- 1.0Definition and Characteristics of Bolts

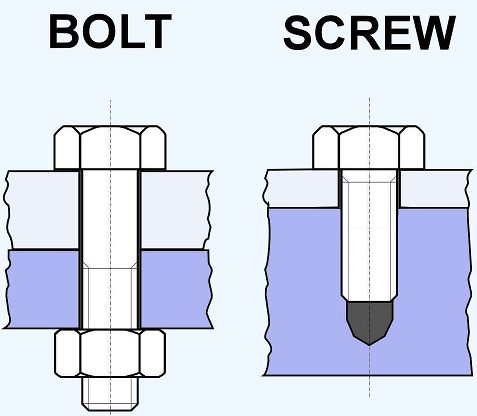

- 2.0Bolts vs. Screws: Core Differences Behind Similar Appearance

- 3.0Common Types of Bolts and Their Applications

- 4.0Bolt Manufacturing Process: From Raw Material to Finished Product

- 5.0Key Terminology and Bolt Specification Interpretation

- 6.0Bolt Strength Grades: Understanding “Number Markings”

- 7.0Bolt Selection and Installation Guidelines

- 8.0Conclusion

In mechanical manufacturing, construction engineering, the automotive industry, and even everyday furniture assembly, bolts serve as fundamental and essential fasteners. They play a critical role in joining components, transmitting loads, and ensuring structural stability. Whether it is the steel connections of a large bridge or the secure fastening of core parts in precision machinery, the performance and selection of bolts directly influence the overall system’s safety and service life.

