire rod or bar stock (commonly low-carbon steel, aluminum, or copper alloys), cut into billets of fixed length.

- Surface Treatment:Apply treatments when necessary—such as phosphating and soaping for steel, or solid lubricant coatings for aluminum—to reduce the friction coefficient between metal and die (kept below 0.05). This minimizes die wear and improves metal flow.

- Die Pressing:

- Place the billet into a precisely engineered die cavity, and apply high pressure using a mechanical or hydraulic press.

- The metal gradually fills the die cavity, transforming from a billet into a near-net-shape part.

- For complex components, multiple forming stages (e.g., pre-forging → final forging) are required. This avoids excessive deformation in one step (generally limited to ≤50%), which could otherwise cause cracking.

- Post-Processing:

- Stress Relief:Cold forging induces work hardening (increased strength and hardness, but reduced ductility). Some parts require low-temperature annealing (e.g., steel heated to 200–300°C) to restore plasticity.

- Finishing Operations:For components with extremely tight tolerances, additional fine pressing, polishing, or other secondary processes may be applied to further enhance dimensional accuracy and surface quality.

Recommended Reading:Forging Process Explained: Types and Techniques

3.0Advantages and Limitations of Cold Forging

The strengths and weaknesses of cold forging are directly linked to its low-temperature forming characteristics. The comparison is as follows:

| Aspect | Advantages | Limitations |

| Workpiece Properties | Work hardening increases strength and hardness by 15–30% (e.g., in cold-forged steel); microstructure is dense and uniform. | Reduced ductility, risk of internal stress; annealing may be required. |

| Accuracy & Surface Quality | High dimensional accuracy (IT6–IT9) and smooth surface finish (Ra 0.4–3.2 μm). | Requires extremely precise dies (CNC machining), leading to high upfront tooling costs. |

| Material & Energy Efficiency | Material utilization of 85–95%; no high-temperature heating; energy consumption only 1/5–1/10 of hot forging. | Limited to ductile metals (low-carbon steel, aluminum, copper, etc.); brittle metals such as cast iron are unsuitable. |

| Production Efficiency | Ideal for high-volume production; each press stroke can produce one part with short cycle times. | Complex parts may require multiple forming steps, increasing process costs. |

| Die Life | – | Dies endure extreme pressures (up to 2000 MPa) and wear quickly; typical lifespan is on the order of tens of thousands of cycles. |

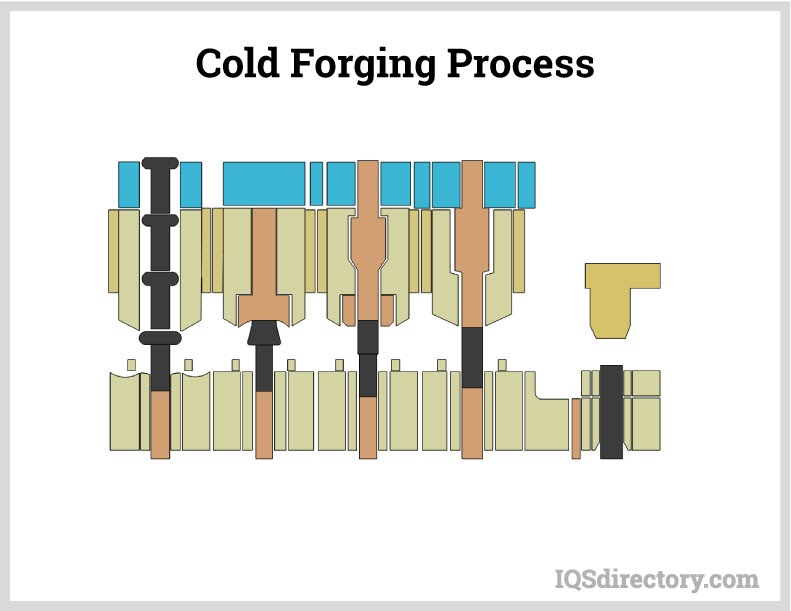

4.0Eight Core Cold Forging Processes and Their Industrial Applications

With the advancement of metal forming technologies, cold forging has developed into several specialized processes. Each is optimized for specific forming requirements, with the common goal of achieving high-efficiency production with minimal or no secondary machining.

