Advantages

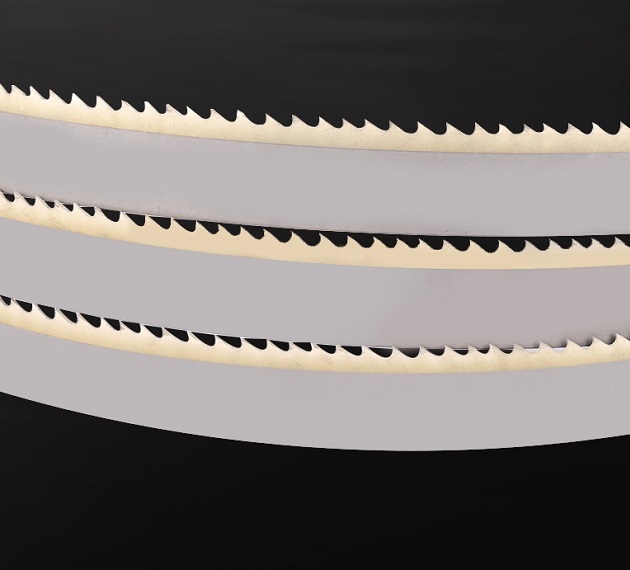

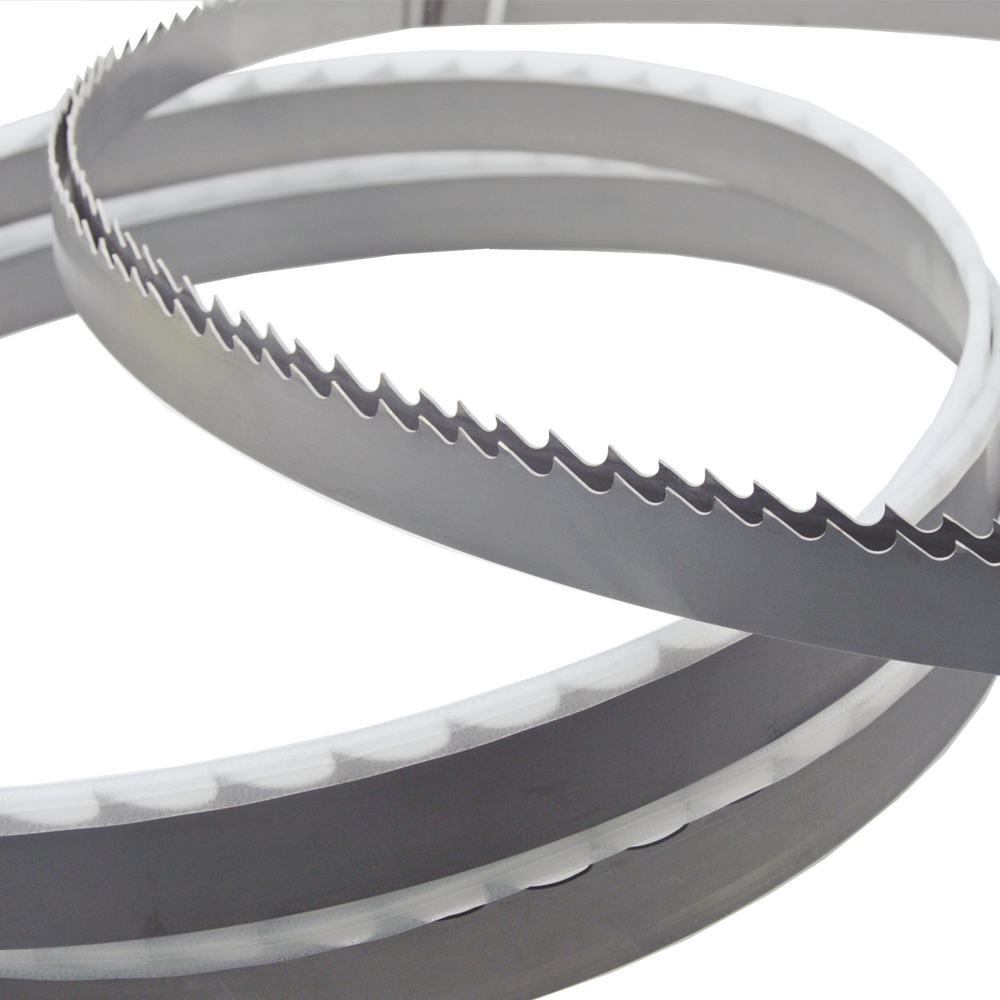

- PVD Coating Technology: Boosts cutting performance by 30%+ with high wear resistance, excellent heat insulation, and superior hardness. Reduces cutting costs significantly while enhancing work efficiency.

- WRC(PRO) Premium Coating: Universal design for wide-ranging cutting needs, delivering strong wear resistance and minimizing blade breakage. Easily handles complex and high-load cutting challenges.