1.0Definition and Characteristics of Bolts

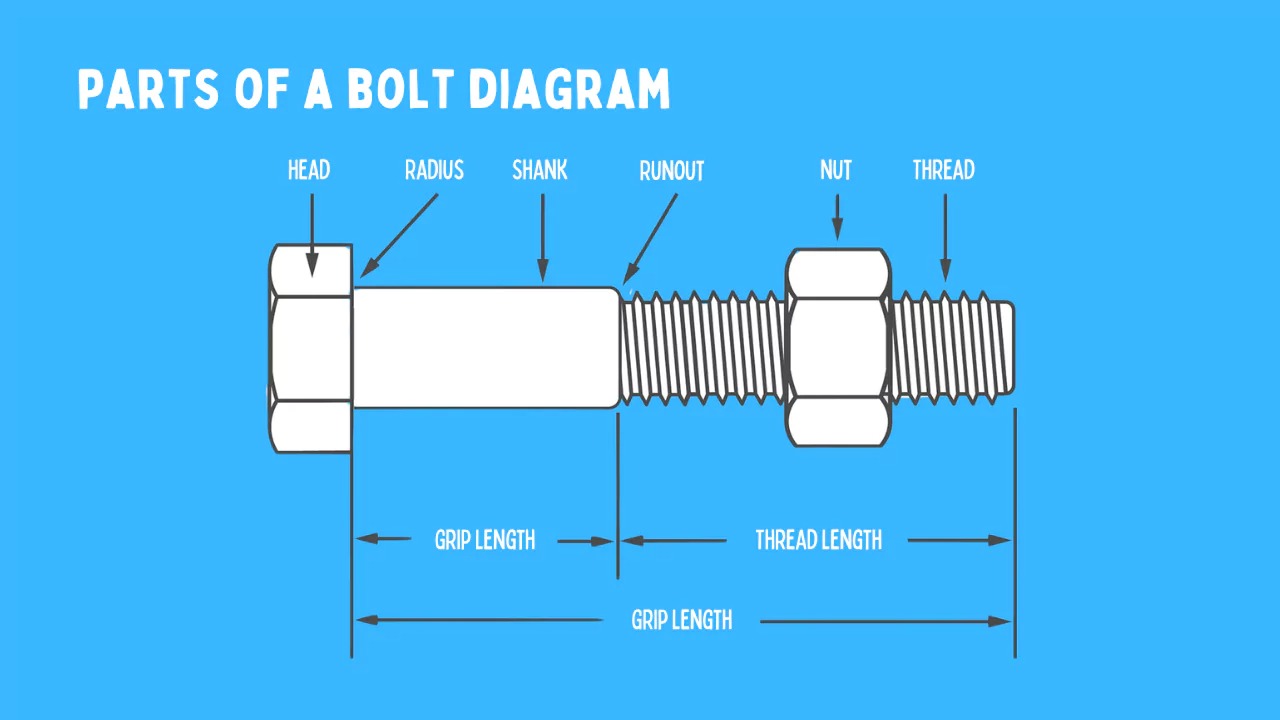

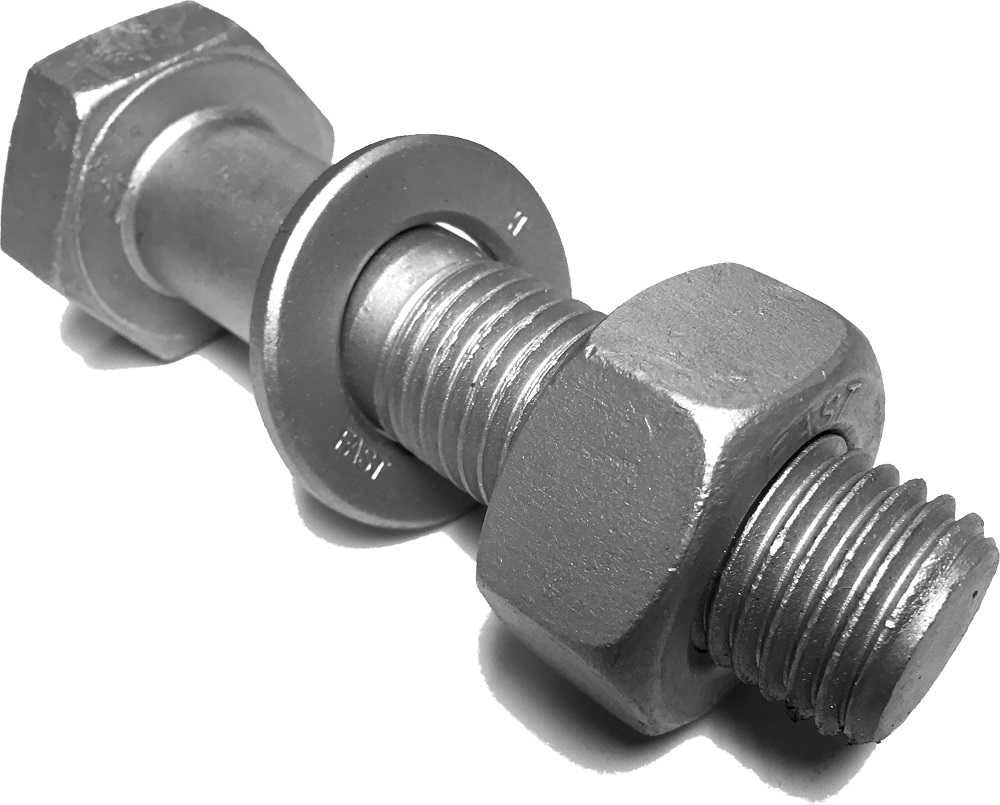

A bolt is a cylindrical fastener with external threads, designed to tightly join two or more components with aligned through-holes by applying axial clamping force. This prevents both axial and radial displacement of the parts. Structurally, a standard bolt consists of three main parts, each serving an essential function:

1.1Bolt Head

The head is located at one end of the bolt and typically has a diameter larger than the shank. Its primary functions are:

- Distributing load: Spreads the pressure generated during tightening evenly across the surface of the connected part, preventing localized stress that could cause deformation or damage.

- Providing a grip point: Offers a stable surface for tools (e.g., wrenches, sockets) to apply torque for tightening or loosening.

Common head shapes include hex, round, countersunk, and square:

- Hex head: The most widely used—its six-sided design is easy to manufacture, provides multiple gripping angles, and enables efficient torque transfer, making it ideal for high-torque applications.

- Countersunk head: Suited for scenarios requiring a smooth surface (e.g., furniture panels, equipment casings), as the head embeds in the material for a flush finish.

1.2Shank

The shank connects the head to the threaded section and typically includes two parts:

- Smooth section (body): Engages precisely with the hole in the connected component to prevent radial movement. The absence of threads avoids stress concentration at the thread root (a common failure point) and enhances shear resistance. For applications with significant shear loads (e.g., steel structure joints), the smooth section must fully pass through the mating surface to ensure shear force is borne by the body rather than the threads.

- Threaded section: Located at the other end of the shank, it engages with a nut or an internally threaded hole. Its helical design converts torque into axial clamping force to secure the connected components.

