Main Features

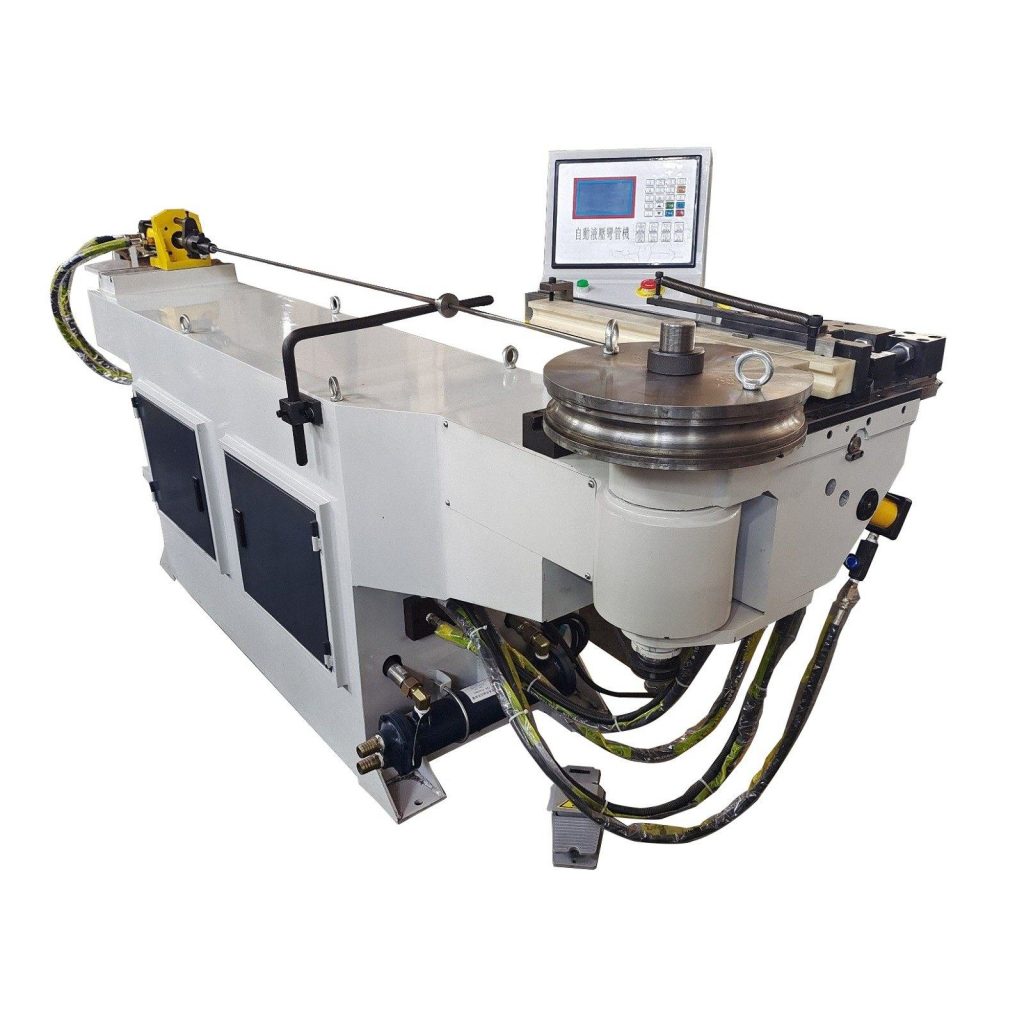

- CNC automation: Fully automatic pipe bending with 3 servo motor programmable axes (feeding, rotation, bending).

- High precision: Hydraulic bending with encoder feedback and servo motor reducer drive.

- Advanced control system: Standard imported hydraulic system and PLC; optional IPC upgrade.

- Smart operation: Touch-screen with HMI interface for easy data input and program storage.

- Reliable performance: Automatic lubrication, electric cabinet cooling, and hydraulic cooling ensure stable long-time operation.

- Safety system: Foot-switch supports auto start, emergency stop, and resume functions.

- Error management: Real-time self-diagnosis and alarm messages enhance reliability.