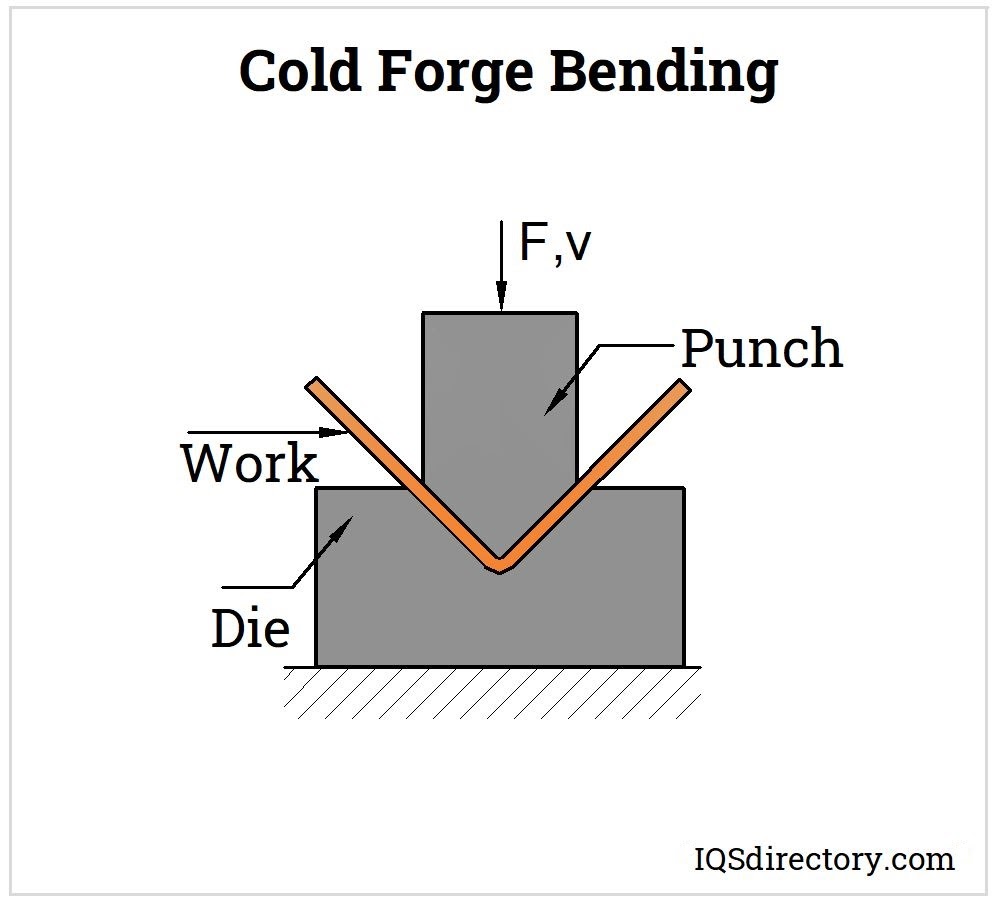

Bending:

- Principle:A press and die force the workpiece against a forming tool (sometimes referred to as “pyramid rolling”), producing deformation along a single axis to achieve the required angle.

- Features:Simple to operate, often used as a pre-treatment step in preparation for subsequent forging stages.

- Note:Friction can generate slight temperature rises; lubricants are required to control heat and reduce sticking.