1.3Thread

Threads are continuous helical ridges (crests) and grooves (roots) on the bolt’s surface, whose geometry directly affects connection stability and compatibility.

- Common profiles:

- Triangular threads (e.g., standard metric threads): Widely used for general fastening due to self-locking ability and ease of manufacture.

- Trapezoidal/square threads: Rare in bolts—mostly used for power transmission (e.g., jacks).

- Direction: Right-handed (tightened clockwise) is standard; left-handed (tightened counterclockwise) is only used in special cases (e.g., bicycle pedals, circular saw blades) where operational forces might loosen right-hand threads.

2.0Bolts vs. Screws: Core Differences Behind Similar Appearance

| Dimension | Bolt | Screw |

| Core Definition | Passes through unthreaded holes in components; tightened with a nut. | Inserts into holes, engages pre-formed threads or cuts its own (self-tapping); tightened via the head (no nut needed). |

| Thread Characteristics | Mostly partially threaded (smooth shank + shorter threaded section); fully threaded types exist for specific needs. | Almost fully threaded (threads run from just below the head to the tip; no distinct smooth shank). |

| Installation Dependency | Requires a nut for opposing clamping force; no tapped hole needed in components. | No nut required; engages pre-tapped holes or cuts threads into materials (wood, thin sheet metal). |

| Tool Usage | Tightened with a wrench/socket on the head (or fixed head + rotating nut, e.g., carriage bolts). | Tightened via tools (screwdrivers, hex keys) on the head; no nut. |

| Load Performance | Smooth shank distributes shear force; superior shear and tensile strength (suitable for heavy loads). | Strong holding power but stress concentrates at thread roots; lower shear strength (suitable for light-duty use). |

| Typical Applications | Structural steel connections, machine bases, pipe flanges, and automotive chassis. | Furniture assembly, electronic housings, sheet-metal fastening, and woodworking. |

Special Note: Boundary cases (e.g., a hex bolt threaded directly into a tapped hole) do not alter their fundamental distinction: Bolts are inherently designed for use with nuts, while screws are defined by direct engagement with materials/nuts.

3.0Common Types of Bolts and Their Applications

Bolt design must align with operating conditions (load, component material, environment, disassembly frequency). Below are 10 widely used bolt types in industry, with their key features and applications:

3.1Hex Bolts

- Key Features: Six-sided head (standard or low-profile) for easy wrench grip; available in partially threaded (smooth shank for shear resistance) or fully threaded designs.

- Advantages: Versatile, cost-effective, efficient torque transfer, compatible with most tools.

- Applications: General machinery connections (motor base-to-frame), steel structure secondary joints, automotive engine accessory mounting, household appliance internal fastening.

3.2Carriage Bolts

- Key Features: Rounded/dome-shaped head (no gripping flats) with a short square neck below the head (locks into square holes/materials to prevent rotation); almost exclusively fully threaded (partial threading rare for large sizes).

- Advantages: Enables single-handed tightening (no need to hold the head); prevents protruding heads from damaging goods.

- Applications: Guardrail assembly, wooden crates/pallets, outdoor furniture (park benches), agricultural machinery with wooden components.

3.3Flange Bolts

- Key Features: Integral circular flange (larger than the head) on the head; flange surfaces often have serrations (anti-slip); some designs include rubber/plastic washers (sealing + vibration resistance).

- Advantages: Spreads clamping force over a large area (prevents soft material deformation, e.g., plastic/aluminum); serrations reduce loosening in high-vibration environments.

- Applications: Pipe flange connections (chemical/water pipelines), pressure vessel covers, automotive transmission-to-engine joints, medical equipment casings.

3.4Shoulder Bolts

- Key Features: Precision-machined smooth cylindrical “shoulder” (h6/h7 tolerance) between the head and threaded section; shoulder diameter > thread diameter; customizable shoulder length.

- Advantages: Shoulder acts as a locating reference for rotating/sliding parts (bearings, gears) to ensure coaxiality; bears radial loads to protect threads.

- Applications: Bearing housing alignment, machine tool fixtures, printing press rollers, precision instrument assemblies.

3.5Expansion Bolts

- Key Features: Consists of a threaded rod (Q235/45# steel or stainless steel for corrosion resistance), thin-walled expansion sleeve (galvanized/stainless steel), nut, and washer; rod end has a tapered head.

- Working Principle: Inserted into pre-drilled concrete/masonry holes; tightening the nut pulls the tapered head into the sleeve, expanding it against hole walls for friction anchoring.

