Advantages of ALEKVS Roll Forging

Our roll forging process combines the benefits of forging and rolling:

- Superior precision and surface quality: uninterrupted grain flow ensures uniform structure, excellent mechanical properties, and often eliminates secondary machining.

- High throughput: continuous roll rotation enables rapid, efficient, high-volume production.

- Extended die life: minimal sliding between die and metal reduces wear.

- Lower tonnage requirements: gradual, localized deformation allows for lighter machine design.

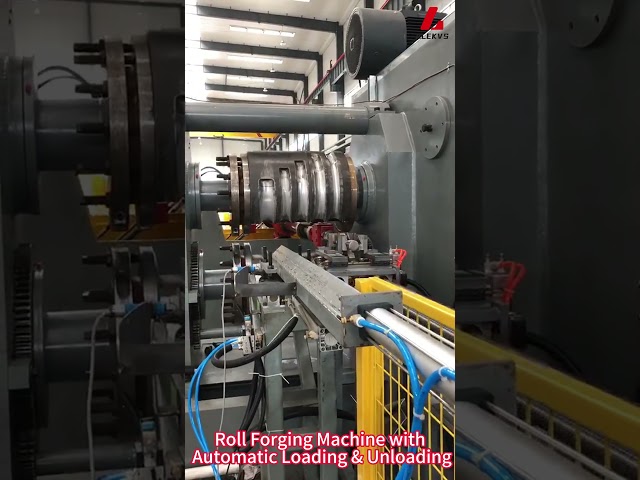

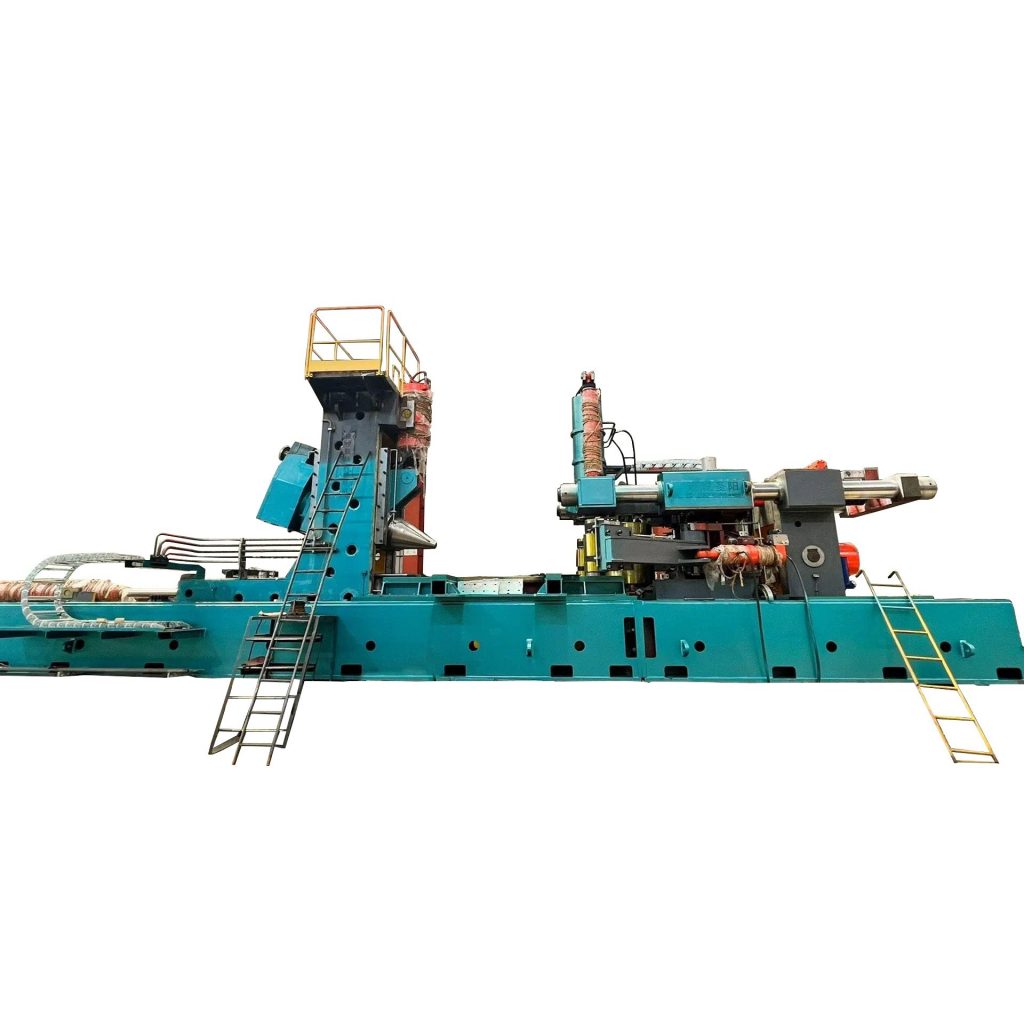

- Automation-ready: smooth, vibration-free process integrates easily into automated lines, improving safety and efficiency.