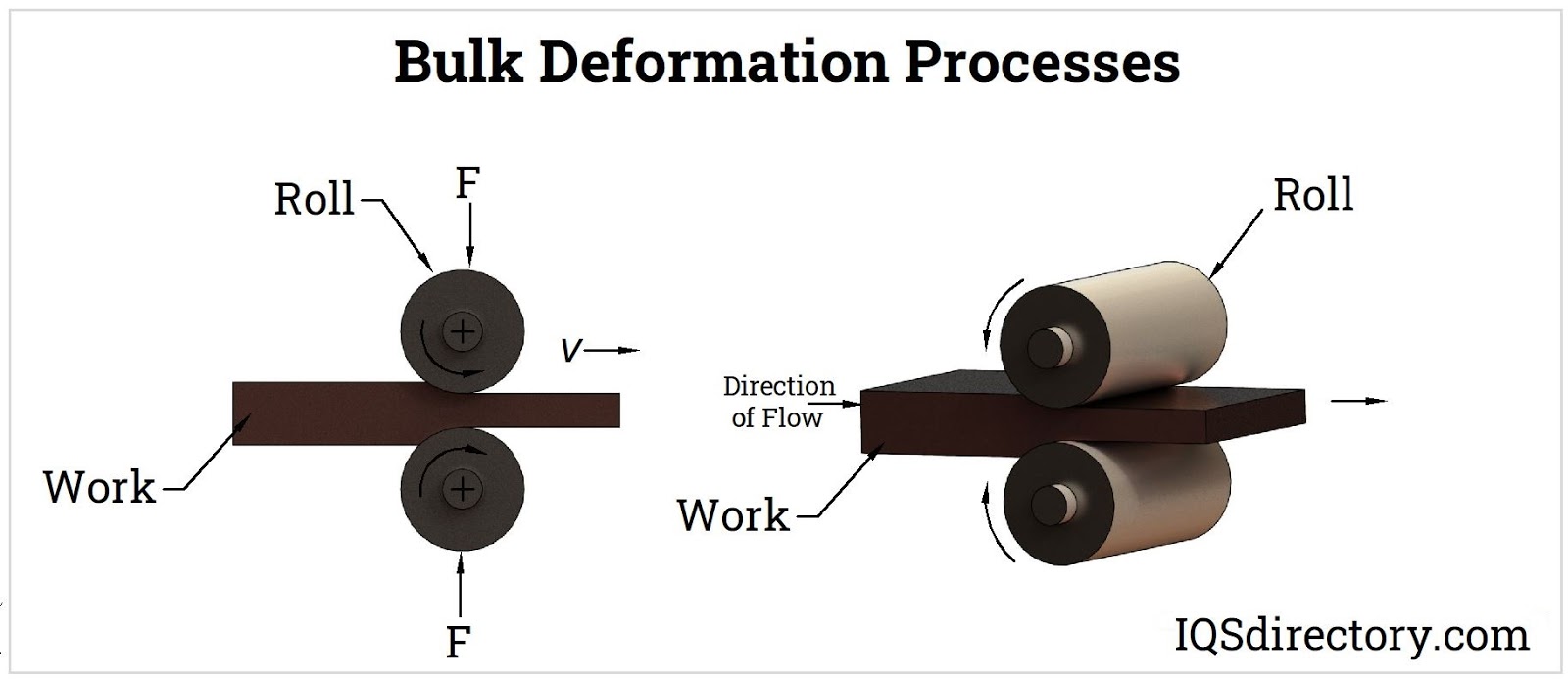

Cold Rolling:

- Principle:A billet passes between rotating rolls. Friction between rolls and billet induces compressive stresses, causing plastic deformation.

- Features:Classified as a bulk deformation process, producing uniform deformation. Widely used for mass production of steel sheets and wires, while improving surface finish.

- Applications:Suitable for long strip-shaped or sheet-type forged products, which can later be cut or further formed.

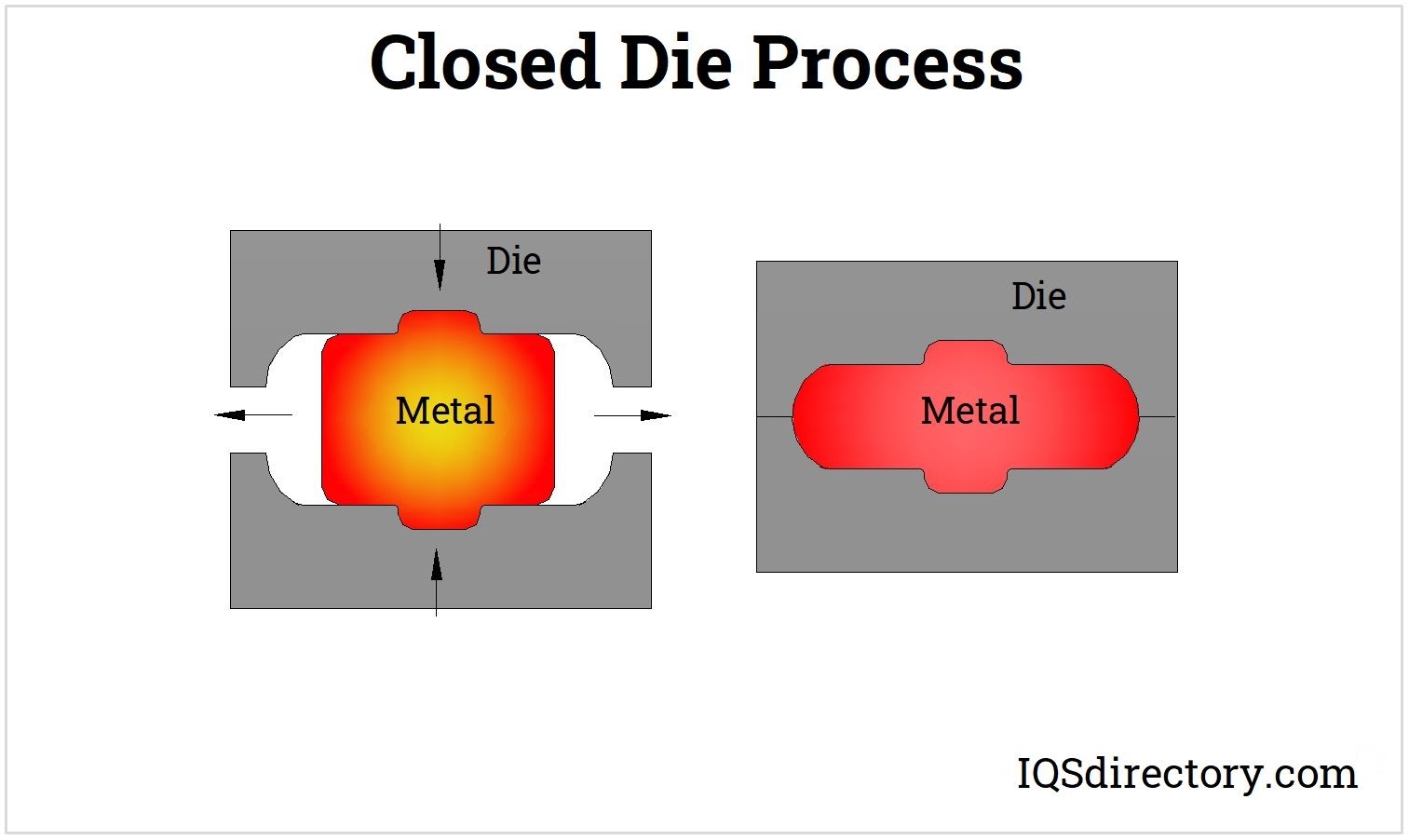

Closed-Die Forging (Impression Die Forging):

- Principle:A workpiece is placed between two dies with pre-cut cavities. Successive mechanical blows (e.g., drop hammer forging) force the metal to flow and completely fill the cavity.