- Applications: Ceiling frame installation, air conditioning brackets, electrical boxes, wall-mounted water heaters, signboards.

3.6Anchor Bolts

- Key Features: Long rods with embedded ends (hook, L-bend, or anchor plate) for bonding with concrete; exposed end is threaded; materials include medium carbon steel (Q345), alloy steel, or stainless steel (corrosive environments).

- Advantages: Cast into concrete foundations; provides exceptional holding strength for heavy equipment (prevents movement/tipping under load/vibration).

- Applications: Power plant steam turbines/generators, large motors (fans, pumps), heavy machine tools, bridge supports.

3.7Stud Bolts

- Key Features: Threaded at both ends (same or different diameters for mismatched holes); smooth shank in between (smaller sizes may be fully threaded).

- Advantages: One end (“fixed end”) permanently installed in a tapped hole; the other (“service end”) secured with a nut—enables frequent disassembly without damaging fixed threads.

- Applications: Chemical piping flanges, automotive cylinder head-to-block connections, valve body-to-cover joints, boiler inspection doors.

3.8U-Bolts

- Key Features: U-shaped design with threaded ends; inner radius matches the cylindrical object (pipe/rod) being secured.

- Advantages: Even clamping around round objects (no surface damage); easy to install without complex fixtures.

- Applications: Securing water/heating/gas pipes, suspending cable trays, attaching tractor exhaust pipes.

3.9Eye Bolts

- Key Features: Circular loop (eye) at one end (for lifting hooks) and external threads at the other; available in fixed-eye (welded) or swivel-eye (rotatable) designs.

- Advantages: Enables safe lifting of components; swivel-eye models accommodate angular loads.

- Applications: Lifting machinery parts, suspending overhead equipment (lighting, fans), marine hardware.

3.10High-Strength Structural Bolts

- Key Features: Manufactured from alloy steels (40Cr, 35CrMo, 42CrMo) and heat-treated (quenching + tempering); strength grades: ISO 10.9/12.9 or ASTM A325/A490; head marked with grade (e.g., “10.9,” “A325”); paired with high-strength nuts/washers.

- Advantages: Exceptional tensile, yield, and fatigue strength; resists high loads/dynamic stresses without plastic deformation.

- Applications: Large bridge steel joints (cable-stayed bridge towers), high-rise steel frameworks, crane booms, offshore platforms.

4.0Bolt Manufacturing Process: From Raw Material to Finished Product

A bolt’s manufacturing process determines its mechanical properties, dimensional accuracy, and service life. The core stages are as follows:

4.1Raw Material Preparation

- Material Selection:

- Standard bolts (≤ISO 8.8): Medium/low carbon steel (Q235, 45#).

- High-strength bolts (≥ISO 10.9): Alloy steel (40Cr, 35CrMo, 42CrMo, or 40CrNiMoA for fatigue resistance).

- Corrosion-resistant bolts: Stainless steel (304, 316), brass, nylon.

- High-temperature bolts: Heat-resistant alloys (Inconel 718, ASTM A193 B7).

- Pre-treatment: Use steel bars (large bolts) or wires (medium/small bolts); clean surfaces (remove rust/oil) and inspect material for defects (e.g., cracks, inclusions).