- Compact and efficient: reduced foundation requirements save space and installation costs.

Applications and Typical Parts

ALEKVS roll forging machines support high-precision, high-strength production across multiple industries:

- Automotive: connecting rods, steering arms, rocker arms, axles, ball stud pins, rack bars.

- Agricultural machinery: blades, plowshare parts, torsion rods, support struts.

- Railroad: flat bars, rail fasteners, tie plates.

- General industrial: shafts, pins, handles, hooks, camshaft blanks.

By preserving grain alignment and surface integrity, ALEKVS roll forging reduces the need for further processing while ensuring stronger, lighter, and more reliable parts.

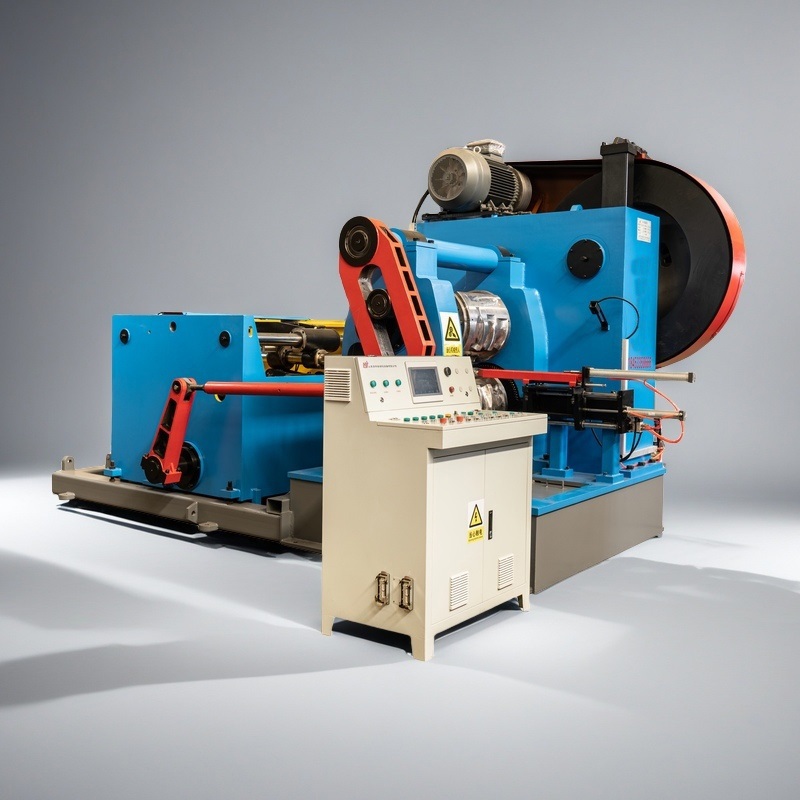

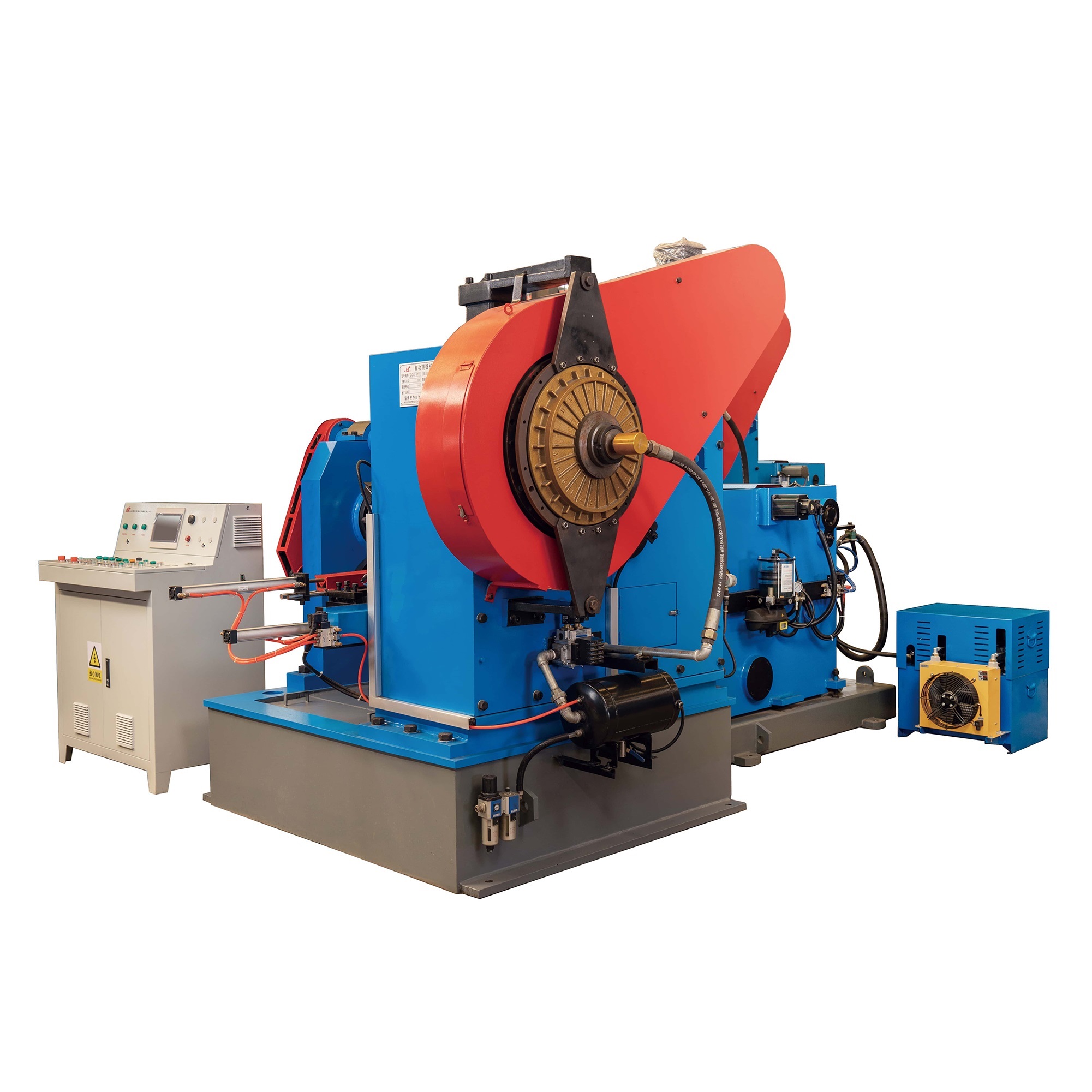

Key Technical Highlights

- Wide model selection: from small-scale precision forgings to large structural shafts.

- Powerful drive units deliver consistent, high-speed deformation.

- Extensive feed strokes are adaptable to long or complex contours.

- Tight concentricity control (≤0.5 mm) for accurate forging.

- Robust thermal management: billet temperatures maintained between 1050–1150 °C for optimal ductility and grain flow.

