- 1.0Choosing Between CO₂ and Fiber Lasers

- 2.0What Is a CO₂ Laser?

- 3.0What Is a Fiber Laser?

- 4.0Understanding the Key Differences Between CO₂ and Fiber Lasers

- 5.0CO₂ vs. Fiber Laser: Which Technology Is Safer to Use?

- 6.0CO₂ vs. Fiber Lasers: Which Is More Energy Efficient?

- 7.0CO₂ vs. Fiber Lasers: Capital Investment Comparison

- 8.0CO₂ vs. Fiber Lasers: Maintenance and Operating Costs

- 9.0CO₂ vs. Fiber Laser: Cutting Speed Comparison

- 10.0CO₂ Laser vs. Fiber Laser — Material Processing Comparison Table

- 11.0Fiber Laser vs. CO₂ Laser: Which Should You Buy and Why?

- 12.0CO₂ Laser vs. Fiber Laser — Frequently Asked Questions

1.0Choosing Between CO₂ and Fiber Lasers

The Core Role of the Laser Source: At the heart of every laser system is its laser source. This component generates the laser beam by energizing particles of light and releasing them in a focused stream.

Common Types of Laser Sources and Their Advantages: The two most widely used laser sources today are CO₂ lasers and fiber lasers. Each offers distinct performance benefits. Selecting the right laser source can significantly enhance processing efficiency, precision, and flexibility.

