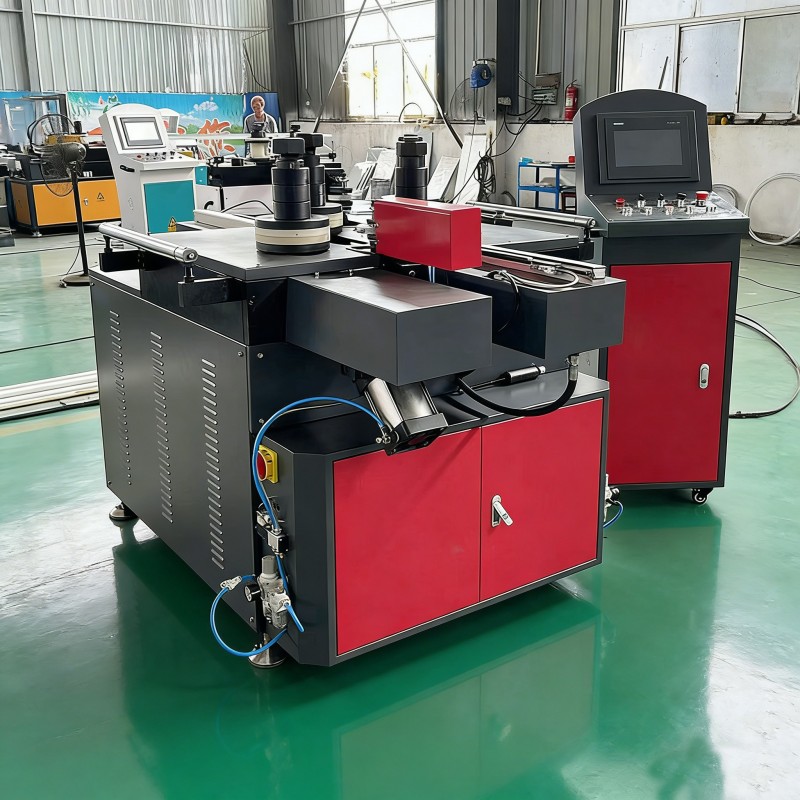

Aluminum Bending Machine – Application

The machine is suitable for bending and forming:

- Aluminum window and door profiles

- Thermal break aluminum and aluminum-clad wood profiles

- Curtain wall and architectural façade profiles

- Automotive aluminum components such as bumpers, window frames, and structural sections

- Profiles requiring U-shape, C-shape, S-shape, circular, elliptical, square, spiral, irregular, and multi-radius bending