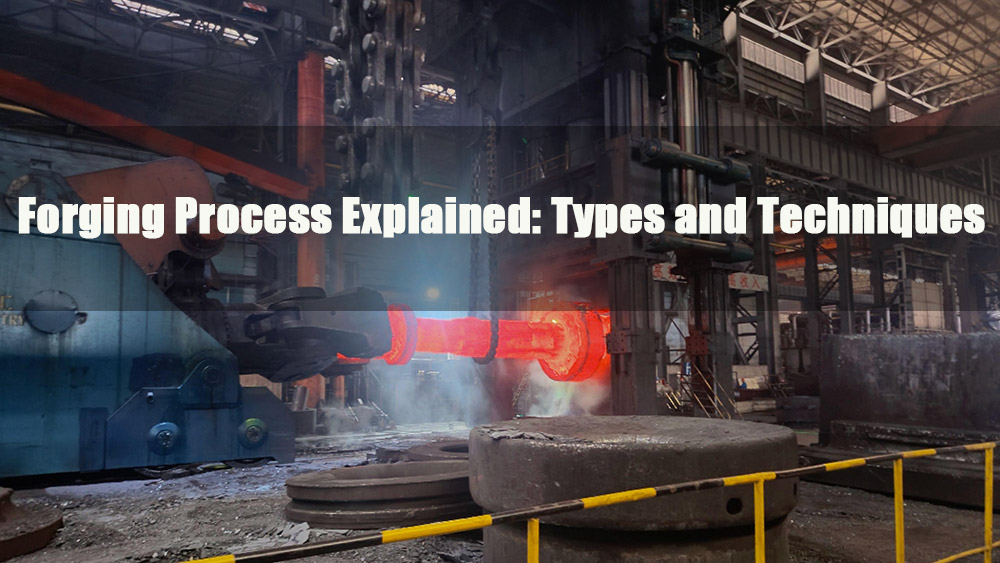

What is Roll Forging

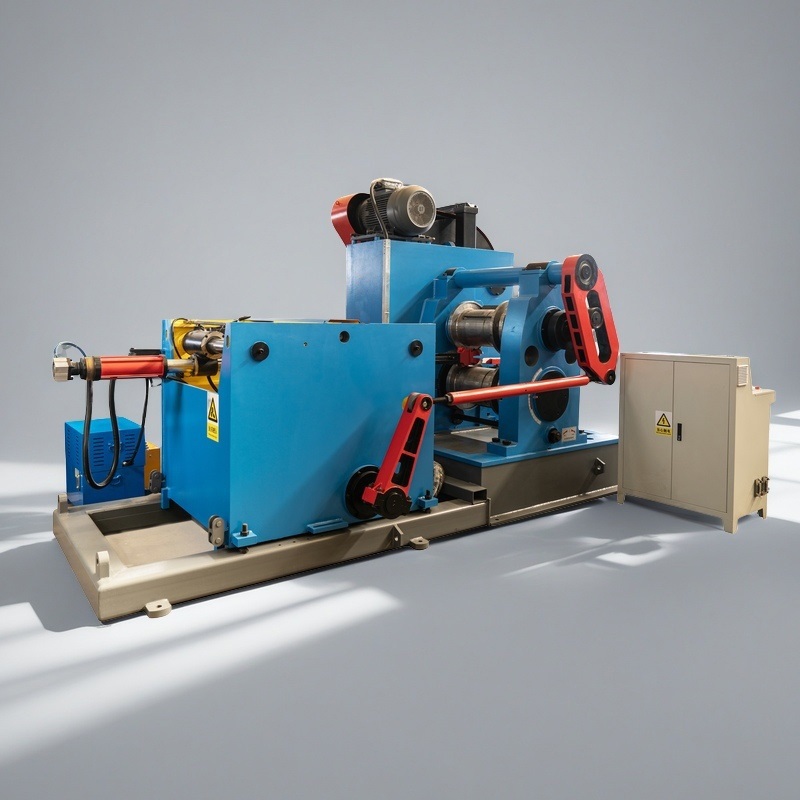

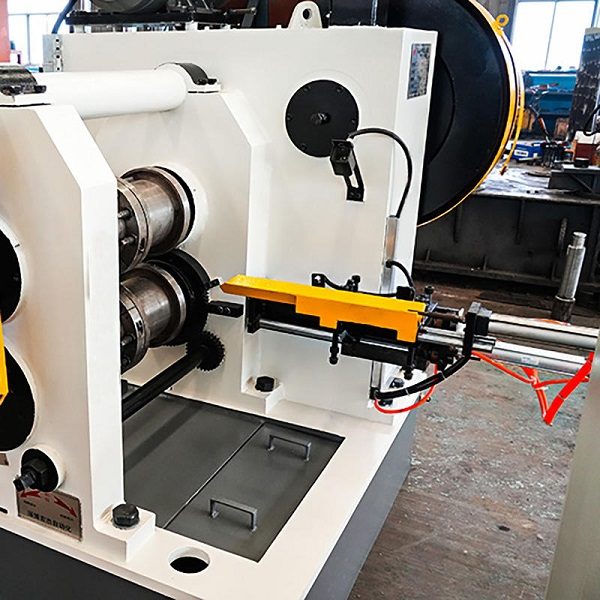

ALEKVS roll forging machines utilize a pair of opposing, rotating sector-shaped dies to plastically deform heated billets, producing the desired forgings or billets.

- During roll forging, pressure compresses the billet in the thickness direction, causing most metal to flow along the billet’s length, while only a small portion spreads laterally.

- The essence of roll forging is lengthwise elongation under pressure, ideal for operations that reduce cross-sectional area, such as shaft elongation or billet flattening.

- In industrial applications, roll forging can:

- Serve as a preform step for conventional forging, providing high-quality blanks for long shaft components.

- Be used to directly produce finished forgings entirely on the roll forge machine.

Why Choose ALEKVS Roll Forging Machines

- Reduces scrap and machining by producing near-net shape forgings.

- Ensures high repeatability and part consistency across extended production runs.

- Improves mechanical performance via optimized grain orientation.

- Adapts to various industries and materials, including medium-carbon steel, alloy steels, and select non-ferrous alloys.

- Compact, low-vibration design for easy integration into production lines.

Production Workflow

- Heat billet

- Load into the open roll forge

- Stepwise deformation under rotating roll dies

- Progressive elongation and shaping

- Finished part exits ready for downstream processing

Operation is simple—manual or robotic loading is possible, and the machine performs continuous, efficient deformation with minimal supervision.

Please fill out this form to submit a request for quote. One of our team members will review the details and be in touch within 12 business hours.