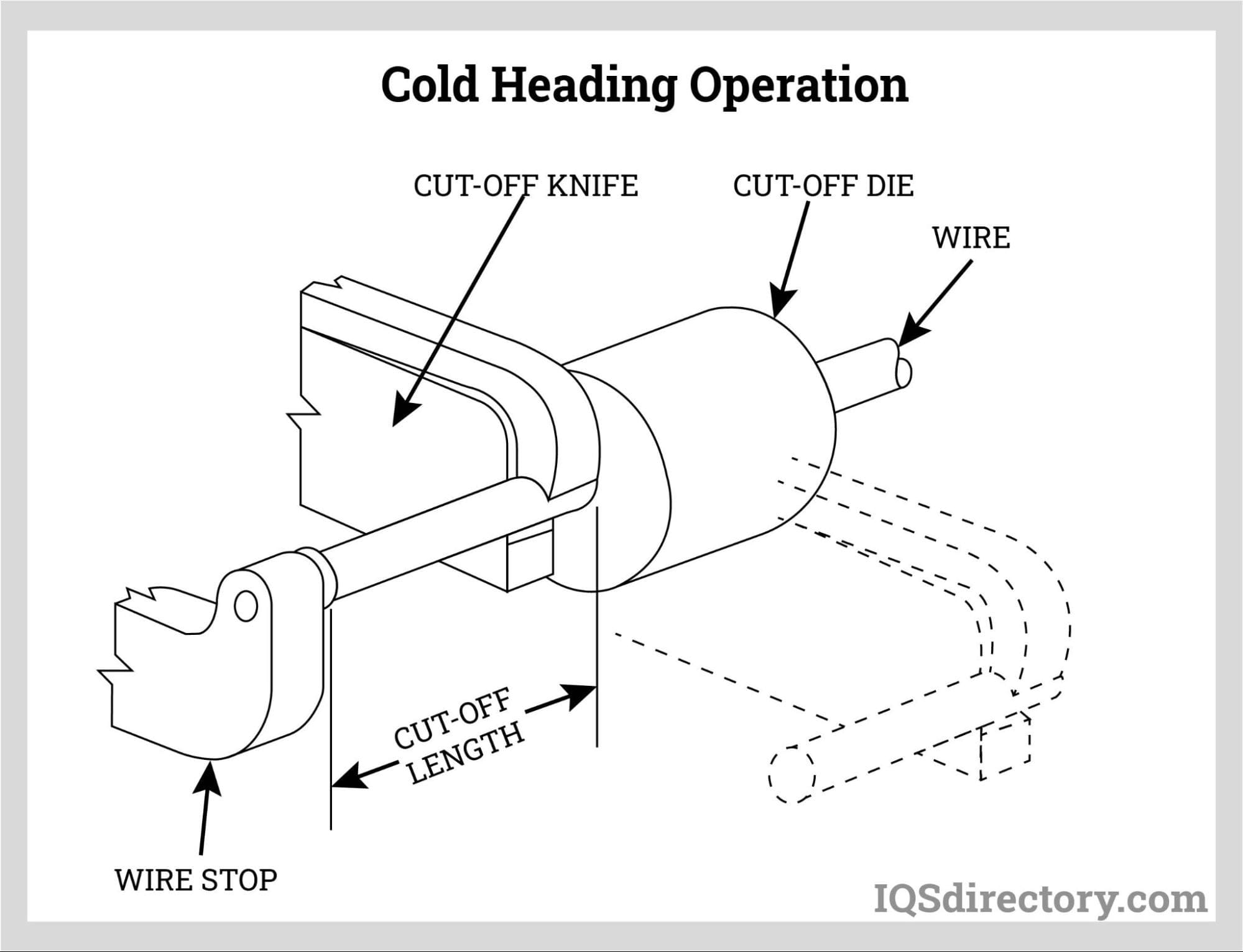

4.2Forming: Shaping Head and Shank

- Cold Heading: Most common for medium/small bolts; forms blanks at room temperature using multi-station machines (high efficiency, good surface finish).

- Hot Forging: Used for large/thick bolts; heats steel above recrystallization temperature (~800–1200°C) and presses into molds (accommodates high-strength materials).

4.3Chamfering

- Purpose: The threaded end of a bolt is chamfered at a 45°–60° angle, with a length of about 0.5–1× the thread pitch. This taper helps guide the bolt smoothly into holes and prevents thread damage during installation.

- Process & Equipment: Chamfering is typically performed after forming and before threading to ensure dimensional precision. In industrial production, a Bar Chamfering Machine is often used, as it provides consistent angles, smooth finishes, and higher efficiency compared to manual processing.

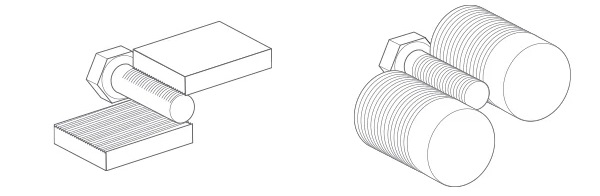

4.4Threading

- Thread Rolling: For high-strength bolts, threading is most commonly achieved using a Thread Rolling Machine. In this process, pre-formed blanks are pressed between rollers with spiral grooves, causing the metal to plastically flow and form threads. This method does not remove material, resulting in stronger threads with improved fatigue resistance. For bolts made of high-strength alloys, pre-annealing may be required to reduce hardness and minimize roller wear.

