Applications

- Applicable for round, square, and special-shaped tubes (stainless steel, iron, copper, aluminum, galvanized steel)

- Automotive components

- Furniture structures

- Air-conditioning and fuel pipelines

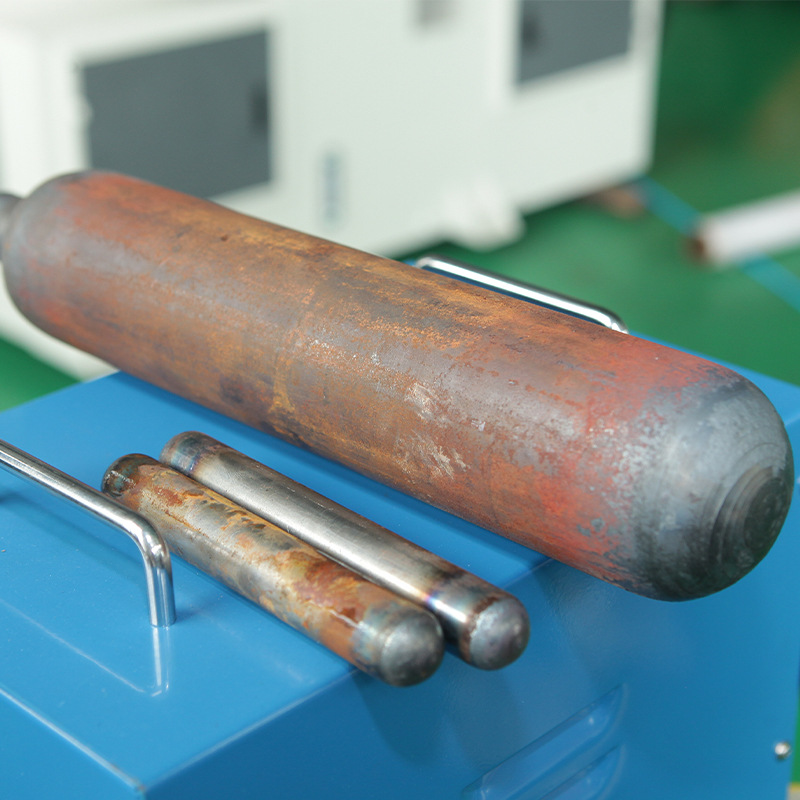

- Gas springs

- Heat pipes

- Hydraulic fittings

- Metal construction products

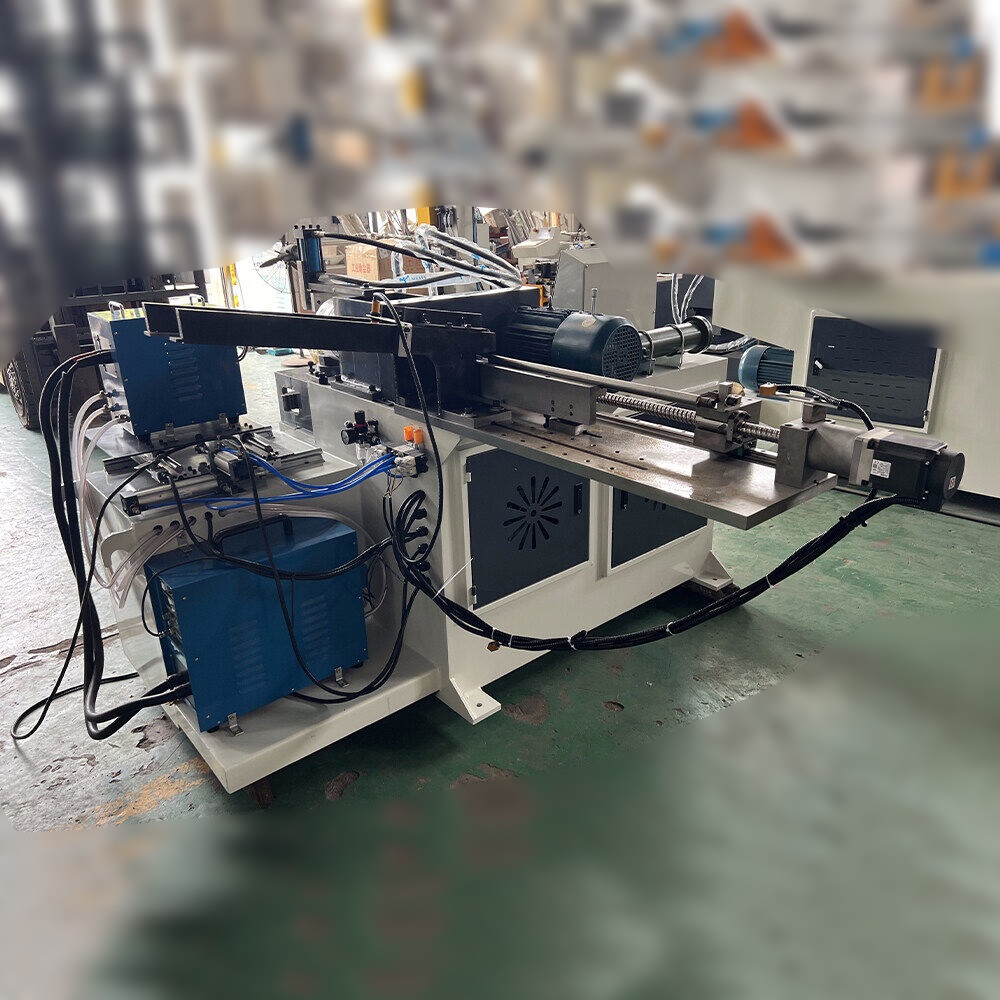

Automatic Feeding & Unloading Systems

Multiple feeding systems can be customized according to production needs:

- Vibration Bowl Feeding System: Ideal for small or lightweight tubes

- Hopper + Pusher Feeding System: Suitable for bulk material feeding

- Servo Roller Feeding System: Ensures precise, stable feeding

- Chain/Belt Conveyor System: Designed for continuous mass production

- Robotic Arm Handling System: Enables flexible automated integration

Each system can be tailored to achieve fully automated loading, forming, and unloading workflows.