- Features:High forming accuracy, capable of producing complex geometries (with grooves, bosses, etc.) in one or multiple strikes.

- Applications:Mass production of small to medium precision parts such as gear blanks and bolt heads.

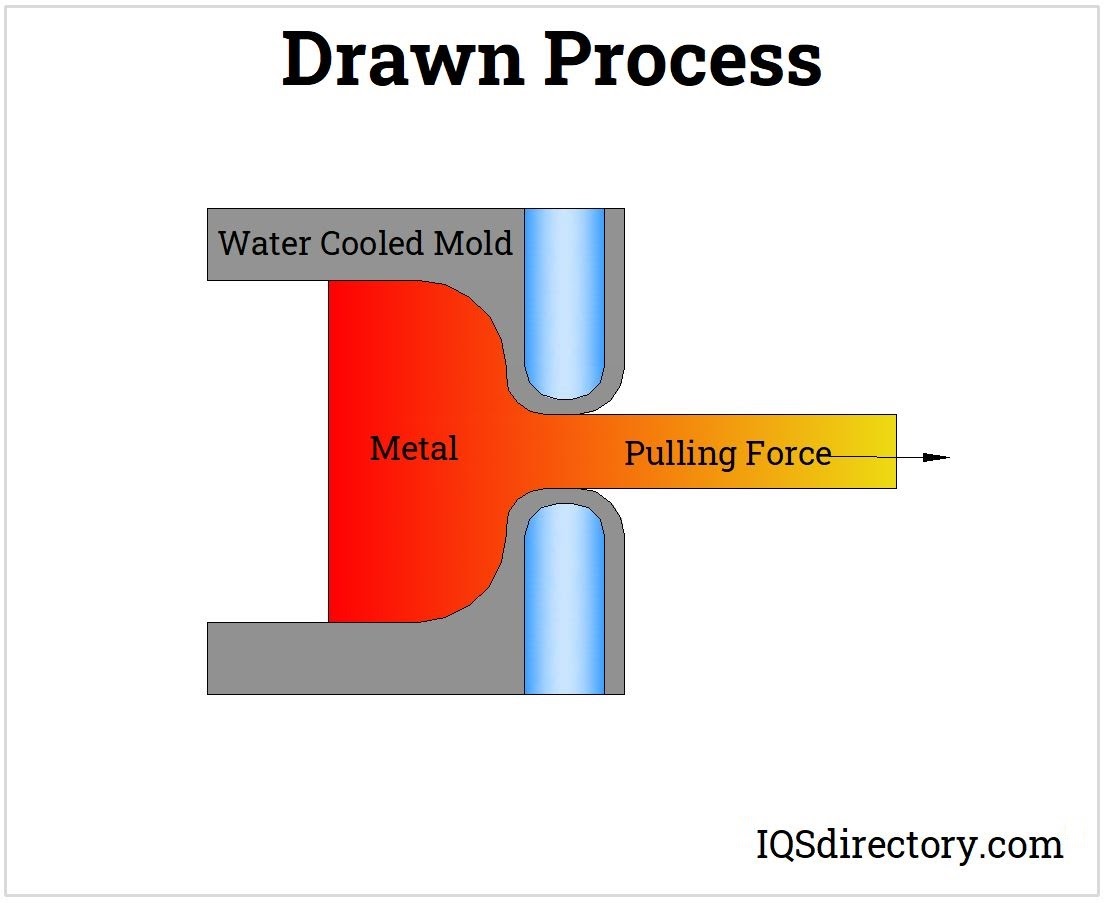

Drawing (Wire/Tube Drawing):

- Principle:Tensile force pulls the billet (wire or tube) through a die with a defined opening, reducing its cross-sectional area and increasing length.

- Features:Tighter dimensional tolerances compared to rolling; produces excellent surface finish; ideal for slender components.

- Key Advantage:Finished parts exhibit high straightness, eliminating the need for extra straightening operations.