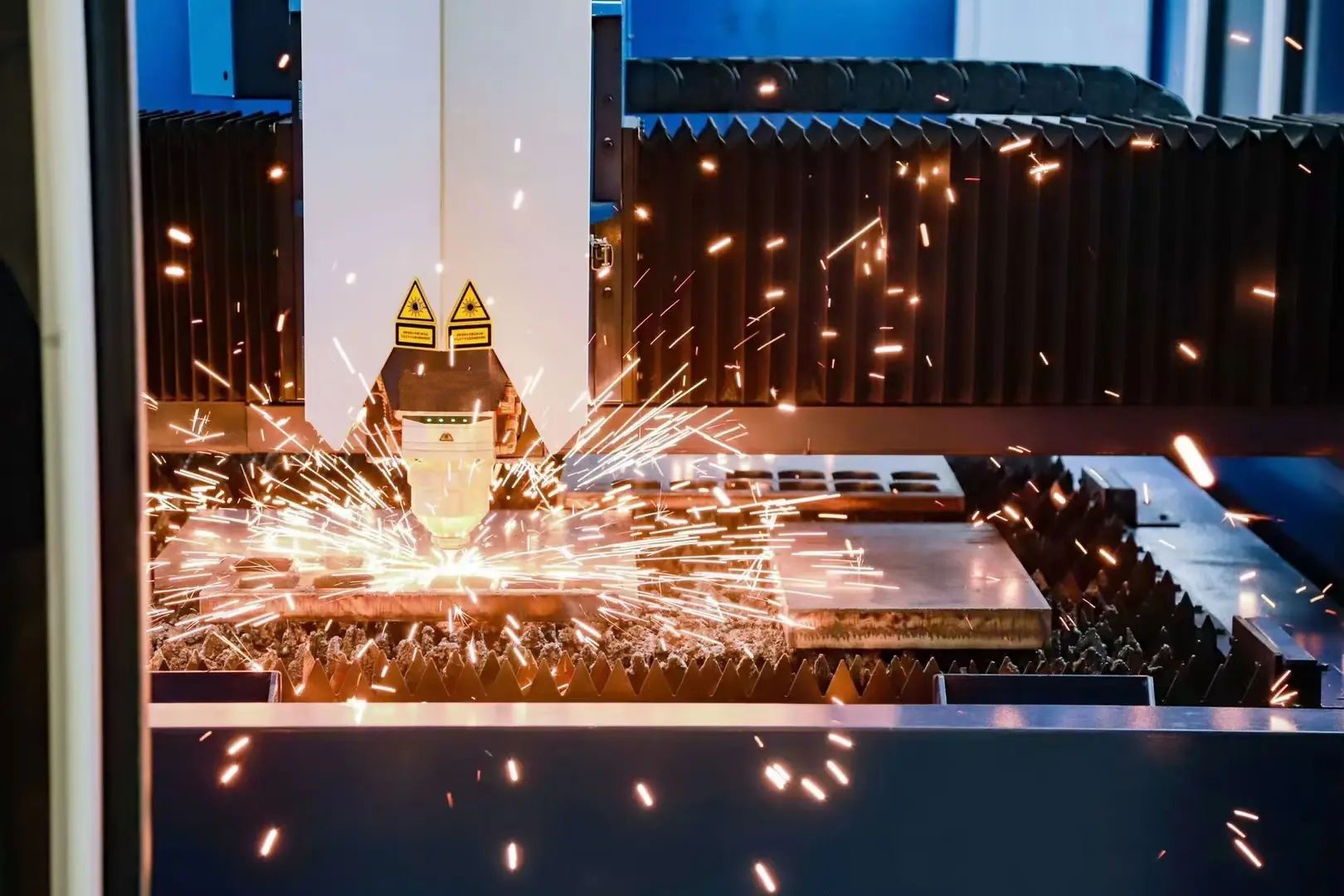

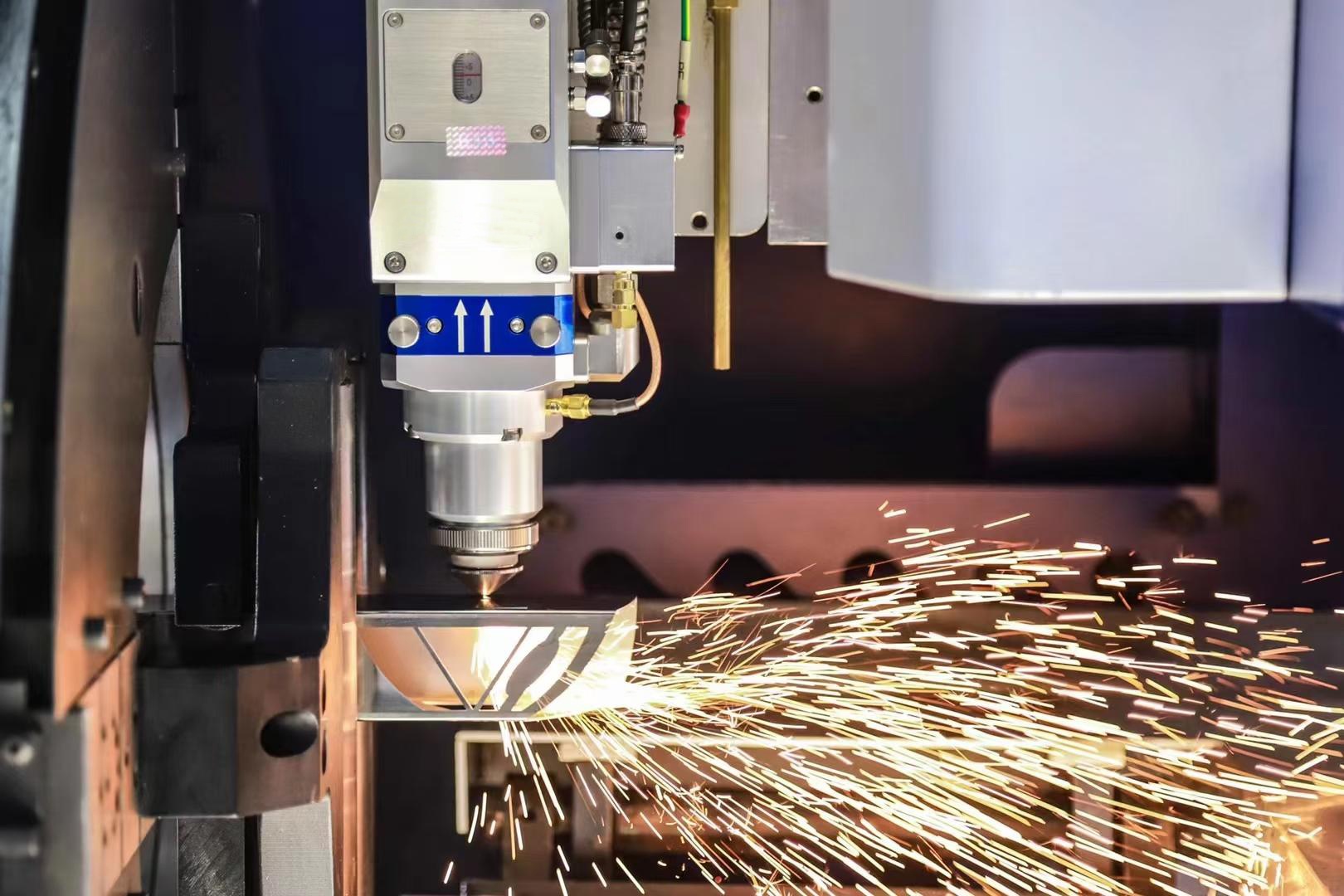

CO₂ vs. Fiber Laser Cutting for Metal Processing: Manufacturing professionals have long debated which technology is better suited for metal cutting. Some favor the time-tested CO₂ systems, while others prefer the modern advantages offered by fiber lasers.

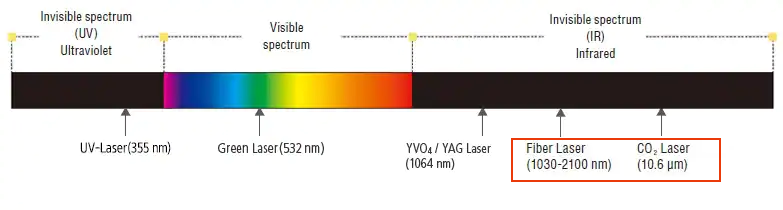

Key Factors in Choosing a Laser Source: The primary difference between these two laser types lies in their wavelength and beam delivery method:

- Fiber Lasers: Designed for metal cutting, they operate at shorter wavelengths, making them highly efficient for cutting a wide range of metals.

- CO₂ Lasers: Broader material compatibility, ideal for cutting non-metallic materials and certain metals with the right setup.

2.0What Is a CO₂ Laser?

CO₂ lasers are among the most versatile and widely used laser types, favored for their broad material compatibility. They cut and engrave by vaporizing material, making them particularly effective for non-metal substrates.

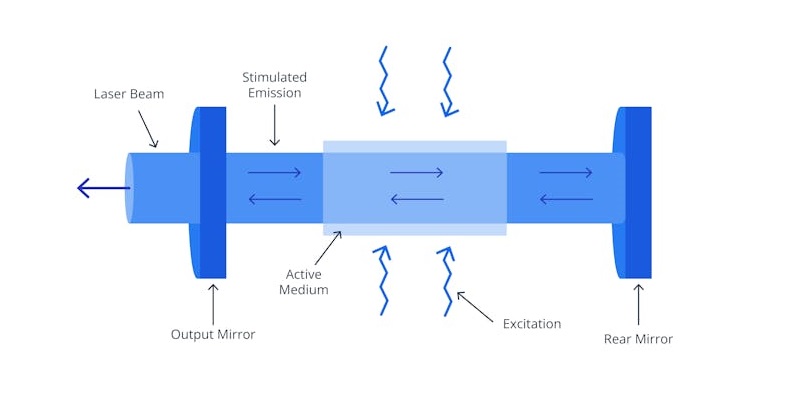

How It Works:

A CO₂ laser operates by exciting a gas mixture—primarily carbon dioxide (CO₂), nitrogen (N₂), and helium. An electrical field energizes nitrogen molecules, which transfer energy to CO₂ molecules through resonance. The CO₂ molecules then emit photons, creating the laser beam. Helium helps reset the CO₂ molecules to their ground state, enabling continuous output.

Laser Characteristics:

- Wavelength:~10.6 microns; falls in the mid-to-far infrared spectrum.

- Output: High-efficiency laser generation.

- Design: Simple structure with low production cost.

- Power Range: Adjustable from milliwatts to kilowatts.

- Beam Quality: Delivers continuous, stable peak power.

- Scalability: Output power can be increased by extending the laser tube.

- Modulation: Q-switching via rotating mirrors allows higher pulse power.

- Advancements: Variants like RF-excited CO₂ lasers offer better power, longevity, and efficiency.

CO₂ Laser Features:

- System Types: Compatible with multiple CO₂ laser system formats.

- Customization: Available in various power levels and working area sizes.

- Material Flexibility: Supports a wide range of substrates.

Affordability: Lower initial cost makes it a cost-effective option for engraving.