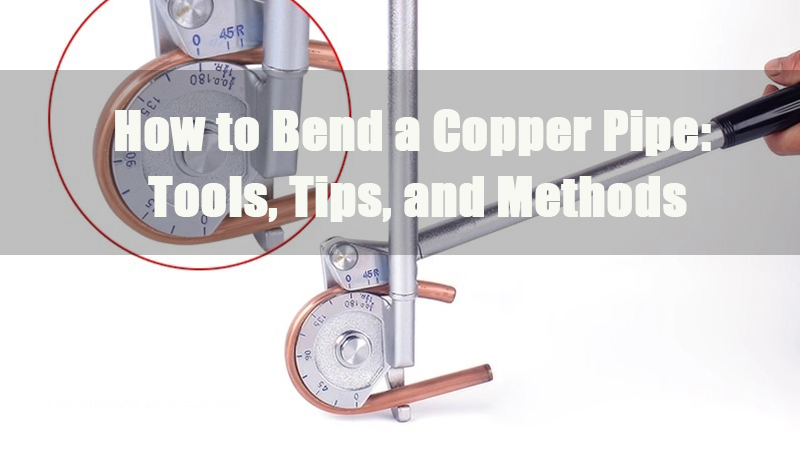

- Versatile tooling: Interchangeable bending molds meet various bending requirements.

Product Details

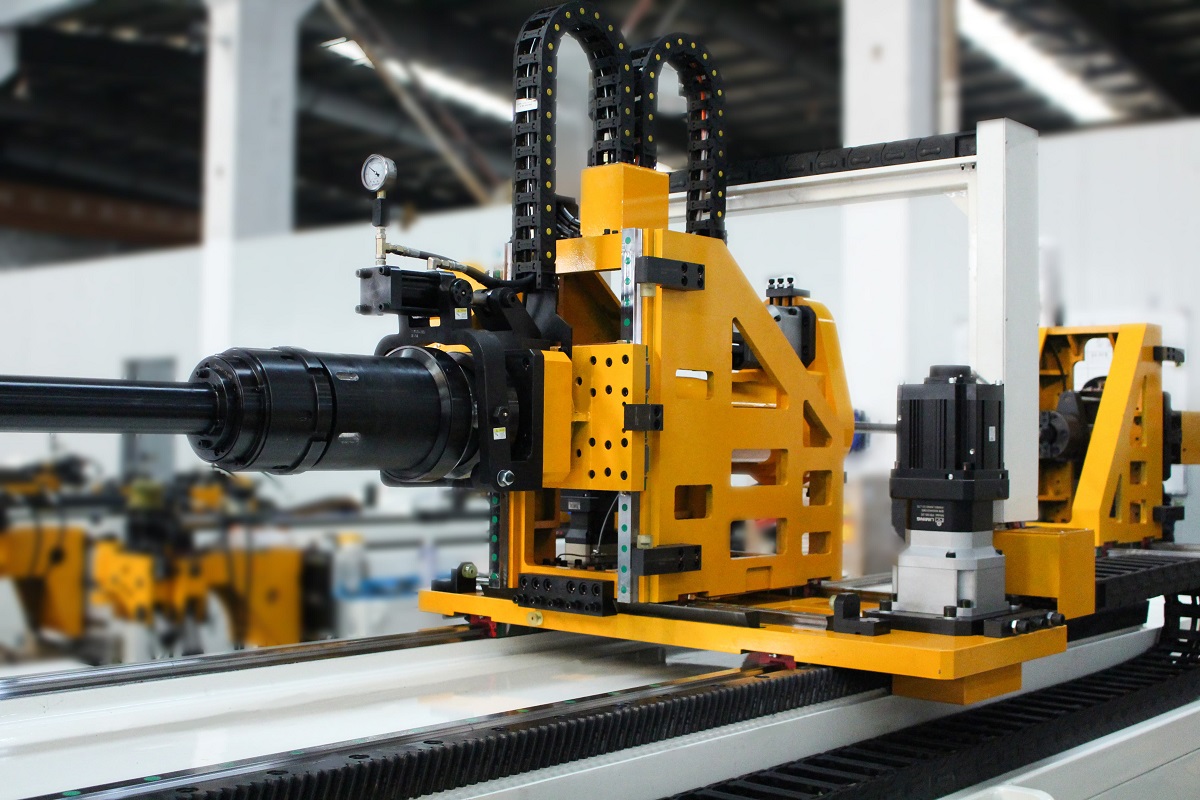

- Servo Motor System: Controls feeding, rotation, and bending for high-precision forming.

- Bending Arm: High-strength, stable structure ensures smooth bending performance.