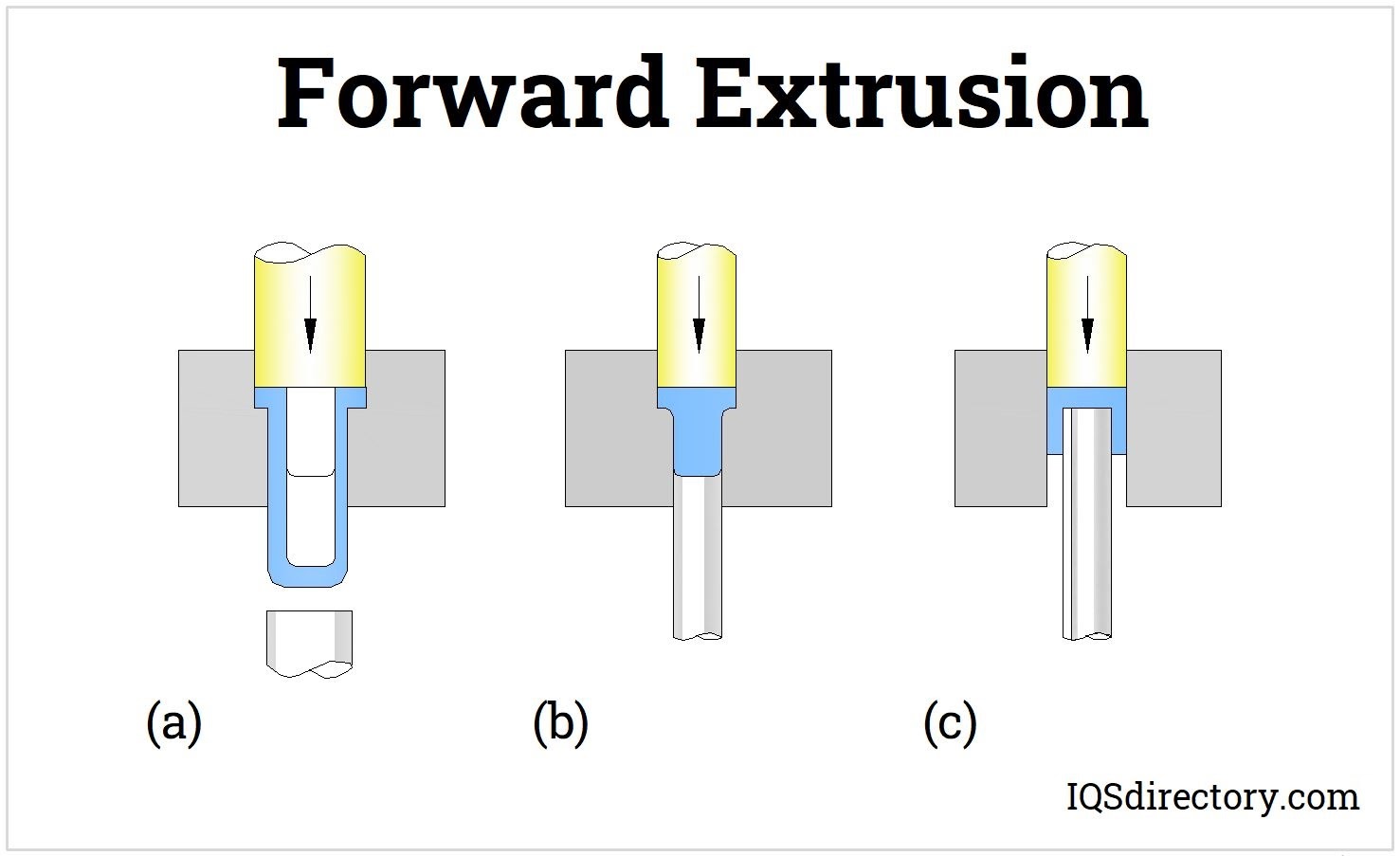

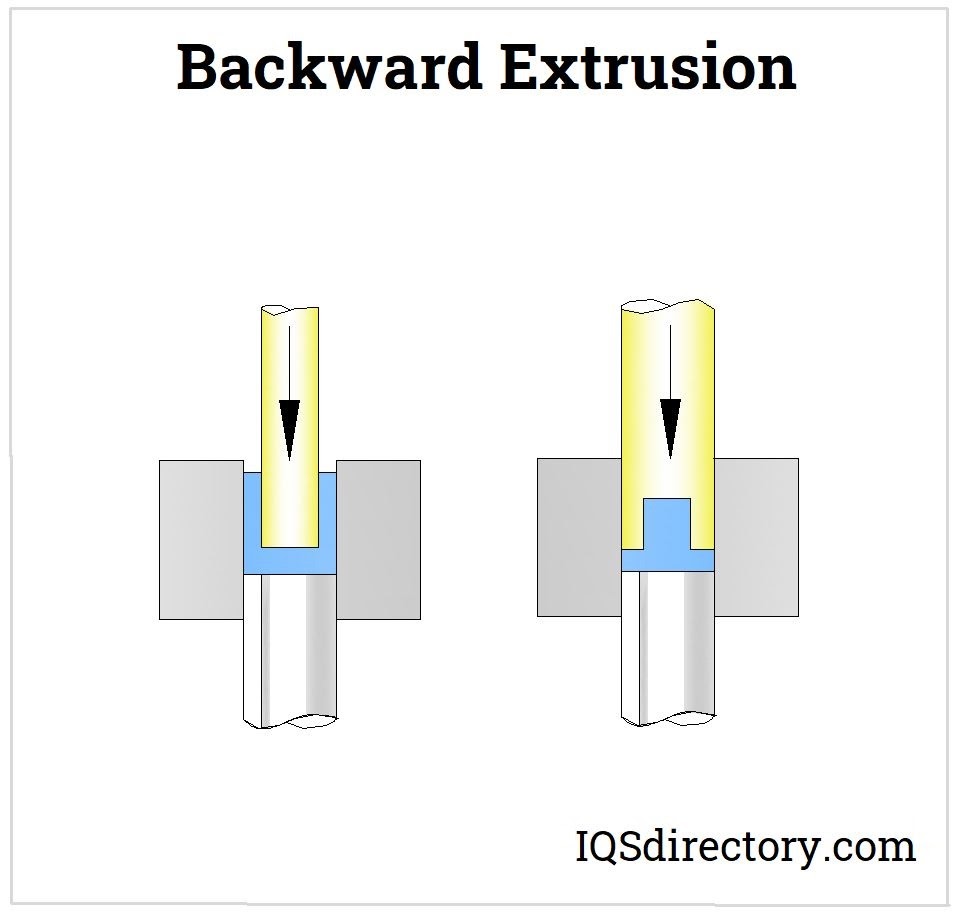

Extrusion:

- Principle:A billet is subjected to extremely high pressures (up to 20,000 kN, or ~2007 tons), forcing metal through a die opening to form a part profile, later cut to length.

- Subtypes:

- Forward Extrusion:Metal flows in the same direction as the applied pressure; suitable for solid long parts (e.g., shafts).

- Backward Extrusion:Metal flows opposite to the applied pressure; used for parts with thicker bottoms, such as bearing sleeves or cups.

- Lateral Extrusion:Pressure is applied perpendicular to the main axis, adding secondary features such as side holes or ribs.