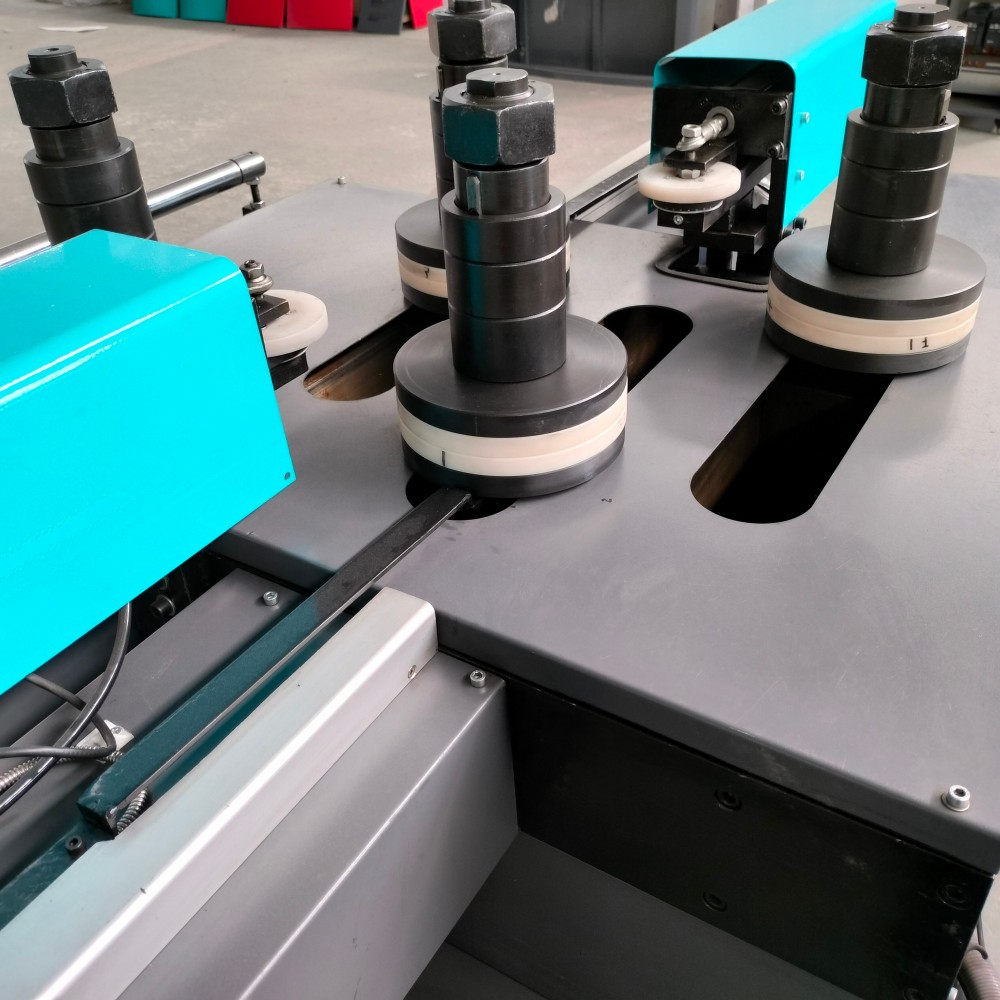

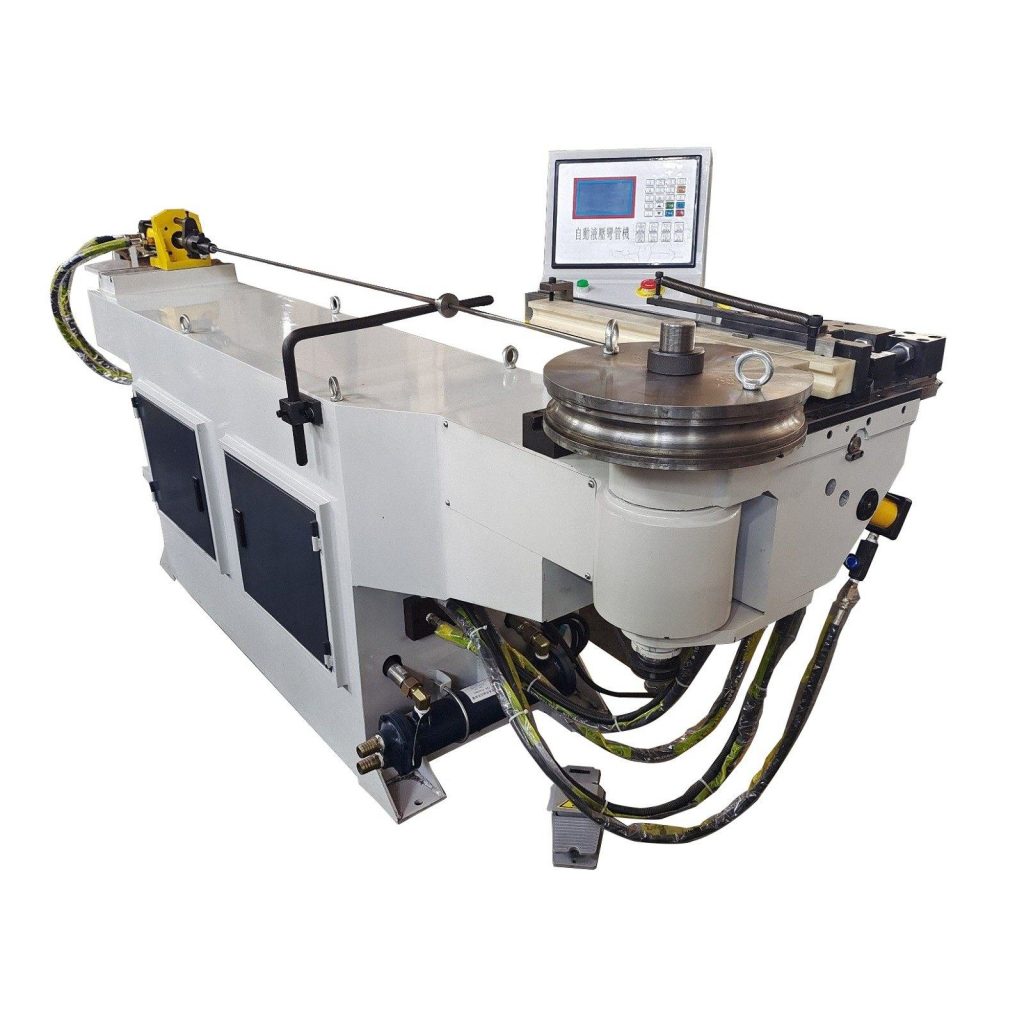

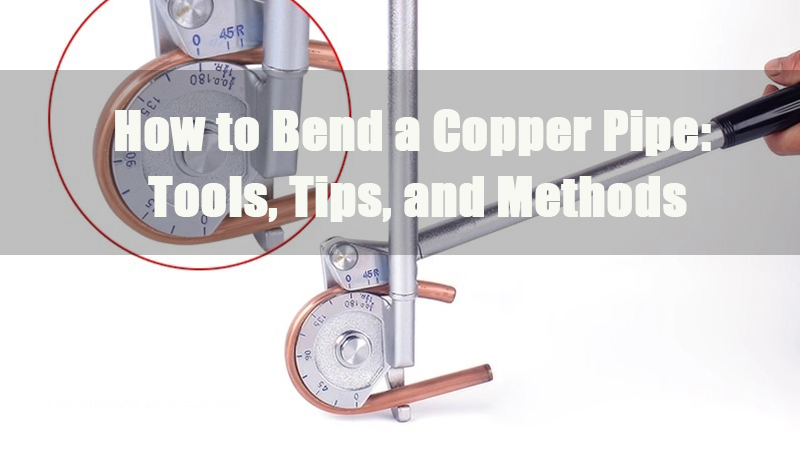

This four-roll profile bending machine supports forward and lateral bending and allows flexible conversion between three-axis and four-axis bending modes according to profile shape requirements.

Forming System and Mechanical Structure

- The hydraulic drive provides a stable forming force

- Hydraulic cylinder pressure: 20–25 T, ensuring consistent bending accuracy

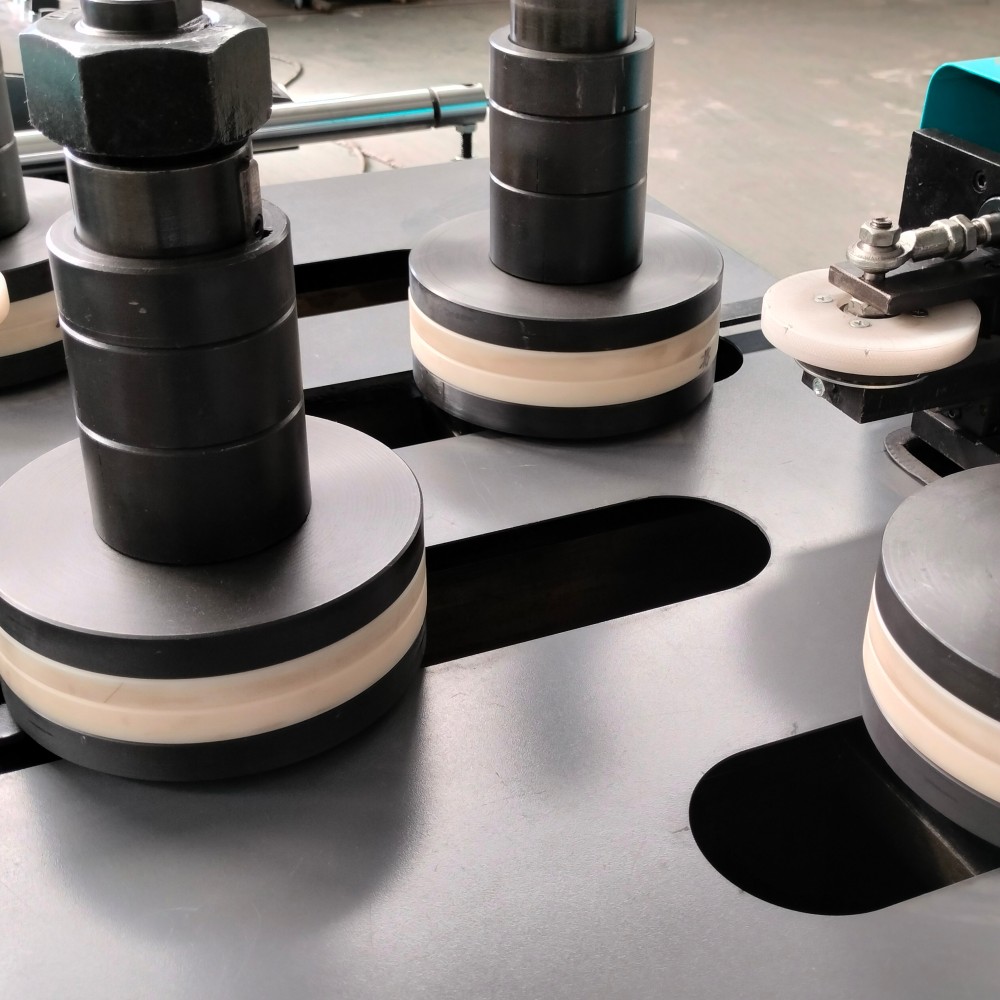

- Roll diameter: 200 mm

- Shaft rotation speed: 0–15 r/min, adjustable for different materials and profile sections

PU Roller / Rubber-coated Roller

Positioning Accuracy and Compensation

- Y-axis positioning accuracy: ±0.02 mm

- Maximum Y-axis travel: 200–220 mm

- Automatic compensation based on profile springback data to improve forming precision and repeatability

Structural Design

- Top axis with straight I-shaped linear movement for smooth and stable operation

- Anti-tilt support to prevent shaft deviation during bending

- Welded frame constructed from galvanized steel pipes

- Anti-static coated sheet metal for corrosion resistance and long-term stability

Please fill out this form to submit a request for quote. One of our team members will review the details and be in touch within 12 business hours.