- Superior to Standard M42 Uncoated Blades: Tooth hardness reaches 65–67 HRC, reducing cutting friction. Ensures higher stability and doubles the service life (standard uncoated blades: 3–5 days).

- Advanced Heat Treatment: Integrated online production with dual-direction tempering enhances tooth strength, wear resistance, and fatigue resistance. Solves blade-bending issues and ensures smooth cutting.

- Consistent Batch Performance: Outperforms traditional heat treatment with longer service life and minimal performance variation across batches, guaranteeing stable and reliable cutting results.

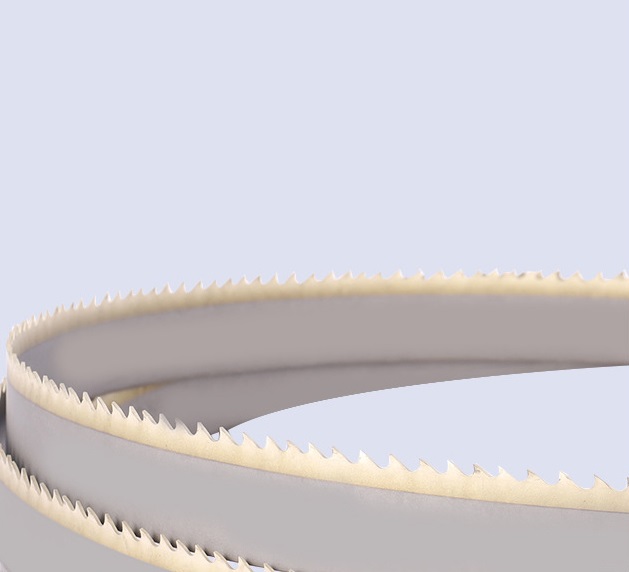

Tooth Geometry (Versatile for Multiple Scenarios)

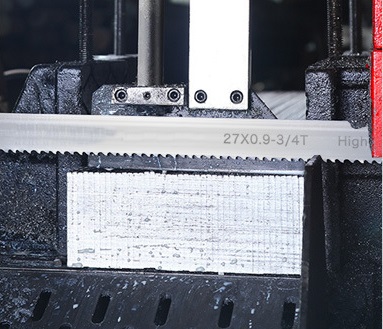

- 3/4 Anti-Pull Tooth: Hollow pipes (wall thickness > 10 mm)

- 2/3 Pointed Tooth: Solid materials (diameter 150–500 mm)

- 4/6 Anti-Pull Tooth: Hollow pipes (wall thickness < 10 mm)

- 3/4 Pointed Tooth: Solid materials (diameter 60–150 mm)