Processable Materials:

- Cutting and Engraving: Plastic, acrylic, wood, cardboard, paper, fabric, rubber.

- Engraving Only: Glass, ceramics, stone, coated metals. Bare metal generally cannot be processed directly and may require marking sprays or coatings.

Typical Applications:

- Signage and display manufacturing

- Acrylic cutting and engraving

- Custom gifts and toy personalization

- Trophy and award production

3.0What Is a Fiber Laser?

Fiber lasers use a rare-earth-doped fiber as the gain medium and are specifically designed for metal marking and high-contrast plastic applications. They excel in tasks where CO₂ lasers fall short, offering high speed, low power consumption, and virtually maintenance-free operation.

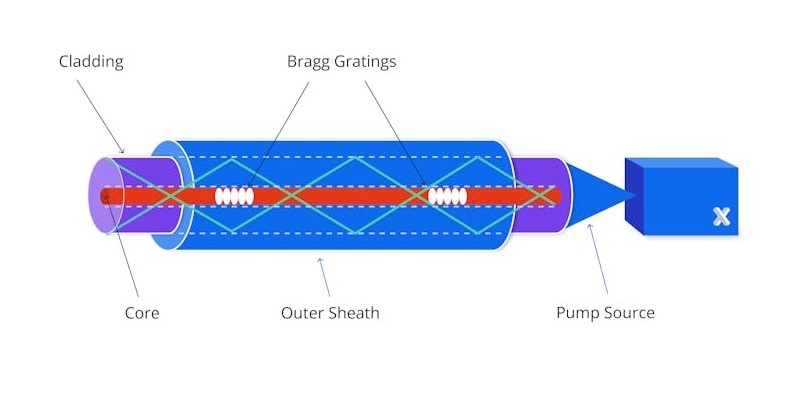

How It Works:

Built around a monolithic architecture, fiber lasers generate light by stimulating doped optical fiber (e.g., ytterbium). Laser energy is amplified within the fiber cavity and reflected by Bragg gratings, producing a collimated beam that is focused onto the material surface through a lens.

Advantages of Fiber Lasers:

- Maintenance: Virtually maintenance-free over long periods.

- Size: Compact and easy to integrate.

- Stability: High beam quality with low noise and flicker.

- Cost: Lower than comparable systems at the same power output.

- Environment: Performs well under variable temperature and industrial conditions.

- Speed & Power: Fast cutting speeds with available power levels reaching 12kW or more.

Fiber Laser Cutting Technology and Benefits

Fiber lasers emit highly focused beams with excellent absorption in metals, making them particularly effective for metal cutting. Their low reflectivity and efficient beam delivery outperform CO₂ lasers in many metal applications.

- Material Suitability: Ideal for stainless steel, aluminum, brass, and copper.

- Cutting Thickness: Capable of cutting metal sheets over 1 inch (25 mm), with optimal performance below 0.5 inch (12.5 mm).

- Assist Gases: Use of nitrogen or oxygen helps improve slag removal, cut speed, and edge quality.

- Power Consumption: Operates at one-half to one-third the running cost of CO₂ lasers.

- Cutting Speed: Up to 5 times faster than traditional CO₂ systems.

- Maintenance: Sealed optics system minimizes cleaning and lens replacement.

- Productivity: Increases throughput and reduces per-part production cost.

Key Features of Fiber Lasers

- Direct Marking: Capable of engraving and marking bare metals without sprays or coatings.

- Durability: Long service life (minimum 25,000 hours).

- Rotary Axis: Optional rotary attachments enable marking on cylindrical or tapered surfaces.

Processable Materials:

- Metals: Aluminum, bronze, copper, gold, platinum, silver, stainless steel, titanium.

- Plastics: ABS, polyamide, polycarbonate, PMMA (acrylic), laser-markable additives.

