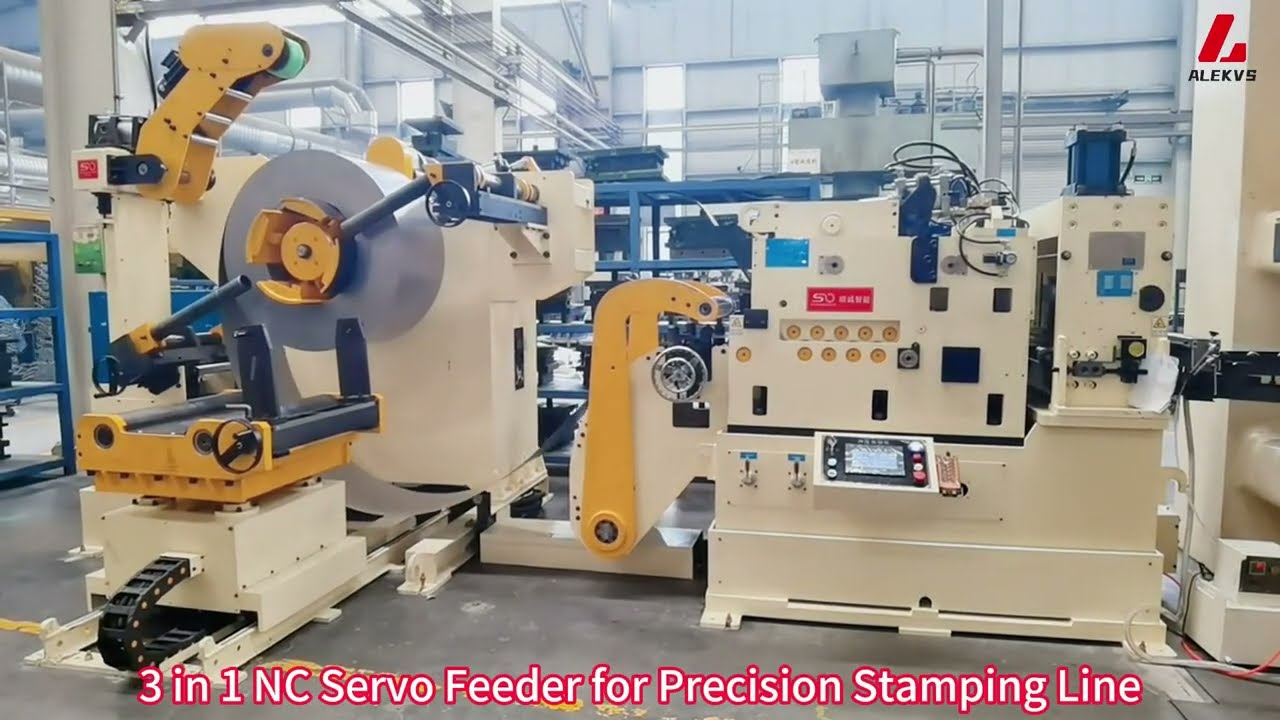

ALEKVS Coil Press Blanking Solutions – From Servo Blanking to Fine Blanking Precision

ALEKVS servo blanking lines are designed to manufacture shaped blanks with high precision and throughput efficiently. By utilizing advanced servo press technology, the press slide motion is dynamically adapted to the die geometry, increasing both production output and tool life.

These servo-driven blanking press lines are ideal for a wide range of materials—including aluminum, high-strength steels, and even surface-sensitive metals—without sacrificing quality or speed.

Key Advantages:

- Perfect for shaped and complex blank geometries

- High-speed operation: up to 105 strokes per minute

- Tonnage options: 6,300 to 12,500 kN

- Optimized slide motion via ALEKVS ServoMotion™ Technology

- Gentle on dies, increasing tooling life and reducing downtime

- Smart automation reduces labor needs and simplifies operations

- Proven reliability under continuous industrial production

Whether you’re looking to boost productivity or process challenging materials, ALEKVS offers press blanking solutions that deliver performance with precision.