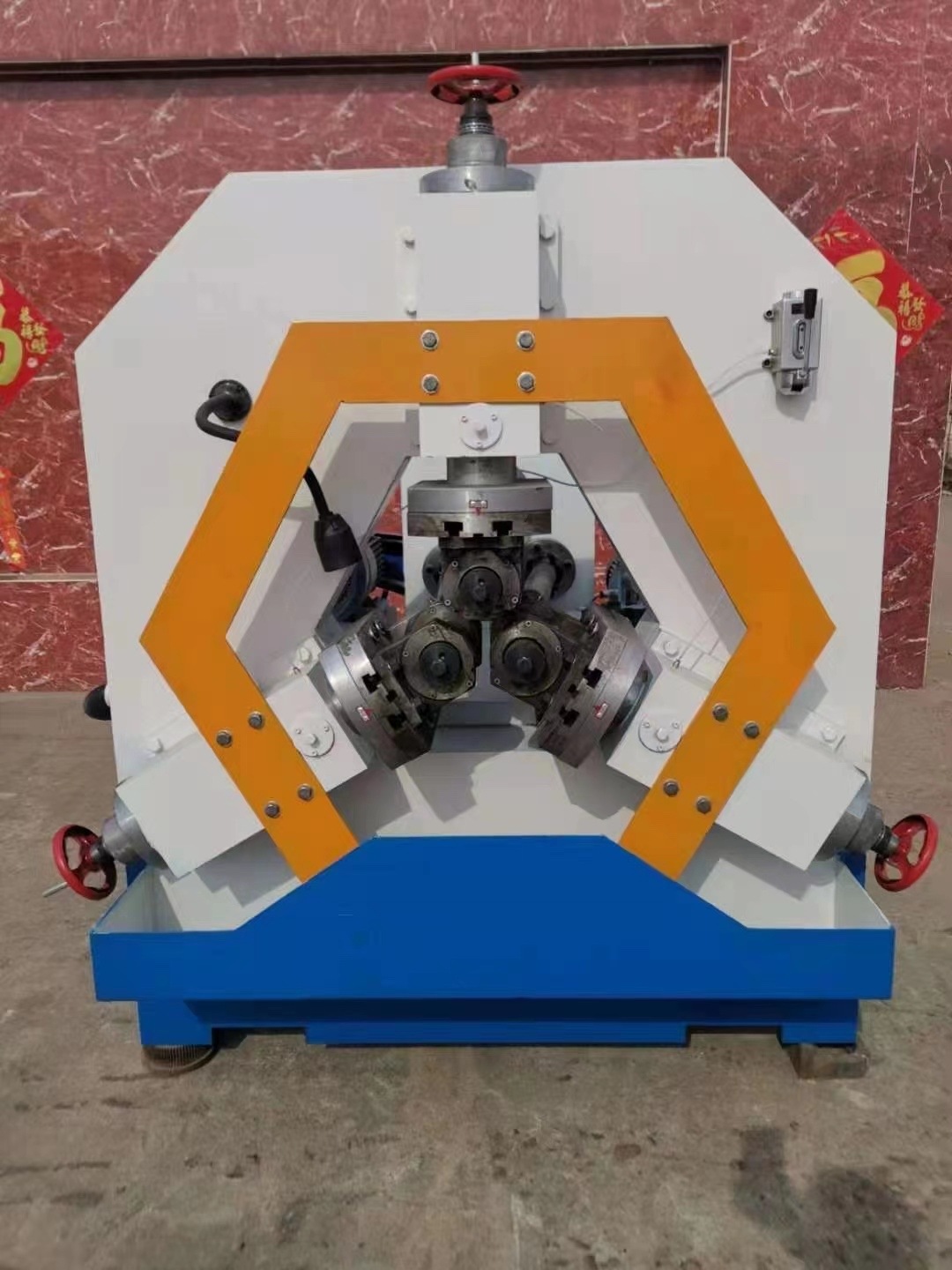

CNC 3-Die Thread Rolling Machine

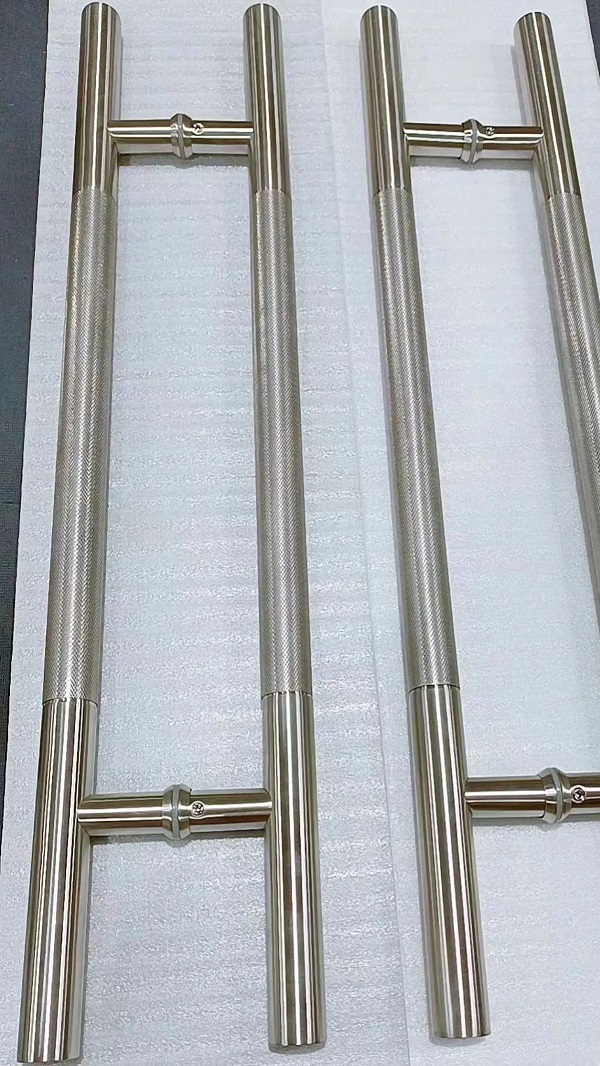

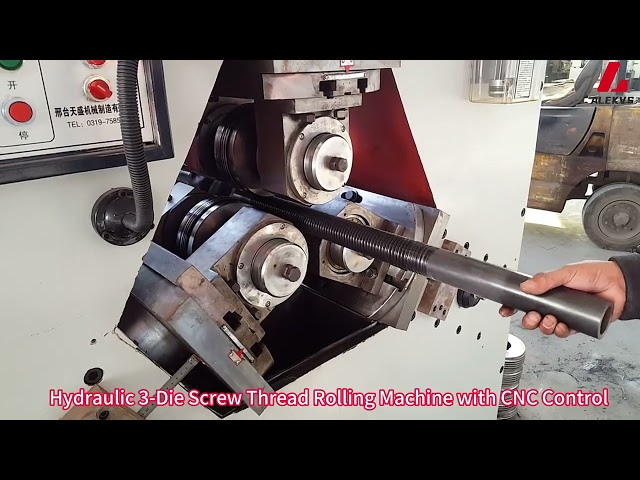

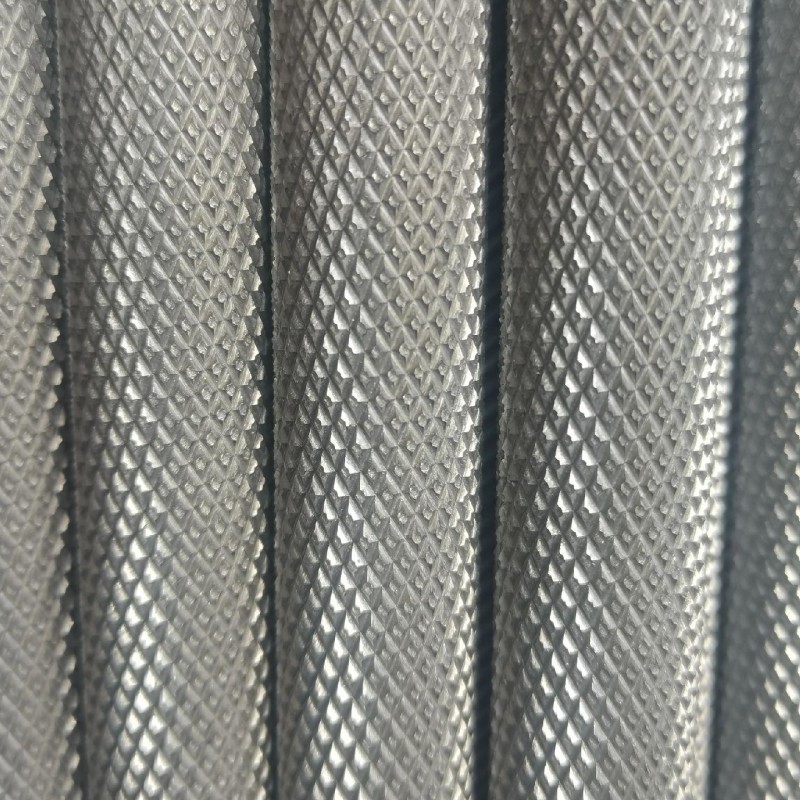

The AEK-ZP28-65 CNC 3-Die Thread Rolling Machine is a high-performance cold extrusion forming machine engineered for precision rolling of threads, splines, knurls, worms, serrations, and annular grooves. Its three-roll design, combined with a servo-controlled 3-axis system, ensures uniform pressure distribution and outstanding accuracy across both solid and hollow workpieces.

Key Benefits

- High Precision– Achieves ±0.01mm accuracy, ensuring consistent screw thread quality.

- Improved Strength– Cold rolling generates radial compressive stress, enhancing fatigue resistance and torsional strength.

- Versatile Applications– Suitable for thread rolling, spline forming, straightening, diameter reduction, and burnishing.