- Applications:Efficient for forming complex cross-section components like multi-tooth gears and hollow tubing.

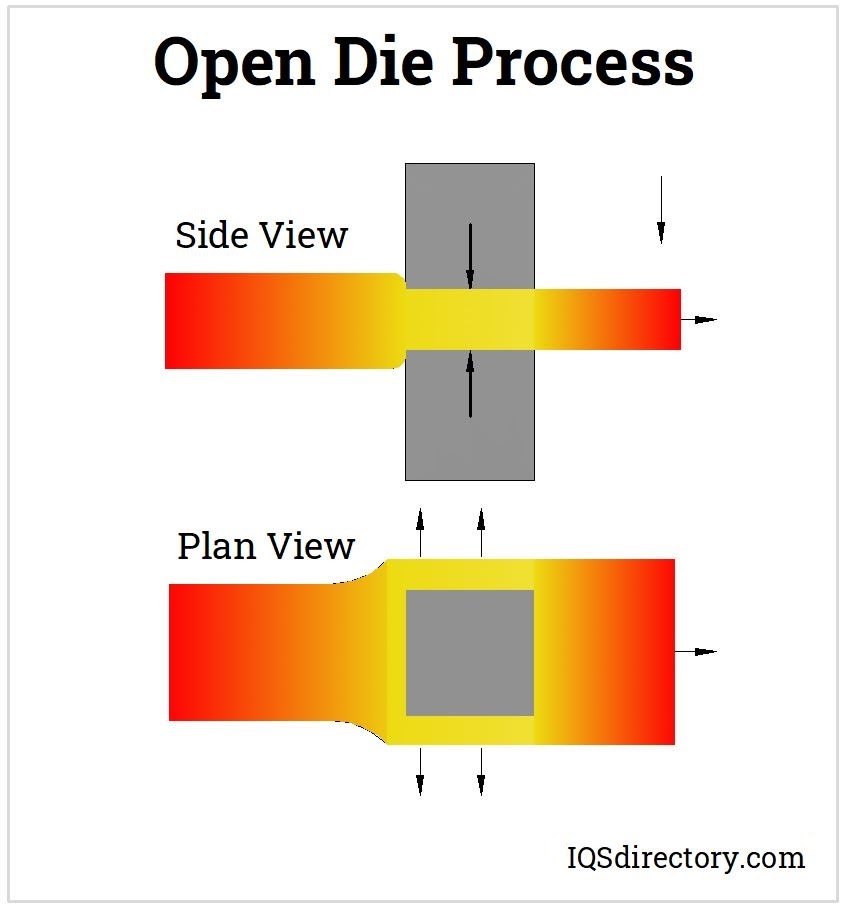

Open-Die Forging:

- Principle:Flat dies without pre-cut cavities gradually deform the workpiece through multiple passes and repositioning.

- Features:High flexibility, suitable for producing components of varying shapes and sizes, especially large parts requiring structural integrity.

- Special Variant:Upsetting/sizing processes apply concentrated force over short distances for dimensional calibration (e.g., flange diameter adjustment).