- Thread Cutting: For small-batch or customized bolts, threading can be done by cutting with lathes, taps, or dies. While this method allows flexibility in production, it produces threads with relatively lower strength compared to rolled threads and typically comes with higher processing costs.

4.5Heat Treatment

- Standard bolts (≤ISO 8.8): Normalizing (improves ductility, reduces internal stress).

- High-strength bolts (≥ISO 10.9): Quenching (heat to 800–900°C, rapid cooling) + tempering (heat to 400–600°C, slow cooling) to enhance strength and toughness.

- Special bolts: Solution treatment (stainless steel, improves corrosion resistance) or carburizing (wear-resistant bolts, e.g., agricultural machinery).

4.6Surface Treatment

- Zinc plating (electroplating/hot-dip): Corrosion resistance for indoor/dry environments; hot-dip zinc offers better protection for outdoor use.

- Nickel/chrome plating: Decorative + corrosion resistance (e.g., furniture, consumer electronics).

- Dacromet coating: Superior corrosion resistance for marine/chemical environments (no hydrogen embrittlement risk).

- Blackening/phosphating: Low-cost rust prevention for indoor, low-corrosion environments (e.g., machinery internal bolts).

4.7Quality Inspection

- Dimensional checks: Verify thread diameter (major/minor/pitch), length, chamfer, and tolerance (e.g., IT8 for pitch diameter).

- Mechanical tests: Tensile strength, yield strength, hardness (Rockwell/Brinell), and shear strength.

- Surface checks: Inspect for plating defects (peeling, blisters) or cracks.

5.0Key Terminology and Bolt Specification Interpretation

Understanding technical parameters is critical for bolt compatibility and load-bearing capacity. Below are core terms and specification 解读 methods:

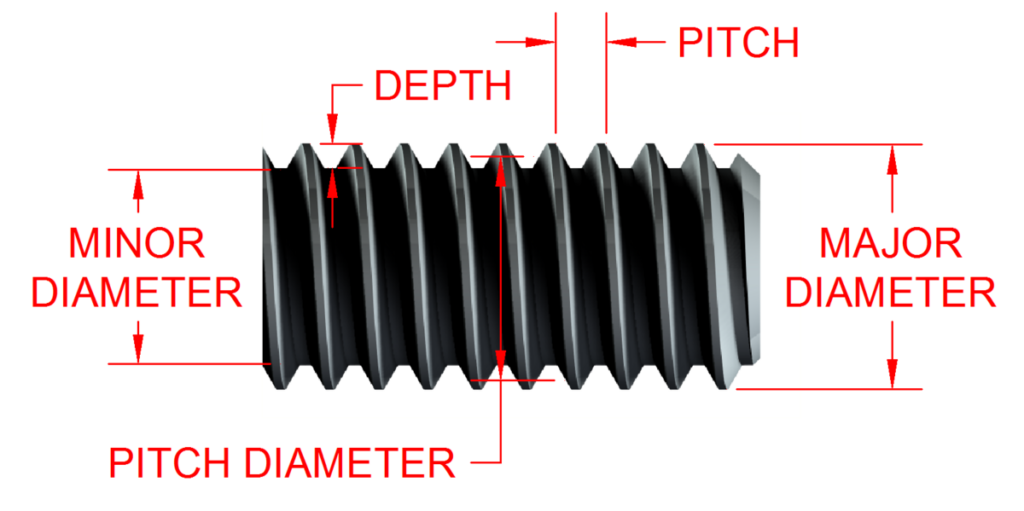

5.1Thread-Related Terms

(1) Thread Diameter

- Major Diameter (d): Largest thread diameter (crest-to-crest); equals the nominal bolt diameter (e.g., M10 = 10 mm). Determines nut selection (nut minor diameter must match bolt major diameter).

- Minor Diameter (d1): Smallest thread diameter (root-to-root); directly affects shear strength (larger d1 = greater shear area).

- Pitch Diameter (d2): Average of major/minor diameters; key for thread fit (deviation causes loose/tight assembly, controlled to IT8 class).

(2) Pitch and Threads Per Inch (TPI)

- Pitch (P, metric): Axial distance between adjacent crests (mm). Coarse pitch is default (e.g., M10 = 1.5 mm); fine pitch is marked explicitly (e.g., M10×1.0).

- TPI (imperial): Number of threads per inch (1 inch = 25.4 mm). Example: 1/4”-20 = 20 TPI (pitch ≈ 1.27 mm).