Typical Applications:

- Promotional item marking

- High-contrast plastic marking

- Direct part marking

- Barcode and nameplate engraving

4.0Understanding the Key Differences Between CO₂ and Fiber Lasers

| Comparison Criteria | CO₂ Laser | Fiber Laser |

| Power Consumption & Efficiency: | High power consumption, low efficiency (~5–10%); higher operational costs. | Low power consumption, high efficiency (>90% typical); energy-saving and cost-effective. |

| Initial Cost: | Lower cost; good price-to-performance ratio. | Higher cost per watt; total equipment cost can be 5–10 times that of a CO₂ laser. |

| Service Life: | Shorter lifespan; limited refurbishment options. | Long lifespan (up to 25,000 hours), around 10× longer than CO₂; refurbishment readily available. |

| Cutting Precision: | Lower precision. | Higher precision; ideal for fine, detailed work. |

| Typical Cut Materials: | Acrylic, melamine, mother of pearl, paper, polyester film, plastic, rubber, wood, POM, fabric, Corian®, cork, fiberglass, leather, cardboard, plywood, etc. | Metals (including stainless steel, aluminum, titanium, and other reflective materials), glass, acrylic (PMMA), POM, paper, cardboard, most foams, etc. |

| Material Compatibility: | Best suited for non-metal and some non-ferrous materials. | Suitable for most materials, especially metals; optimal for cutting workpieces ≤20 mm thick. |

| Power Range: | Tens of watts up to ~100 kW; high power requires large-scale cooling. | Power output can approach 1 megawatt (MW); low cooling requirements. |

| Wavelength: | 10.6 µm or 9.6 µm (longer wavelength). | 1064 nm (1.064 µm; shorter wavelength). |

| Operating Costs: | Low electrical efficiency; high energy usage. | High electrical efficiency; excellent economic performance. |

| Industries: | Medical, defense, telecommunications, general manufacturing; well-suited for thick plate cutting (>10 mm), often used with oxygen assist. | Telecommunications, medical, precision machining, automotive, electronics; excels at cutting reflective metals like titanium, brass, and aluminum. |

5.0CO₂ vs. Fiber Laser: Which Technology Is Safer to Use?

Laser Safety Risks: Regardless of type, laser radiation—whether direct or reflected—can pose serious hazards to human eyes and skin. To mitigate this, laser systems are classified based on potential biological risks, with mandatory safety labeling as defined by BS EN 60825-1 (IEC 60825-1). This standard outlines laser classes and corresponding emission limits:

- Class 1:Safe under normal operation, even with prolonged direct viewing or observation through optical instruments such as magnifiers or telescopes.

- Class 2M: Emits visible radiation; typically safe for short-term naked-eye exposure but may cause harm if viewed through optical aids.

- Class 4:High risk of eye and skin injury, even from diffuse reflections; also presents fire hazards.

Safety Measures in Laser Cutting Systems

While fiber lasers are inherently Class 4 due to their high output power, most fiber laser cutting systems are engineered to meet Class 1 safety standards through robust protective features:

- Interlock Systems: Automatically disable laser emission if access panels or enclosure doors are not securely closed, preventing accidental exposure.

- Protective Viewing Windows: Specialized laser safety glass shields operators from beam exposure while allowing visual monitoring. The glass must be rated based on laser power, focus, and beam characteristics.

CO₂ Laser Safety Characteristics

- Open Design: CO₂ laser machines often use open-top configurations. Even when reflected, the beam is significantly diffused, reducing the likelihood of severe harm.

- Cost-Effective Protection: The safety glass used is typically semi-transparent and lower in cost, offering sufficient protection while maintaining visibility for the operator.

Fiber Laser Safety Considerations

- Certification Requirement: When purchasing fiber laser equipment, ensure that both the laser source and the complete system are CE certified, confirming compliance with international safety standards.

- Enhanced Containment: Due to the shorter wavelength and higher energy density, fiber lasers require more stringent shielding and enclosure design to prevent hazardous exposure, even at high power levels.

6.0CO₂ vs. Fiber Lasers: Which Is More Energy Efficient?

Power Consumption Comparison:

Fiber lasers offer a significant advantage over CO₂ lasers in terms of energy efficiency and sustainability.

CO₂ Laser Efficiency: With an electrical efficiency of around 10%, a 6kW CO₂ laser typically requires approximately 60kW of input power.

Fiber Laser Efficiency: Fiber laser systems operate at around 45% efficiency (up to 50%), needing only about 13kW of input to achieve the same 6kW output.

As laser output power increases, so do the demands on the cooling system. CO₂ lasers require considerably more energy to maintain proper cooling, resulting in higher electrical costs compared to fiber lasers.

Additionally, the power needed for fume extraction and filtration depends on the machine size and cutting bed area. Higher cutting power increases the load on the extraction systems.