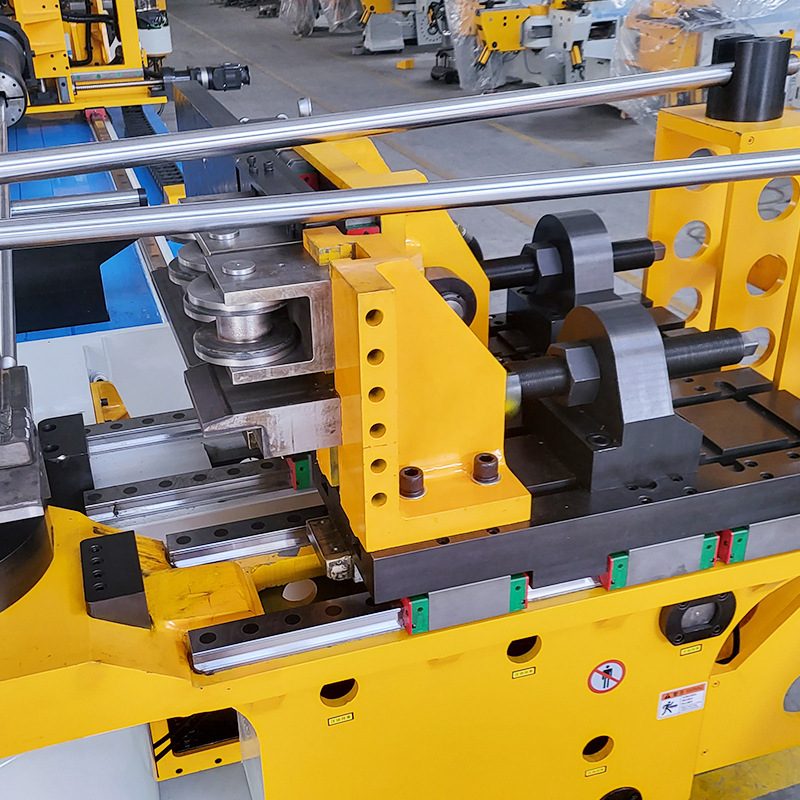

- Mold Section: Flexible mold replacement for different bending requirements.

- Core Pulling Cylinder: Enhances mandrel support for complex bends.

- PLC Controller: Mitsubishi PLC with optional advanced programming functions.

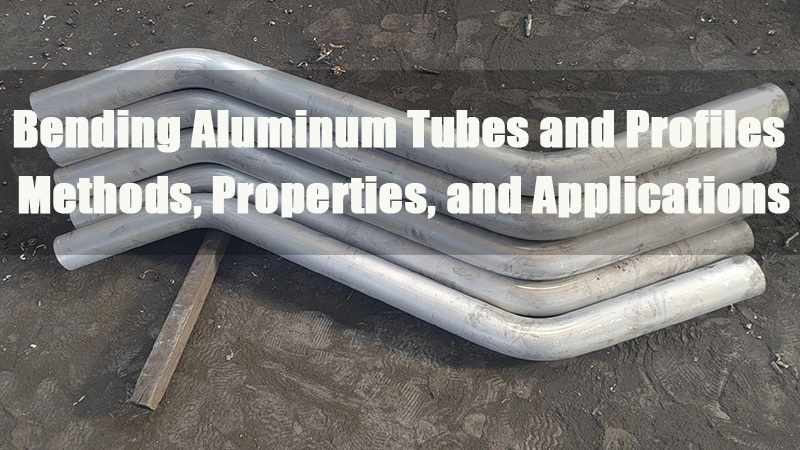

Applications

The AEK-CNC T Series is designed for industries requiring precision tube and pipe bending, including:

- Automotive and aerospace

- Motor and pump components

- Steel and aluminum processing

- General pipe fitting manufacturing

Technical Advantages

- High accuracy: Bending angle control with encoder, precision ±0.1°.

- Flexible operation: Manual, semi-automatic, or full-cycle modes available.

- Durability: Equipped with a large-capacity cooling system for stable operation under high temperatures.

- Wide material compatibility: Suitable for stainless steel, carbon steel, aluminum, copper, alloy, and brass pipes.

- 3D bending capability: Customizable mandrel length, bending range 0–190°.

- Global adaptability: Multiple voltage options available.

Please fill out this form to submit a request for quote. One of our team members will review the details and be in touch within 12 business hours.