(3) Thread Direction and Profile

- Direction: Right-hand (RH, standard); left-hand (LH, marked, e.g., M10×1.0×50-LH).

- Profile: 60° triangular (standard metric/UNC/UNF threads); 55° Whitworth (piping, rare for bolts).

5.2Dimension-Related Terms

(1) Nominal Length (L)

- Definition: Axial length of the bolt, measured differently by head type:

- Hex/round head: From the head’s bearing surface (bottom flat) to the shank end.

- Countersunk head: From the head’s top surface (flush with material) to the shank end.

- Selection Rule: Ensure the bolt passes through all components, with 1–3 thread turns protruding from the nut (too short = low clamping force; too long = material waste/interference).

(2) Shank Diameter (d)

- Diameter of the smooth shank (equal to nominal diameter, e.g., M10 = 10 mm). Hole size in components: 0.1–0.3 mm (metric) or 0.004–0.012 inch (imperial) larger than shank diameter (for smooth insertion).

(3) Chamfer (C)

- Tapered end of the shank (45°/60° angle, length 0.5–1× pitch) to guide installation and protect threads.

5.3Specification Examples

Metric Bolt (ISO Standard): M12-1.75×60-8.8-Zn

- M: Metric thread

- 12: Nominal diameter (12 mm)

- 75: Pitch (coarse, default for M12)

- 60: Nominal length (60 mm)

- 8: Strength grade (tensile strength ≥800 MPa, yield strength ≥640 MPa)

- Zn: Zinc-plated surface

Imperial Bolt (SAE Standard): 5/16”-18×3”-Grade 5-HD

- 5/16”: Nominal diameter (~7.94 mm)

- 18: TPI = 18 (pitch ≈1.41 mm)

- 3”: Nominal length (~76.2 mm)

- Grade 5: Strength grade (tensile ≥120 ksi, yield ≥92 ksi)

- HD: Hex head

6.0Bolt Strength Grades: Understanding “Number Markings”

Strength grades reflect a bolt’s tensile/yield strength, with standards varying by region. The most common are ISO (metric), SAE (imperial), and ASTM (special applications).

6.1ISO Standards (Metric Bolts, Global Use)

Defined by ISO 898-1, denoted as two numbers separated by a dot (e.g., 8.8):

- First number: Minimum tensile strength (UTS) in MPa × 100 (e.g., “8” = ≥800 MPa).

- Second number: Yield ratio (yield strength/UTS) × 0.1 (e.g., “8” = yield strength ≥800×0.8=640 MPa).

| ISO Grade | Min Tensile Strength (MPa) | Min Yield Strength (MPa) | Material | Typical Applications |

| 4.6 | 400 | 240 | Low carbon steel (Q215) | Light-duty (furniture, simple brackets) |

| 5.8 | 500 | 400 | Medium carbon steel (Q235) | General machinery (motor attachments) |

| 8.8 | 800 | 640 | 45# steel / 40Cr | Heavy-duty (equipment bases, pipelines) |

| 10.9 | 1000 | 900 | 35CrMo, 40CrNiMoA | High-strength (automotive chassis) |

| 12.9 | 1200 | 1080 | 42CrMo, 30CrNiMo8 | Extreme-strength (aerospace, heavy machinery) |

6.2SAE Standards (Imperial Bolts, U.S. Dominant)

Defined by SAE J429, denoted as “Grade + number” (e.g., Grade 5), units in ksi (1 ksi = 6.89 MPa):

| SAE Grade | Min Tensile Strength (ksi) | Min Yield Strength (ksi) | Material | Typical Applications |

| Grade 2 | 74 | 33 | Low carbon steel | Light-duty (appliance housings) |

| Grade 5 | 120 | 92 | 1045 steel | General heavy-duty (engine brackets) |

| Grade 8 | 150 | 130 | 4140 steel | High-strength (drive shafts, heavy equipment) |

6.3ASTM Standards (Special Applications, U.S. Dominant)

Focus on high-temperature, high-pressure, or corrosion-resistant scenarios:

| ASTM Standard | Strength Equivalent | Material | Applications |

| ASTM A307 | SAE Grade 2 | Carbon steel | Light-duty building (ceiling frameworks) |

| ASTM A325 | ISO 8.8 (approx.) | Alloy steel (1045, 4140) | Steel structures (bridges, high-rises) |

| ASTM A490 | ISO 10.9 (approx.) | High-strength alloy steel | Extreme-load steel structures |

| ASTM A193 B7 | ISO 10.9 | Chromium-molybdenum steel | High-temperature (chemical pipelines, 482°C max) |

| ASTM A193 B16 | ISO 12.9 | Nickel-chromium-molybdenum steel | Ultra-high-temperature (boilers, 649°C max) |

6.4Principles for Selecting Strength Grades

- Avoid over-specification: High-strength bolts are costly and require matching nuts/washers (e.g., 4.6/5.8 suffices for furniture).