Conclusion: Fiber laser cutting machines consume significantly less energy, resulting in measurable cost savings over time, particularly in high-volume or long-duration production environments.

7.0CO₂ vs. Fiber Lasers: Capital Investment Comparison

While the initial purchase price of a fiber laser cutter is typically higher than that of a CO₂ laser, its faster cutting speeds—especially for thin materials—boost productivity. Combined with lower power consumption, fiber systems help reduce the cost per part.

Automation Capability:

Both CO₂ and fiber laser systems support high levels of automation, including:

- Lights-out manufacturing

- Automatic nozzle changers

- Autofocus lens systems

These features reduce manual intervention and idle time, increasing efficiency. Though higher automation raises upfront costs, it significantly reduces downtime caused by operator errors and enhances long-term ROI.

Factors Influencing Laser System Costs:

- Laser power

- Cutting area size

- Level of automation

Typical Price Range:

- Used industrial CO₂ systems: £150,000 and up

- New industrial fiber laser systems: £275,000 to £550,000, with some exceeding £1 million

While fiber laser prices are gradually decreasing thanks to advances in solid-state laser technology, CO₂ laser pricing remains relatively stable.

8.0CO₂ vs. Fiber Lasers: Maintenance and Operating Costs

Maintenance Requirements:

Fiber lasers require significantly less maintenance than CO₂ lasers, largely due to differences in beam delivery systems.

- Fiber Lasers: Use sealed fiber-optic cables to transmit the laser beam directly to the cutting head. The closed beam path eliminates contamination risk.

- Consumables: Mainly nozzles and protective windows

- Typical Maintenance Time: Less than 30 minutes per week

- CO₂ Lasers: Rely on articulated arms with multiple mirrors and bellows to guide the beam.

- Maintenance Needs: Mirrors and bellows are prone to dust buildup and wear, requiring regular cleaning and replacement

- Mechanical Wear : Bellows movement can cause pinholes and misalignment

- Thermal Effects: Heat from the laser can deform mirrors, misaligning the beam and requiring recalibration

- Damage Risk: Beam reflection may damage costly components like oscillators

- Typical Maintenance Time:4–5 hours per week

Beam Alignment:

Accurate beam alignment is essential for consistent cutting quality.

- CO₂ Lasers: Involve multiple mirrors; realignment is complex and time-consuming.

- Fiber Lasers: Require only a single lens adjustment; alignment is quick and straightforward.

9.0CO₂ vs. Fiber Laser: Cutting Speed Comparison

Cutting Performance Overview:

Fiber lasers deliver significantly faster cutting speeds than CO₂ lasers when processing thin materials (under 8 mm), with the most noticeable advantages seen in stainless steel applications.

1 mm Thickness: Fiber lasers cut approximately 6× faster than CO₂ lasers.

5 mm Thickness: The speed gap narrows to around 2×.

Power Scaling: Increasing laser power by about 2 kW can boost cutting speed for thin materials by 2 to 3 times.

As material thickness increases under equivalent power conditions, CO₂ lasers can approach—or in some cases exceed—fiber laser cutting speeds. However, this advantage is relatively limited, and high-power CO₂ lasers (above 6kW) are less common in industrial settings.

Fiber lasers, by contrast, remain effective across a broad range of material thicknesses, particularly in high-power systems, where they consistently outperform in speed and efficiency.

Note: Optimal cutting speed should be evaluated not only by speed metrics, but also by consumable life and assist gas efficiency to ensure cost-effective operation.

Cutting Speed Comparison Table (6kW Laser vs. 170A Plasma Cutter)

| Material & Thickness | 6kW Fiber Laser (m/min) | 6kW CO₂ Laser (m/min) | High-Definition Plasma (m/min) |

| Stainless Steel 5 mm | 6.00 | 2.70 | 2.69 |

| Stainless Steel 10 mm | 1.30 | 1.50 | 1.61 |

| Stainless Steel 15 mm | 0.90 | 0.75 | 1.23 |

| Mild Steel 5 mm | 4.20 | 4.20 | 2.32 |

| Mild Steel 10 mm | 2.00 | 2.40 | 2.68 |

| Mild Steel 15 mm | 1.20 | 1.75 | 2.27 |

Note: The speeds shown reflect straight-line cutting performance. Real-world cutting involving complex geometries or nested layouts may yield lower effective speeds. Machine acceleration and deceleration capabilities also influence overall throughput.

