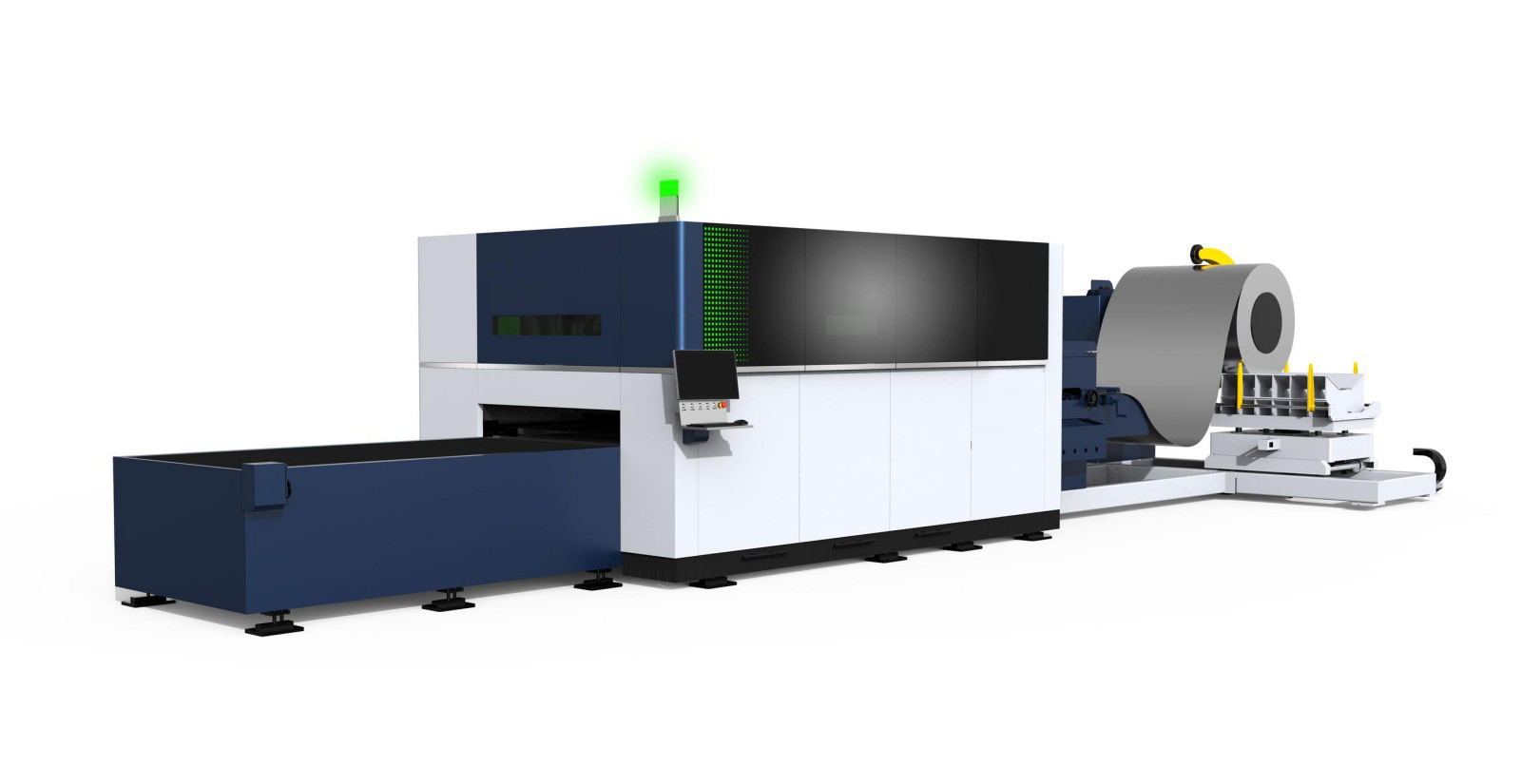

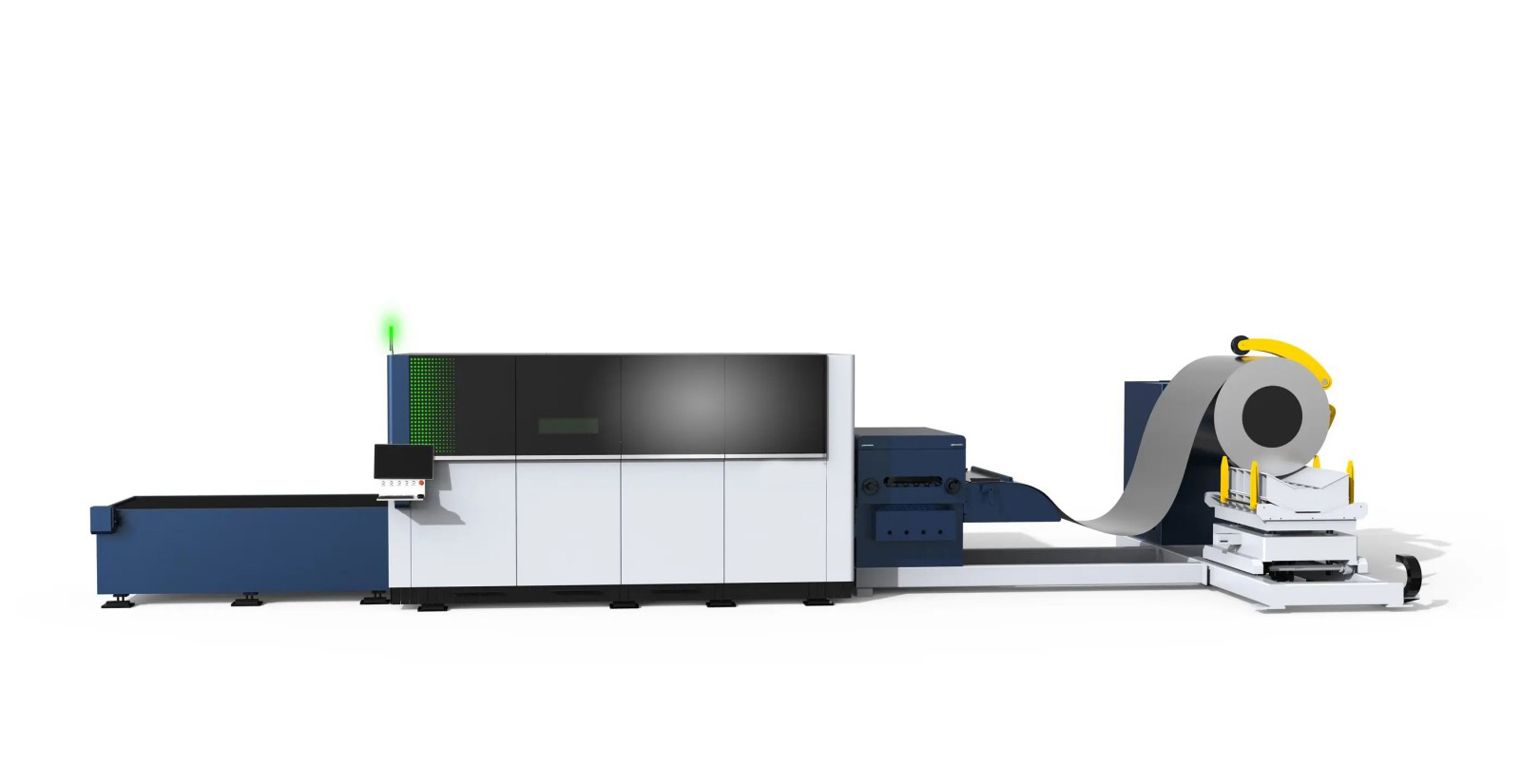

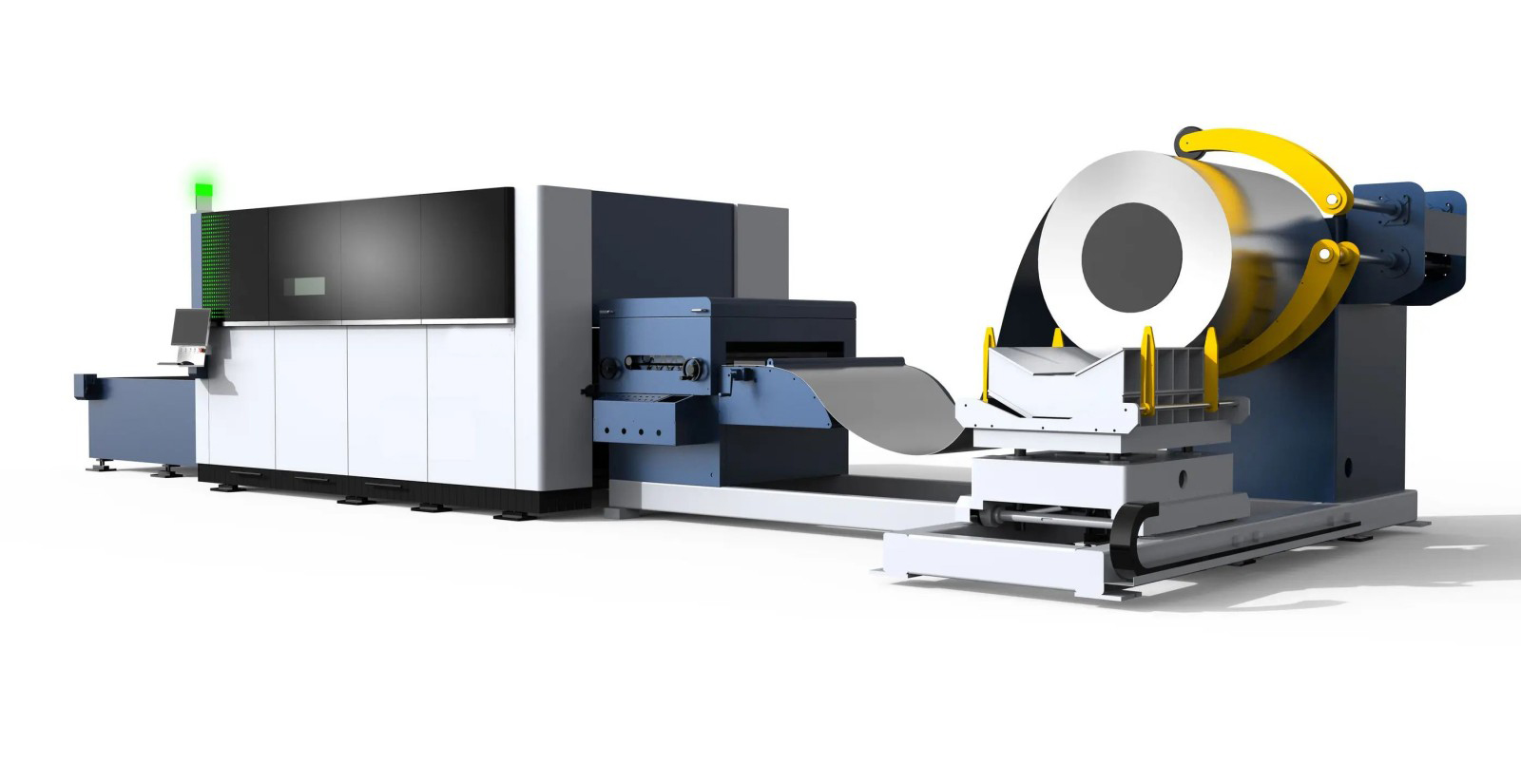

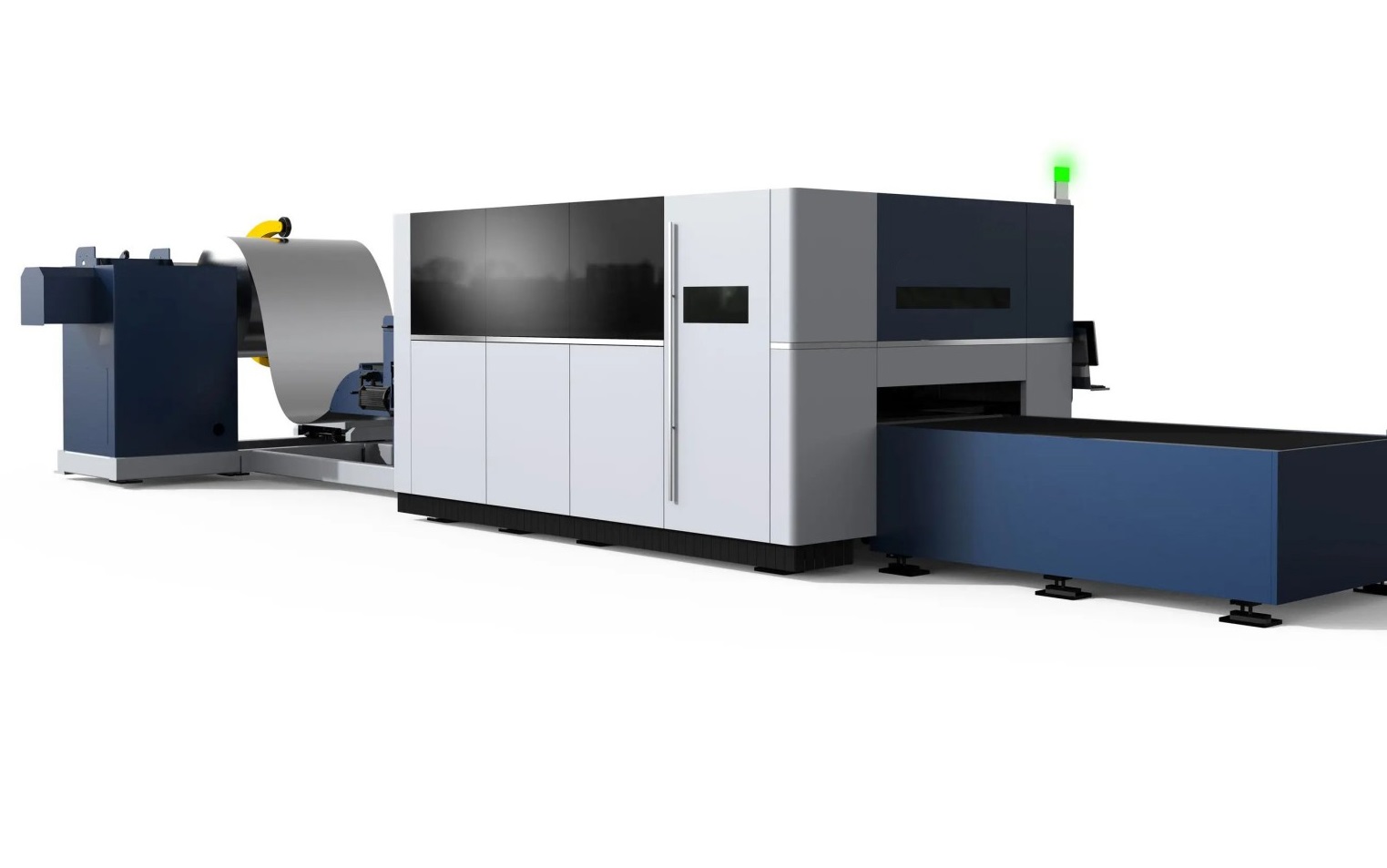

ALEKVS Coil Fed Laser Blanking System: Redefining Sheet Metal Blanking

The ALEKVS Coil Fed Laser Blanking Line is a high-performance solution that integrates automated decoiling, straightening, feeding, and fiber laser cutting into a single continuous process.

Designed for materials such as aluminum alloys, galvanized steel, stainless steel, and carbon steel, this system enables flexible or high-efficiency blanking for a wide range of production volumes. It’s ideally suited for industries such as automotive manufacturing, home appliances, architectural metalwork, and general sheet metal fabrication.