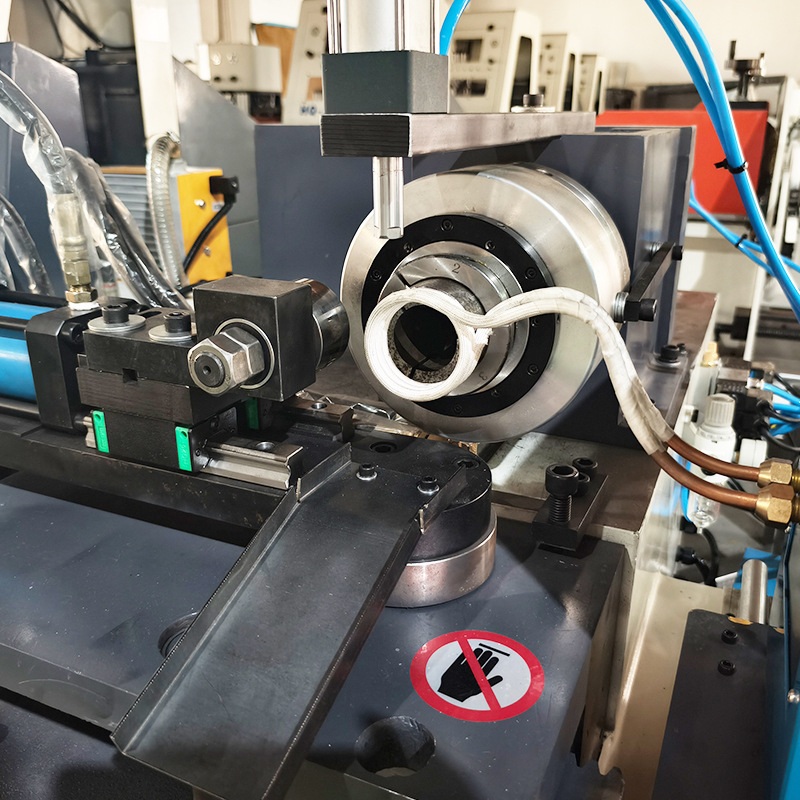

Main Features

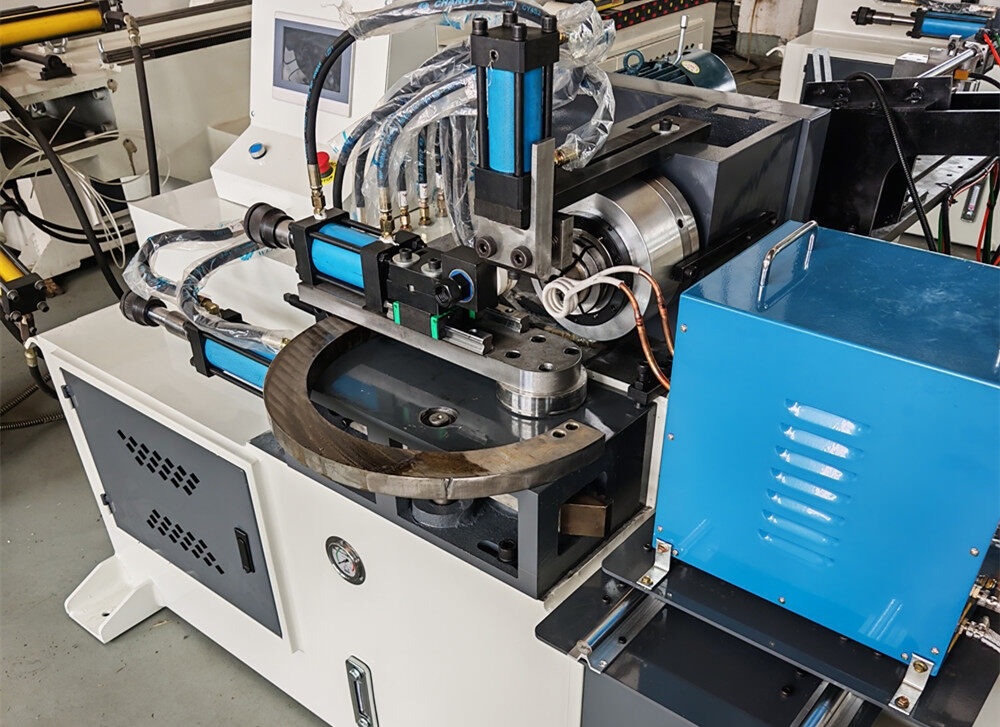

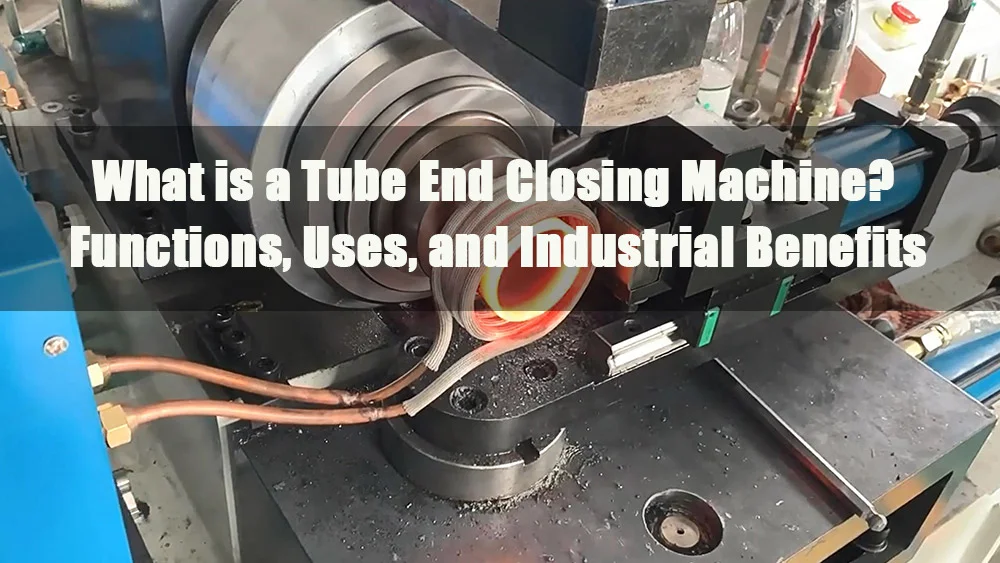

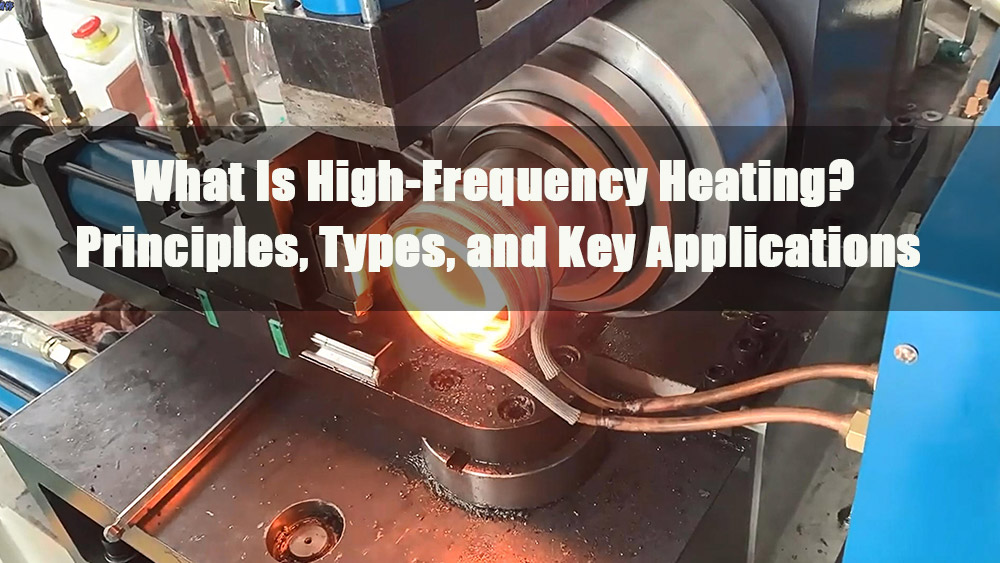

Efficient Tube End Forming

- RF heating ensures rapid and even heating for consistent forming quality

- Adjustable residual hole size or fully closed end using the tube’s own material