Edge Quality Comparison

CO₂ Lasers:

CO₂ lasers feature a larger beam spot size, making them well-suited for cutting materials of various thicknesses. This larger spot produces smoother edge finishes, particularly as material thickness increases. The quality of the cut edge improves with depth, making CO₂ lasers a preferred option when edge smoothness is a key requirement for thicker materials.

Fiber Lasers:

Fiber lasers have a smaller beam diameter, which enables narrow kerfs and high-speed cutting on thin materials. This focused beam increases energy absorption, resulting in fast and efficient processing.

However, when cutting thicker materials, the fiber laser’s beam primarily affects the top of the cut zone. The laser must rely on multiple internal reflections to reach the bottom of the kerf, which can lead to:

Rougher surface finishes

Fine striations along the edge

Increased assist gas pressure requirements to effectively evacuate molten material

As a result, the cut edge quality may be inferior to that of CO₂ lasers when processing thick sections, especially in applications requiring minimal post-processing.

10.0CO₂ Laser vs. Fiber Laser — Material Processing Comparison Table

| Material Type | Examples | CO₂ Laser Cutting | CO₂ Laser Engraving | CO₂ Laser Marking | Fiber Laser Cutting | Fiber Laser Engraving | Fiber Laser Marking | Notes |

| Wood & Paper | Plywood, MDF, cardboard, veneer | √ | √ | √ | × | × | × | Fiber lasers not suitable for organic materials |

| Acrylic & Plastics | Cast acrylic, ABS, Delrin (POM) | √ | √ | √ | × | √ | √ | Fiber lasers suitable for plastics with additives |

| Textiles & Leather | Cotton, felt, synthetic leather | √ | √ | √ | × | × | × | Fiber lasers not recommended for fibrous materials |

| Glass & Ceramics | Flat glass, ceramic cups | × | √ | √ | × | × | √ | Fiber laser marking limited to surface discoloration |

| Rubber Materials | Laser-grade rubber, silicone sheets | √ | √ | √ | × | × | × | Fiber lasers cannot process soft materials |

| Paper Products | Cardstock, drawing paper | √ | √ | √ | × | × | × | Flame control important when cutting with CO₂ lasers |

| Stone | Granite, marble, slate | × | √ | √ | × | × | Limited | Fiber laser marking depth limited; for shallow marks only |

| Foam Materials | EVA foam, PE foam | √ | √ | √ | × | × | × | Fiber lasers not suitable for highly absorbent foams |

| Metals (Bare Metal) | Stainless steel, aluminum, copper, brass, titanium | × | × | √ (with spray) | √ | √ | √ | Fiber lasers can directly process metals |

| Coated Metals | Anodized aluminum, painted metals | × | √ | √ | × (cutting not recommended) | √ | √ | Fiber lasers excel in high-contrast surface marking |

| Precious Metals | Gold, silver, platinum | × | × | √ (with spray) | √ | √ | √ | Fiber lasers widely used in jewelry and high-value metal processing |

| Highly Reflective Metals | Mirror aluminum, copper, brass | × | × | √ (with spray) | √ | √ | √ | Fiber lasers require high power or special settings to avoid reflection damage |

| Fiberglass Materials | Fiberglass board, epoxy sheets | × | × | × | × | × | × | Processing releases toxic gases; not recommended |

| PVC & Vinyl | PVC materials, vinyl films | × | × | × | × | × | × | Both laser types are unsuitable for chlorine-containing materials |

11.0Fiber Laser vs. CO₂ Laser: Which Should You Buy and Why?

Choosing Between CO₂ and Fiber Laser Cutters

If you are planning to purchase a laser cutting machine but are unsure whether to choose a CO₂ laser or a fiber laser, understanding the differences between these two technologies will help you make an informed decision.

A clear grasp of the advantages and limitations of each laser type will clarify which is better suited for your specific needs.