- 3/4 Camel-Back Tooth: Bundled or high-load materials

- 4/6 Pointed Tooth: Medium-to-light cutting loads

Material & Product Details

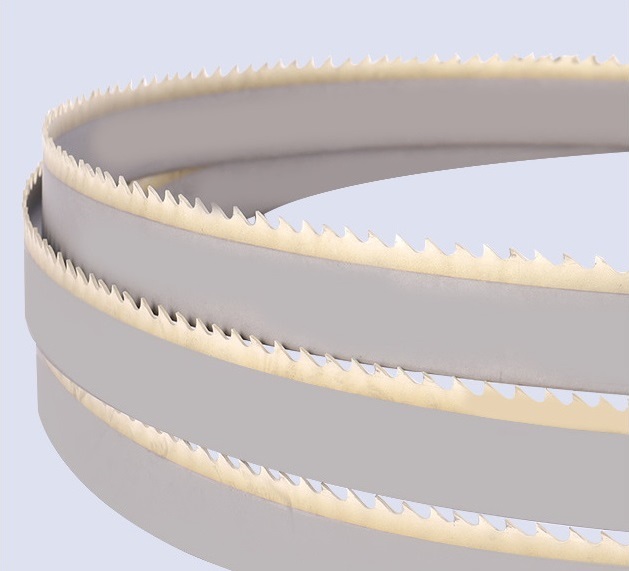

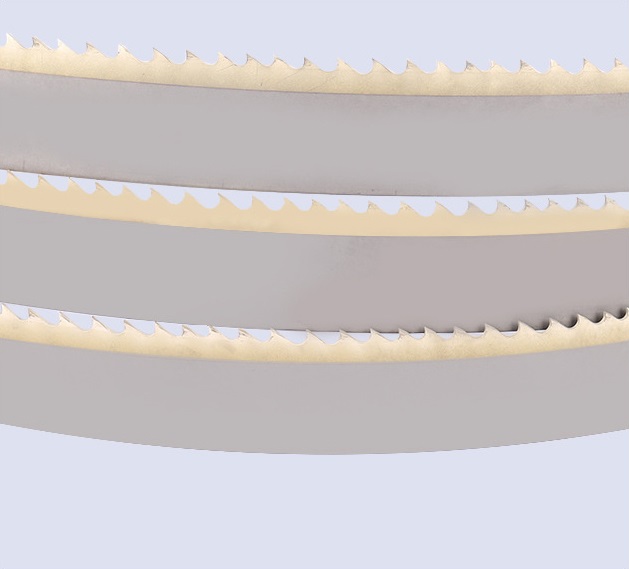

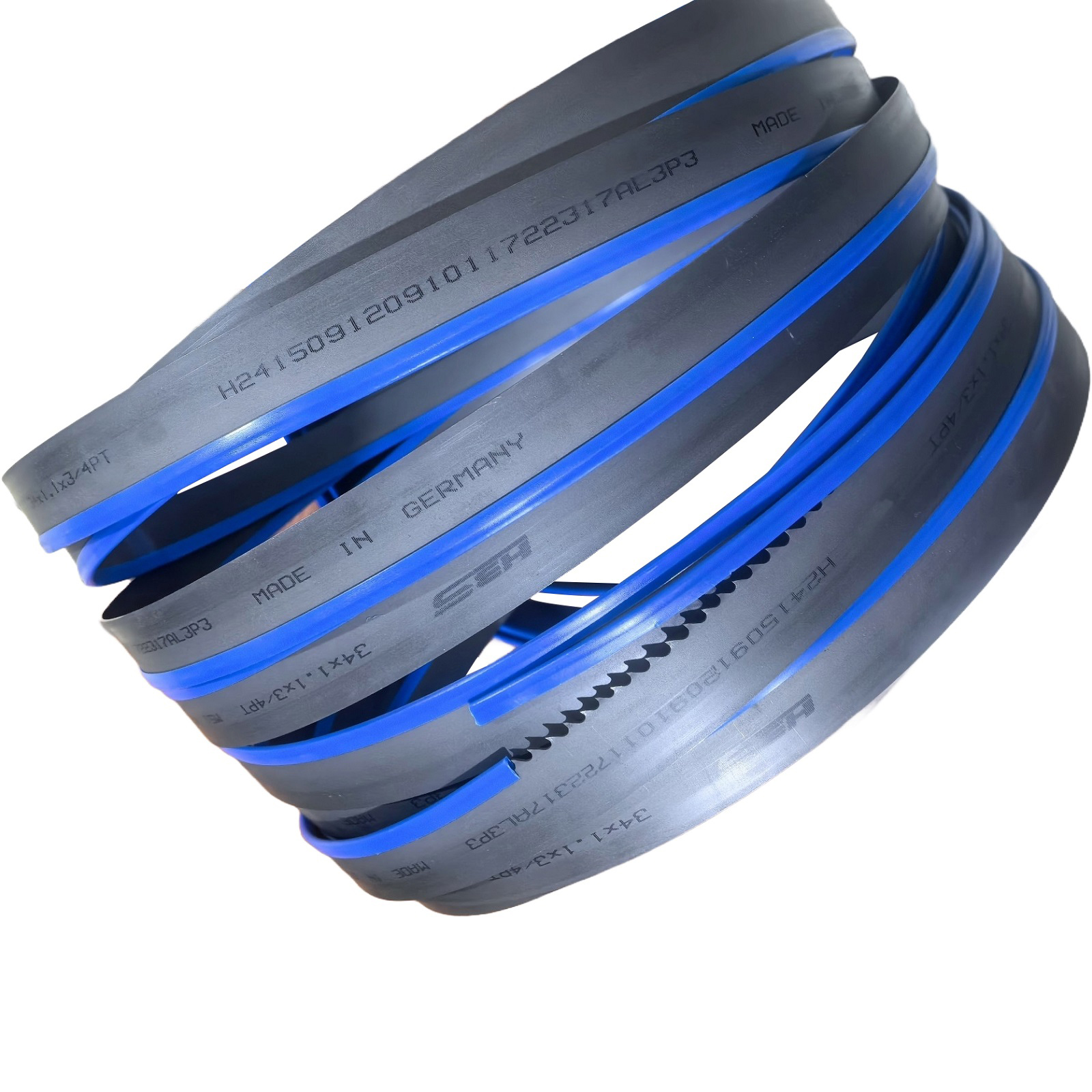

- Base Material: M42 bi-metal with high-toughness spring steel backing, balancing hardened hardness, wear resistance, flexibility, and fatigue resistance.

- Teeth & Coating: Dual-direction quenching sharpens teeth for smooth chip removal and narrower cutting paths. PVD coating protects teeth, reduces friction, and improves feed rate.

- Protective Design: 1 cm-thickened anti-wear interlocking tooth strip prevents oxidation and transportation damage, fully safeguarding the cutting edge.

Applicable Materials

Stainless Steel (304/316), Tool Steel, Bearing Steel, 45# Steel, A3 Steel, Q235 Steel, hollow pipes, solid materials, and bundled materials.

Please fill out this form to submit a request for quote. One of our team members will review the details and be in touch within 12 business hours.