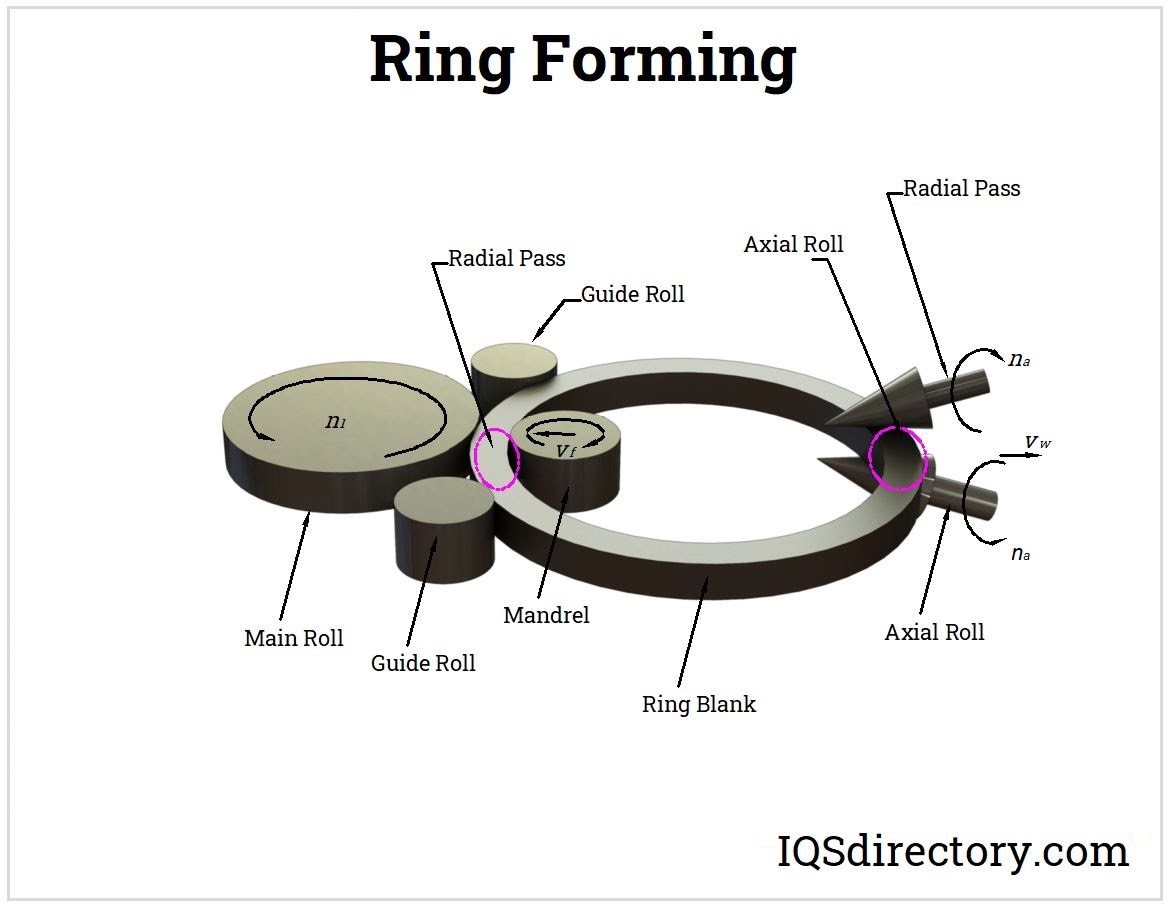

Ring Rolling:

- Principle:A preform with a central hole (doughnut-shaped) is subjected to combined rotation and compressive forces, expanding the outer diameter and shaping the inner bore to produce a seamless ring.

- Features:Rings offer high dimensional accuracy, uniform strength, and no weld defects, making them capable of withstanding radial and axial loads.

- Applications:Bearing rings, flanges, gear rings, and other precision circular components (e.g., wind turbine bearing races).

Radial Forging (Swaging):

- Principle:Directional pressure is applied using dies or hammers to ensure precise fit between parts. The process is highly automated and reliable.

- Subtypes:

- Tube Forging:Similar to extrusion; billets are pressed into dies to form tubular parts such as hydraulic fittings.

- Radial Swaging:Multiple hammers (two or more) compress the workpiece radially, refining diameters or forming steps on shafts and rods.

- Applications:Used for assemblies requiring precise mating surfaces, such as motor shafts and rotor connections.

5.0Lubricant Selection as a Critical Support Process in Cold Forging

Although cold forging is performed at room temperature, operations such as bending and extrusion generate frictional heat. Lubricants are therefore essential to ensure process stability, prevent defects, and extend die life.

- Functions:Reduce forming defects, minimize sticking, and improve tool longevity.

- Common Types:

- Chemical Coatings:Zinc phosphate, phosphate, calcium aluminate, aluminum fluoride (suitable for steel and aluminum, forming a protective wear-resistant layer).

- Polymer/Solid Lubricants:Various polymer coatings, graphite lubricants, and graphite-free types (graphite offers strong lubrication; graphite-free coatings are preferred for high-cleanliness applications such as electronic parts).

- Selection Principles:Must be tailored to metal type (e.g., steel uses phosphating soaping; aluminum uses solid lubricants) and process type (e.g., extrusion requires high-pressure-resistant lubricants, drawing requires low-friction lubricants). Complex processes may require custom lubricant formulations.