11.15mm Stainless Steel Cutting Comparison

- CO₂ Laser Cutting 5mm Stainless Steel Sample

- Fiber Laser Cutting 5mm Stainless Steel Sample

(Insert diagram or comparison photos here)

11.2Key Factors in Selecting a Laser Cutting System

Choosing the right automated laser cutting system requires a comprehensive evaluation of your current applications, requirements, constraints, and future growth plans. Main considerations include:

- Material types and thicknesses

- Processing accuracy

- Production efficiency

- Purchase budget

- Operating costs

11.3Technology Comparison and Conclusion

While CO₂ laser technology is well-established and remains superior for cutting many non-metal materials, fiber lasers offer up to 5 times faster cutting speeds on thin metals (under 8 mm) and can reduce operating costs by approximately 50%.

Higher productivity and lower total cost of ownership position fiber lasers as a transformative force within the industry.

11.4Key Performance Comparison of Laser Technologies

| Function / Performance | Fiber Laser | CO₂ Laser |

| Metal Sheet Cutting | ✓ | |

| Metal Engraving | ✓ | |

| Organic Material Cutting | ✓ | |

| Thin Material Cutting (<8 mm) | ✓ | |

| Thick Material Cutting | ✓ | ✓ |

| Surface Roughness (Better Finish) | ✓ | |

| Cutting Speed (<8 mm) | ✓ | |

| Energy Consumption | ✓ | |

| Operating Costs | ✓ | |

| Maintenance Costs | ✓ | |

| Machine Setup & Idle Time | ✓ | |

| Total Cost of Ownership | ✓ | |

| Footprint (Space Required) | ✓ | |

| Safety | ✓ |

12.0CO₂ Laser vs. Fiber Laser — Frequently Asked Questions

What is a CO₂ laser?

A CO₂ laser generates laser light by exciting CO₂ gas molecules, producing a wavelength around 10.6 microns. It is suitable for cutting and engraving a wide range of non-metal materials and is currently the most widely used laser type.

What is a fiber laser?

A fiber laser uses a rare-earth-doped optical fiber (commonly ytterbium) as the gain medium, with a shorter wavelength of approximately 1.064 microns. It is specifically designed for metal cutting and marking, offering high efficiency and easy maintenance.

What are the main differences between CO₂ lasers and fiber lasers?

Wavelength: CO₂ lasers operate at 10.6 microns, fiber lasers at 1.064 microns.

Material Suitability: CO₂ lasers excel at non-metal materials, while fiber lasers are optimized for metal cutting.

Efficiency & Maintenance: Fiber lasers provide higher energy efficiency and simpler maintenance; CO₂ lasers consume more power and require more complex upkeep.

Which laser is better for cutting metal?

Fiber lasers, with their shorter wavelength and higher absorption efficiency, are ideal for cutting various metals—especially thin metal sheets (<8 mm)—offering faster cutting speeds and lower energy consumption.

What advantages do CO₂ lasers offer?

CO₂ lasers support a wide range of materials (plastics, wood, acrylic, etc.), have simpler structures, lower upfront costs, and deliver high-quality cutting and engraving on non-metal materials.

Is there a big difference in operating costs?

Fiber lasers are approximately 4 to 5 times more energy-efficient than CO₂ lasers, resulting in significantly lower power consumption and maintenance costs—making them more economical over the long term.

Which laser is safer?

Both are high-power lasers requiring strict safety measures. Most laser cutting systems are designed to meet Class 1 laser safety standards, ensuring safe operation.

Is fiber laser maintenance complicated?

Maintenance is simple, mainly involving cleaning of nozzles and protective windows, with typical weekly maintenance time under 30 minutes.

Is CO₂ laser maintenance difficult?

Maintenance is more complex, requiring regular cleaning of mirrors and bellows. Weekly maintenance can take 4 to 5 hours.

Is there a significant difference in purchase cost?

Fiber lasers generally have a higher initial investment, often multiple times the cost of CO₂ lasers. However, their higher efficiency and lower operating costs can recover the investment over time.

Are fiber lasers suitable for plastics and organic materials?

Generally not recommended. Fiber lasers are better suited for metals and plastics containing laser-sensitive additives.

References

www.researchgate.net/publication/335334467_The_Analysis_of_Fiber_and_CO_2_Laser_Cutting_Accuracy

https://www.xometry.com/resources/sheet/co2-laser-vs-fiber-laser/

https://www.tubeformsolutions.com/blog/tube-bender-7/fiber-vs-co2-laser-cutting-understanding-the-differences-448