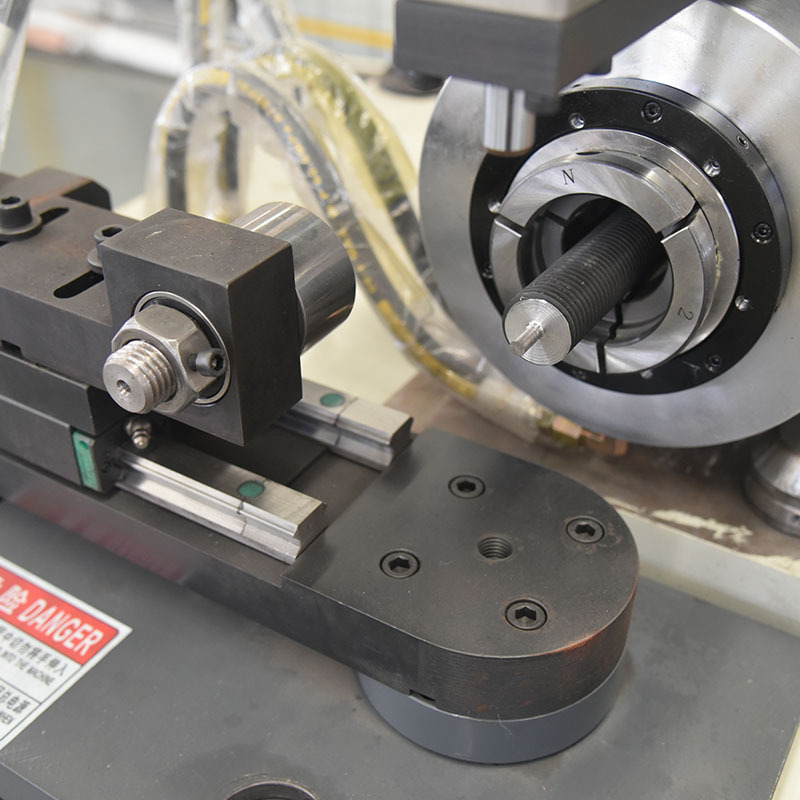

Quick Mold Change

- Molds can be easily replaced to achieve different closing shapes

- Simple setup and adjustment for various tube sizes

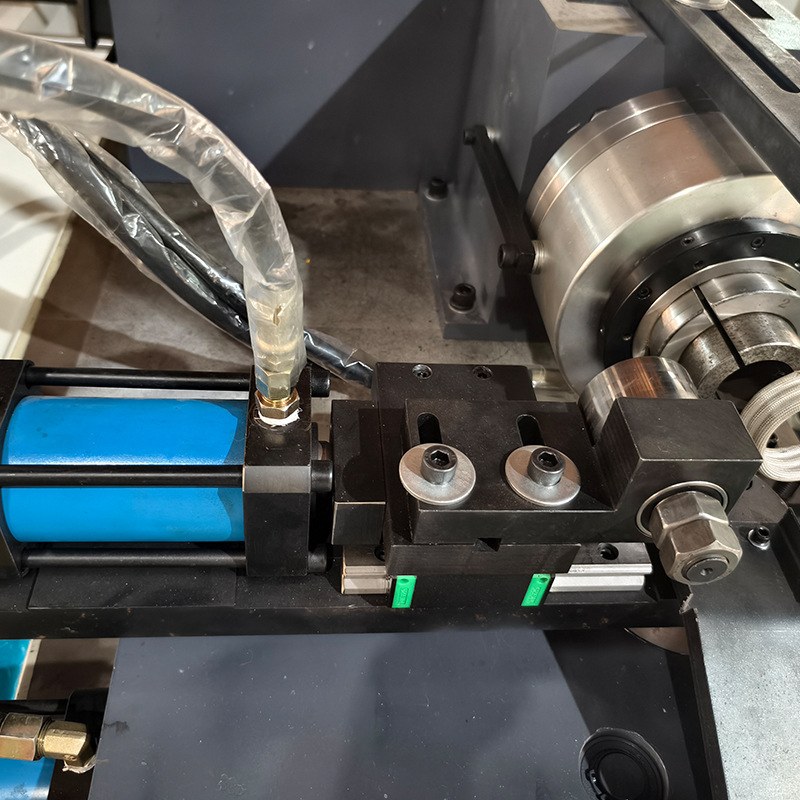

Hydraulic Clamping and Drive System

- Imported hydraulic clamps provide secure and automatic holding

- Mold steel tooling resists high temperature and wear

- Hydraulic drive system ensures smooth, low-noise operation

Precision Positioning System

- Rear-end positioning and front-end auxiliary tools maintain forming accuracy even with varying tube lengths

Lubrication and Control System

- Automatic lubrication improves forming consistency and extends tool life

- Visualized control panel for straightforward operation and real-time monitoring

Please fill out this form to submit a request for quote. One of our team members will review the details and be in touch within 12 business hours.