- Match load/environment: Shear/dynamic loads (automotive chassis) need ≥ISO 8.8; high-temperature (boilers) need ASTM A193; corrosion needs stainless steel (304/316) with matching strength.

- No grade mixing: Do not replace Grade 8 with Grade 2 (insufficient strength) or vice versa (excessive clamping force deforms components).

7.0Bolt Selection and Installation Guidelines

Bolt selection must balance operating conditions, parameter matching, and cost control. Follow this step-by-step logic:

7.1Clarify Operating Conditions

(1) Load Type and Magnitude

- Load Type:

- Tension (e.g., lifting bolts): Full/partially threaded bolts (ensure sufficient thread engagement).

- Shear (e.g., steel joints): Partially threaded bolts (smooth shank distributes shear force, avoids thread root failure).

- Combined tension-shear (e.g., drive shafts): High-strength bolts (≥ISO 8.8) with smooth shanks.

- Load Magnitude: Calculate required tensile/yield strength (e.g., ≥600 MPa → ISO 8.8).

(2) Installation Environment

- Corrosive (humid/acidic/marine): Stainless steel (304/316) or Dacromet-coated bolts.

- High-temperature (>200°C): ASTM A193 B7/B16 or Inconel bolts.

- High-vibration (engines): Flange bolts (serrated) + locking nuts/thread-locking adhesives.

(3) Assembly/Maintenance Needs

- Frequent disassembly: Stud bolts (fixed end protects tapped holes).

- Limited space: Low-profile hex bolts or countersunk bolts.

- Single-handed operation: Carriage bolts (square neck prevents rotation).

7.2Match Core Parameters

- Dimensional Matching:

- Diameter: Match component through-hole (0.1–0.3 mm larger than shank).

- Length: Total component thickness + nut thickness + 1–3 thread turns (e.g., 20 mm components + 8 mm nut → 30 mm bolt).

- Thread type: Metric/imperial (not interchangeable).

- Material/Surface Treatment Matching:

- General use: 45# steel + zinc plating.

- Corrosion: 316 stainless steel.

- Outdoor: Hot-dip zinc plating.

7.3Cost Control

- Prefer standard sizes: M6/M8/M10 (mass-produced, lower cost) over custom sizes.

- Optimize material/process: Carbon steel (cheaper than alloy steel) + cold heading (cheaper than hot forging) + thread rolling (cheaper than cutting).

7.4Installation Notes

- Use correct tools: Match wrench/socket size (avoid adjustable wrenches, which slip and damage heads).

- Control tightening torque: Follow torque tables (e.g., M10×8.8 → 35–45 N·m; excess torque = bolt breakage/deformation; insufficient = low clamping force).

- Prevent hydrogen embrittlement: High-strength bolts (≥ISO 10.9) need post-plating hydrogen relief (200–230°C for 2–4 hours).

- Regular inspection: Vibration-prone bolts (engine) → periodic retightening.

8.0Conclusion

Bolts, though small, are the backbone of mechanical and structural safety. Their design, manufacturing, and selection are rooted in precise engineering logic—from the “smooth shank for shear loads” to “ISO 12.9 for extreme strength,” every detail aligns with real-world needs.

To ensure connection reliability, avoid misconceptions like “bolts are generic” or “higher strength = better.” Instead, systematically analyze loads, environments, and parameters, and link terminology (e.g., chamfer) to manufacturing (e.g., post-forming chamfering) and installation (e.g., guided insertion).

For engineers, technicians, and operators, mastering this knowledge not only improves efficiency but also safeguards equipment/structure stability over the long term.

References

wilsongarner.com/what-is-a-bolt/

www.fastenright.com/blog/bolts-and-screws-what-is-the-difference

www.iqsdirectory.com/articles/bolts/types-of-bolts.html

www.bwindustrialsales.com/resources/difference-between-screw-and-bolt