- Flexible Operation– Supports manual, semi-automatic, and fully automatic modes.

- Efficient & Energy Saving– Advanced cold forming process with low material waste and high throughput.

Mold Customization-3-Die Thread Rolling Machine

Structural Features

- Synchronized Three-Die Motion– Ensures concentricity and stability during rolling.

- Hydraulic & Servo Drive Options– Stable feeding power up to 160kN.

- Horizontal & Vertical Axis Configurations– Vertical axis improves loading and unloading efficiency.

- Universal Joint Power Transmission– Smooth speed change and reliable torque delivery.

- High Stiffness Rolling Frame– Guarantees precision under heavy-duty operations.

- Advanced Cooling & Lubrication System– Flood-type lubrication extends die life and ensures consistent rolling quality.

Applications

The AEK-ZP28-65 3-Axis Thread Rolling Machine is widely used in industries requiring high-precision thread forming and cold rolling:

- Aerospace and automotive fasteners

- Steel pipe joints and fittings

- Lead screws, precision drive shafts, and rebar threads

- Bicycle spokes and turbine studs

- Hydraulic cylinder rods and other precision engineering components

Why Choose AEK-ZP28-65?

Whether referred to as a Hydraulic 3-Die Screw Thread Rolling Machine with CNC Control, a High Precision CNC Thread Rolling Machine with Three-Roll Design, or an Automatic Screw Thread Rolling Machine with Drive Shafts & Precision Screws, the AEK-ZP28-65 offers unmatched accuracy, durability, and efficiency. It is the ideal solution for manufacturers seeking advanced thread and spline production equipment.

Please fill out this form to submit a request for quote. One of our team members will review the details and be in touch within 12 business hours.