6.0Typical Applications of Cold Forging

Thanks to its precision, efficiency, and material savings, cold forging is widely adopted in industries where components must meet high standards of accuracy and strength. The automotive industry alone accounts for more than 60% of cold-forged parts.

| Industry | Typical Applications |

| Automotive | Engine valve tappets, transmission gears, axle splines, high-strength bolts and nuts, bearing races |

| Electronics & Electrical | Connector pins, relay contacts, motor rotor cores, aluminum smartphone frames |

| Machinery Manufacturing | Hydraulic valve spools, oil pump plungers, carbide tool holders |

| Hand Tools | Wrench and screwdriver heads (requiring only polishing), chain rollers |

| Heavy Equipment | Wind turbine bearing rings, large machinery support bases (produced by open-die or ring forging) |

7.0Key Differences Between Cold Forging and Hot Forging

Cold and hot forging differ fundamentally in processing temperature, deformation characteristics, achievable accuracy, and suitable applications. The comparison is as follows:

| Category | Cold Forging | Hot Forging |

| Processing Temperature | Room temperature up to recrystallization threshold (typically <400°C) | Above recrystallization temperature (steel 800–1250°C, copper 700–800°C) |

| Metal Plasticity | Lower plasticity; requires high pressure and lubrication for deformation | High plasticity; lower resistance to deformation, enabling large reductions |

| Workpiece Accuracy | High (IT6–IT9); smooth surface finish (Ra 0.4–3.2 μm) | Lower (IT10–IT13); rougher surfaces, usually requiring post-machining |

| Mechanical Properties | Higher strength and hardness, slightly reduced toughness | Lower strength but better toughness; uniform microstructure after hot working |

| Die Requirements | High-strength tool steel (e.g., Cr12MoV) with hardness HRC 58–62 | Heat-resistant tool steel; lower friction but prone to oxidation |

| Die Life | Shorter, due to high pressure and wear | Longer, since friction is lower at elevated temperatures |

| Suitable Parts | Small to medium-sized, precision, high-strength components (bolts, gears) | Large, complex parts with lower accuracy demands (crankshafts, connecting rods) |

8.0Key Technologies in Cold Forging

The successful implementation of cold forging relies on three core technologies that directly determine part quality and production efficiency:

Die Design and Manufacturing:

- Die Materials:High-strength tool steels such as Cr12MoV or DC53 are used. Vacuum heat treatment is applied to achieve hardness levels of HRC 58–62, ensuring the dies can withstand high pressures.

- Cavity Design:Metal flow must be simulated to prevent folding, cracking, or other defects. For complex parts, transitional fillets are incorporated to guide uniform filling of the die cavity.

Lubrication Technology:

- Core Objective:Maintain a friction coefficient below 0.05 between the metal and die to minimize wear and extend die life.

- Common Solutions:Steel components typically undergo phosphating + soaping treatment, forming a phosphate film that absorbs the soap layer. Aluminum components are coated with solid lubricants such as molybdenum disulfide (MoS₂).

Materal Selection and Pre-Treatment:

- Material Requirements:Metals with good ductility and low yield-to-tensile strength ratios are preferred, such as low-carbon steels (10#, 20#), low-alloy steels (20Cr, 40Cr), pure aluminum (1060), and brass (H62).

- Pre-Treatment:High-carbon and high-alloy steels require spheroidizing annealing before forging to reduce hardness, improve ductility, and prevent cracking during deformation.

9.0Cold Forging Process: Frequently Asked Questions (FAQ)

Q1: What is the main difference between cold forging and hot forging?

A1: Cold forging is carried out at room temperature or below the metal’s recrystallization point, offering high dimensional accuracy and excellent surface finish. Hot forging, performed above the recrystallization temperature, allows larger deformation with lower force but typically requires secondary machining for accuracy.

Q2: Which materials are most suitable for cold forging?

A2: Cold forging works best with ductile metals such as low-carbon steels, aluminum, copper, and their alloys. Brittle materials like cast iron are not suitable.

Q3: What are the biggest advantages of cold forging?

A3: High precision (IT6–IT9), smooth surfaces (Ra 0.4–3.2 μm), material savings (utilization up to 95%), and low energy consumption (only 1/5–1/10 of hot forging).

Q4: What are the main limitations of cold forging?

A4: High die costs, limited material options, reduced ductility due to work hardening, and complex shapes often requiring multiple forging stages.

Q5: In which industries is cold forging most widely applied?

A5: The automotive sector dominates (over 60% of parts), followed by electronics, machinery, hand tools, and heavy equipment manufacturing.

References

https://www.iqsdirectory.com/articles/forging/cold-forging.html

https://www.tfgusa.com/cold-forging/#FAQs

https://www.fictiv.com/articles/hot-forging-vs-cold-forging

https://www.forcebeyond.com/cold-forging/

https://ecenarro.com/blog-en/from-machining-to-cold-forging/